Turbos, Tanks and Transmissions: 29 Years as an Automotive Engineer

If you’re a regular on the forum, you might recognize my name, as I’ve been contributing here for years. Under strict instructions from the editorial staff, I’m going to write about whatever I happen to think of. Look out.

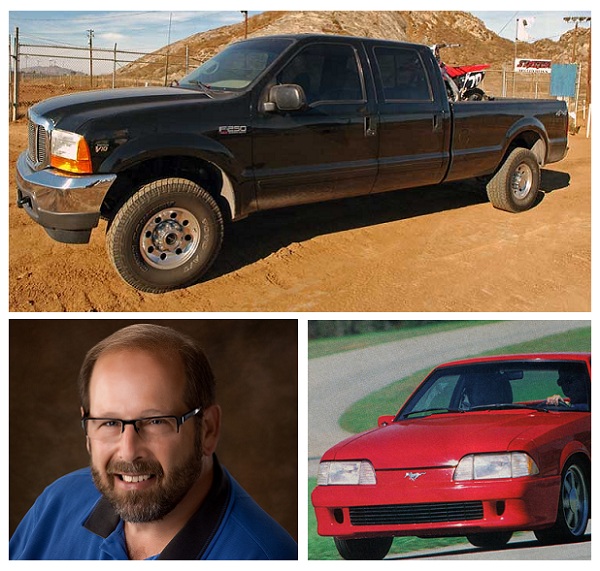

Some of it will be technical, some of it may be about my experiences as an engineer developing engines, transmissions, and differentials over the course of a 29 year career as an Automotive Engineer in Detroit.

For an idea of what kind of stuff I’ll be posting, you can check out a piece I wrote about a fast Fox Body for our sister site, TheMustangSource.

First, some background.

I graduated from Lawrence Technological University (then Lawrence Institute of Technology) with a Bachelor of Science in Mechanical Engineering in June, 1980. I immediately went to work at Chrysler Defense, Inc.

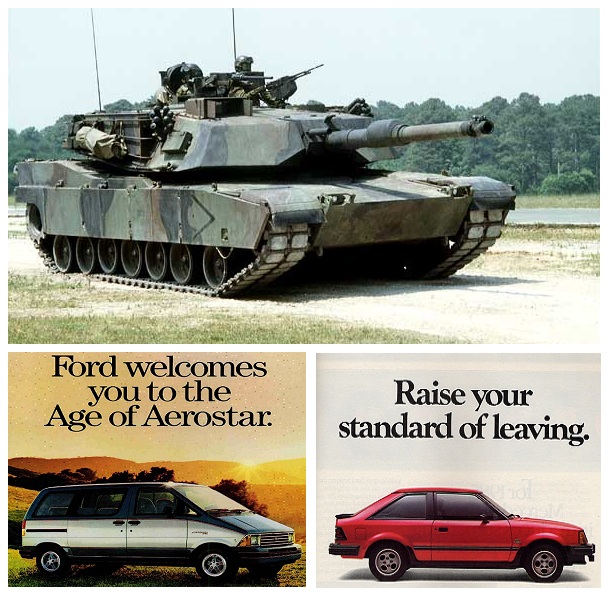

I was an engineer on the M1 Abrams Main Battle Tank transmission. That’s a four speed forward, two speed reverse automatic transmission. The transmission weighs 4,500 pounds and holds 45 gallons—not quarts—of Mobil 1 Synthetic ATF. After two and a half years of that I left and went to work at Roush Industries, where I worked on a couple of production-bound programs. These included the 5.8L four barrel light truck engine and the 1.6L Turbo that went into Escorts and EXPs in the mid 80’s.

The 1.6L was only the second EEC-IV program at Ford.

I also worked on many concept vehicles. Some notable ones were a 3.0L turbocharged Aerostar. This was before the Aerostar was even in production. Ford had found out that GM was going to have a 4.3L in the Astro/Safari and the Aerostar only had a 3.0L. The 3.8L was too wide to fit, so maybe a turbo could make the 3.0L competitive with the GM 4.3L.

It was never was seriously considered for production.

I also worked on a proposal for a 25th Anniversary Mustang. This car had a 5.8L with twin turbos. You can read the full story over on our sister site, TheMustangSource, but we built that car in such a hurry that we never even ran the engine on a dyno. Jack Roush it made about 400 flywheel horsepower. I drove the car it’s first 2000 miles developing the engine calibration, commonly called the tune.

In 1988 I left Roush to work at Ford in the Automatic Transmission Engineering Office. One bit of trivia? My new desk at Ford was about 500 feet from my old desk at Roush. It was right across the street!

At Ford I started with the AXODE. It was a modification to the AXOD transmission used in the Taurus. We changed the hydraulic controls to electronic controls. We were the second Ford electronic transmission right behind the E4OD.

Next I was promoted to engineering supervisor and put in charge of a small group developing the on board and off board diagnostics for all Ford transmissions.

After three years of that I moved to supervising a calibration group that developed the transmission tunes for the Lincoln LS. But almost five years in that position, I realized I really wanted to be an engineer, not an administrator, so I requested a “demotion” back to Product Engineer. In the TorqShift Transmission Department, where I developed the tunes in the 2005 Diesel F-Series tranny, which would remain basically unchanged for 2006 and 2007. In 2004, I moved to Transmission Cooling, where I developed cooling procedures to insure every vehicle we produced would keep the transmission in the proper operating range.

Ford offered most of the white collar workforce a buyout in 2007. I decided to accept that offer and left Ford—along with approximately 14,000 others—on February 28, 2007.

My plan was to take a couple months off and relax before looking for a new job. But I didn’t count on employers searching me out, and was back to work in three weeks at a German supplier to the auto industry called Getrag. There, I worked on electronically controlled limited slip differentials, once again developing the tune. It was much more than locking the axle when there was slip. We could lock or unlock anywhere from 0-100% to provide traction and control handling.

For example, if the car was oversteering (loose) we would lock the axle which moved it towards understeer (tight). This cancelled the oversteer and made the car neutral. The opposite happened with understeer.

This system was going to be in the 2009 Cadillac CTS-V, but we had supplier issues and had to delay the program. The next one we were slated for was the 2012 Corvette ZR1. Unfortunately GM ran out of money and cancelled our program. We were all laid off.

After a couple of years owning and operating a shop in Ocala my wife and I moved to South Florida to be near our children and granddaughter. I now live in paradise, never shovel snow, and write about my experiences in the industry.

Stay tuned, I’ve got a lot more stories to share!