53 F100 Cab parts Dimensions

#1

53 F100 Cab parts Dimensions

So I got my cab in the shop finally and that thing is a mess. Floor is almost completely gone. Rockers hanging on by a thread, literally. Since I am a glutton for punishment and love to test my own patience I have opted to try and make the entire floor pan instead of buying the re-pops from Mid-Fifty (Almost $700 for two cab corners, front & rear pans and trans hump plus shipping. NO Thanks!). I feel like I can pull it off for cheaper. But I will buy the corners.

So to get to my question: Is there a resource that has the dimensions for individual panels before they are welded together?

I have the shop manual and the parts catalog and neither shows that.

I would just bust it apart at the seams and measure but some of the seams are gone or ragged so it would be a partial guess.

Am planning on using 16 gauge metal for the floor so it will be a little stiffer than stock plus adding some additional bracing underneath where I can.

Thanks for any help.

So to get to my question: Is there a resource that has the dimensions for individual panels before they are welded together?

I have the shop manual and the parts catalog and neither shows that.

I would just bust it apart at the seams and measure but some of the seams are gone or ragged so it would be a partial guess.

Am planning on using 16 gauge metal for the floor so it will be a little stiffer than stock plus adding some additional bracing underneath where I can.

Thanks for any help.

#2

#4

#5

I am in the same boat, my floor is pretty bad, a few holes, part of the battery hole is gone. I am debating the premade or just getting sheet metal to do it with since it is mostly flat myself.

I am getting prices from various sources on the premade panels still have not went to look for any LMS around here for prices on just sheet metal, although I will need some for body repairs as well. Keep us updated as it may help other like myself as well

I am getting prices from various sources on the premade panels still have not went to look for any LMS around here for prices on just sheet metal, although I will need some for body repairs as well. Keep us updated as it may help other like myself as well

#6

The main concern is to make sure that the doors fit first before you start cutting things apart. Make sure that you do not try to cut out the rocker panels AND the floor at the same time. If your body is already compromised to the point where the doors do not open and close correctly you should correct that first before starting to cut out any parts. I would suggest a port-a-power between the firewall and the back of the cab (pad each end so that it doesn't leave witness marks in the sheet metal). Once you get the door openings right then spot weld in some temporary braces. Do one side at a time.

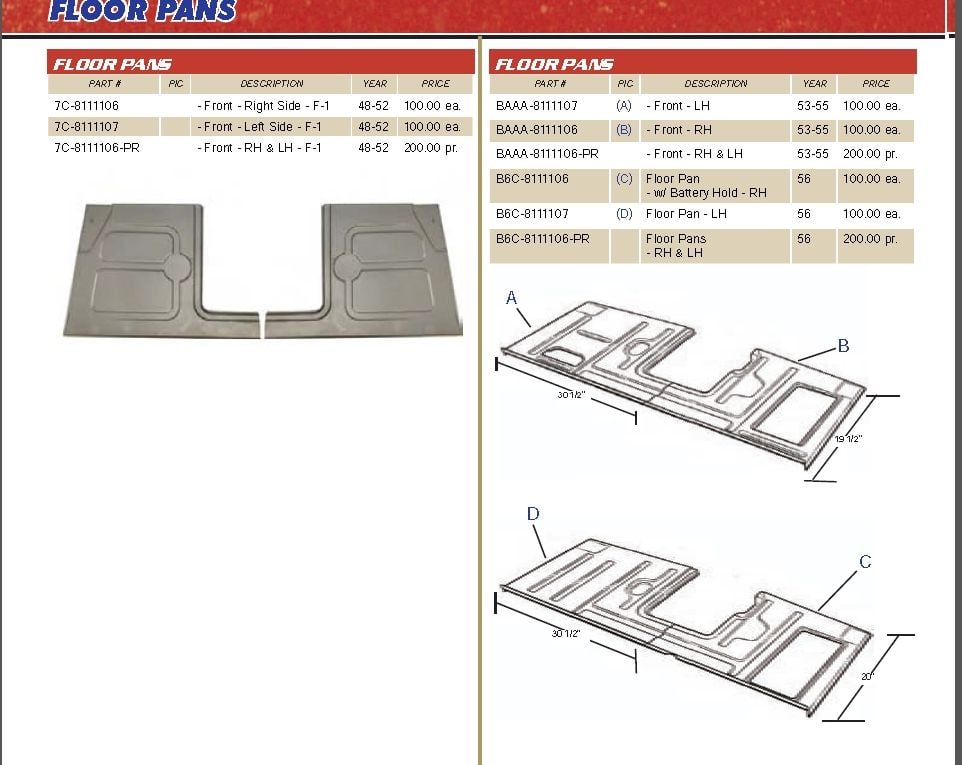

I get my sheetmetal from Northern Classic Truck as they maintain their dies well. I see that they have the left and right side front floor panels for $75 each.

