Crankcase vent

#1

Crankcase vent

I am currently replacing the engine in my van. It is an 84, I bought an 89 for the IDI, and later added a remote turbo. The replacement is a rebuilt later turbo engine.

What are the current thoughts on crank case ventilation? When I added the turbo I turned the CDR around and provided ways to vent it either in front of the turbo intake, the tail pipe, or the air. When I saw how much liquid oil was coming out I added a Mann separator after the CDR. I also tried the Mann without the CDR.

Might there be less oil flying around to be sucked into the vent if I vented off one or maybe both valve covers?

And, is the CDR useless because there would never be enough vacuum from any of the possible dump points to close the valve?

What are the current thoughts on crank case ventilation? When I added the turbo I turned the CDR around and provided ways to vent it either in front of the turbo intake, the tail pipe, or the air. When I saw how much liquid oil was coming out I added a Mann separator after the CDR. I also tried the Mann without the CDR.

Might there be less oil flying around to be sucked into the vent if I vented off one or maybe both valve covers?

And, is the CDR useless because there would never be enough vacuum from any of the possible dump points to close the valve?

#2

There is a lot about this on this forum. Search for things like "CDR delete." The general consensus is to keep your CDR, otherwise there will be smoking issues IIRC.

On my vans, I had a Banks van turbo kit, and my current van has the hypermax. The hypermax design is nice cuz it's short and emerges from the driver's side valve cover and connect to the inlet of the air intake housing pipe. Since there isn't a lot of room, this design is the most efficient. however, the grommet gets pliable after a few years and tears easily from the oil.

On the other van, I had the Banks system. While the Banks turbo and up-pipes seem heftier, the CDR design was rather convoluted. It comprised of a 1" dia bib eminating from the oil fill nozzle on the front of the engine, and three cobbed together sections of 1" dia rubber hose that worked their way around the driver's side valve cover over to the air intake housing.

That uses up a lot of space, but it vents from the gear housing plate, so I'm not sure about the splashback.

On a different topic, got any pics of your remote turbo setup?

On my vans, I had a Banks van turbo kit, and my current van has the hypermax. The hypermax design is nice cuz it's short and emerges from the driver's side valve cover and connect to the inlet of the air intake housing pipe. Since there isn't a lot of room, this design is the most efficient. however, the grommet gets pliable after a few years and tears easily from the oil.

On the other van, I had the Banks system. While the Banks turbo and up-pipes seem heftier, the CDR design was rather convoluted. It comprised of a 1" dia bib eminating from the oil fill nozzle on the front of the engine, and three cobbed together sections of 1" dia rubber hose that worked their way around the driver's side valve cover over to the air intake housing.

That uses up a lot of space, but it vents from the gear housing plate, so I'm not sure about the splashback.

On a different topic, got any pics of your remote turbo setup?

#3

[QUOTE=genscripter;17490666]There is a lot about this on this forum. Search for things like "CDR delete." The general consensus is to keep your CDR, otherwise there will be smoking issues IIRC.[QUOTE]

Keep the valve even if it will never close?

So is the vent just a piece of hose, there is a CDR in there, or what?

What I have is here. I will post more when I get it back together.

https://goo.gl/photos/LJNV4esgmYmSzKdL8

Keep the valve even if it will never close?

my current van has the hypermax. The hypermax design is nice cuz it's short and emerges from the driver's side valve cover and connect to the inlet of the air intake housing pipe. Since there isn't a lot of room, this design is the most efficient. however, the grommet gets pliable after a few years and tears easily from the oil.

