Proportioning Valve Cleaning

#1

Proportioning Valve Cleaning

I wanted to contribute with a tech thread on these gremlin valves. My brakes were acting up so I decided instead of replacing this valve $$$$ I refurbished it.

Tools I used. Note wood handled tools are clay sculpting tools from hobby store. Brush has nylon bristles not metal. If bad O rings are found go to Amazon and look for BRAKE part O rings. There is a specific type of O ring out there that is resistant to brake fluid trust me.

Valve:

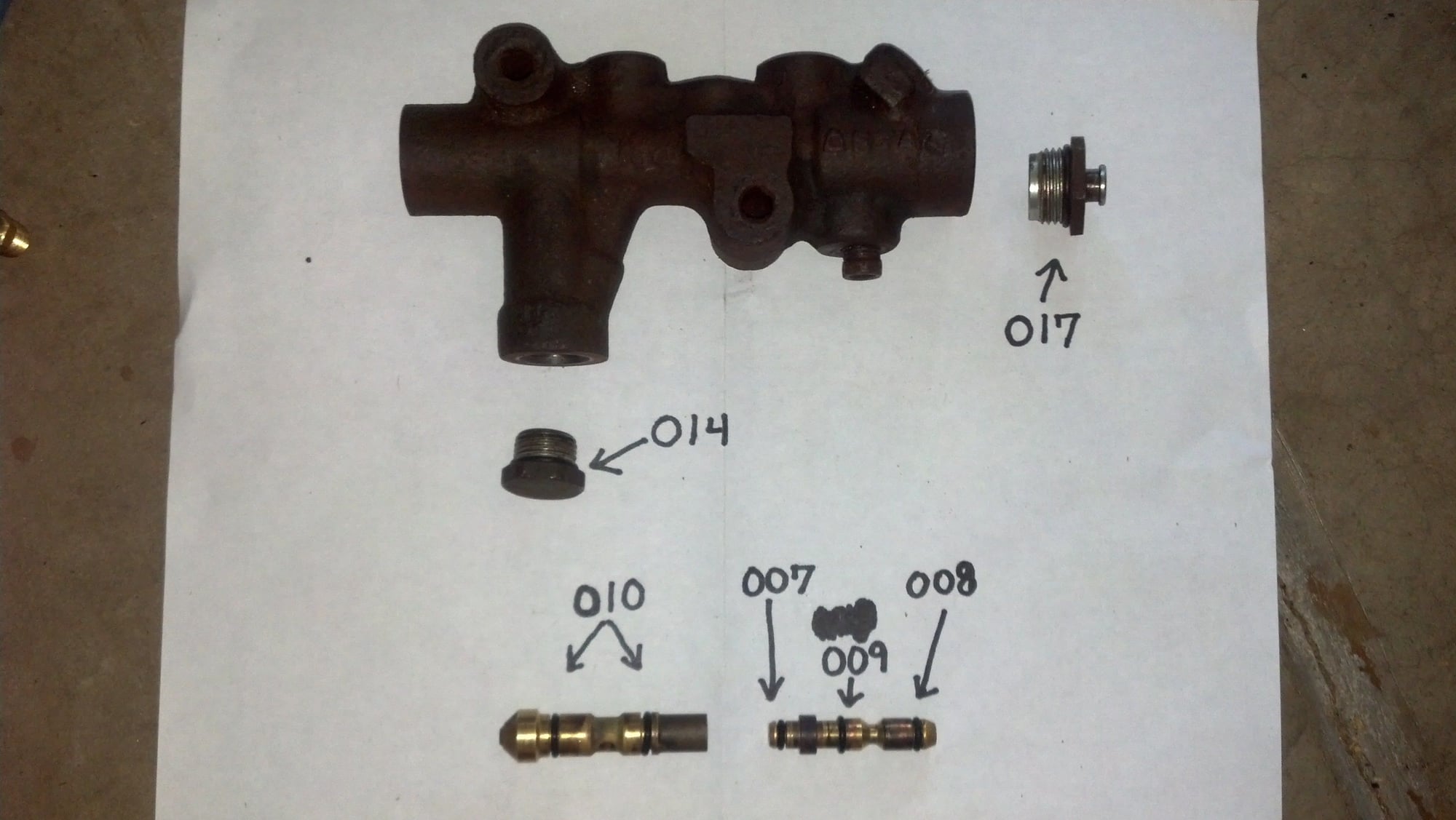

Exploded View

Step 1: Remove Large cap on bottom with socket. (Can't remember the size me thinks 3/4 or 7/8) You may need the vise. CAUTION: Spring loaded remove slowly.

