Massive valve guide wear? What happened?

#1

Massive valve guide wear? What happened?

Yeah, I think I did more expensive damage to my engine, somehow...

I was trying to figure out this ticking noise:

...and I think I found it...

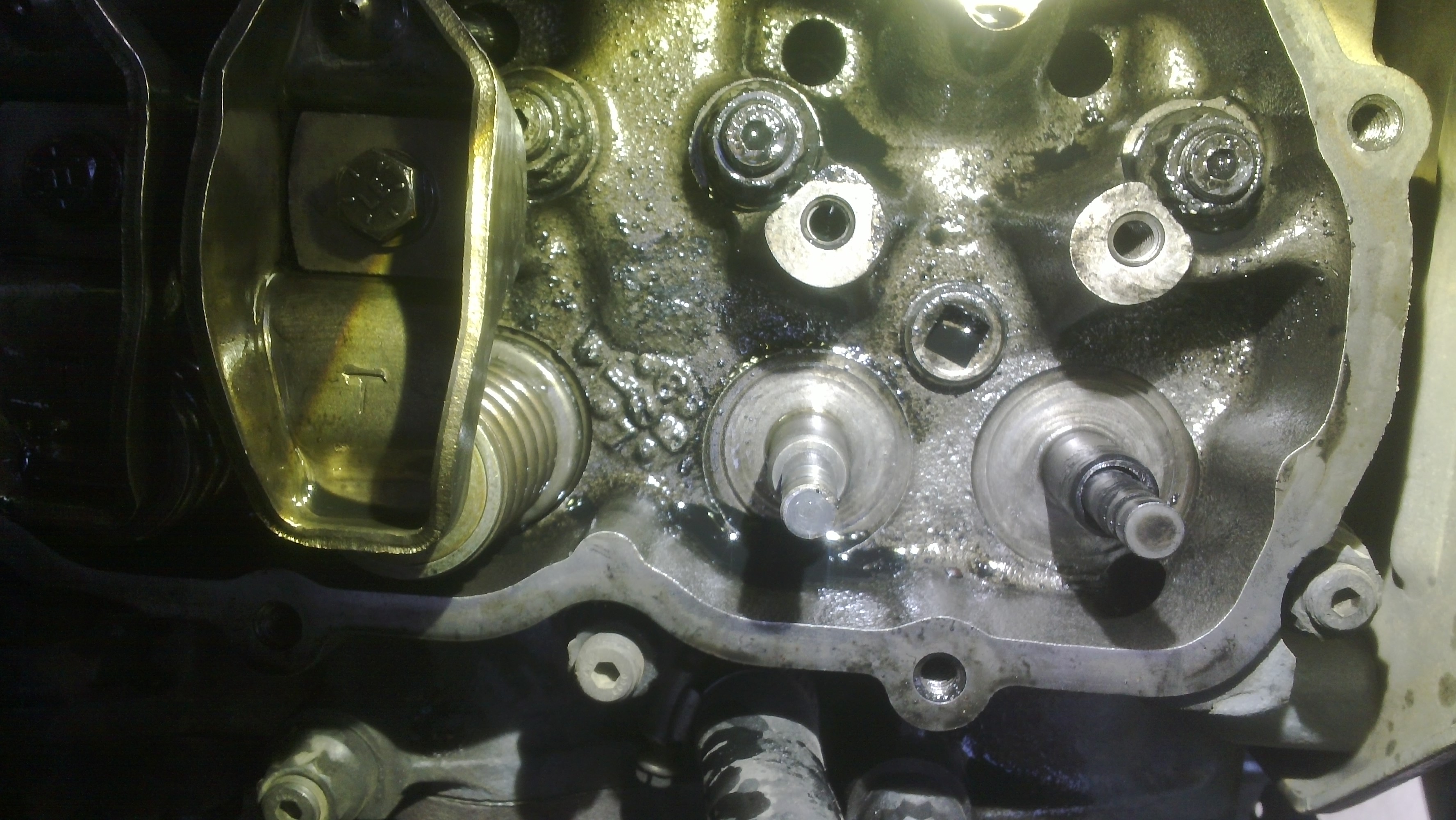

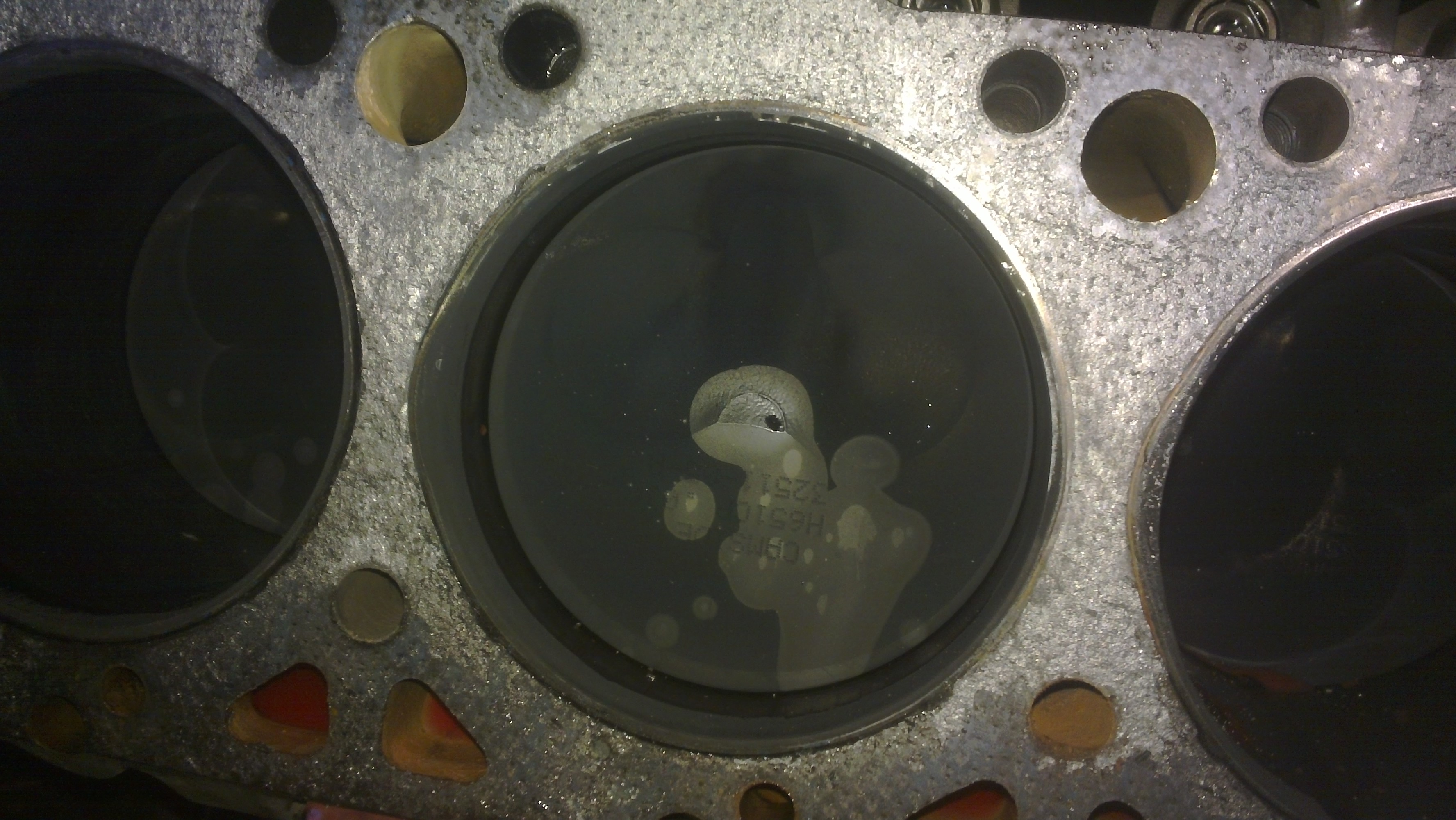

#1 exhaust valve does not look like the others....

This was the spring I pulled out of it; covered in crud, but looked in good shape.

The rocker was also just fine, well oiled and no unusual wear, but the end of the rocker had definitely gotten *very* hot.

The valve cover right above that valve was also discolored.

The

The pushrods were straight and just fine; nothing odd with them.

One thought I had is that when taking apart that valve, I found the little coil spring in picture 1. That *should* be off of an intake valve stem seal. So I think I swapped the two seals on that cylinder. The rest of the seal was totally gone; I found a couple of bits of rubber next to that valve stem...

Anyway, obviously I'm going to be pulling the heads pretty quickly, that doesn't look good. Interesting thing is it is /not/ a dead skip or anything. Valve rotated freely, just with a lot of play.