On a different topic, got any pics of your remote turbo setup?[/

https://goo.gl/photos/LJNV4esgmYmSzKdL8

#4

#5

Sorry, I should have mentioned that the CDR is mounted to the side of the air intake housing. Here's a link to my website that contains more photos of this kind of van stuff: IDI Online ? DIY Repair for the 7.3 and 6.9 IDI Diesel Van

Here are the pics of the hypermax install and its CDR location: Hypermax Van Turbo Install for the 7.3 IDI in a 1988 Ford Clubwagon ? IDI Online

Here is the write-up about the Banks Turbo setup in the '84 van, and you can see the weird longer CDR routing setup: Pulling a 6.9 IDI Engine from a 1984 E350 Econoline Van ? IDI Online

Here are the pics of the hypermax install and its CDR location: Hypermax Van Turbo Install for the 7.3 IDI in a 1988 Ford Clubwagon ? IDI Online

Here is the write-up about the Banks Turbo setup in the '84 van, and you can see the weird longer CDR routing setup: Pulling a 6.9 IDI Engine from a 1984 E350 Econoline Van ? IDI Online

#6

What I have is here. I will post more when I get it back together.

https://goo.gl/photos/LJNV4esgmYmSzKdL8

https://goo.gl/photos/LJNV4esgmYmSzKdL8

Holy *****. that's some creative IDI mods. You should really considering writing a blog or a thread on your mods here on the FTE IDI forum.

Like the idler pulley idea. The alternator really whips a lot. Clever stuff.

You should consider tossing those transfer e-pumps. Mr Gasket style pumps fall apart or fail very easily, and I doubt they are pushing the requisite pressure and flow necessary for an IDI. You should really find a Facet Duralift e-pump with at least 7-9 or 9-11.5 psi operating pressure.

But more importantly, I gotta see pics of the turbo location on the y-pipe. Are you using the stock y-pipe? Or did you fab up custom exhaust?

Why did you run an electronic temp sensor on your boost air? Are you expecting higher temps due to the lack of an innercooler? I guess with your remote setup, you could more easily install an undermount innercooler than the standard Banks and Hypermax van setup.

In your pics, you have some creative ways to run the CDR stuff, but you might want to simplify it like the Hypermax kit. I really think you would benefit from the Hypermax design, because all you need is a valve cover hole, grommet, nylon bib, and section of hose to the CDR on the air intake. You could have the CDR installed on the valve cover housing, and then run the hose up to the air filter housing. Speaking of that, where is your air filter?

#7

Notice he is running a Mann ProVent unit, this separates oil from the vented air before putting it into the intake... Keeps turbo, plumbing, intercooler clean and drains separated oil into the pan. Though in another picture it looks like maybe later on switched to running a crankcase evac down into the exhaust... But it wouldn't make sense to put that before the turbo so maybe it runs down to the intake and no longer goes through the oil separator? ... Please explain your setup, I'm curious. I also want to try the Mann ProVent to keep keep so much oil from going through the intake.

Trending Topics

#8

Notice he is running a Mann ProVent unit, this separates oil from the vented air before putting it into the intake... Keeps turbo, plumbing, intercooler clean and drains separated oil into the pan. Though in another picture it looks like maybe later on switched to running a crankcase evac down into the exhaust... But it wouldn't make sense to put that before the turbo so maybe it runs down to the intake and no longer goes through the oil separator? ... Please explain your setup, I'm curious. I also want to try the Mann ProVent to keep keep so much oil from going through the intake.

Run to the exhaust it added grey smoke; there was none before.

The last place before tear down was to the air because I wanted to see if there was any oil passing the Mann. And yes, it looked like the underside of the van was on fire. But the engine did seem to run better on diesel fuel than crankcase fumes.

I had the Mann drain into a catch can while I was sorting out other things.

#9

[QUOTE=genscripter;17491487]Holy *****. that's some creative IDI mods. You should really considering writing a blog or a thread on your mods here on the FTE IDI forum.[QUOTE]

Did you note the filter is no longer on the engine. I'll say more about that later.

The pump you see on the frame and the second pump pic, I don't recall having one of those fail. I have added a couple pumps that I an using to the van album. The 55 wagon I am building - sorry not diesel - is getting this pair. https://photos.app.goo.gl/1hwvcHD9pVNY7gzH2

It is the stock Y pipe with a piece added to mate to the turbo. I'll add pics after I get it back together.

I am actually kinda surprised you noticed. How would I know if an intercooler was needed or useful if I did not know the temp without one? The gauge is digital, starts at 40C. I need to climb mountains to get it much above that. But note, there is about five feet of aluminum tubing between the compressor and intake. I have an intercooler that I could stuff in there. But it had not become a priority.

