Not Even A 5 Ton Puller Will Do It(with pics)!!

#1

Not Even A 5 Ton Puller Will Do It(with pics)!!

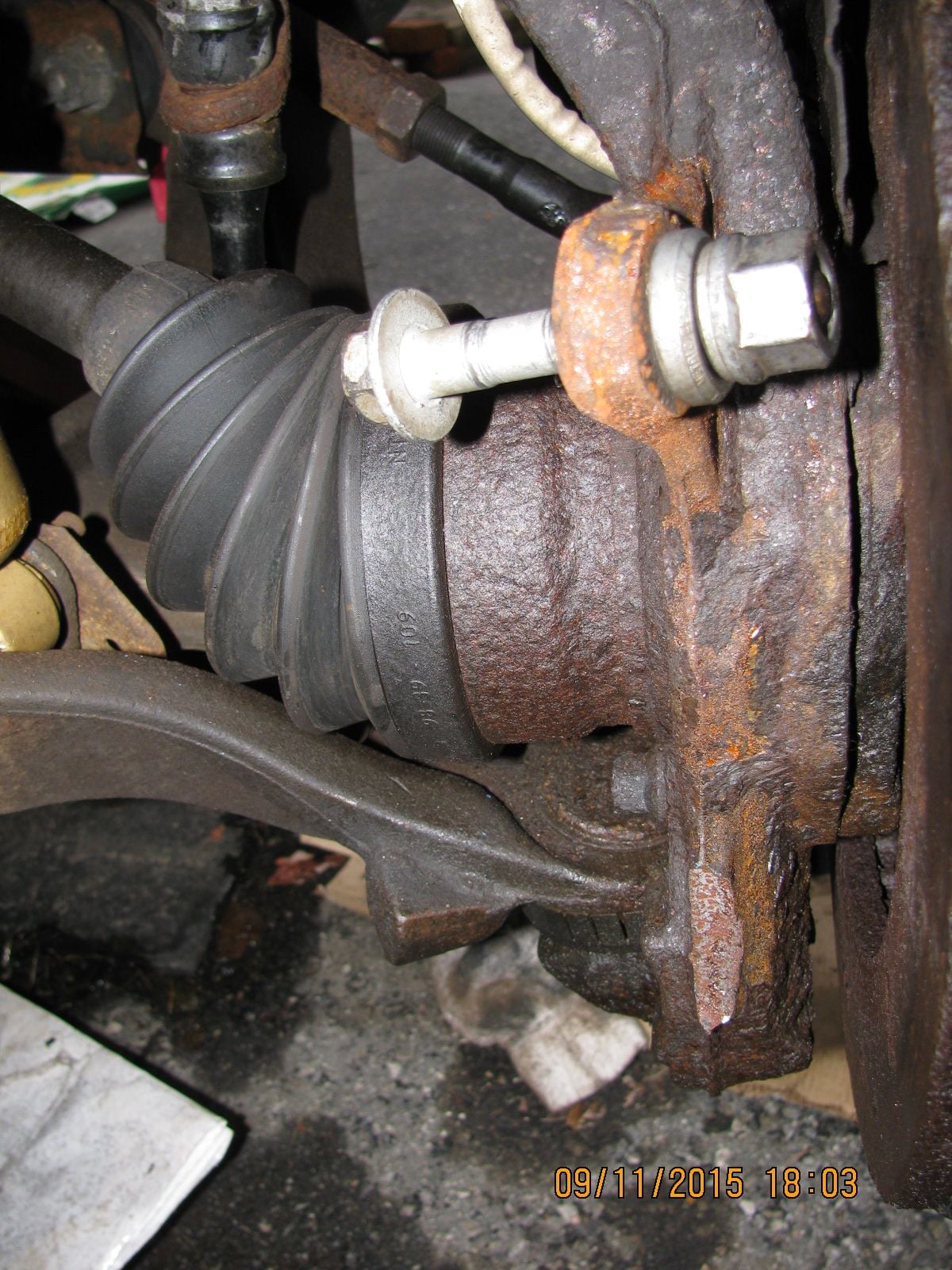

Not even a 5 ton puller will get my friggin' rotor off. WTH could be keeping it on?!?