In the mean time, I didn't really want to shut the truck down for a while, and didn't like the /ton/ of exhaust gasses blowing past it, so I did this:

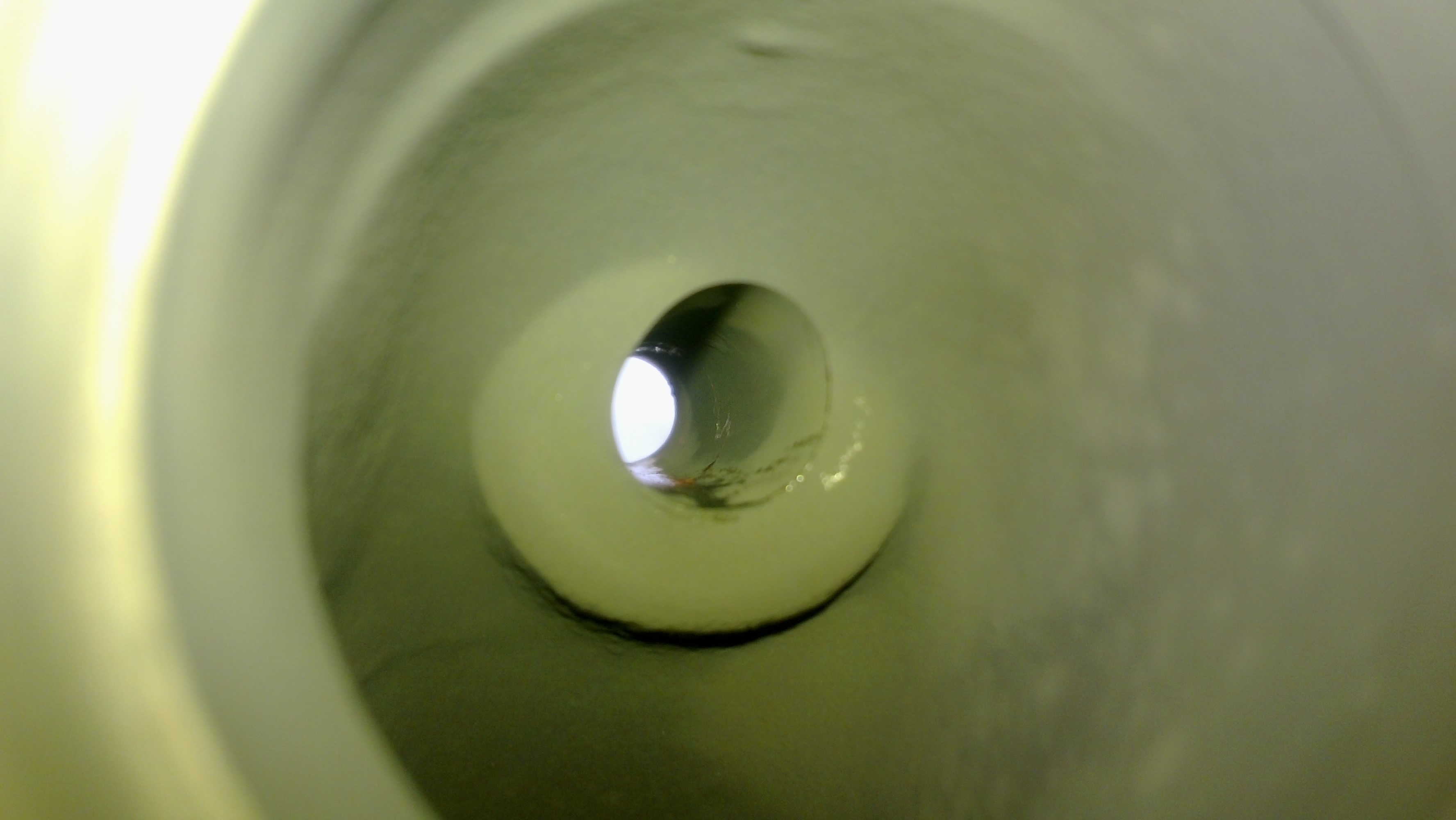

I made a little "sleeve" to go over the valve guide "column", inside the spring, that should keep the valve centered. It's just mild steel, so no telling how long it will last, but hopefully it'll help a bit.

It seems to run a little quieter with that mod, but it still needs fixing ASAP.

Any thoughts on what might have caused it? Again, my best theory is intake seal on exhaust valve / no lubrication.

Also, it might be helpful to note that it wasn't like this about 5K ago, when I put the new springs on(and would have swapped the seals). So that's pretty darn quick wear.

Thanks,

-Rob

I was trying to figure out this ticking noise:

...and I think I found it...

#1 exhaust valve does not look like the others....

This was the spring I pulled out of it; covered in crud, but looked in good shape.

The rocker was also just fine, well oiled and no unusual wear, but the end of the rocker had definitely gotten *very* hot.

The valve cover right above that valve was also discolored.

The

The pushrods were straight and just fine; nothing odd with them.

One thought I had is that when taking apart that valve, I found the little coil spring in picture 1. That *should* be off of an intake valve stem seal. So I think I swapped the two seals on that cylinder. The rest of the seal was totally gone; I found a couple of bits of rubber next to that valve stem...

