Is there a torque spec for hood bolts?

#1

Is there a torque spec for hood bolts?

How tight are the hinge arms bolts supposed to be? I was looking in my shop manual for a 56 F100 and towards the back where they list such things I could not find a torque spec. The hood opens and closes good. It just every now and then every couple of years, one of the bolts strip out. Yes they are safety wired togethet. I usually take a 5/16 NF repair tap and then thread in a new hood arm bolt and it's good to go. Just curious how tight they are really supposted to be.

#2

From what I have read, not real tight. I think so that everything is free to move and hence the safety wire....

But what do I know? I'm having problems now with my hood. I put new hinges on and discovered on the drivers side the one captured nut is missing and the other nut is crudely welded in place but it is not fine thread, so I had to be a course thread bolt in there instead of a shouldered hood bolt.

Mid-fifty sells an over sized hood hinge bolt, but can I tap a course thread nut into a fine thread?

But what do I know? I'm having problems now with my hood. I put new hinges on and discovered on the drivers side the one captured nut is missing and the other nut is crudely welded in place but it is not fine thread, so I had to be a course thread bolt in there instead of a shouldered hood bolt.

Mid-fifty sells an over sized hood hinge bolt, but can I tap a course thread nut into a fine thread?

#3

#4

From what I have read, not real tight. I think so that everything is free to move and hence the safety wire....

But what do I know? I'm having problems now with my hood. I put new hinges on and discovered on the drivers side the one captured nut is missing and the other nut is crudely welded in place but it is not fine thread, so I had to be a course thread bolt in there instead of a shouldered hood bolt.

Mid-fifty sells an over sized hood hinge bolt, but can I tap a course thread nut into a fine thread?

But what do I know? I'm having problems now with my hood. I put new hinges on and discovered on the drivers side the one captured nut is missing and the other nut is crudely welded in place but it is not fine thread, so I had to be a course thread bolt in there instead of a shouldered hood bolt.

Mid-fifty sells an over sized hood hinge bolt, but can I tap a course thread nut into a fine thread?

I think I remember reading somewhere on this forum, (maybe Ax Racer?), was saying something about them being just hand tight with a 3/4" socket. Mine were tighter than that I know. In fact the wire I did use, just plain old mechanic's wire, would eventually break due to the fact I am always opening and shutting the hood to work on the truck, and the bolts would eventually turn so much, they would break the wire! Maybe I'll just skip the lock wire, and just snug them up every time I am done under the hood. I think though next time I have the hood off, I am just going to re-drill and re-tap all of them to 3/8" and use the larger diameter bolts from Mid Fifty.

About your problem of the wrong threaded nut a PO welded in. A few years back when I first had this issue of stripping hood arm bolts, I took I think a 5/16" X 1 1/4 long bolt, and I found a steel spacer at the hardware store, that was 5/16 I.D. and IIRC close to 7/16 outer diameter. Put a fender washer over the bolt, slipped on the steel spacer, and then after using a thread repair tap, threaded it in. It worked great until I got the new hood bolts! Good question though about the 5/16 NC vs 3/8 NF conversion. I would think you could do it. Me, I would try it on a random nut in a vice to see what happens.

#5

The safety wire is a dead giveaway...stretching the bolt (a measure of which is the torque reading) is not necessary when the bolt is held in place with safety wire. I would use some Loctite 271 threadlocker on the bolts the next time you replace them and they won't wobble loose again.

Hey Charlie, is the Loctite 271 the Red stuff? I tried Loctite Blue on them and they got loose again with the safety wire used.

#6

#7

I think I remember reading somewhere on this forum, (maybe Ax Racer?), was saying something about them being just hand tight with a 3/4" socket. Mine were tighter than that I know. In fact the wire I did use, just plain old mechanic's wire, would eventually break due to the fact I am always opening and shutting the hood to work on the truck, and the bolts would eventually turn so much, they would break the wire! Maybe I'll just skip the lock wire, and just snug them up every time I am done under the hood. I think though next time I have the hood off, I am just going to re-drill and re-tap all of them to 3/8" and use the larger diameter bolts from Mid Fifty.

About your problem of the wrong threaded nut a PO welded in. A few years back when I first had this issue of stripping hood arm bolts, I took I think a 5/16" X 1 1/4 long bolt, and I found a steel spacer at the hardware store, that was 5/16 I.D. and IIRC close to 7/16 outer diameter. Put a fender washer over the bolt, slipped on the steel spacer, and then after using a thread repair tap, threaded it in. It worked great until I got the new hood bolts! Good question though about the 5/16 NC vs 3/8 NF conversion. I would think you could do it. Me, I would try it on a random nut in a vice to see what happens.