And you can see what happened to the steering knuckle when I tried to use 2 nuts & bolts thru the caliper bracket mounting holes to push it from inside to get it off the hub. It worked great for the other side.

5 Ton Puller

#2

Looks like you have a bad case of rust going on there. Spray it good with PB blaster and let it soak. Then whack it with a dead blow all around. With the jaws of a puller spread out that far you lose a lot of force. If all else fails go to AutoZone or other parts house and rent a large slide hammer puller.

#3

Thanks kd4gij.

I've been at this thing for days now. It has been soaking with PB Blaster and I bought another 2 cans yesterday while at AutoZone getting several of their loaner tools. One of which is the slide hammer. I've never used one before and I'm not sure how to attach it but I'll figure it out. I've been beating this thing with my 4# sledge all around the front & back of it. I've also heated it up with a blow torch and this thing hasn't budged. I really don't need to be trying to separate it at this point because I'll be taking the hub off to replace the steering knuckle. At which time, I can bring it to a machine shop & have them press it off. But I sure would like to do it myself & not feel so defeated. So, we'll see what happens.

I've been at this thing for days now. It has been soaking with PB Blaster and I bought another 2 cans yesterday while at AutoZone getting several of their loaner tools. One of which is the slide hammer. I've never used one before and I'm not sure how to attach it but I'll figure it out. I've been beating this thing with my 4# sledge all around the front & back of it. I've also heated it up with a blow torch and this thing hasn't budged. I really don't need to be trying to separate it at this point because I'll be taking the hub off to replace the steering knuckle. At which time, I can bring it to a machine shop & have them press it off. But I sure would like to do it myself & not feel so defeated. So, we'll see what happens.

#5

#6

worse case scenario...like a buddy of mine had to do...get a good metal cutting blade for the Saws-all & saw from the outside toward the bolt (wheel stud). Oh before ya'll say why not try a torch 1st...well he is a farmer & has access to that too...didn't help. The only way it went was with sawing relief cuts with saws-all

#7

Trending Topics

#8

I was told not to use an impact on the puller. It's a loaner from AutoZone. So, I don't want to own a broken puller. I used a 3/4" ratchet. I've never used a puller before so I don't know how much torque they can take. I did use my 4# sledge hammer on the front & back in different areas of the rotor while the puller was pulling. And there is no indication of it starting to break free.

How do I use a slide hammer on it? How would I attach it?

How do I use a slide hammer on it? How would I attach it?

#10

Usually if its stuck, you need that impact force to break it free. More likely to bend the puller using a long handle ratchet, unless its not on straight. If you do get it off, or replace the assembly, use some anti seize behind there. Just hit it from the back side with a big hammer and keep spinning it it will come off, I had one not to long ago that I wasn't sure would come off, but I got it

#13

Put on safety glasses, and get a couple good hammers out. I've gotten some the rustiest rotors and drums off with this method. This is actually me in this video, I've done it thousands of times, so I'm positive it works. I've received ALOT of criticism about this technique, due to hitting a hardened metal object with another, so I can't stress enough to use safety glasses and gloves. That puller is applying the wrong force needed.

#14

Thread

Thread Starter

Forum

Replies

Last Post

64deville

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

19

03-27-2012 07:57 PM

f350rebel7788

1994.5 - 1997 7.3L Power Stroke Diesel

38

02-17-2011 01:50 PM

robertbruce

1973 - 1979 F-100 & Larger F-Series Trucks

5

12-30-2010 05:03 PM

holland501

Brakes, Steering, Suspension, Tires, & Wheels

12

10-25-2006 02:13 PM

It took a 30 ton press to get that damn rotor off the hub!

It took a 30 ton press to get that damn rotor off the hub!