How do you mount the alternator and P/S pump on a 302?

#1

How do you mount the alternator and P/S pump on a 302?

I'm not over here much, usually on the '87-'96 F-series forum since that's the truck I'm working on most. But I'm getting a little stuck on my Bronco and I'm hoping someone can post some close-up pictures of how the alternator and power steering pump and their brackets go on the 302.

Many years ago I replaced the V-belt accessory drive with a serpentine system off an '88 F-150, but that didn't work out so well for me. There wasn't room for a mechanical (or even a thin electric) fan between the water pump and radiator, so I ended up using two small electric fans. But the cooling system has always been marginal like that, so for years I've been planning to go back to the V-belts.

About 5 years ago I pulled all the brackets off a junkyard Bronco with a 302. It had power steering, so I got those too. Now a water pump leak has prompted me to finally do this project. Unfortunately I can't figure out how all the brackets go. I'm hoping someone can post a few pictures that show the brackets and how both the alternator and the power steering pump fit in them.

Thanks

Many years ago I replaced the V-belt accessory drive with a serpentine system off an '88 F-150, but that didn't work out so well for me. There wasn't room for a mechanical (or even a thin electric) fan between the water pump and radiator, so I ended up using two small electric fans. But the cooling system has always been marginal like that, so for years I've been planning to go back to the V-belts.

About 5 years ago I pulled all the brackets off a junkyard Bronco with a 302. It had power steering, so I got those too. Now a water pump leak has prompted me to finally do this project. Unfortunately I can't figure out how all the brackets go. I'm hoping someone can post a few pictures that show the brackets and how both the alternator and the power steering pump fit in them.

Thanks

#2

alternator.... there are two brackets stock... a triangle looking thing and a bar... the triangle thing is the upper bracket and the bar is the lower bracket.... the triangle bracket mounts to the water pump and is detained by the water pump mounting bolts.. the bar mount to a boss of the water pump and you tension the alternator by itself.... the alternator also mounts to the first groove in the crank puller... There is one snag with the alt setup: there is a spacer that sits behind the alt there the alternator mounts to the triangle bracket and a long bold that anchors in the lower outside head bolt boss.... You can however, overcome the loss of the proper spacer/spacers by using a long bolt and a die to cut threads all the way down the bolt length and then use two nuts... what you do is install the bolt through the bracket and alt and then thread the two nuts onto the bolt... and then thread the bold into the block... you cannot use the conventional lock washer between the bold head and the bracket and remember to use a bolt that threads into the block 1/2 to 5/8" blue locktite would not be a terrible idea here either.... then run the first nut up to the back of the alternator but still allow the alt to move into and away from the block... install the belt and then after putting tension on the belt snug the first bolt to the back of the alt with fingers and then tighten the detent bolt on the bar... then the bold at the other end of the bar that goes to the h2o pump boss and then the first bolt to the back of the alt with and then the second... it works... not as good as the proper spacer/spacers.... (this setup is the same as the 67 mustang setup)

The PS setup is a little different... stock its a two bracket deal, but you may want to just do with a Jeff Bronco bracket that work without spacers and for both stock and saginaw pumps... Wild Horses and Toms have them too...

Stock works like this: outer bracket hold the pump and is held into the head by one bolt. Then there is another bracket that like the alt bracket is held in place by the water pump bolts and has two holes that face the outside of the engine compartment... one hole mounts to the same head bolt hole as the bracket that actually holds the ps pump... the other lines up with a threaded hole in the ps pump bracket and is used to tension the belt... the belt generally runs on the second groove of the water pump...

The PS setup is a little different... stock its a two bracket deal, but you may want to just do with a Jeff Bronco bracket that work without spacers and for both stock and saginaw pumps... Wild Horses and Toms have them too...

Stock works like this: outer bracket hold the pump and is held into the head by one bolt. Then there is another bracket that like the alt bracket is held in place by the water pump bolts and has two holes that face the outside of the engine compartment... one hole mounts to the same head bolt hole as the bracket that actually holds the ps pump... the other lines up with a threaded hole in the ps pump bracket and is used to tension the belt... the belt generally runs on the second groove of the water pump...