Anyway, obviously I'm going to be pulling the heads pretty quickly, that doesn't look good. Interesting thing is it is /not/ a dead skip or anything. Valve rotated freely, just with a lot of play.

In the mean time, I didn't really want to shut the truck down for a while, and didn't like the /ton/ of exhaust gasses blowing past it, so I did this:

I made a little "sleeve" to go over the valve guide "column", inside the spring, that should keep the valve centered. It's just mild steel, so no telling how long it will last, but hopefully it'll help a bit.

It seems to run a little quieter with that mod, but it still needs fixing ASAP.

Any thoughts on what might have caused it? Again, my best theory is intake seal on exhaust valve / no lubrication.

Also, it might be helpful to note that it wasn't like this about 5K ago, when I put the new springs on(and would have swapped the seals). So that's pretty darn quick wear.

Thanks,

-Rob

#2

Join Date: Mar 2005

Location: Marlboro Mental Hospital.

Posts: 61,020

Received 3,124 Likes

on

2,179 Posts

#4

Join Date: Mar 2005

Location: Marlboro Mental Hospital.

Posts: 61,020

Received 3,124 Likes

on

2,179 Posts

#5

Bummer.  Do you know if all new valve guides were installed when the engine was rebuilt? Could be the new guide was not honed exactly straight or exactly to spec. Alternately, if they were not replaced it could have had extra wear from before. I'm also thinking that oiling may be inadequate at 4,000+ rpm's. It could have gotten hot and started a cycle of galling and wear. I have also been suspicious of the 7.3 valve guide clearances and larger oil shields than the 6.9 (changed for emissions and reduced oil consumption I think) but resulted in more valve issues than the 6.9 had. I'd rather the engine burned a little more oil than have valve issues... too bad all the service parts are 7.3 style.

Do you know if all new valve guides were installed when the engine was rebuilt? Could be the new guide was not honed exactly straight or exactly to spec. Alternately, if they were not replaced it could have had extra wear from before. I'm also thinking that oiling may be inadequate at 4,000+ rpm's. It could have gotten hot and started a cycle of galling and wear. I have also been suspicious of the 7.3 valve guide clearances and larger oil shields than the 6.9 (changed for emissions and reduced oil consumption I think) but resulted in more valve issues than the 6.9 had. I'd rather the engine burned a little more oil than have valve issues... too bad all the service parts are 7.3 style.

Do you know if all new valve guides were installed when the engine was rebuilt? Could be the new guide was not honed exactly straight or exactly to spec. Alternately, if they were not replaced it could have had extra wear from before. I'm also thinking that oiling may be inadequate at 4,000+ rpm's. It could have gotten hot and started a cycle of galling and wear. I have also been suspicious of the 7.3 valve guide clearances and larger oil shields than the 6.9 (changed for emissions and reduced oil consumption I think) but resulted in more valve issues than the 6.9 had. I'd rather the engine burned a little more oil than have valve issues... too bad all the service parts are 7.3 style.

Do you know if all new valve guides were installed when the engine was rebuilt? Could be the new guide was not honed exactly straight or exactly to spec. Alternately, if they were not replaced it could have had extra wear from before. I'm also thinking that oiling may be inadequate at 4,000+ rpm's. It could have gotten hot and started a cycle of galling and wear. I have also been suspicious of the 7.3 valve guide clearances and larger oil shields than the 6.9 (changed for emissions and reduced oil consumption I think) but resulted in more valve issues than the 6.9 had. I'd rather the engine burned a little more oil than have valve issues... too bad all the service parts are 7.3 style.

#6

Machinists tend these days just to drill the old ones out and make their own guides or use cheep Chinese crap. It happened to me twice on the ww II jeep engines.The problem is when they drill them out,they make the hole larger thus unable to use stock replacement.

Plus I have the same experience as Tom said.

Plus I have the same experience as Tom said.

#7

Trending Topics

#8

I also wonder about lubrication when you have serious amounts of exhaust backpressure from the turbo... it could easily blow any oil /up/ the stem?

I have also been suspicious of the 7.3 valve guide clearances and larger oil shields than the 6.9 (changed for emissions and reduced oil consumption I think) but resulted in more valve issues than the 6.9 had. I'd rather the engine burned a little more oil than have valve issues... too bad all the service parts are 7.3 style.

I mean, sure, it might use a little more oil. But how much, really?

Also, on a NA engine you might have a venturi sucking oil down the stems, but with a turbo? Any speed above idle, you've got positive pressure on both the exhaust and intake sides.

I'll probably try that and see what happens; worst case I get extra smoke, I think.