Remove Cap

Remove spring and plunger. Clean parts with brake cleaner except rubber parts. Use brush for chamber. Set aside in order of removal.

Step 2:Remove plunger cap and spring assembly from end with brass rod. Use socket and needle nose. Be careful not to bend brass rod or tear rubber cap. Clean and set aside.

The assembly above can be disassembled if necessary.

Step 3: Remove plastic brake sensor with socket. Caution can be brittle and there is a small brass plunger inside that needs to come out with it. Clean and set aside.

Step 4: Remove outlet to rear brakes. Top in pic below.

Then push with thin rod of wood or long allen wrench from rear and gradually push brass torpedo out. Be careful as the torpedo is two sections together.

Now separate torpedo in to its two sections. Use hook toll or fingers to gently remove and inspect O rings. Clean torpedo with brake cleaner.

This is how your brake system warning light comes on when the brass torpedo slides towards either the front or rear brake leak then the brass rod inside the plastic brake light switch slides up completing the circuit. When the leak is repaired and you depress and hold the brake pedal for a few seconds the pressure equalizes in the proportioning valve causing the brass torpedo to slide back to its normal position allowing the brass rod of the switch to slide down and turning off your brake light.

Now everything should be inspected cleaned reassembled and lubed with fresh brake fluid before reassembly which is in reverse order of dis-assembly. Note: when re inserting brass torpedo be sure not to push in too far and look down through the hole where the (green plunger in step 1 inserts) to make sure that the hole in the brass torpedo is lined up with it.

I hope this helps my friends.

Tools I used. Note wood handled tools are clay sculpting tools from hobby store. Brush has nylon bristles not metal. If bad O rings are found go to Amazon and look for BRAKE part O rings. There is a specific type of O ring out there that is resistant to brake fluid trust me.

Valve:

Exploded View

Step 1: Remove Large cap on bottom with socket. (Can't remember the size me thinks 3/4 or 7/8) You may need the vise. CAUTION: Spring loaded remove slowly.

Remove Cap

Remove spring and plunger. Clean parts with brake cleaner except rubber parts. Use brush for chamber. Set aside in order of removal.

Step 2:Remove plunger cap and spring assembly from end with brass rod. Use socket and needle nose. Be careful not to bend brass rod or tear rubber cap. Clean and set aside.

The assembly above can be disassembled if necessary.

Step 3: Remove plastic brake sensor with socket. Caution can be brittle and there is a small brass plunger inside that needs to come out with it. Clean and set aside.

Step 4: Remove outlet to rear brakes. Top in pic below.

Then push with thin rod of wood or long allen wrench from rear and gradually push brass torpedo out. Be careful as the torpedo is two sections together.

Now separate torpedo in to its two sections. Use hook toll or fingers to gently remove and inspect O rings. Clean torpedo with brake cleaner.

This is how your brake system warning light comes on when the brass torpedo slides towards either the front or rear brake leak then the brass rod inside the plastic brake light switch slides up completing the circuit. When the leak is repaired and you depress and hold the brake pedal for a few seconds the pressure equalizes in the proportioning valve causing the brass torpedo to slide back to its normal position allowing the brass rod of the switch to slide down and turning off your brake light.

Now everything should be inspected cleaned reassembled and lubed with fresh brake fluid before reassembly which is in reverse order of dis-assembly. Note: when re inserting brass torpedo be sure not to push in too far and look down through the hole where the (green plunger in step 1 inserts) to make sure that the hole in the brass torpedo is lined up with it.

I hope this helps my friends.

#3

#6

Sorry for the late response thatsrealnice. Yes cleaning it did improve my brakes considerably. I didn't initially replace my o rings but now I'm going to have to as the valve sprung a leak from a bad seal for the rear brakes. The front brakes work great though. It is now spewing brake fluid out of the sensor up top because of it.

The O rings you need have to be made of either BunaN or EPDM so they do not disintegrate. I found this site with O ring types and functions to help: eFunda: O-Ring Materials Compatibile with Chemical Brake Fluid

This is the company I ordered from: https://www.theoringstore.com/

I will post the appropriate sizes that fix the problem soon.

The O rings you need have to be made of either BunaN or EPDM so they do not disintegrate. I found this site with O ring types and functions to help: eFunda: O-Ring Materials Compatibile with Chemical Brake Fluid

This is the company I ordered from: https://www.theoringstore.com/

I will post the appropriate sizes that fix the problem soon.

