Speed Daddy Stainless headers for a 351w

#31

#33

I don't have an measurement but the holes are egg shaped and needed to be more round. They didn't have to drill out the entire hole more or anything but i would think you need some good tools to cut through the metal. The flange is thick

#35

#37

OK, I finally popped for these. Put driver's side on. Three bolt holes didn't line up. Not my first header rodeo. Pulled back and started the offending bolts first. That left only the frontmost one missing by a little. Whipped out the carbide grinder, egg-shaped that one a bit, and on it went. Found my parts store aftermarket header bolts to be woefully short. Flanges look to be about 3/8" thick. Header box included some utterly useless bolts that were a size too small to even thread into the heads. Tossed those in the junk box and ordered some Allen bolts from a local bolt store.

To the passenger side. Broke two manifold bolts off in the head. One came out other had to be drilled and retapped. Luckily both towards the rear where I had good access with the inner fender pulled. Put header on. Slammed one tube right into the starter with a very noticeable gap at the head. That would never seal, even tried fitting with triple gaskets. Had doubts but marked the tube for hammer work. No help and bloody hard to dent. That and I didn't wish to beat more than a biggish ding. Considered options and decided to mill the flange at an angle so that the outlet would be moved further from the engine. Halfassedly mounted in my mill and my flycutter sort of bounced off the flange rather than hacking into it as desired.

Plan B. Had a couple of leftover grinding stones retired from a flywheel grinding machine. I made up an adapter to mount one of those in the mill. Took FOREVER but worked nicely. My mill isn't set up for fluid cooling and I found the wheels would burn up used dry. I compromised with some treated water and a spray bottle. That worked. While I was at this I chuckled at how badly the flange was warped from the tubes being welded to it. Stopped chuckling when I realized I had already bolted on the other header which was surely just as warped. Son of a.... I used a belt sander to sort that one out rather than attempt a second Rube Goldberg mill mounting. Used up two sanding belts, stainless is tough! I KNEW better than to not check the flange first but I think I was overly impressed by the unusual thickness.

My totally eyeball calculated 18.5 (or something) degree angle cut positioned the pipe about halfway between the starter and the framerail. Perfect!

The EGR tube was aimed slightly incorrectly and despite the looks, the EGR tube isn't flexible, it broke. OK, as it was also too long. Ground down the inner to just fit on, gorped some hitemp copper RTV where the inner and outer tubes slid together, and forced it on. Seems OK after two weeks of commuting but I'll still keep an eye on it as I have doubts about it for the long term. Had to slightly egg two of the bolt holes in the flange, but not much.

My truck uses only one O2 sensor. It wouldn't fit on the passenger side so I had to lengthen the wires to allow to to reach the driver's side bung where it fit fine. My truck is somewhat unique in having a 5.8 and a 4R70W, folks with the more usual transmissions may not have such a fitment problem.

I really like headers and I REALLY like stainless ones. I really appreciate how the diameter of the tubing necks down a bit just before the flanges. You'd never get bolts in if they didn't. Also they clear regular old 90 degree angled spark plug wire boots just fine too. But I know a lot of folks would be thrown under the bus if they had to deal with what I did. Egging a couple of holes and buying some bolts is no big deal but that business with the flange being welded to the tubes at wrong angle is a pretty serious problem for the majority of backyard mechanics. Even many shops might balk at dealing with that.

I still really like them despite the issues but can't say I recommend them. I enjoy mild challenges and was equipped to deal with them. But the great majority of folks just want to bolt stuff like this on and go though.

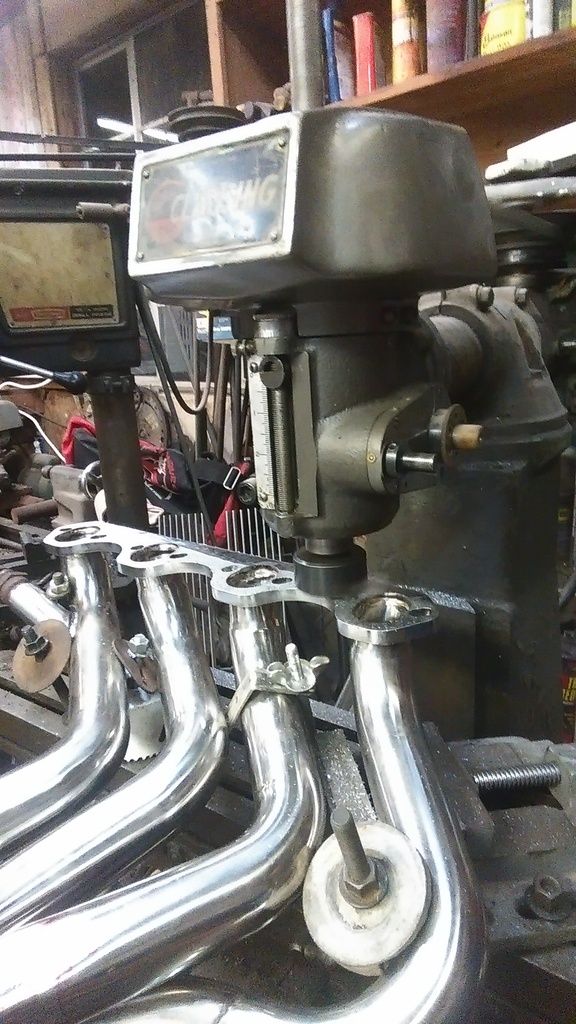

Picture is a flycutter ineffectually bouncing off the flange. I only posted it so you professional machinists could get a big laugh out of my mounting setup. I STILL can't actually believe that worked as well as it did. There was a slight variation from end to end but it happened to be to my advantage so I ran with it.

