Setting the timing on 05 5.4l 3V

#46

Yes kevizhere,

They are very expensive in Canada, at almost $20 apiece for the roller followers and about $1.50 cheaper for the lash adjuster.

The US is about $10 for the roller follower and around the same for the lash adjuster.

Remember, redfish posted that pre covid, which will reflect the lower package price.

If you pull the covers, inspect them to be sure they are all failing.

I would love to afford them to complete my timing job, but they are all still quite firm and run very true, so their going back in and i shall replace as needed.

Good luck and keep us posted

They are very expensive in Canada, at almost $20 apiece for the roller followers and about $1.50 cheaper for the lash adjuster.

The US is about $10 for the roller follower and around the same for the lash adjuster.

Remember, redfish posted that pre covid, which will reflect the lower package price.

If you pull the covers, inspect them to be sure they are all failing.

I would love to afford them to complete my timing job, but they are all still quite firm and run very true, so their going back in and i shall replace as needed.

Good luck and keep us posted

#47

Timing being a pain.

Iím replacing phasers, timing components al that jazz you all know. So I took everything off since I was replacing the rollers as well. Put everything back on and got the phasers on as close to their needed position for timing. Buttoned it all up and proceeded to do the timing Iíve done it 3 times now and everytime I go to hand crank to check the timing is off.

So should I go all the way back remove the cams and start from there? (Phasers are torqued on) and if I do do that can I not just have all of the rollers in? I thought I could.

lastly if I go all the way back and remove the cams again when placing them in I was under the impression my lobes on #1 should be 11oclock and #5 should be like 5-4 oíclock.

thanks in advance at this point Iíll take anything.

So should I go all the way back remove the cams and start from there? (Phasers are torqued on) and if I do do that can I not just have all of the rollers in? I thought I could.

lastly if I go all the way back and remove the cams again when placing them in I was under the impression my lobes on #1 should be 11oclock and #5 should be like 5-4 oíclock.

thanks in advance at this point Iíll take anything.