#3

Thanks. I've been dealing with storm damage in my yard which slowed down progress for a while, but I'm back now...

My alternator bracket (off a junkyard Bronco a few years ago) looked nothing like what you were describing. It's a cast iron piece. In the end I decided to get brackets from Jeff's. I think the cast iron one could have worked with a thicker water pump, but things just weren't lining up with what I have.

With the brackets from Jeff's I'm getting close. The alternator hangs down from the triangle bracket, right? With the slot in the bar attaching to a boss on the bottom of the alternator? I think from there I can tell which boss on the water pump the bar must mount to.

The only issue I have with the alternator now is clearance between the lower bar and the power steering pump belt. My p/s pump has a single pulley that I mounted on the pump with the grooved hub to the front and the pulley hub even with the end of the shaft (same as the old pump and pulley). This makes the p/s pulley line up with the back groove in the water pump and crank pulleys. My alternator has a double groove pulley and both grooves line up with the grooves on the water pump and crank pulleys, so it'll work fine to have the alternator use the front groove.

But the problem is that when the back belt comes up from the crank to the waterpump pulley on the rigt side (like it has to do to go to the p/s pump), then the back of the belt rubs against the front edge of the bar that goes from the water pump over to the bottom of the alternator.

I can probably bend the bar a little to make some clearance. But since I just bought it new it doesn't seem like I should need to do that. Am I missing something else?

My alternator bracket (off a junkyard Bronco a few years ago) looked nothing like what you were describing. It's a cast iron piece. In the end I decided to get brackets from Jeff's. I think the cast iron one could have worked with a thicker water pump, but things just weren't lining up with what I have.

With the brackets from Jeff's I'm getting close. The alternator hangs down from the triangle bracket, right? With the slot in the bar attaching to a boss on the bottom of the alternator? I think from there I can tell which boss on the water pump the bar must mount to.

The only issue I have with the alternator now is clearance between the lower bar and the power steering pump belt. My p/s pump has a single pulley that I mounted on the pump with the grooved hub to the front and the pulley hub even with the end of the shaft (same as the old pump and pulley). This makes the p/s pulley line up with the back groove in the water pump and crank pulleys. My alternator has a double groove pulley and both grooves line up with the grooves on the water pump and crank pulleys, so it'll work fine to have the alternator use the front groove.

But the problem is that when the back belt comes up from the crank to the waterpump pulley on the rigt side (like it has to do to go to the p/s pump), then the back of the belt rubs against the front edge of the bar that goes from the water pump over to the bottom of the alternator.

I can probably bend the bar a little to make some clearance. But since I just bought it new it doesn't seem like I should need to do that. Am I missing something else?

#4

"With the brackets from Jeff's I'm getting close. The alternator hangs down from the triangle bracket, right? With the slot in the bar attaching to a boss on the bottom of the alternator? I think from there I can tell which boss on the water pump the bar must mount to." Exactly

The problem you are facing is that you have what I would call and "all sorts" setup. Ford used an incomparable amount of pullers and brackets for different vehicles, different years, and different engines... then as people swapped and added components you have an even worse mess....

The Bronco stock never had double groove alternator pulleys... my guess is that is a later F series truck pulley (maybe car) pulley. I think that one has to go.... and then the rest of the setup will fall into place....

On a Bronco the alternator uses the rearward groove on the crank and water pump pulley, and the PS uses the forward groove.

I had a 75 F-150 with a setup that was kinda like what you are describing... and the alternator used a completely different mounting setup... but that again was a one groove alt pulley.... I would say that pulley mounted high... my current 79 began as a friends 6 cyl truck and we converted it using the engine and trans. That truck had a double groove alt pulley.....

My recommendation: Set up the PS side first and see if you can get it to use the front pulley groove..... then sway to a one groove alt pulley and then everything should work... and if you can't use the front pulley groove for the ps side... go to a u pull it yard and look for the alt mount from a 75 something life that F-150.... but again... the F-150 uses a different H20 pump.... see where this gets you.

