390 build

#106

#107

#108

#111

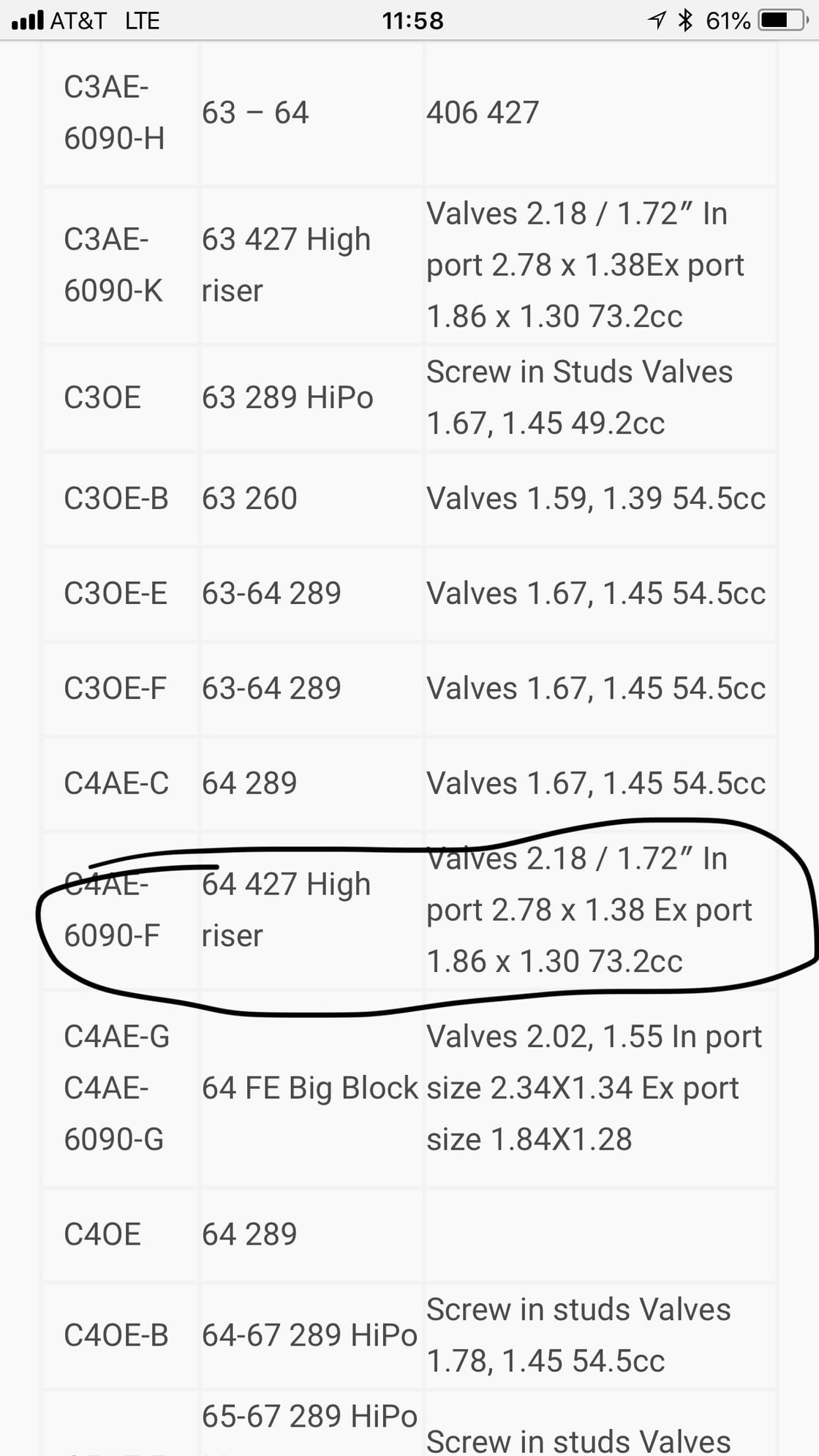

I have no knowledge of head functions and differences, sounds like you would need to talk to a Racer for knowledge about that unless the guy who did your heads would know.