About your problem of the wrong threaded nut a PO welded in. A few years back when I first had this issue of stripping hood arm bolts, I took I think a 5/16" X 1 1/4 long bolt, and I found a steel spacer at the hardware store, that was 5/16 I.D. and IIRC close to 7/16 outer diameter. Put a fender washer over the bolt, slipped on the steel spacer, and then after using a thread repair tap, threaded it in. It worked great until I got the new hood bolts! Good question though about the 5/16 NC vs 3/8 NF conversion. I would think you could do it. Me, I would try it on a random nut in a vice to see what happens.

So with the fender washer and the spacer you made your own shoulder bolt? How did it work and last for you?

Trending Topics

#8

Torque specs for 5/16-24 (NF) @80% Yeild strength.

These specs are assuming the material it is being bolted in to has the same tensile strength as the bolt and has adequate thread count.

Grade 2 Tensile strength (Minimum) 74,000 PSI 14ft lbs

Grade 5 Tensile strength (Minimum) 120,00 PSI 22ft lbs,

Grade 8 Tensile strength (Minimum) 160,000 PSI 31ft lbs

These specs are assuming the material it is being bolted in to has the same tensile strength as the bolt and has adequate thread count.

Grade 2 Tensile strength (Minimum) 74,000 PSI 14ft lbs

Grade 5 Tensile strength (Minimum) 120,00 PSI 22ft lbs,

Grade 8 Tensile strength (Minimum) 160,000 PSI 31ft lbs

#9

But it never seemed to effect the way the hood opened, stayed in the open position, or closed. I just used it as a "temporary" repair until i got the real ones. And this was only on one bolt. It was the top one on the passenger side. It just looked a little "shade tree". I think Gina at Mid Fifty told me some years back that someones you have to get creative to keep these old trucks on the road. She was right about that!

#10

Torque specs for 5/16-24 (NF) @80% Yeild strength.

These specs are assuming the material it is being bolted in to has the same tensile strength as the bolt and has adequate thread count.

Grade 2 Tensile strength (Minimum) 74,000 PSI 14ft lbs

Grade 5 Tensile strength (Minimum) 120,00 PSI 22ft lbs,

Grade 8 Tensile strength (Minimum) 160,000 PSI 31ft lbs

These specs are assuming the material it is being bolted in to has the same tensile strength as the bolt and has adequate thread count.

Grade 2 Tensile strength (Minimum) 74,000 PSI 14ft lbs

Grade 5 Tensile strength (Minimum) 120,00 PSI 22ft lbs,

Grade 8 Tensile strength (Minimum) 160,000 PSI 31ft lbs

#11

No problem I seem to recall that these bolts are softer than the hood hinge and designed to wear instead of the hinge so I would stick to the torque setting for grade 2 bolts and safety wire them. I imagine that is why Ford had provision for lock wire.

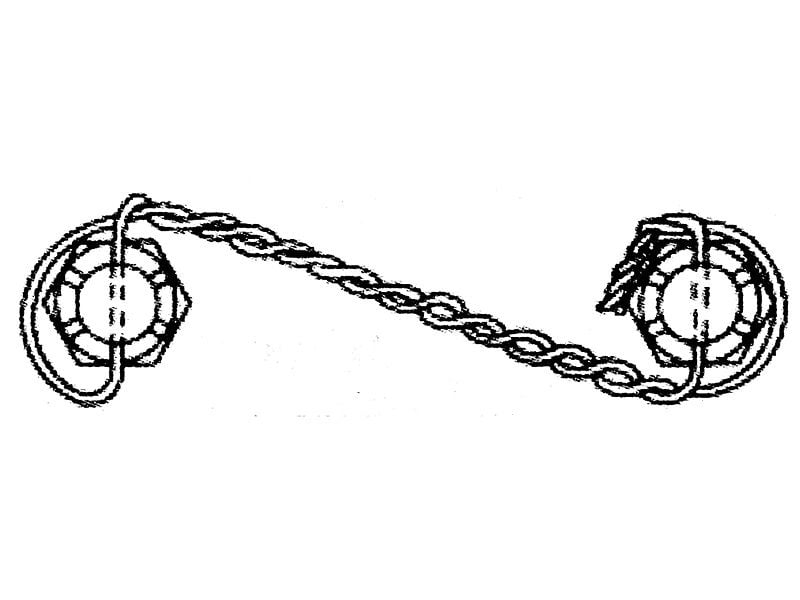

Safety wiring 2 bolts/nuts should look something like this. See below.

Jay Z has a good tutorial on lock wire on you tube.

#12

Thread

Thread Starter

Forum

Replies

Last Post

eberhama

1948 - 1956 F1, F100 & Larger F-Series Trucks

13

04-14-2012 11:19 PM

medicpg

1948 - 1956 F1, F100 & Larger F-Series Trucks

3

07-31-2008 02:06 PM

imlowr2

1948 - 1956 F1, F100 & Larger F-Series Trucks

12

07-06-2005 08:07 PM

F250Rob

1948 - 1956 F1, F100 & Larger F-Series Trucks

10

01-15-2005 12:44 PM