#48

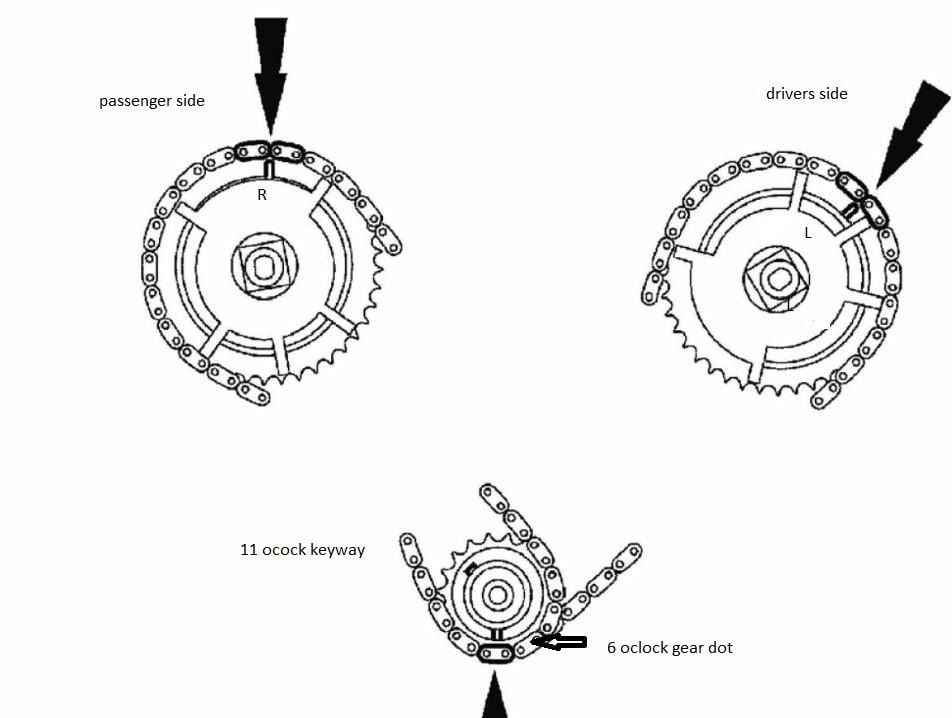

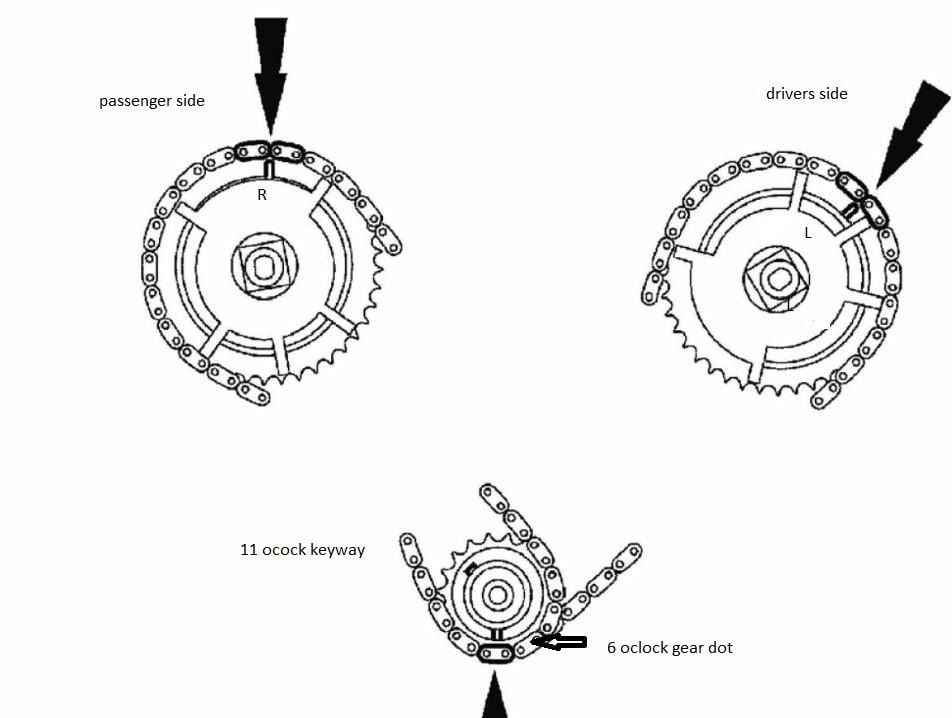

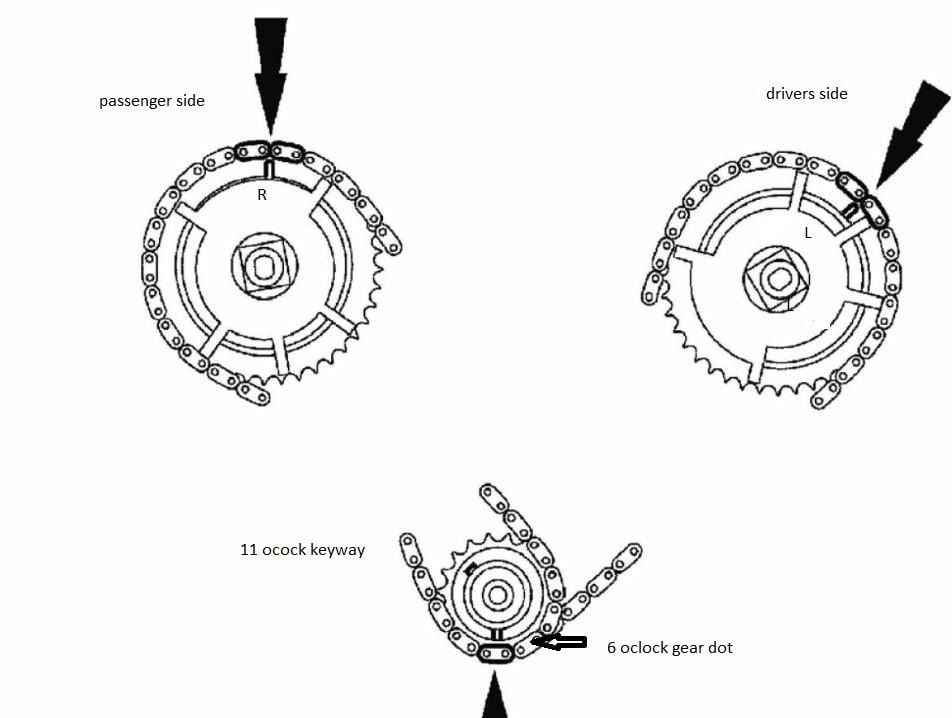

With the crank dot at six you don't have to pay attn to no 1 piston . How ever the cam lobes position of no1 and no 5 and the phasor Land r in the right configuration per drawing verify cams correct . The pistons are firmly attached to the crank and there is only one place in a 360 degree position it can be in.

The cams turn one half turn of crank full turn , if you look at cam gear and crank gear you will see phasor gear twice as large . The cam decides which stroke its in not the crank . Cam decides valves position . put all your followers back in then check .Yes you must turn the crank two cw revs by hand and prove no valve to piston contact . And yes you will lose all your timing marks for 122revs .

don't get confused with crank key its just easier to see from the top than the crank dot most guys use a mirror to confirm dot /keyway . You can buy a tool that locks it in to pin on timing case if you like ,its not expensive . but the best tool is the toothed cam phasor tool that holds phasor in place for torquing and removal .

Believe me I went thru all that no 1 tdc stuff until I found out I was worried over nothing - besides timing is not right at no 1 tdc anyway .

