Measuring for Correct Pushrod Length

#1

Measuring for Correct Pushrod Length

Info:

66 f100, 352fe, reworked stock heads, RV cam, factory non adjustable rocker arms

Best procedure for measuring for the correct length pushrods? I have this tool: Click

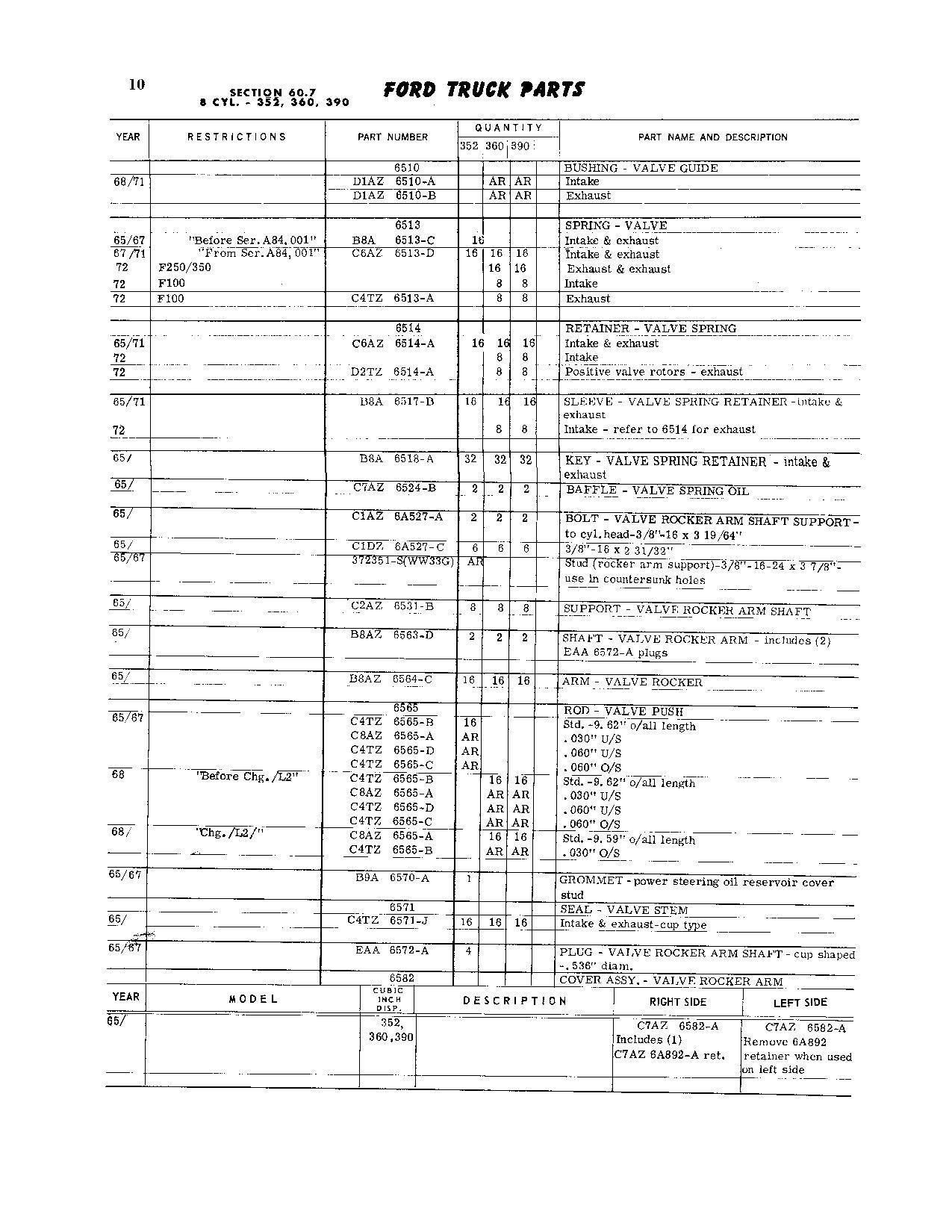

ive searched forums and recommendations seem to be all over the place and Iíve looked in Section 8, page 9 (8-9) in the 66 Shop Manual and I donít believe the manual holds true for my situation (cam, heads, etc) because it uses a step tool to measure for stock length pushrods or .060 longer or shorter than stock.

I ordered the book by Steve Christ to see if it has any info on the matter, and as a reference for other things, but if anyone has a step by step in the mean time Iíd appreciate it.

66 f100, 352fe, reworked stock heads, RV cam, factory non adjustable rocker arms

Best procedure for measuring for the correct length pushrods? I have this tool: Click

ive searched forums and recommendations seem to be all over the place and Iíve looked in Section 8, page 9 (8-9) in the 66 Shop Manual and I donít believe the manual holds true for my situation (cam, heads, etc) because it uses a step tool to measure for stock length pushrods or .060 longer or shorter than stock.

I ordered the book by Steve Christ to see if it has any info on the matter, and as a reference for other things, but if anyone has a step by step in the mean time Iíd appreciate it.