I wonder... If the guide was already worn, or the reamer used wasn't perpendicular, it might have created a slightly oval hole, or something like that.

#9

#10

This has me a little unsettled. I have an IDIT being overhauled right now (with only 168k and no actual problems) to put in my daily truck, every one OB is suggesting i have valve guides and seats replaced, but what's the point if they are fine? It seems like a poor machined or manufactured valve guide could be installed and cause this same issue here where as an old one might at worst just leak a little, but not cause catastrophic failure in such a short time.

#11

Any thoughts on what might have caused it? Again, my best theory is intake seal on exhaust valve / no lubrication.

Also, it might be helpful to note that it wasn't like this about 5K ago, when I put the new springs on(and would have swapped the seals). So that's pretty darn quick wear.

Thanks,

-Rob

Also, it might be helpful to note that it wasn't like this about 5K ago, when I put the new springs on(and would have swapped the seals). So that's pretty darn quick wear.

Thanks,

-Rob

#12

Once I get the heads off, I'll hopefully have more information.

This has me a little unsettled. I have an IDIT being overhauled right now (with only 168k and no actual problems) to put in my daily truck, every one OB is suggesting i have valve guides and seats replaced, but what's the point if they are fine? It seems like a poor machined or manufactured valve guide could be installed and cause this same issue here where as an old one might at worst just leak a little, but not cause catastrophic failure in such a short time.

Usually, though, replacement valves seem to have oversize stems to allow the machinist to ream out the old guides, so if you replace any valves, you'll probably need to have the heads reamed to match.

-----

As of now, I've decided to swap out my one failing head with an old head I have off another 88. It had no work done on it, but doesn't look horrible; all the valves are still there, and while the exhaust mating surfaces(on the valves, seats look mint) are all dimpled/worn a bit, they seem like they still seat.

I also found no appreciable wear on the valve guides of this head. cleaning all the oil and crud out of the guides and off the stems, they have a little bit of play(few thou), but after coating the valve stems with some wheel bearing grease, that play disappears and they slide smoothly.

I'm thinking that as all the valve head wear is in a narrow band the exact width of the seat, that they were going up and down right on center.

The other thing I noticed was that the exhaust seals were the plastic "oil shield" type and, well, didn't really do a great job; there was a nice bunch of "grease"(old oil and crud) right at the top of the valve guide on each of these valves. Which might be why they didn't wear...

#13

So... Update!

At first glance, the head looks just fine. Valves are all where they should be, etc.

Note that I did scratch it a little pulling it out, so some of those marks in the carbon might be from that.

Also had coolant come out of it, so there is wetness, but it was all new.