I have a simpler method without pulling followers and using that expensive hard to use tool but I won't go into that now .

#49

After putting all 24 followers

With the crank dot at six you don't have to pay attn to no 1 piston . How ever the cam lobes position of no1 and no 5 and the phasor Land r in the right configuration per drawing verify cams correct . The pistons are firmly attached to the crank and there is only one place in a 360 degree position it can be in.

The cams turn one half turn of crank full turn , if you look at cam gear and crank gear you will see phasor gear twice as large . The cam decides which stroke its in not the crank . Cam decides valves position . put all your followers back in then check .Yes you must turn the crank two cw revs by hand and prove no valve to piston contact . And yes you will lose all your timing marks for 122revs .

don't get confused with crank key its just easier to see from the top than the crank dot most guys use a mirror to confirm dot /keyway . You can buy a tool that locks it in to pin on timing case if you like ,its not expensive . but the best tool is the toothed cam phasor tool that holds phasor in place for torquing and removal .

Believe me I went thru all that no 1 tdc stuff until I found out I was worried over nothing - besides timing is not right at no 1 tdc anyway .

I have a simpler method without pulling followers and using that expensive hard to use tool but I won't go into that now .

what crank position you put at before starting on or u do the 6 clock position dot and 11 clock key and have cylinder one top dead center??

#50

Setting the timing

With the crank dot at six you don't have to pay attn to no 1 piston . How ever the cam lobes position of no1 and no 5 and the phasor Land r in the right configuration per drawing verify cams correct . The pistons are firmly attached to the crank and there is only one place in a 360 degree position it can be in.

The cams turn one half turn of crank full turn , if you look at cam gear and crank gear you will see phasor gear twice as large . The cam decides which stroke its in not the crank . Cam decides valves position . put all your followers back in then check .Yes you must turn the crank two cw revs by hand and prove no valve to piston contact . And yes you will lose all your timing marks for 122revs .

don't get confused with crank key its just easier to see from the top than the crank dot most guys use a mirror to confirm dot /keyway . You can buy a tool that locks it in to pin on timing case if you like ,its not expensive . but the best tool is the toothed cam phasor tool that holds phasor in place for torquing and removal .

Believe me I went thru all that no 1 tdc stuff until I found out I was worried over nothing - besides timing is not right at no 1 tdc anyway .

I have a simpler method without pulling followers and using that expensive hard to use tool but I won't go into that now .

#51

#52

My method is to remove cams carefully with the Phasors on them . Always set the timing points first before removing chains , Its just good procedure .

You' re going to remove cam bolts after you mark everything , it must go back exactly as it was. you are going to use the sequence to slowly loosen bolts . The idea is to not stress the camshaft . Once they are both off you have no valve being pushed down so no contact with pistons if crankshaft is moved . You can play with crank and pistons all you like . But when you go to assemble you must have crank dot on crank gear at six oplock and stay there.

Do all your cleaning and hand oiling including soaking lashs in oil overnight . New items -rollers can go anywhere ,old items return to where they were.

Now place rollers and watch carefully as you set cam in place Noting lobes positions as well as phasor mark in correct place . You are then going to slowly sneak up in sequence tightening bolts until you get real snug . Then you will slowly aim for 89 inch pounds of torque in sequence . The positions are approximate the chain installation will make it exact .

The problem now is spring pressure pushing on cam as you put chain on It takes three hands . So get anyone to hold a socket wrench on phasor bolt while you put chain on it only takes a little movement of socket wrench against springs .Once chain is on you can install tensioner.

The other procedure allows a single person to not have to fight springs by removing followers that would push against cam . That is your choice . Using the valve tool can be tiresome and if you dont push on valve you can lose keepers and drop a valve .

I skipped changing the phasor once cam was bolted down , the toothed holding tool is cheap and beats trying to use vise grips on the cam shaft . The phasor bolt is one time use and has a two step torque procedure . You should use a paint pen for these two step bolts , crank bolt is same .

Once you do this timing it will seem so simple in retrospect . You must use passenger / driver side to keep from getting confused . You must know where no 1 and 5 are at . You don't need to know TDC . You do need cam bolt sequence .

You' re going to remove cam bolts after you mark everything , it must go back exactly as it was. you are going to use the sequence to slowly loosen bolts . The idea is to not stress the camshaft . Once they are both off you have no valve being pushed down so no contact with pistons if crankshaft is moved . You can play with crank and pistons all you like . But when you go to assemble you must have crank dot on crank gear at six oplock and stay there.

Do all your cleaning and hand oiling including soaking lashs in oil overnight . New items -rollers can go anywhere ,old items return to where they were.