I did read something about hardened seats and the possibility of C4AE heads needing them with the unleaded fuel, but I had no knowledge of this.

I did read something about hardened seats and the possibility of C4AE heads needing them with the unleaded fuel, but I had no knowledge of this.

#112

Well I’ve narrowed the noise down to about 3 possible causes, spark knock (haven’t gotten to even see if that’s a possibility but I have been having issues with timing) wrist pin knock, although no noise difference happened when spark plugs were unplugged and the noise is on both sides of the engine, and I know my pin tolerances are very tight on them. or piston to head clearance being too small. Really hoping for just a clearance issue, because if it is it’s VERY LITTLE. Spark knock is not likely but I’m still gonna check it out as a possibility.

#113

Im sure many have lost interest in my build now, but engine is out and tore down to a short block. For whatever reason #2 cylinder rod bearing didn’t do its job and I had several thousandths of an inch ground out of my rod journal, all have some weird shapes on my camshaft lobes. As to not continually spam the forums with my information I will hold off on updates till engine is back together. I will be having a performance shop assemble my short block so as to insure a proper assembly, then back to running it again.

ALSO does anyone know of a engine test stand that will mount up to these FEs? I wish to break in and retest my engine before I go through the effort of installing it back into the pickup

ALSO does anyone know of a engine test stand that will mount up to these FEs? I wish to break in and retest my engine before I go through the effort of installing it back into the pickup

#114

Weird looking cam lobes means the cam wasn't "broken in" on the 1st start up. Camshaft break in fluid should be put on all the new lobes and the bottom of the lifters. Upon 1st start up, one needs to rev the engine up to at least 2000 RPM for 30 minutes straight. Varying the RPM a little here and there. As the cam lobes wear, the lifters get farther from the rocker arms. Farther than the pushrods can reach.

#115

Im sure many have lost interest in my build now, but engine is out and tore down to a short block. For whatever reason #2 cylinder rod bearing didnít do its job and I had several thousandths of an inch ground out of my rod journal, all have some weird shapes on my camshaft lobes. As to not continually spam the forums with my information I will hold off on updates till engine is back together. I will be having a performance shop assemble my short block so as to insure a proper assembly, then back to running it again.

ALSO does anyone know of a engine test stand that will mount up to these FEs? I wish to break in and retest my engine before I go through the effort of installing it back into the pickup

ALSO does anyone know of a engine test stand that will mount up to these FEs? I wish to break in and retest my engine before I go through the effort of installing it back into the pickup

Sorry to hear about the bearings and cam. Will look forward to you getting it back together and running.

Also as far as testing the engine sounds like Jeff would recommend putting it fully in the truck so that upon initial cranking it can be run for the 30 minutes, And I guess the wear on the cams he speaks of calls for readjusting?? push rods?? or rocker arms tightening?? maybe to reset gap caused from the breaking in wear?? I'm kinda guessing at what he was talking about.

#116

Break-in information that I found online: Engine Break-in information, instructions

Engine start-up and the first few hours is probably the most critical time for your engine to survive a long healthy life! Every engine needs what is called an engine break-in procedure. Remember, do not tow heavy loads, or pull steep hills until your engine is fully broken in. If possible after your first and second oil and filter changes.

When your engine was first taken out of your vehicle, some things should have been marked so they can go back in the same way. These things include, but are not limited to, marking all vacuum lines, all grounds, distributor timing, spark plug wires, brackets and spacers, timing belt and gears and marks, hood placement, etc., etc., etc. All engine support systems have to be in good operational condition! A bad water pump for example could cause engine overheating. Make sure you install a new one and any other components that needs to be replaced. Remember, when your vehicle was new, all the rest of everything under your hood was new too. You will need new spark plugs, cap and rotor, possibly spark plug wires, air filter, pcv valve, thermostat, oxygen sensor (if computer controlled), etc. Be sure your radiator is in really good condition.