[QUOTE]In your pics, you have some creative ways to run the CDR stuff, but you might want to simplify it like the Hypermax kit. I really think you would benefit from the Hypermax design, because all you need is a valve cover hole, grommet, nylon bib, and section of hose to the CDR on the air intake. You could have the CDR installed on the valve cover housing, and then run the hose up to the air filter housing.[QUOTE]

The CDR tries to be an oil separator. I think the consensus is that it is not very good at that. Then there is the valve function. Supposedly, vacuum on the CDR outlet will close the valve. It is not clear to me what conditions make it desirable to close. A turbo installation will often result in use of a cone filter - I currently use a cone but that could change. Cone filters tend to get dirty and constrict sooner than stock filters. I have a vacuum gauge in front of the compressor intake. If the gauge ever moves the filter is dirty. If that doesn't get your attention maybe the black soot will. My inclination is to run the front of both valve covers to a Mann. For the output of the Mann I still have the three options. Running it to the compressor intake is the cleanest externally.

The current location of the air filter, is the end of the current chapter, of a long and initially frantic evolution, of the installation of a turbo system. I may discuss that later - or not.

Did you note the filter is no longer on the engine. I'll say more about that later.

You should consider tossing those transfer e-pumps. Mr Gasket style pumps fall apart or fail very easily, and I doubt they are pushing the requisite pressure and flow necessary for an IDI. You should really find a Facet Duralift e-pump with at least 7-9 or 9-11.5 psi operating pressure.

But more importantly, I gotta see pics of the turbo location on the y-pipe. Are you using the stock y-pipe? Or did you fab up custom exhaust?

Why did you run an electronic temp sensor on your boost air? Are you expecting higher temps due to the lack of an innercooler? I guess with your remote setup, you could more easily install an undermount innercooler than the standard Banks and Hypermax van setup.

[QUOTE]In your pics, you have some creative ways to run the CDR stuff, but you might want to simplify it like the Hypermax kit. I really think you would benefit from the Hypermax design, because all you need is a valve cover hole, grommet, nylon bib, and section of hose to the CDR on the air intake. You could have the CDR installed on the valve cover housing, and then run the hose up to the air filter housing.[QUOTE]

The CDR tries to be an oil separator. I think the consensus is that it is not very good at that. Then there is the valve function. Supposedly, vacuum on the CDR outlet will close the valve. It is not clear to me what conditions make it desirable to close. A turbo installation will often result in use of a cone filter - I currently use a cone but that could change. Cone filters tend to get dirty and constrict sooner than stock filters. I have a vacuum gauge in front of the compressor intake. If the gauge ever moves the filter is dirty. If that doesn't get your attention maybe the black soot will. My inclination is to run the front of both valve covers to a Mann. For the output of the Mann I still have the three options. Running it to the compressor intake is the cleanest externally.

Speaking of that, where is your air filter?

#10

Amazing ideas. Very creative too. I put a bunch of stuff on my IDI van, but I went down a more conventional route, except for the custom biofuel mods.

I weighed the options of remote- vs local-turbo setups, but after after seeing the sale price of the hypermax system, I figured that I wouldn't be fab up a custom remote setup for less than the $1500 for brand new. Granted the hypermax kit has it's design problems, but the prospect of all the pieces fitting on the first try felt a lot better considering this is my hobby and I can't afford to dink around much with a kid to take care of. Also, my innercooler plans are a lot more daunting with this hypermax kit than I want to admit, but a remote setup would leave a lot more options for you.

I'd love to hear more about if your remote setup has any turbo lag, and also if the temp sensor readings are substantially less after your install the innercooler.

My current design plan for my inner cooler is to route the inlet and outlet innercooler piping under the passenger side battery and move the tranny cooler lower so the innercooler can site in front of the condenser. That's probably the least invasive design with the conventional innercooler. However, a friend said I should consider running the innercooler above the air intake hat, and install an electric fan on the cooler that has a temp controller. IDK. Seems like it would just be blowing hat engine air on the cooler.