Now place rollers and watch carefully as you set cam in place Noting lobes positions as well as phasor mark in correct place . You are then going to slowly sneak up in sequence tightening bolts until you get real snug . Then you will slowly aim for 89 inch pounds of torque in sequence . The positions are approximate the chain installation will make it exact .

The problem now is spring pressure pushing on cam as you put chain on It takes three hands . So get anyone to hold a socket wrench on phasor bolt while you put chain on it only takes a little movement of socket wrench against springs .Once chain is on you can install tensioner.

The other procedure allows a single person to not have to fight springs by removing followers that would push against cam . That is your choice . Using the valve tool can be tiresome and if you dont push on valve you can lose keepers and drop a valve .

I skipped changing the phasor once cam was bolted down , the toothed holding tool is cheap and beats trying to use vise grips on the cam shaft . The phasor bolt is one time use and has a two step torque procedure . You should use a paint pen for these two step bolts , crank bolt is same .

Once you do this timing it will seem so simple in retrospect . You must use passenger / driver side to keep from getting confused . You must know where no 1 and 5 are at . You don't need to know TDC . You do need cam bolt sequence .

The following users liked this post:

#53

My method is to remove cams carefully with the Phasors on them . Always set the timing points first before removing chains , Its just good procedure .

You' re going to remove cam bolts after you mark everything , it must go back exactly as it was. you are going to use the sequence to slowly loosen bolts . The idea is to not stress the camshaft . Once they are both off you have no valve being pushed down so no contact with pistons if crankshaft is moved . You can play with crank and pistons all you like . But when you go to assemble you must have crank dot on crank gear at six oplock and stay there.

Do all your cleaning and hand oiling including soaking lashs in oil overnight . New items -rollers can go anywhere ,old items return to where they were.

Now place rollers and watch carefully as you set cam in place Noting lobes positions as well as phasor mark in correct place . You are then going to slowly sneak up in sequence tightening bolts until you get real snug . Then you will slowly aim for 89 inch pounds of torque in sequence . The positions are approximate the chain installation will make it exact .

The problem now is spring pressure pushing on cam as you put chain on It takes three hands . So get anyone to hold a socket wrench on phasor bolt while you put chain on it only takes a little movement of socket wrench against springs .Once chain is on you can install tensioner.

The other procedure allows a single person to not have to fight springs by removing followers that would push against cam . That is your choice . Using the valve tool can be tiresome and if you dont push on valve you can lose keepers and drop a valve .

I skipped changing the phasor once cam was bolted down , the toothed holding tool is cheap and beats trying to use vise grips on the cam shaft . The phasor bolt is one time use and has a two step torque procedure . You should use a paint pen for these two step bolts , crank bolt is same .

Once you do this timing it will seem so simple in retrospect . You must use passenger / driver side to keep from getting confused . You must know where no 1 and 5 are at . You don't need to know TDC . You do need cam bolt sequence .

You' re going to remove cam bolts after you mark everything , it must go back exactly as it was. you are going to use the sequence to slowly loosen bolts . The idea is to not stress the camshaft . Once they are both off you have no valve being pushed down so no contact with pistons if crankshaft is moved . You can play with crank and pistons all you like . But when you go to assemble you must have crank dot on crank gear at six oplock and stay there.

Do all your cleaning and hand oiling including soaking lashs in oil overnight . New items -rollers can go anywhere ,old items return to where they were.

Now place rollers and watch carefully as you set cam in place Noting lobes positions as well as phasor mark in correct place . You are then going to slowly sneak up in sequence tightening bolts until you get real snug . Then you will slowly aim for 89 inch pounds of torque in sequence . The positions are approximate the chain installation will make it exact .

The problem now is spring pressure pushing on cam as you put chain on It takes three hands . So get anyone to hold a socket wrench on phasor bolt while you put chain on it only takes a little movement of socket wrench against springs .Once chain is on you can install tensioner.

The other procedure allows a single person to not have to fight springs by removing followers that would push against cam . That is your choice . Using the valve tool can be tiresome and if you dont push on valve you can lose keepers and drop a valve .

I skipped changing the phasor once cam was bolted down , the toothed holding tool is cheap and beats trying to use vise grips on the cam shaft . The phasor bolt is one time use and has a two step torque procedure . You should use a paint pen for these two step bolts , crank bolt is same .

Once you do this timing it will seem so simple in retrospect . You must use passenger / driver side to keep from getting confused . You must know where no 1 and 5 are at . You don't need to know TDC . You do need cam bolt sequence .

Thread

Thread Starter

Forum

Replies

Last Post

ElectroVeeDub

2004 - 2008 F150

39

10-06-2020 12:26 AM

Handegard

Big Block V8 - 385 Series (6.1/370, 7.0/429, 7.5/460)

5

06-13-2007 10:16 AM

jcg82

335 Series- 5.8/351M, 6.6/400, 351 Cleveland

2

12-20-2006 08:38 PM