To the passenger side. Broke two manifold bolts off in the head. One came out other had to be drilled and retapped. Luckily both towards the rear where I had good access with the inner fender pulled. Put header on. Slammed one tube right into the starter with a very noticeable gap at the head. That would never seal, even tried fitting with triple gaskets. Had doubts but marked the tube for hammer work. No help and bloody hard to dent. That and I didn't wish to beat more than a biggish ding. Considered options and decided to mill the flange at an angle so that the outlet would be moved further from the engine. Halfassedly mounted in my mill and my flycutter sort of bounced off the flange rather than hacking into it as desired.

Plan B. Had a couple of leftover grinding stones retired from a flywheel grinding machine. I made up an adapter to mount one of those in the mill. Took FOREVER but worked nicely. My mill isn't set up for fluid cooling and I found the wheels would burn up used dry. I compromised with some treated water and a spray bottle. That worked. While I was at this I chuckled at how badly the flange was warped from the tubes being welded to it. Stopped chuckling when I realized I had already bolted on the other header which was surely just as warped. Son of a.... I used a belt sander to sort that one out rather than attempt a second Rube Goldberg mill mounting. Used up two sanding belts, stainless is tough! I KNEW better than to not check the flange first but I think I was overly impressed by the unusual thickness.

My totally eyeball calculated 18.5 (or something) degree angle cut positioned the pipe about halfway between the starter and the framerail. Perfect!

The EGR tube was aimed slightly incorrectly and despite the looks, the EGR tube isn't flexible, it broke. OK, as it was also too long. Ground down the inner to just fit on, gorped some hitemp copper RTV where the inner and outer tubes slid together, and forced it on. Seems OK after two weeks of commuting but I'll still keep an eye on it as I have doubts about it for the long term. Had to slightly egg two of the bolt holes in the flange, but not much.

My truck uses only one O2 sensor. It wouldn't fit on the passenger side so I had to lengthen the wires to allow to to reach the driver's side bung where it fit fine. My truck is somewhat unique in having a 5.8 and a 4R70W, folks with the more usual transmissions may not have such a fitment problem.

I really like headers and I REALLY like stainless ones. I really appreciate how the diameter of the tubing necks down a bit just before the flanges. You'd never get bolts in if they didn't. Also they clear regular old 90 degree angled spark plug wire boots just fine too. But I know a lot of folks would be thrown under the bus if they had to deal with what I did. Egging a couple of holes and buying some bolts is no big deal but that business with the flange being welded to the tubes at wrong angle is a pretty serious problem for the majority of backyard mechanics. Even many shops might balk at dealing with that.

I still really like them despite the issues but can't say I recommend them. I enjoy mild challenges and was equipped to deal with them. But the great majority of folks just want to bolt stuff like this on and go though.

Picture is a flycutter ineffectually bouncing off the flange. I only posted it so you professional machinists could get a big laugh out of my mounting setup. I STILL can't actually believe that worked as well as it did. There was a slight variation from end to end but it happened to be to my advantage so I ran with it.

#38

#40

While after reading the last install post I wouldn't either but when I asked my shop if they had fitment issues he just laughed in a real deep smokers laugh and said yeah they all do but it wasn't too bad and they only charged me $425 for the install then more of course for routing and welding the rest of the exhaust and I've not had any issues with leaks, ticks or anything. But I understand what you are saying for sure. Who knows one set may be made closer to spec than the other. Did you see the box mine came in? Look up in this thread for pics if you didn't

#41

This is a classic example of you get what you pay for, and these headers are cheap. They seem reasonably well constructed but honestly that's the easy part in fabrication/manufacturing, hitting tolerances and having good fitment in quantity is what takes skill.

#43

I just put these on my boys f150 and they woke the truck up. Only downfall besides breaking the manifold bolts taking the old exhaust off is these headers literally are up against the starter. I'm talking less than a 1/16". I thought I could run for awhile like this but the starter shot crap in less than two weeks. I ended up getting a new summit mini starter that's adjustable to try and move it away from the headers along with a heat shield. The other issue is the cheap header gasket they give you. I blew a gasket right before the starter went out so I ended up getting the good gaskets. One more thing is the passenger o2 bung was too high on the collector so it was against the transmission lines preventing the o2 sensor from being installed. I ended up welding a new bung just below the other. I'll try to post some pics tonight.

Thread

Thread Starter

Forum

Replies

Last Post

AstroFab

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

5

11-16-2011 07:13 PM

14&Ford

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

4

08-21-2011 06:25 AM

rwsam

1978 - 1996 Big Bronco

6

06-15-2002 04:29 PM