Another idea is to run a heat exchanger instead of an innercooler. I would run smaller hydraulic hose to an aux engine cooler in front of the condenser and a small transfer pump with oil that is constantly flowing from the cooler to the heatexchanger and back again. I'm just not convinced it would really change much of the air temp after all that investment.

I weighed the options of remote- vs local-turbo setups, but after after seeing the sale price of the hypermax system, I figured that I wouldn't be fab up a custom remote setup for less than the $1500 for brand new. Granted the hypermax kit has it's design problems, but the prospect of all the pieces fitting on the first try felt a lot better considering this is my hobby and I can't afford to dink around much with a kid to take care of. Also, my innercooler plans are a lot more daunting with this hypermax kit than I want to admit, but a remote setup would leave a lot more options for you.

I'd love to hear more about if your remote setup has any turbo lag, and also if the temp sensor readings are substantially less after your install the innercooler.

My current design plan for my inner cooler is to route the inlet and outlet innercooler piping under the passenger side battery and move the tranny cooler lower so the innercooler can site in front of the condenser. That's probably the least invasive design with the conventional innercooler. However, a friend said I should consider running the innercooler above the air intake hat, and install an electric fan on the cooler that has a temp controller. IDK. Seems like it would just be blowing hat engine air on the cooler.

Another idea is to run a heat exchanger instead of an innercooler. I would run smaller hydraulic hose to an aux engine cooler in front of the condenser and a small transfer pump with oil that is constantly flowing from the cooler to the heatexchanger and back again. I'm just not convinced it would really change much of the air temp after all that investment.

#11

Here is a bit of an update on the van. The new engine now has 2400 miles. Pics are linked below.

The crankcase vent seems to work very well. Both valve covers vent to a Mann separator. I initially took the output to the atmosphere so I could see if there was smoke and/or oil. The Mann drains to a catch can that has a valve on the bottom. I just opened that valve for the first time; nothing came out. That would indicate there is no oil exiting the valve covers. The CDR in the old engine passed a lot of oil.

The Mann still exits at frame level. Output vapor is barely noticeable.

I have a vacuum/boost gauge and I am not aware of turbo lag. The output piping should be as small as possible without causing a restriction.

The air intake temp gauge just before the intake manifold starts at 40c and around town never moves. Third gear, foot on the floor, up a mountain, it can get over 100c. I think that condition would over power any realistic inter-cooler. I am not going to bother trying to install one.

When I could not get a turbo flexplate I pulled the rotating assembly and took it and the 89 flexplate/flywheel to a balance shop. They matched the damper to the crank and the crank to the 89 flexplate/flywheel. I have a Yoda bobble-head on the dog house. At a stop light with the old engine his head would bounce a quarter inch. Now it barely moves. $145.

Ray

https://photos.google.com/share/AF1Q...9laHRsbGlJZkdB

The crankcase vent seems to work very well. Both valve covers vent to a Mann separator. I initially took the output to the atmosphere so I could see if there was smoke and/or oil. The Mann drains to a catch can that has a valve on the bottom. I just opened that valve for the first time; nothing came out. That would indicate there is no oil exiting the valve covers. The CDR in the old engine passed a lot of oil.

The Mann still exits at frame level. Output vapor is barely noticeable.

I have a vacuum/boost gauge and I am not aware of turbo lag. The output piping should be as small as possible without causing a restriction.

The air intake temp gauge just before the intake manifold starts at 40c and around town never moves. Third gear, foot on the floor, up a mountain, it can get over 100c. I think that condition would over power any realistic inter-cooler. I am not going to bother trying to install one.

When I could not get a turbo flexplate I pulled the rotating assembly and took it and the 89 flexplate/flywheel to a balance shop. They matched the damper to the crank and the crank to the 89 flexplate/flywheel. I have a Yoda bobble-head on the dog house. At a stop light with the old engine his head would bounce a quarter inch. Now it barely moves. $145.