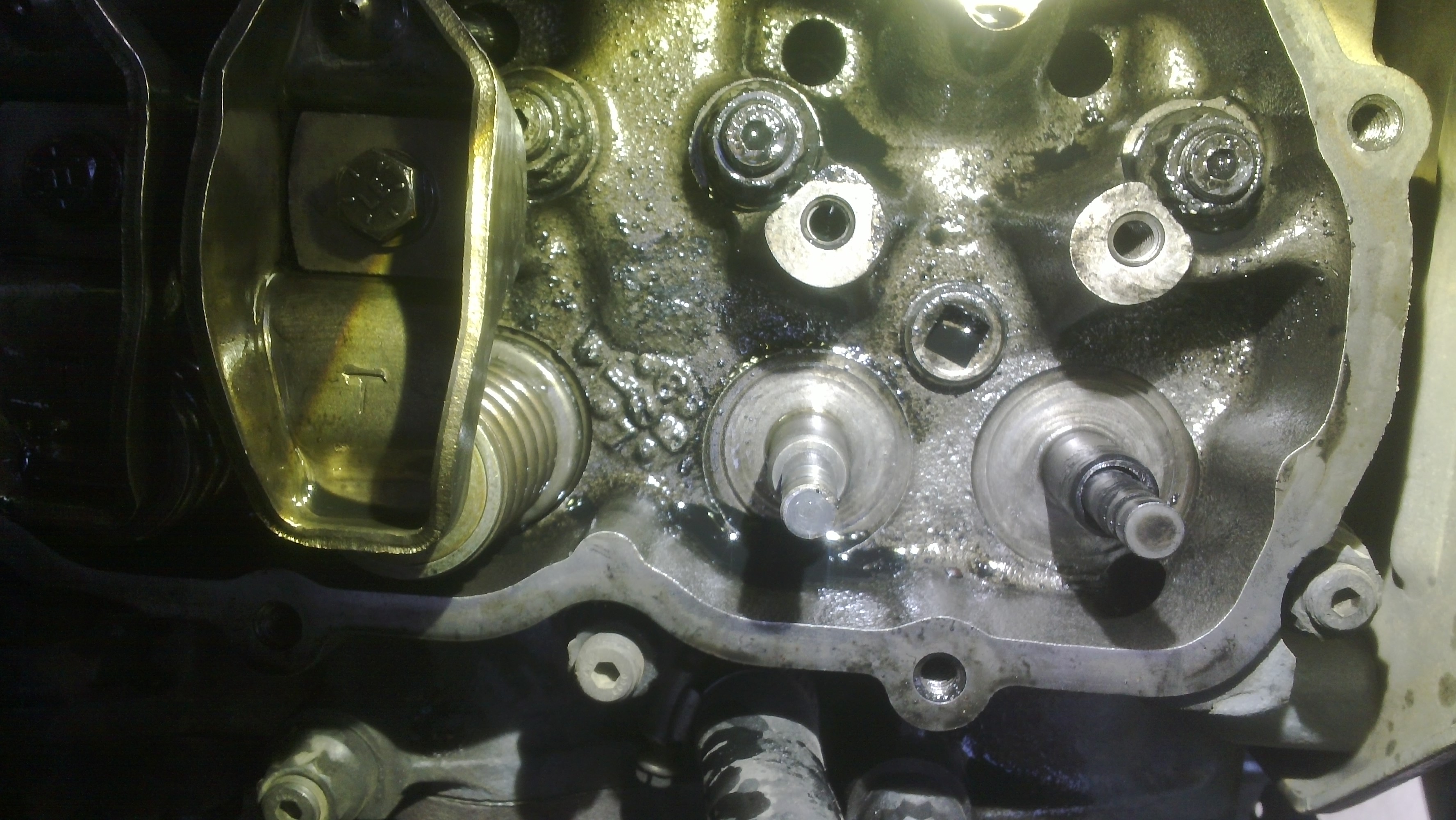

#3 cylinder looked... very odd. What is with that non-sooty patch in the middle?

After I removed the soot with a paper towel, it looked just like the other ones, so...?

#7 looked to have a little bit of edge-recision on the upper side, but had some sort of deposit next to the intake valve(left side); might have been from when the rockers came loose?

Also a slight valve imprint on the /intake/ side, but not the exhaust? Odd.

#1 however... Wow. Very light imprint on the intake side, not enough to remove the engraving...

Exhaust side, it's like .010 deep!

What's odd is that I don't recall ever replacing pushrods on #1; they were always just fine. All 8 that came out today were straight as well, so...

A random exhaust valve that came out of my 93 engine that I had lying around compared to the one from #1 exhaust.

The #1 valve was .020 shorter overall, and .030 shorter above the spring retainer. It looked hammered on top, but where did all that material go? Just compressed the entire valve stem?