A timing light needs to be hooked (in most cases) to number 1 spark plug wire before engine start-up, total timing checked, so you don't do damage to your new engine. Your engine needs to be primed with oil before engine start-up.

Have someone sitting in drivers seat at all times on engine start-up, monitoring water temperature, oil pressure, and rpm. It is critical that the engine never idles for the first half hour! You could get a flat camshaft, seized wrist pins, spun engine bearings, and sever engine damage if you let it idle for any reason.

On non computer cars, ignition timing should be approx. 22-25 degrees timing @ 1800 rpms. Less at lower rpm.

Start the engine and bring rpm up to 1200-1300 rpm until water temperature just begins to rise. It is a good idea to leave your radiator cap off until your thermostat opens and water starts to circulate. Add coolant to bring coolant level up when the air locks circulate to radiator. Have some coolant mix ready to add to the radiator when this happens.Watch your timing mark to make sure you are between 15-25 degrees. As soon as your water temperature just starts to rise, bring rpm up to 1800 rpm, and check ignition timing to make sure you are approx. 22-25 degrees timing for engine break-in. Run the engine at 1800 rpm for at least half an hour, making sure someone is monitoring oil pressure and water temperature at all times! After your half hour or more break-in, bring engine up to 3000 rpm and check total timing. Most engines need to be between 32-38 degrees total timing. Bring engine to idle and quickly check initial timing. Time to factory specs. You can give a little bit more timing at idle for higher elevations, but total timing cannot be too much or engine damage can occur. You may have to have your distributor re-curved if the timing curve is not correct. Most non-computer vehicles need about 8 to 12 degrees at idle, and 32 to 38 degrees total timing.

If your car is computer controlled, then you will have to follow instructions for your particular vehicle to do the ignition timing, but rpm is followed in the same manor as above.

After engine break-in, turn engine off and let it cool. After it has cooled down, check for leaks (oil and water), check your oil for discoloration and level, and check your coolant level.

If everything looks and sounds OK, then take it out for a test drive. Still don't let the engine idle for any length of time. If you get stuck in traffic, or at a long light, then place car in neutral or park and bring rpm up slightly until you are ready to proceed.

Take your vehicle someplace where you can drive between 30 and 65 mph. Take vehicle up to 65 mph then let completely off the gas and let vehicle come down to approx. 30 mph. Do this about 10 times to help your rings seat. Do not beat your new engine! Just drive normal. Do not take engine above 4000 rpm, and do not pull any heavy loads for the first 2 oil and filter changes. Your first oil and filter change should be done at or before 500 miles. Preferably right away. Remember that everything in that new engine has to wear-in, and all that wear-in metal needs to get out of the system. Your second oil and filter change should be done approx. 1500 miles after your first one was done. Then every 2500-3000 increments for the rest of its life.

You should also check under your vehicle for the first two weeks for any leaks, and check your oil and coolant levels daily for the first two weeks.

That should do it! Happy motoring!

RPM - RON'S PRECISION MACHINE, INC.

69 E. 580 N.

Santaquin, Utah 84655

1-801-754-5338 or Toll free 1-866-700-5877 ron@rpmrons.com

Engine start-up and the first few hours is probably the most critical time for your engine to survive a long healthy life! Every engine needs what is called an engine break-in procedure. Remember, do not tow heavy loads, or pull steep hills until your engine is fully broken in. If possible after your first and second oil and filter changes.

When your engine was first taken out of your vehicle, some things should have been marked so they can go back in the same way. These things include, but are not limited to, marking all vacuum lines, all grounds, distributor timing, spark plug wires, brackets and spacers, timing belt and gears and marks, hood placement, etc., etc., etc. All engine support systems have to be in good operational condition! A bad water pump for example could cause engine overheating. Make sure you install a new one and any other components that needs to be replaced. Remember, when your vehicle was new, all the rest of everything under your hood was new too. You will need new spark plugs, cap and rotor, possibly spark plug wires, air filter, pcv valve, thermostat, oxygen sensor (if computer controlled), etc. Be sure your radiator is in really good condition.