The problem you are facing is that you have what I would call and "all sorts" setup. Ford used an incomparable amount of pullers and brackets for different vehicles, different years, and different engines... then as people swapped and added components you have an even worse mess....

The Bronco stock never had double groove alternator pulleys... my guess is that is a later F series truck pulley (maybe car) pulley. I think that one has to go.... and then the rest of the setup will fall into place....

On a Bronco the alternator uses the rearward groove on the crank and water pump pulley, and the PS uses the forward groove.

I had a 75 F-150 with a setup that was kinda like what you are describing... and the alternator used a completely different mounting setup... but that again was a one groove alt pulley.... I would say that pulley mounted high... my current 79 began as a friends 6 cyl truck and we converted it using the engine and trans. That truck had a double groove alt pulley.....

My recommendation: Set up the PS side first and see if you can get it to use the front pulley groove..... then sway to a one groove alt pulley and then everything should work... and if you can't use the front pulley groove for the ps side... go to a u pull it yard and look for the alt mount from a 75 something life that F-150.... but again... the F-150 uses a different H20 pump.... see where this gets you.

#5

The double groove alternator pulley isn't the problem. Both grooves line up so I could use either one for the alternator belt. The problem is that the P/S pulley lines up with the rear groove.

Here is a picture showing the belt alignment I've got now:

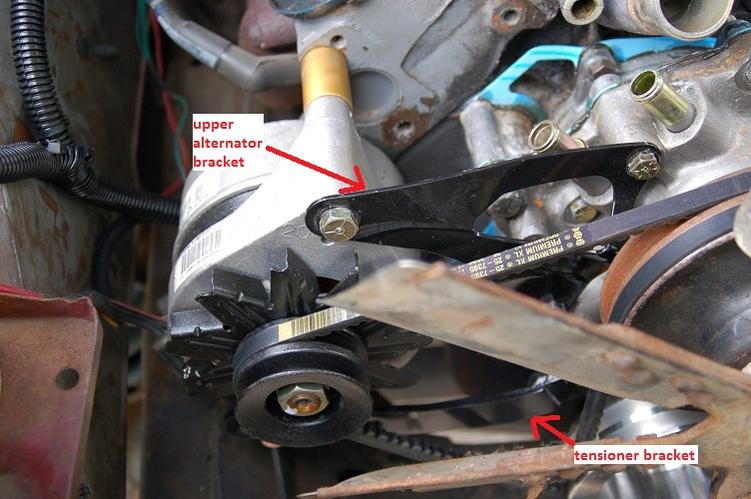

And for grins, here is a front view of the alternator side:

If I didn't already have the pulley on the P/S pump I'd maybe try to put it on the other way so the groove was further forward and I could line it up with the front groove. But it went on so hard I really don't want to fight it off. So I'm thinking my best bet at this point is to persuade a little more clearance between the lower alternator bracket and the power steering belt in the rear groove.

Here is a picture showing the belt alignment I've got now:

And for grins, here is a front view of the alternator side:

If I didn't already have the pulley on the P/S pump I'd maybe try to put it on the other way so the groove was further forward and I could line it up with the front groove. But it went on so hard I really don't want to fight it off. So I'm thinking my best bet at this point is to persuade a little more clearance between the lower alternator bracket and the power steering belt in the rear groove.

#6

The pics are a great help.... Two comments:

March Pulleys are aluminum.... March is really good.. They can get you pulleys that will work with you accessories even when you swap aspect ratios or use different manufacturers pieces on your engine..... the one problem is, and I wish they would sell them like this, but they are IMHO sold to be pretty for the street rod set, aluminum is soft, and when you run the hell out of a engine your v-belts will dig grooves in them.... if they sold them hard-coat anodized they would not shine, but they would be a hell of a lot tougher.... That said:

Looks great. I would see if you can clearance they one arm.... it is probably your only solution..... I would not re-bend the arm because I think you will not get it to line up properly after bending.... and it will probably take a torch to bend it.... I would weld a piece on the back of that area where it hits... not a big piece because it will likely cause conflict with your lower coolant hose.... but about the same size as what you grind away to clearance the arms and that should do it....