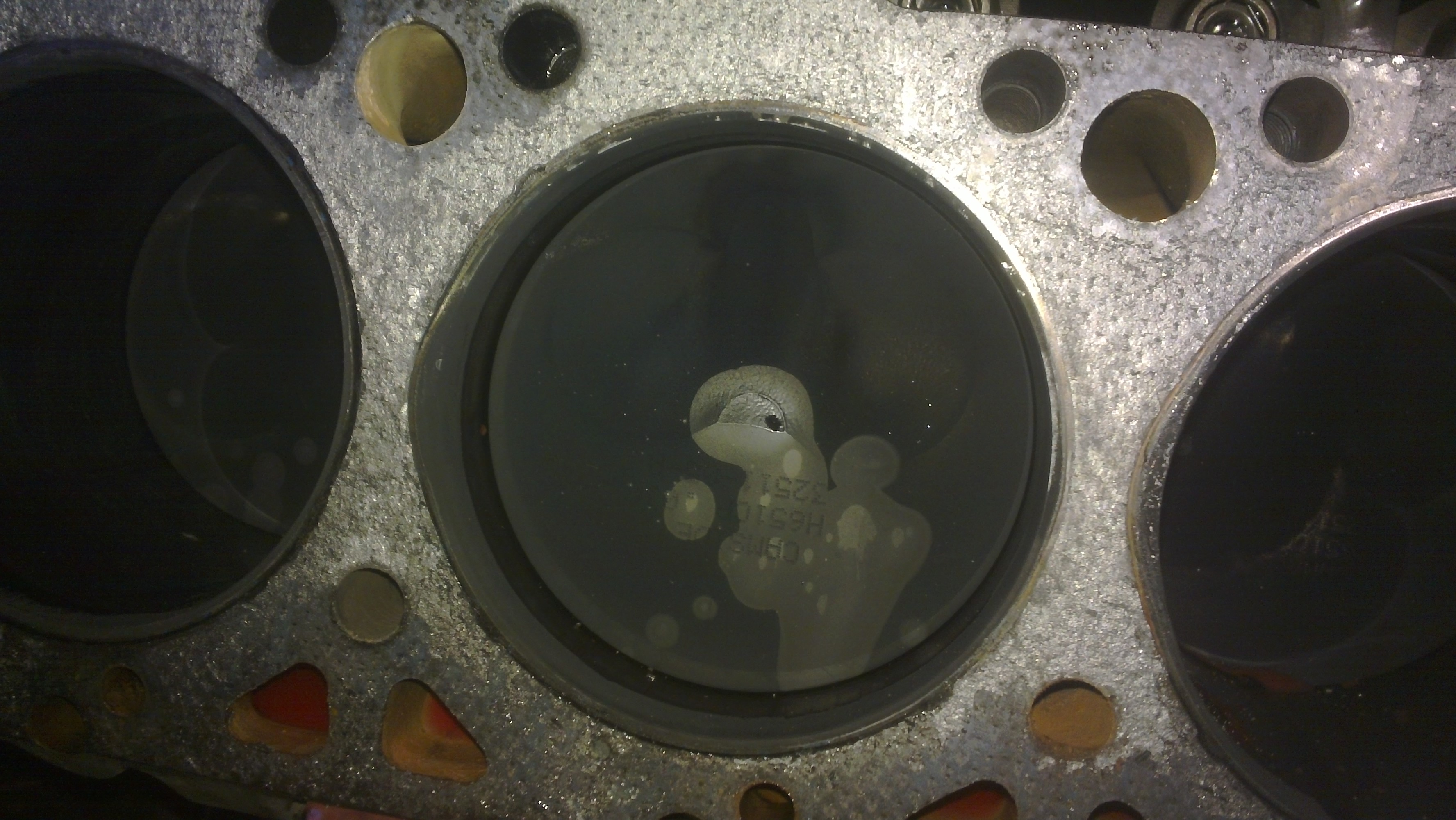

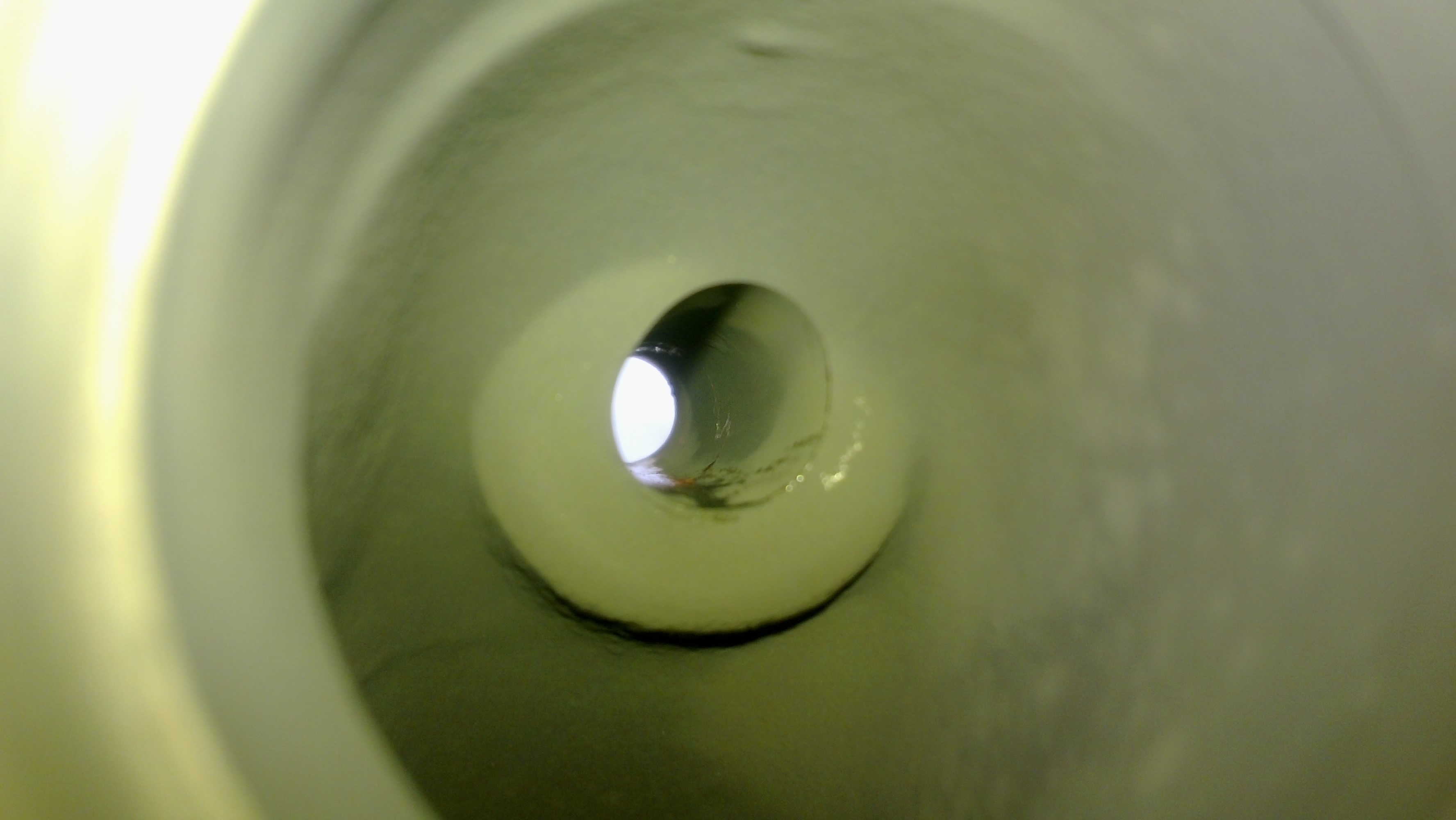

This was the best picture I could get of the #1 valve guide from the bottom.

It was totally egg-shaped, like a good .050+"

Horrible. It won't be just a matter of rework; that's a new valve guide right there.

Stem looked just fine, oddly enough(see previous pic).

So.. truck is out of commission for a little while. I really need to figure out where that valve-piston interaction is coming from. I mean, the cam is a stock cam that my machine shop installed when they did the heads and bottom end... and why is it just the #1 exhaust, #1 intake and #7 intake(slightly)?

Odd.

At first glance, the head looks just fine. Valves are all where they should be, etc.

Note that I did scratch it a little pulling it out, so some of those marks in the carbon might be from that.

Also had coolant come out of it, so there is wetness, but it was all new.

#3 cylinder looked... very odd. What is with that non-sooty patch in the middle?

After I removed the soot with a paper towel, it looked just like the other ones, so...?

#7 looked to have a little bit of edge-recision on the upper side, but had some sort of deposit next to the intake valve(left side); might have been from when the rockers came loose?

Also a slight valve imprint on the /intake/ side, but not the exhaust? Odd.

#1 however... Wow. Very light imprint on the intake side, not enough to remove the engraving...

Exhaust side, it's like .010 deep!

What's odd is that I don't recall ever replacing pushrods on #1; they were always just fine. All 8 that came out today were straight as well, so...

A random exhaust valve that came out of my 93 engine that I had lying around compared to the one from #1 exhaust.

The #1 valve was .020 shorter overall, and .030 shorter above the spring retainer. It looked hammered on top, but where did all that material go? Just compressed the entire valve stem?

This was the best picture I could get of the #1 valve guide from the bottom.

It was totally egg-shaped, like a good .050+"

