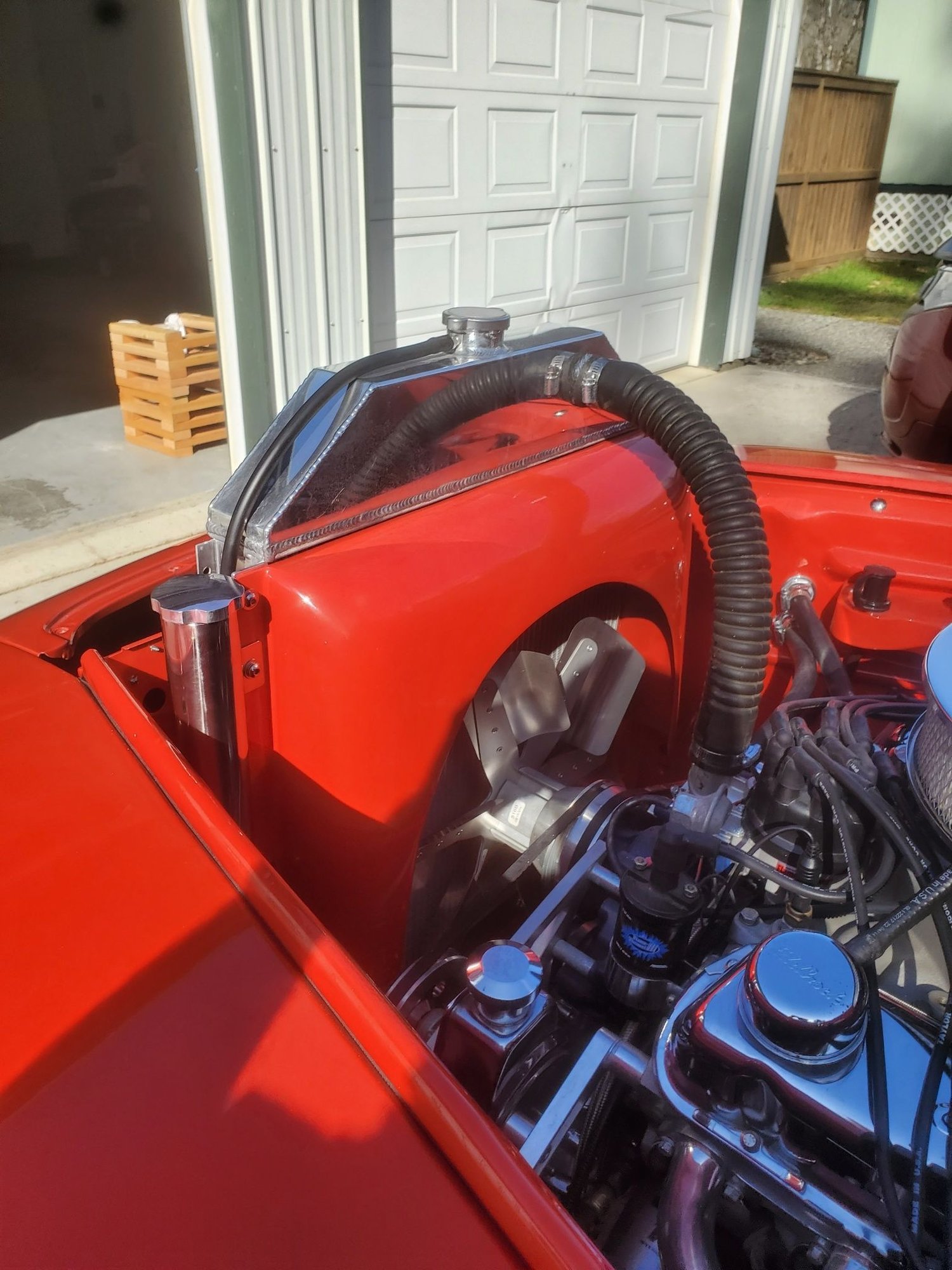

Fan Shroud Project

#1

The following 12 users liked this post by Pokee:

#2

Wow, that came out nice.

For the 10-fingered folks who want to stay that way........for six bucks this would match nicely.

https://www.ebay.com/itm/33484700407...Bk9SR5a5kb76YQ

Tom

For the 10-fingered folks who want to stay that way........for six bucks this would match nicely.

https://www.ebay.com/itm/33484700407...Bk9SR5a5kb76YQ

Tom

The following users liked this post:

#4

The following 2 users liked this post by Pokee:

#6

Join Date: Oct 2005

Location: northwestern Ontario

Posts: 263,287

Received 4,174 Likes

on

2,680 Posts

#7

Trending Topics

#8

#9

The foam is just 2 pieces of 2" pink foam board glued together from home depot that I had. I got the fiberglass supplies from HD also. 4" depth is what I needed. I had some card stock from picture framing used for the base and curved center section. I covered it all first with 2" clear packing tape. The tape acts as release agent and protects the foam from being eating by the resin. I hot glued the foam down to the card stock and glued the piece of card stock to the inside curve. The flanges I made extra wide then trimmed to fit when later. I layer one layer of cloth, one layer of matt then one more layer of cloth. The flanges I used to layers of cloth to make them thick. I used pain stir sticks covered with tape as a form for outside edges of flange as a guide for flange thickness. Sanded fiberglass, smoothed it with body filler, sanded and painted. Trimmed flanges down first.

The following users liked this post:

#10

Thanks for the info. I would have never thought you could use packing tape. I probably would have got suckered into buying special fiberglass products I obviously don't need. The only fiberglass work I have done was on an old boat of mine. I might try this instead of aluminum or steel on my non Ford project. It needs a "unique" shroud. Thanks for posting.

Scott

Scott

#11

Nice job I just dont like the after affect of working with fiber glass

If you wanted it to help with temp the fan has to be no more than half in or out of the shroud and the tips about 1" from the shroud edge for motor movement.

It looks like the fan is a little farther from the shroud edge and maybe in to far?

Also the bottom is open still yes? If so would need to be closed up.

Just saying but yours you will keep your finger on your hands

There is a Youtube video of a guy making one from sheet metal for a stock car race car that looks easy to do at home.

Dave ----

If you wanted it to help with temp the fan has to be no more than half in or out of the shroud and the tips about 1" from the shroud edge for motor movement.

It looks like the fan is a little farther from the shroud edge and maybe in to far?

Also the bottom is open still yes? If so would need to be closed up.

Just saying but yours you will keep your finger on your hands

There is a Youtube video of a guy making one from sheet metal for a stock car race car that looks easy to do at home.

Dave ----

The following users liked this post:

#12

#13

The following users liked this post:

Thread

Thread Starter

Forum

Replies

Last Post

ihcc104

1961 - 1966 F-100 & Larger F-Series Trucks

5

08-21-2016 08:58 AM

PRIMERED79 SHORT BED

1973 - 1979 F-100 & Larger F-Series Trucks

14

08-09-2012 09:57 PM