#7

Trending Topics

#8

#9

#11

One Step Closer

Thank you for the reps fellas. Well after placing 3 separate orders for different sized o rings and some trial and error, I still have not fixed the problem.  All of the o rings are new and as close as a couple thousandths of an inch of the old ones. Front brakes still hold good pressure but the rear brakes keep squeaking past a seal. It is as though there is a clog building too much pressure but I have torn this bugger apart with no signs of too much build up anywhere. I did notice the master cylinder pops fluid out of the front reservoir with the lid off as the brake peddle is depressed. Doesn't seem normal to me at all. Any thoughts?

All of the o rings are new and as close as a couple thousandths of an inch of the old ones. Front brakes still hold good pressure but the rear brakes keep squeaking past a seal. It is as though there is a clog building too much pressure but I have torn this bugger apart with no signs of too much build up anywhere. I did notice the master cylinder pops fluid out of the front reservoir with the lid off as the brake peddle is depressed. Doesn't seem normal to me at all. Any thoughts?

Not giving up yet. I do have sizes for the o rings but don't want to post them till this issue is resolved so others have the correct sizes and avoid this nightmare HAHAHA.

All of the o rings are new and as close as a couple thousandths of an inch of the old ones. Front brakes still hold good pressure but the rear brakes keep squeaking past a seal. It is as though there is a clog building too much pressure but I have torn this bugger apart with no signs of too much build up anywhere. I did notice the master cylinder pops fluid out of the front reservoir with the lid off as the brake peddle is depressed. Doesn't seem normal to me at all. Any thoughts?

All of the o rings are new and as close as a couple thousandths of an inch of the old ones. Front brakes still hold good pressure but the rear brakes keep squeaking past a seal. It is as though there is a clog building too much pressure but I have torn this bugger apart with no signs of too much build up anywhere. I did notice the master cylinder pops fluid out of the front reservoir with the lid off as the brake peddle is depressed. Doesn't seem normal to me at all. Any thoughts?Not giving up yet. I do have sizes for the o rings but don't want to post them till this issue is resolved so others have the correct sizes and avoid this nightmare HAHAHA.

#12

O-ring Sizes

Sorry for the lapse in time here fellas but here is the scoop. The valve is still leaking from the sensor with the new O-rings. I did not have access to another valve to confirm whether or not there is another hidden issue or that the valve is worn past its original tolerances. So I picked up a brass one from Jeff's Bronco Graveyard so I could drive her and to rule out other parts of the system. Curious to see if some one else could try to use the O-rings and have better results. Here are the sizes and picks I used:

#13

This is the link and chart for O-ring compatibilities:eFunda: O-Ring Materials Compatibile with Chemical Brake Fluid

<table border="0" cellpadding="0" cellspacing="0" width="100%"><tbody><tr><td height="20">

</td></tr> <tr><td class="text" align="left" width="100%"> Instructions </td></tr> <tr><td> </td></tr> <tr><td height="10">

</td></tr> <tr><td height="10">

</td></tr> </tbody></table> <table border="0" cellpadding="0" cellspacing="0" width="100%"> <tbody><tr><td class="smalltext"> This page contains a guide to selecting O-ring materials based on chemical compatibility requirements. The chemical compatibility data can be presented in one of two ways. First, you can select a specific O-ring material to view its compatible chemicals. Or second, you can select a specific chemical to view all its compatible O-ring materials.

Chemical compatibilities are rated and displayed according to the following scale:

</td></tr> <tr><td height="20">

</td></tr> </tbody></table> <table border="0" cellpadding="0" cellspacing="0" width="100%"> <tbody><tr><td> <table align="center" border="0" cellpadding="0" cellspacing="0"> <tbody><tr bgcolor="cccc99"> <td colspan="3" height="2">

</td> </tr> <tr bgcolor="cccc99"> <td height="1" width="2">

</td> <td class="smalltext" align="center" nowrap="nowrap"> Key to O-Ring Material Compatibility Ratings </td> <td width="2">