A timing light needs to be hooked (in most cases) to number 1 spark plug wire before engine start-up, total timing checked, so you don't do damage to your new engine. Your engine needs to be primed with oil before engine start-up.

Have someone sitting in drivers seat at all times on engine start-up, monitoring water temperature, oil pressure, and rpm. It is critical that the engine never idles for the first half hour! You could get a flat camshaft, seized wrist pins, spun engine bearings, and sever engine damage if you let it idle for any reason.

On non computer cars, ignition timing should be approx. 22-25 degrees timing @ 1800 rpms. Less at lower rpm.

Start the engine and bring rpm up to 1200-1300 rpm until water temperature just begins to rise. It is a good idea to leave your radiator cap off until your thermostat opens and water starts to circulate. Add coolant to bring coolant level up when the air locks circulate to radiator. Have some coolant mix ready to add to the radiator when this happens.Watch your timing mark to make sure you are between 15-25 degrees. As soon as your water temperature just starts to rise, bring rpm up to 1800 rpm, and check ignition timing to make sure you are approx. 22-25 degrees timing for engine break-in. Run the engine at 1800 rpm for at least half an hour, making sure someone is monitoring oil pressure and water temperature at all times! After your half hour or more break-in, bring engine up to 3000 rpm and check total timing. Most engines need to be between 32-38 degrees total timing. Bring engine to idle and quickly check initial timing. Time to factory specs. You can give a little bit more timing at idle for higher elevations, but total timing cannot be too much or engine damage can occur. You may have to have your distributor re-curved if the timing curve is not correct. Most non-computer vehicles need about 8 to 12 degrees at idle, and 32 to 38 degrees total timing.

If your car is computer controlled, then you will have to follow instructions for your particular vehicle to do the ignition timing, but rpm is followed in the same manor as above.

After engine break-in, turn engine off and let it cool. After it has cooled down, check for leaks (oil and water), check your oil for discoloration and level, and check your coolant level.

If everything looks and sounds OK, then take it out for a test drive. Still don't let the engine idle for any length of time. If you get stuck in traffic, or at a long light, then place car in neutral or park and bring rpm up slightly until you are ready to proceed.

Take your vehicle someplace where you can drive between 30 and 65 mph. Take vehicle up to 65 mph then let completely off the gas and let vehicle come down to approx. 30 mph. Do this about 10 times to help your rings seat. Do not beat your new engine! Just drive normal. Do not take engine above 4000 rpm, and do not pull any heavy loads for the first 2 oil and filter changes. Your first oil and filter change should be done at or before 500 miles. Preferably right away. Remember that everything in that new engine has to wear-in, and all that wear-in metal needs to get out of the system. Your second oil and filter change should be done approx. 1500 miles after your first one was done. Then every 2500-3000 increments for the rest of its life.

You should also check under your vehicle for the first two weeks for any leaks, and check your oil and coolant levels daily for the first two weeks.

That should do it! Happy motoring!

69 E. 580 N.

Santaquin, Utah 84655

1-801-754-5338 or Toll free 1-866-700-5877 ron@rpmrons.com

#117

Cam break in is critical. There are special break in oils for this purpose that "must be used". They are high in zinc (zddp) to help with the lack of lead in today's fuels. Several of the car shows on TV have talked and shown the affects of "wiping out" cam loves. With out proper oil and procedures followed you can destroy a cam in about 15 minutes. The oil is available from Comp Cams, Lucas and Royal Purple that I know of.

#119

I did break in the engine correctly, however I made a complacent mistake and didnít take out my inner spring on my heads due to me believing the poundage wasnít high since the shop that did the heads I bought claimed they were good to .600 lift. So I had too much pressure on the cam during break in, also two lifters appear to not have rotated in the bore. Next time this engine starts again I will make sure to take out the inner spring and I plan on honing the lifter bores