March Pulleys are aluminum.... March is really good.. They can get you pulleys that will work with you accessories even when you swap aspect ratios or use different manufacturers pieces on your engine..... the one problem is, and I wish they would sell them like this, but they are IMHO sold to be pretty for the street rod set, aluminum is soft, and when you run the hell out of a engine your v-belts will dig grooves in them.... if they sold them hard-coat anodized they would not shine, but they would be a hell of a lot tougher.... That said:

Looks great. I would see if you can clearance they one arm.... it is probably your only solution..... I would not re-bend the arm because I think you will not get it to line up properly after bending.... and it will probably take a torch to bend it.... I would weld a piece on the back of that area where it hits... not a big piece because it will likely cause conflict with your lower coolant hose.... but about the same size as what you grind away to clearance the arms and that should do it....

#7

Thanks Boba for all of the advice. Welding and clearancing is exactly what I did. I welded a 1/4" thick piece on the back of the alternator adjusting bracket and then milled away 1/8" from the front. Should give me plenty of clearance for the lower hose and the belt. But then I ran into my next snag...

Turns out the P/S adjusting bracket doesn't work with the P/S on the rear pulley groove. So I'm back to your earlier advice about getting the P/S belt moved to the front. Turns out it wasn't at all difficult. I just put a 5/8" stack of washers between the P/S pump bracket and the head. I'll post pictures later.

So I'm pretty sure I've got it now. The alternator and P/S pump are both on, belts line up and not hitting anything. I've even got the alternator wired up. The only issues now are that my old P/S pressure hose isn't going to fit, but I've got a new one on order, so that should be OK. And it looks like my P/S belt might be a little too long (I'm at the end of the groove in the adjustiing bracket to tighten it). But it shouldn't be hard to get one a little shorter.

Probably won't be until next weekend before I try to put in the new radiator and hoses. Shouldn't be a problem either, but then again I've said that before... Oh well, that's why it's called a project vehicle.

Turns out the P/S adjusting bracket doesn't work with the P/S on the rear pulley groove. So I'm back to your earlier advice about getting the P/S belt moved to the front. Turns out it wasn't at all difficult. I just put a 5/8" stack of washers between the P/S pump bracket and the head. I'll post pictures later.

So I'm pretty sure I've got it now. The alternator and P/S pump are both on, belts line up and not hitting anything. I've even got the alternator wired up. The only issues now are that my old P/S pressure hose isn't going to fit, but I've got a new one on order, so that should be OK. And it looks like my P/S belt might be a little too long (I'm at the end of the groove in the adjustiing bracket to tighten it). But it shouldn't be hard to get one a little shorter.

Probably won't be until next weekend before I try to put in the new radiator and hoses. Shouldn't be a problem either, but then again I've said that before... Oh well, that's why it's called a project vehicle.

Trending Topics

#8

Oh, and on the aluminum crank pulley, I'd have preferred steel, but I have a newer engine and I've had some balance issues with the flywheel. Turns out there are "internally" and "externally" balanced 302s that take different flywheels. I'm afraid if I get the 3 bolt harmonic balancer that Bronco's normally have I'm likely to have vibration problems again. So I figure I ought to stay with the 3 year old harmonic balancer that I already have and know doesn't vibrate. I didn't look real hard, but aluminum was the only choice I found to get the double groove V-belt pulley that attaches to my 4 bolt balancer.

#9

Closing the loop, I've got both the alternator and the power steering pump mounted, belts on and tensioned. I haven't started it yet (still working on the radiator), but as far as this thread is concerned I'm all done! Here are some "after" pictures in case anyone stumbling across this thread later finds them useful.

Power steering pump (I changed from just a stack of washers to a nut and some washers so the stud stays put as I turn the outer nut that holds it all tight):

Alternator:

Power steering pump (I changed from just a stack of washers to a nut and some washers so the stud stays put as I turn the outer nut that holds it all tight):

Alternator:

#11

WoW

Congrats!

Sometimes those "little things" (yeah, right!) give the biggest hassel. Glad U can fab.

Is the 302 'era specific' (ie same generation as '71)? I see you have that era PS pump but looks to be a "different era" bracket... I wish I could post a pic to show how the I6 got it's PS (lotta cheatin).

