Gloria: OBS build thread

#16

Looking good Andrew! Glad my thread was some help to you. Everything I did I owe to all the other guys on here for helping me though. You're doing a great job! And definitely keep the pics coming! Look forward to meeting you at RRE and seeing that sweet looking truck in person!

As a side note, does anyone know what these 160/80 & S366 combo are truly capable of in terms of 1/4 and/or 1/8 times in an OBS? I know a few people figure they are likely hanging out around the 400, 400 and some change range, but dyno's are different ect ect.. Have only ever ridden in modified superdudies, and in theory it'll take a little less to get an OBS running with the weight difference..

#17

#18

Build's looking good! I'm definitely subscribed, to see how the rest of the turbo build plays out! God knows I'm borrowing all sorts of ideas from the S366 conversion to figure out what I'll need to build it!

#19

Hey Guys, I'll do a small update here.

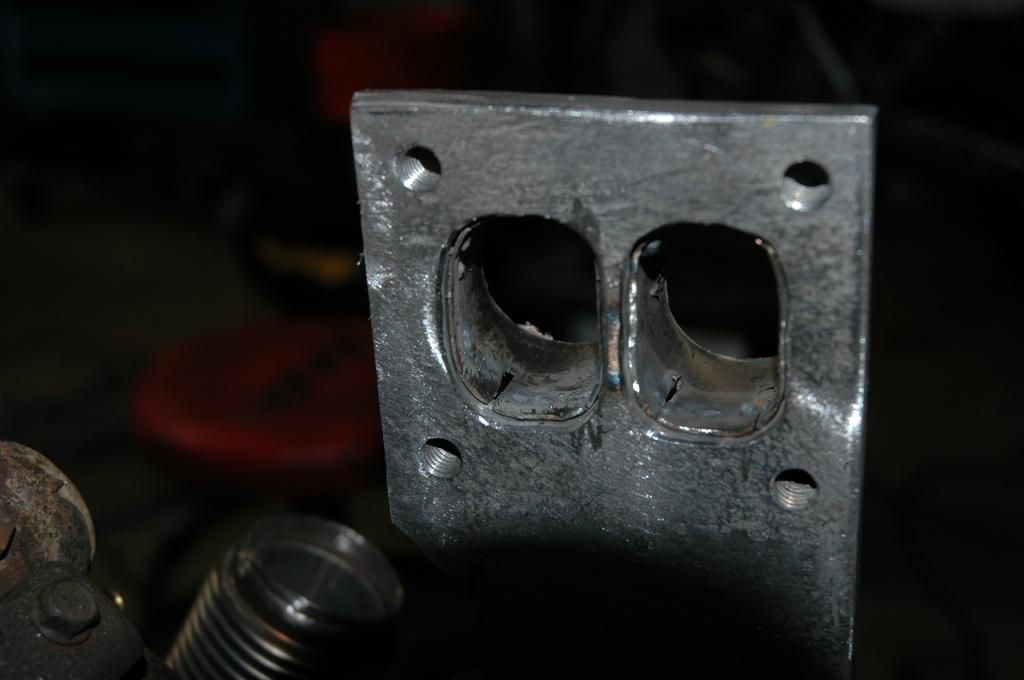

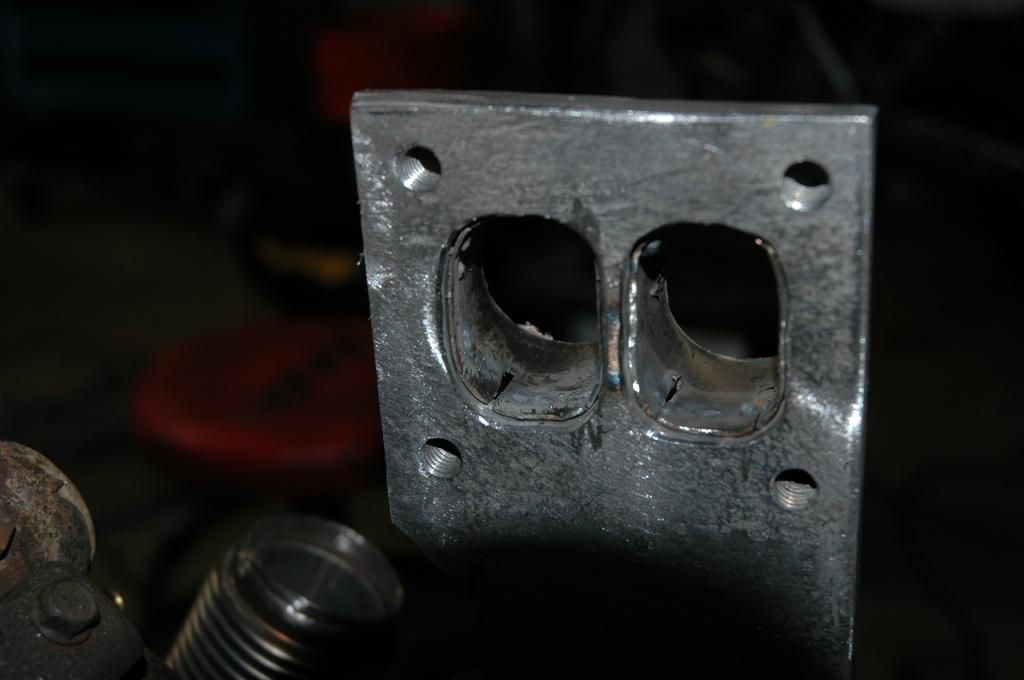

Spent a considerable amount of time working some pieces to fit into the plate. to transition to the up pipes.