#2

Paint the tip of the valve with a magic marker, then cycle the engine through the full valve travel with zero lash (if a hyd lifter) then remove the rocker arm and see where the marker ink has been removed from the tip of the valve. The wear area should be centered on the tip. All the valve tips should be the same elevation, check this by laying a straight edge across them all with the rockers removed. If they're not, then you may need custom length pushrods to compensate for the shorter valves. Be better to take the heads back to the machine shop and tell em to fix their messy work.

#3

Valve tips are all level. I donít think using zero lash as a mesurment is attainable as all the rocker arms are mounted on a single shaft... rather than what Iím used to (one rocker arm/bolt per valve). Shaft has to be torqued in a specific sequence or else you risk damage to the entire assembly

#5

Valve tips are all level. I donít think using zero lash as a mesurment is attainable as all the rocker arms are mounted on a single shaft... rather than what Iím used to (one rocker arm/bolt per valve). Shaft has to be torqued in a specific sequence or else you risk damage to the entire assembly

#6

That is the correct tool. A digital caliper will help with accurate measurements. There is a range for valve lash, and this information is in Steve Christ’s book. With the lifter at the bottom of it’s travel and fully collapsed, measure the valve lash until in specs, then remove the pushrod checker and measure its length. Repeat 15 more times. Make certain that the engine is in the proper position, so that the lifters aren’t on a cam lobe. Do a search on this site, and you can find more detailed information. Good luck.

#7

Paint the tip of the valve with a magic marker, then cycle the engine through the full valve travel with zero lash (if a hyd lifter) then remove the rocker arm and see where the marker ink has been removed from the tip of the valve. The wear area should be centered on the tip. All the valve tips should be the same elevation, check this by laying a straight edge across them all with the rockers removed. If they're not, then you may need custom length pushrods to compensate for the shorter valves. Be better to take the heads back to the machine shop and tell em to fix their messy work.

Trending Topics

#8

#9

The easiest way to deal with the rocker shaft is to disable it by removing all the push rods. If the head is already on and torqued, Put #1 on tdc, put light checking spring on the valve, smear marking compound on valve tip, put adjustable push rod in and the rocker shaft. Set it at zero lash. Turn the crank through a cycle all the while watching that the lifters plunger doesn't compress. Take the shaft off and look at the pattern on the valve tip. Adjust the push rod accordingly and try again till you get a even pattern sweep across the tip. It should start in a little high of center and finish a little low of center. Once you get it adjusted right, remove pushrod and measure it with a 12" dial caliper, then add your lifters preload figure ( I always use .030) to the length you got and your done.

#10

You have to replace them with checking springs. Otherwise the valve spring will collapse the lifters plunger leaving you with messed up false readings. It is very important that the lifters plunger does not move when you turn the crank.

#11

Just an update... Per Steve Christ's book, acceptable space between the valve tip and rocker arm WITH THE LIFTER FULLY DEPRESSED/BLED AND THE PUSH ROD THAT YOU'RE CHECKING ON BASE CIRCLE: .100-.200. This is with non adjustable rocker arms and hydraulic lifters. A different method is used with solid lifters and/or adjustable rockers.

#12

Info:

66 f100, 352fe, reworked stock heads, RV cam, factory non adjustable rocker arms

Best procedure for measuring for the correct length pushrods? I have this tool: Click

ive searched forums and recommendations seem to be all over the place and Iíve looked in Section 8, page 9 (8-9) in the 66 Shop Manual and I donít believe the manual holds true for my situation (cam, heads, etc) because it uses a step tool to measure for stock length pushrods or .060 longer or shorter than stock.

I ordered the book by Steve Christ to see if it has any info on the matter, and as a reference for other things, but if anyone has a step by step in the mean time Iíd appreciate it.

66 f100, 352fe, reworked stock heads, RV cam, factory non adjustable rocker arms

Best procedure for measuring for the correct length pushrods? I have this tool: Click

ive searched forums and recommendations seem to be all over the place and Iíve looked in Section 8, page 9 (8-9) in the 66 Shop Manual and I donít believe the manual holds true for my situation (cam, heads, etc) because it uses a step tool to measure for stock length pushrods or .060 longer or shorter than stock.

I ordered the book by Steve Christ to see if it has any info on the matter, and as a reference for other things, but if anyone has a step by step in the mean time Iíd appreciate it.

The differing push-rod lengths form FORD are for adjusting valve lash on a hydraulic engine.

Thread

Thread Starter

Forum

Replies

Last Post

lannondiesel

Big Block V8 - 385 Series (6.1/370, 7.0/429, 7.5/460)

4

10-14-2014 06:12 PM

crazy96863

Small Block V8 (221, 260, 289, 5.0/302, 5.8/351W)

20

05-25-2013 12:28 AM

roger dowty

Small Block V8 (221, 260, 289, 5.0/302, 5.8/351W)

3

08-27-2006 02:42 PM

1970f2504x4

FE & FT Big Block V8 (332, 352, 360, 390, 406, 410, 427, 428)

12

07-16-2003 01:18 PM