Horrible. It won't be just a matter of rework; that's a new valve guide right there.

Stem looked just fine, oddly enough(see previous pic).

So.. truck is out of commission for a little while. I really need to figure out where that valve-piston interaction is coming from. I mean, the cam is a stock cam that my machine shop installed when they did the heads and bottom end... and why is it just the #1 exhaust, #1 intake and #7 intake(slightly)?

Odd.

#14

Rob I had that happened twice on one engine, rebuild. It was go devil wwII jeep engine, the valve stems failed 500 km after complete rebuild. I claimed waranty at the machine shop, dismantled the engine, they redid the valve guides, unfortunately without me behind their asses and it happened again after 5k km. I changed the shop and it never hapened again. I think they might have had the valves too tight in the guides and they might be sticking under operating temp, and once it seizes just a little the guide quickly gives up. I would change the machine shop for sure.

I do not think the loose rocker contributed to it, when it is loose the valve does not fully open.

BTW how do you check the hydraulic lifters in terms where they are at their adjusting position? Maybe u are fully compressed and it can not compensate for the heat expansion? Just a thought, I know the clearances should disapear almost on hot engine, do not have a clue how materials work in these engines. Some odd engines here have cold valve clearances tighter than hot. Just putting some thought on the table.

I do not think the loose rocker contributed to it, when it is loose the valve does not fully open.

BTW how do you check the hydraulic lifters in terms where they are at their adjusting position? Maybe u are fully compressed and it can not compensate for the heat expansion? Just a thought, I know the clearances should disapear almost on hot engine, do not have a clue how materials work in these engines. Some odd engines here have cold valve clearances tighter than hot. Just putting some thought on the table.