Congrats!

Sometimes those "little things" (yeah, right!) give the biggest hassel. Glad U can fab.

Is the 302 'era specific' (ie same generation as '71)? I see you have that era PS pump but looks to be a "different era" bracket... I wish I could post a pic to show how the I6 got it's PS (lotta cheatin).

#12

My engine is out of a mid-80s Mustang. It's not an HO or anything, so performance-wise it's pretty similar to a stock Bronco 302, but I've run into a few little differences (like a boss missing for the clutch linkage).

I got the P/S brackets out of a junkyard '76 Bronco with a 302. I was assuming they were factory, but I got my first attempt at the alternator brackets from the same vehicle and that wasn't close. So I really can't vouch for the P/S bracket's pedigree. The P/S pump is from NAPA, ordered for a '76 Bronco with a 302.

The radiator was it's own nightmare. My Bronco has the 2WD F-100 power steering box, which takes up a lot of room near the bottom of the driver's side radiator tank. I ordered a 4 core radiator from Jeff's after asking if it would fit with the F-100 box, but it really doesn't. Long story short, a body lift (already done by a previous owner), shoving the lower mounts as far to the right as possible, shimming up the drivers side bottom mount, denting in the drivers side tank, replacing the drain valve with a solid plug and accepting the fact that the top brackets miss the rib their supposed to be on (drivers side is on the tank, passenger side on the core) and it fits! Nothing to it! If I had it to do over I'd go with the standard radiator given the F-100 box.

I got the P/S brackets out of a junkyard '76 Bronco with a 302. I was assuming they were factory, but I got my first attempt at the alternator brackets from the same vehicle and that wasn't close. So I really can't vouch for the P/S bracket's pedigree. The P/S pump is from NAPA, ordered for a '76 Bronco with a 302.

The radiator was it's own nightmare. My Bronco has the 2WD F-100 power steering box, which takes up a lot of room near the bottom of the driver's side radiator tank. I ordered a 4 core radiator from Jeff's after asking if it would fit with the F-100 box, but it really doesn't. Long story short, a body lift (already done by a previous owner), shoving the lower mounts as far to the right as possible, shimming up the drivers side bottom mount, denting in the drivers side tank, replacing the drain valve with a solid plug and accepting the fact that the top brackets miss the rib their supposed to be on (drivers side is on the tank, passenger side on the core) and it fits! Nothing to it! If I had it to do over I'd go with the standard radiator given the F-100 box.

#13

Thanks for the info.

"... standard radiator..."

I thought that wouldn't fit either.

"...like a boss missing for the clutch linkage..."

looked like something was ground-off in the pic

Boy, a real hassle in some mods. OE is the way to go, but with these rigs they just beg for mods (or it aint around anymore). Some day try the saginaw pump. They really are an improvement. That's where I mod - if it's easy, some 1 knows how (I'm not a mechanic so have not problem-solved around enuff probs to be savvy), and it's an upgrade I believe I need for the work the vehicle does.

It's hot out, hope U get er crusin soon...

Well, thanks for bringin us along. Hope you got plenty too.

"... standard radiator..."

I thought that wouldn't fit either.

"...like a boss missing for the clutch linkage..."

looked like something was ground-off in the pic

Boy, a real hassle in some mods. OE is the way to go, but with these rigs they just beg for mods (or it aint around anymore). Some day try the saginaw pump. They really are an improvement. That's where I mod - if it's easy, some 1 knows how (I'm not a mechanic so have not problem-solved around enuff probs to be savvy), and it's an upgrade I believe I need for the work the vehicle does.

It's hot out, hope U get er crusin soon...

Well, thanks for bringin us along. Hope you got plenty too.

Thread

Thread Starter

Forum

Replies

Last Post

LARIAT 85

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

40

06-03-2021 12:49 PM

cyris426

1973 - 1979 F-100 & Larger F-Series Trucks

3

09-25-2014 06:18 PM

califasbob

335 Series- 5.8/351M, 6.6/400, 351 Cleveland

15

06-09-2011 12:52 PM