Dont mind to tacks, I have a harbour freight gas-less welder deal that dosnt do a nice job. These will be cleaned up on a tig shortly.

Started mocking up the first side.

Then I didnt like how the bellow was right near the one transmission bellhousing bolt, was going to make for a tight fit. Also, I came across some for info that suggested I should keep the bellow higher if I could to help maintain room for the downpipe.

So I moved it up a bit.

Some more nasty looking tacks.

As it stands now, I have the remaining side partially mocked up, but I need to weld out the first side before I tack it in. Adding the other side is going to cut off access for a couple areas that will need to be sealed up with the tig. So I am going to get the first side welded up, come back, finish fitting the second side, and then have that welded up as well.

This is what the second side looks like.

-Andrew

Spent a considerable amount of time working some pieces to fit into the plate. to transition to the up pipes.

Dont mind to tacks, I have a harbour freight gas-less welder deal that dosnt do a nice job. These will be cleaned up on a tig shortly.

Started mocking up the first side.

Then I didnt like how the bellow was right near the one transmission bellhousing bolt, was going to make for a tight fit. Also, I came across some for info that suggested I should keep the bellow higher if I could to help maintain room for the downpipe.

So I moved it up a bit.

Some more nasty looking tacks.

As it stands now, I have the remaining side partially mocked up, but I need to weld out the first side before I tack it in. Adding the other side is going to cut off access for a couple areas that will need to be sealed up with the tig. So I am going to get the first side welded up, come back, finish fitting the second side, and then have that welded up as well.

This is what the second side looks like.

-Andrew

#21

Yes looking forward to it as well. Did big red get patched up from the deer inci-dent (hahaaa), or does she sport the battle scar?

Yep Im always up for meeting up and convoying if possible. Although we are a bit further east than you are thinking I believe. I would take I-81 all the way down till the pretty much. But looks like the last 2 hours or so we would be on the same road...

As a side note, does anyone know what these 160/80 & S366 combo are truly capable of in terms of 1/4 and/or 1/8 times in an OBS? I know a few people figure they are likely hanging out around the 400, 400 and some change range, but dyno's are different ect ect.. Have only ever ridden in modified superdudies, and in theory it'll take a little less to get an OBS running with the weight difference..

#23

Yes got them on. Not sure I like them yet or not. But, the is a small dime of rust that I cut out, cleaned up, epoxy primered and painted, in the passenger side rear fender well. Didnt want to have to repaint the bed. So flares are on there for now.

#24

Dont really have an clear answer for you other than I just am doing what most other T4 kits do. I think making a gasket would be very difficult because two surfaces would need to mate really well. Im not going to lie, with a zipcuts to work with, Im depending on a friend with a tig welding to make things fit well. I dont think I could have achieved the correct amount of precision to have it be a gasket fit..

#25

Its already going to have a gasket where it meets the turbo.another gasket is redundant and just a other place to leak.

Andrew,my hat off to your tig welder.filling gaps is difficult with a tig .for me anyway..

I was the guy at rre that was discussing trans coolers and you switching to rsk at the show.

I have the red cc with the bet topper/camper shell and riff raff rocker decal lol

Andrew,my hat off to your tig welder.filling gaps is difficult with a tig .for me anyway..

I was the guy at rre that was discussing trans coolers and you switching to rsk at the show.

I have the red cc with the bet topper/camper shell and riff raff rocker decal lol

#26

Its already going to have a gasket where it meets the turbo.another gasket is redundant and just a other place to leak.

Andrew,my hat off to your tig welder.filling gaps is difficult with a tig .for me anyway..

I was the guy at rre that was discussing trans coolers and you switching to rsk at the show.

I have the red cc with the bet topper/camper shell and riff raff rocker decal lol

Andrew,my hat off to your tig welder.filling gaps is difficult with a tig .for me anyway..

I was the guy at rre that was discussing trans coolers and you switching to rsk at the show.

I have the red cc with the bet topper/camper shell and riff raff rocker decal lol

#27

That wasnt my point tho; i was more interested in why not make the assembly more modular for service. I know thered be two gaskets in that scenario.. If machining wasnt an issue itd be the correct way to go about constructing the assembly; itd actually be even better if the upps were segrigated but retained together w a collar but thats a moot point now...

This way seems like it would just be one less place to have a leak.

#28

Yeah, i hear that.. In the recient BTS thread there was a pic of an up pipe assembly that looked pretty decent, not the welds but the design in particular. Sorry to the op for dragging the comment out; i find fab work enjoyable and like to discuss it..

#30

Its already going to have a gasket where it meets the turbo.another gasket is redundant and just a other place to leak.

Andrew,my hat off to your tig welder.filling gaps is difficult with a tig .for me anyway..

I was the guy at rre that was discussing trans coolers and you switching to rsk at the show.

I have the red cc with the bet topper/camper shell and riff raff rocker decal lol

Andrew,my hat off to your tig welder.filling gaps is difficult with a tig .for me anyway..

I was the guy at rre that was discussing trans coolers and you switching to rsk at the show.

I have the red cc with the bet topper/camper shell and riff raff rocker decal lol

And yes, the tig welder is def challenging. I have had my goes with it, and Im better with a wire feed. I think it's a matter of minimal heat and just dropping some material in at first, then coming back over with another pass or two once there is something there. Hopefully it all goes well. I've tried to minimize the holes, but as I said before, with a one off never having done this without a jig... Its not perfect