And I see that Mac's has rocker panels for $75 a pair.

That is significantly less than $700 (less the cab corners). Those are critical parts in maintaining the cab dimensions and IMHO are worth the money.

I get my sheetmetal from Northern Classic Truck as they maintain their dies well. I see that they have the left and right side front floor panels for $75 each.

And I see that Mac's has rocker panels for $75 a pair.

That is significantly less than $700 (less the cab corners). Those are critical parts in maintaining the cab dimensions and IMHO are worth the money.

#7

Trending Topics

#8

Join Date: Oct 2005

Location: northwestern Ontario

Posts: 263,022

Received 4,132 Likes

on

2,656 Posts

#9

Again I think that your first task should be to get the structure stabilized. I would put the doors back on and get them to fit properly paying attention to gaps and closing effort. Then weld in some braces, remove the doors and just start with one area at a time. 16 ga steel is the correct thickness to use. This will require some level of welding skill to join new metal to old metal even after it has been cut back and cleaned up.

The other option for you to consider is to use construction adhesive and at least 3/16" steel rivets in those blind areas where welding is difficult. 3/16" steel rivets will require an air rivet gun like they use on aircraft. They are available on Amazon for under $100.

Have you tried to find a replacement cab? It would certainly be faster and probably more cost effective.

The other option for you to consider is to use construction adhesive and at least 3/16" steel rivets in those blind areas where welding is difficult. 3/16" steel rivets will require an air rivet gun like they use on aircraft. They are available on Amazon for under $100.

Have you tried to find a replacement cab? It would certainly be faster and probably more cost effective.

#11

I think that your patience could be better tested on a cab that is less a challenge as this one. I have been doing bodywork and fabrication for 50 years and if that cab were in my shop I would first get a tetanus shot and then drag it to the closest recycling yard. This is not a 32 Ford 3W, nor is it anything that would resemble a classic...there are thousands of these cabs out there. Find one that is at least structurally sound and begin there. Many times I have seen projects start like this only to see the owner become overwhelmed and give up. Do yourself a favor and give up now before you have sunk anymore cash/time into it.

#12

I think that your patience could be better tested on a cab that is less a challenge as this one. I have been doing bodywork and fabrication for 50 years and if that cab were in my shop I would first get a tetanus shot and then drag it to the closest recycling yard. This is not a 32 Ford 3W, nor is it anything that would resemble a classic...there are thousands of these cabs out there. Find one that is at least structurally sound and begin there. Many times I have seen projects start like this only to see the owner become overwhelmed and give up. Do yourself a favor and give up now before you have sunk anymore cash/time into it.

#13

Join Date: Oct 2005

Location: northwestern Ontario

Posts: 263,022

Received 4,132 Likes

on

2,656 Posts

#14

Wow,

The picture sure doesn't look very good. Lots of bent and rusted metal in the cab corners and the floor. I have never done one of these but it looks like a lot of work to me. If you do tackle it, I wish you the best. The premade panels would probably be where I would start.

Regards,

Chris

The picture sure doesn't look very good. Lots of bent and rusted metal in the cab corners and the floor. I have never done one of these but it looks like a lot of work to me. If you do tackle it, I wish you the best. The premade panels would probably be where I would start.

Regards,

Chris

Thread

Thread Starter

Forum

Replies

Last Post

Brian1971f100

1967 - 1972 F-100 & Larger F-Series Trucks

23

03-18-2018 12:36 AM

F-1

1948 - 1956 F1, F100 & Larger F-Series Trucks

18

04-02-2017 01:05 PM

Pokey11

1961 - 1966 F-100 & Larger F-Series Trucks

3

11-02-2008 03:16 PM