</td> </tr> <tr bgcolor="cccc99"> <td colspan="3" height="2">

</td> </tr> <tr> <td bgcolor="cccc99" width="2">

</td> <td> <table align="center" border="0" cellpadding="5" cellspacing="0"> <tbody><tr> <td class="smalltext" align="center"> <table border="0" cellpadding="1" cellspacing="2"> <tbody><tr> <td class="smalltext" align="center" bgcolor="ddeedd"> (4) </td> <td class="smalltext" nowrap="nowrap"> Good, both for static and dynamic seals</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="fff8d6"> (3) </td> <td class="smalltext" nowrap="nowrap"> Fair, usually OK for static seals</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="faebd7"> (2) </td> <td class="smalltext" nowrap="nowrap"> Sometimes OK for static seals; not OK for dynamic seals</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="ffdab9"> (1) </td> <td class="smalltext" nowrap="nowrap"> Poor</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="eeeeee"> (0) </td> <td class="smalltext" nowrap="nowrap"> No Data</td> </tr> </tbody></table> </td> </tr> </tbody></table> </td> <td bgcolor="cccc99" width="2">

</td> </tr> <tr bgcolor="cccc99"> <td height="2">

</td> <td>

</td> <td>

</td> </tr> </tbody></table> </td></tr> </tbody></table>

<table border="0" cellpadding="0" cellspacing="0" width="100%"> <tbody><tr><td height="20">

</td></tr> <tr><td class="text" align="left" width="100%"> O-Ring Compatibilities </td></tr> <tr><td> </td></tr> <tr><td height="10">

</td></tr> <tr><td height="10">

</td></tr> </tbody></table> <table border="0" cellpadding="0" cellspacing="1" width="100%"> <tbody><tr> <td class="footnotetext" width="50%">

</td> <td class="footnotetext" align="right" width="50%"> Order by Rating</td> </tr> <tr><td height="10">

</td></tr> </tbody></table> <table border="0" cellpadding="2" cellspacing="1" width="100%"> <tbody><tr> <td class="smalltext" colspan="3" align="center" bgcolor="dddddd" height="50"> O-Ring Materials Compatible with Brake Fluid

(select a material to show its compatible chemicals)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ddeedd" valign="top"> Aflas (4)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Buna-N (Nitrile) (1)</td> <td class="smalltext" bgcolor="ddeedd" valign="top"> Butyl (4)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="eeeeee" valign="top"> Chemraz (0)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Epichlorohydrin (1)</td> <td class="smalltext" bgcolor="ddeedd" valign="top"> Ethylene-Propylene (4)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ffdab9" valign="top"> Fluorocarbon (1)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Fluorosilicone (1)</td> <td class="smalltext" bgcolor="eeeeee" valign="top"> Hypalon (0)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="eeeeee" valign="top"> Kalrez (0)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Natural Rubber (1)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Neoprene (1)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="fff8d6" valign="top"> Nitrile, Hydrogenated (3)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Polyacrylate (1)</td> <td class="smalltext" bgcolor="fff8d6" valign="top"> Polysulfide (3)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ffdab9" valign="top"> Polyurethane, Cast (1)</td> <td class="smalltext" bgcolor="eeeeee" valign="top"> Polyurethane, Millable (0)</td> <td class="smalltext" bgcolor="eeeeee" valign="top"> Silicone (0)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ddeedd" valign="top"> Styrene Butadiene (4)</td> <td class="smalltext" bgcolor="ddeedd" valign="top"> Teflon, Virgin (4)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Vamac (1)</td> </tr> </tbody></table>

<table border="0" cellpadding="0" cellspacing="0" width="100%"><tbody><tr><td height="20">

</td></tr> <tr><td class="text" align="left" width="100%"> Instructions </td></tr> <tr><td>

</td></tr> <tr><td height="10">

</td></tr> <tr><td height="10"></td></tr> </tbody></table> <table border="0" cellpadding="0" cellspacing="0" width="100%"> <tbody><tr><td class="smalltext"> This page contains a guide to selecting O-ring materials based on chemical compatibility requirements. The chemical compatibility data can be presented in one of two ways. First, you can select a specific O-ring material to view its compatible chemicals. Or second, you can select a specific chemical to view all its compatible O-ring materials.

Chemical compatibilities are rated and displayed according to the following scale:

</td></tr> <tr><td height="20">

</td></tr> </tbody></table> <table border="0" cellpadding="0" cellspacing="0" width="100%"> <tbody><tr><td> <table align="center" border="0" cellpadding="0" cellspacing="0"> <tbody><tr bgcolor="cccc99"> <td colspan="3" height="2">

</td> </tr> <tr bgcolor="cccc99"> <td height="1" width="2">

</td> <td class="smalltext" align="center" nowrap="nowrap"> Key to O-Ring Material Compatibility Ratings </td> <td width="2">