Ray

https://photos.google.com/share/AF1Q...9laHRsbGlJZkdB

#12

#13

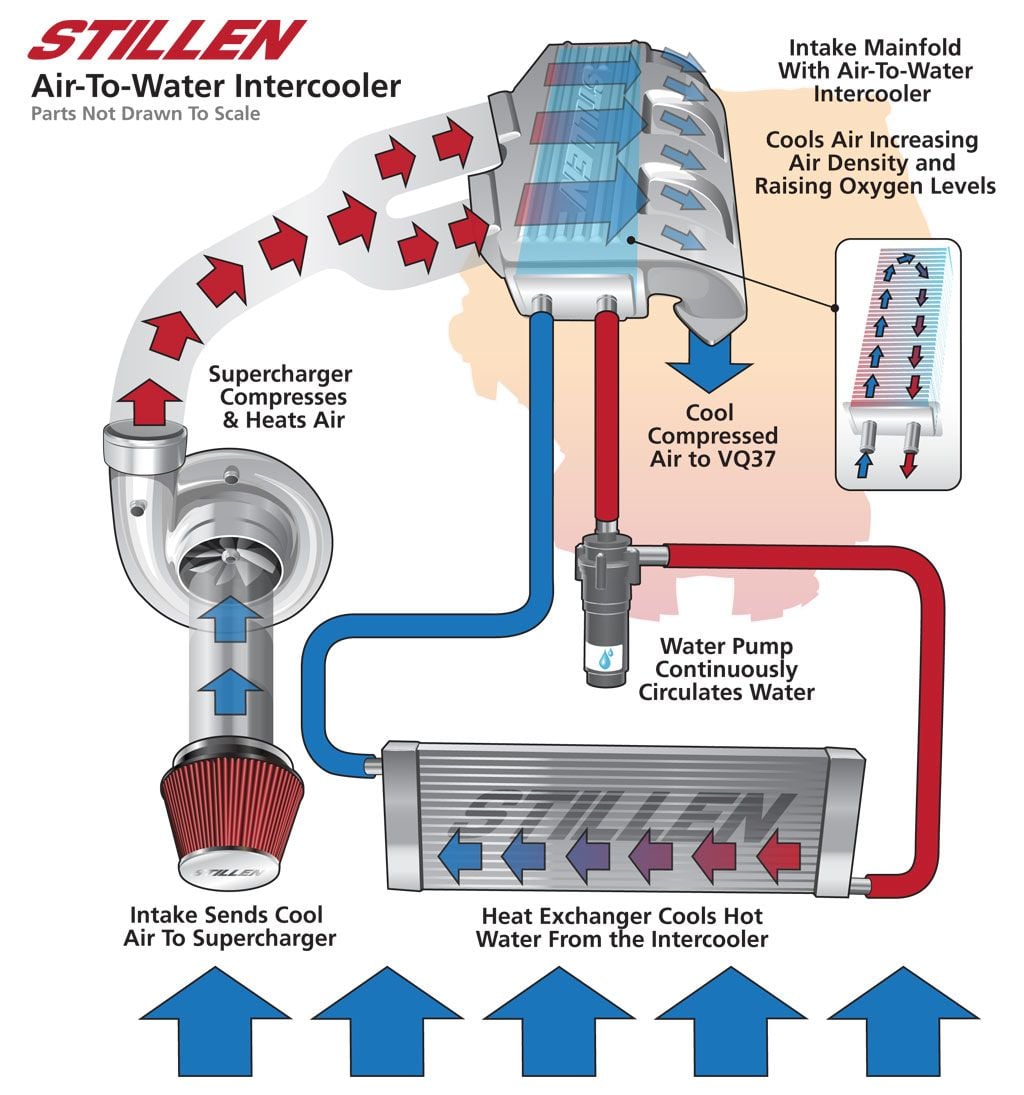

A van seems like a good application for an air to water intercooler. I recall a guy on here frmo MD did one and had temp sensors at various points. I could be mistaken but I think it would get heat soaked when worked hard but it took a while and still an overall intake temp drop.

Thread

Thread Starter

Forum

Replies

Last Post

raydav

Pre-Power Stroke Diesel (7.3L IDI & 6.9L)

9

04-27-2014 10:58 AM