</td> </tr> <tr bgcolor="cccc99"> <td colspan="3" height="2">

</td> </tr> <tr> <td bgcolor="cccc99" width="2">

</td> <td> <table align="center" border="0" cellpadding="5" cellspacing="0"> <tbody><tr> <td class="smalltext" align="center"> <table border="0" cellpadding="1" cellspacing="2"> <tbody><tr> <td class="smalltext" align="center" bgcolor="ddeedd"> (4) </td> <td class="smalltext" nowrap="nowrap"> Good, both for static and dynamic seals</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="fff8d6"> (3) </td> <td class="smalltext" nowrap="nowrap"> Fair, usually OK for static seals</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="faebd7"> (2) </td> <td class="smalltext" nowrap="nowrap"> Sometimes OK for static seals; not OK for dynamic seals</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="ffdab9"> (1) </td> <td class="smalltext" nowrap="nowrap"> Poor</td> </tr> <tr> <td class="smalltext" align="center" bgcolor="eeeeee"> (0) </td> <td class="smalltext" nowrap="nowrap"> No Data</td> </tr> </tbody></table> </td> </tr> </tbody></table> </td> <td bgcolor="cccc99" width="2">

</td> </tr> <tr bgcolor="cccc99"> <td height="2">

</td> <td>

</td> <td>

</td> </tr> </tbody></table> </td></tr> </tbody></table>

<table border="0" cellpadding="0" cellspacing="0" width="100%"> <tbody><tr><td height="20">

</td></tr> <tr><td class="text" align="left" width="100%"> O-Ring Compatibilities </td></tr> <tr><td>

</td></tr> <tr><td height="10">

</td></tr> <tr><td height="10"></td></tr> </tbody></table> <table border="0" cellpadding="0" cellspacing="1" width="100%"> <tbody><tr> <td class="footnotetext" width="50%">

</td> <td class="footnotetext" align="right" width="50%"> Order by Rating</td> </tr> <tr><td height="10">

</td></tr> </tbody></table> <table border="0" cellpadding="2" cellspacing="1" width="100%"> <tbody><tr> <td class="smalltext" colspan="3" align="center" bgcolor="dddddd" height="50"> O-Ring Materials Compatible with Brake Fluid

(select a material to show its compatible chemicals)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ddeedd" valign="top"> Aflas (4)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Buna-N (Nitrile) (1)</td> <td class="smalltext" bgcolor="ddeedd" valign="top"> Butyl (4)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="eeeeee" valign="top"> Chemraz (0)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Epichlorohydrin (1)</td> <td class="smalltext" bgcolor="ddeedd" valign="top"> Ethylene-Propylene (4)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ffdab9" valign="top"> Fluorocarbon (1)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Fluorosilicone (1)</td> <td class="smalltext" bgcolor="eeeeee" valign="top"> Hypalon (0)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="eeeeee" valign="top"> Kalrez (0)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Natural Rubber (1)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Neoprene (1)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="fff8d6" valign="top"> Nitrile, Hydrogenated (3)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Polyacrylate (1)</td> <td class="smalltext" bgcolor="fff8d6" valign="top"> Polysulfide (3)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ffdab9" valign="top"> Polyurethane, Cast (1)</td> <td class="smalltext" bgcolor="eeeeee" valign="top"> Polyurethane, Millable (0)</td> <td class="smalltext" bgcolor="eeeeee" valign="top"> Silicone (0)</td> </tr> <tr bgcolor="eeeeee"> <td class="smalltext" bgcolor="ddeedd" valign="top"> Styrene Butadiene (4)</td> <td class="smalltext" bgcolor="ddeedd" valign="top"> Teflon, Virgin (4)</td> <td class="smalltext" bgcolor="ffdab9" valign="top"> Vamac (1)</td> </tr> </tbody></table>

#14

That style disc/drum combination valve was produced by Kelsey-Hayes. Similar valves were also produced for GM, AMC and Chrysler.

Muscle Car Research has a rebuild procedure on a similar (GM) valve, as well as most but not all of the rebuild seals for it. --I think the proportioning circuit is what they don't have the replacement seals for.

https://www.musclecarresearch.com/19...-valve-autopsy

Muscle Car Research has a rebuild procedure on a similar (GM) valve, as well as most but not all of the rebuild seals for it. --I think the proportioning circuit is what they don't have the replacement seals for.

https://www.musclecarresearch.com/19...-valve-autopsy

Thread

Thread Starter

Forum

Replies

Last Post

ultraranger

1967 - 1972 F-100 & Larger F-Series Trucks

87

12-25-2016 05:24 PM

ifrythings

Pre-Power Stroke Diesel (7.3L IDI & 6.9L)

3

04-03-2015 11:21 PM