Last edit by: IB Advertising

See related guides and technical advice from our community experts:

Browse all: Electrical Guides

- How to Replace Spark Plugs

Step by step instructions for do-it-yourself repairs

Browse all: Electrical Guides

5.4V8 DREADFUL SPARK PLUG ISSUE SOLVED !!

#46

[QUOTE=mig25;11552379] Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.

Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.

I have been contemplating the replacement of my plugs ( 06 Expy EB ) since before It had reached 100K miles.

My idea was to remove the plugs with the engine hot. Ford states it should be room temperature. But if they new better they would not caused this issue on the first place.

I followed the instructions from this guy on You tube ( watch video below )

Within 40 minutes I had all 8 of my plugs on my hands. None broke.

Thanks for posting this most excellent procedure! I think the idea to remove the plugs when hot is absolutely Brilliant. I very much agree that clearly Ford came up with a horrible design, and their procedures in the TSB for extraction are also incredibly wrong.

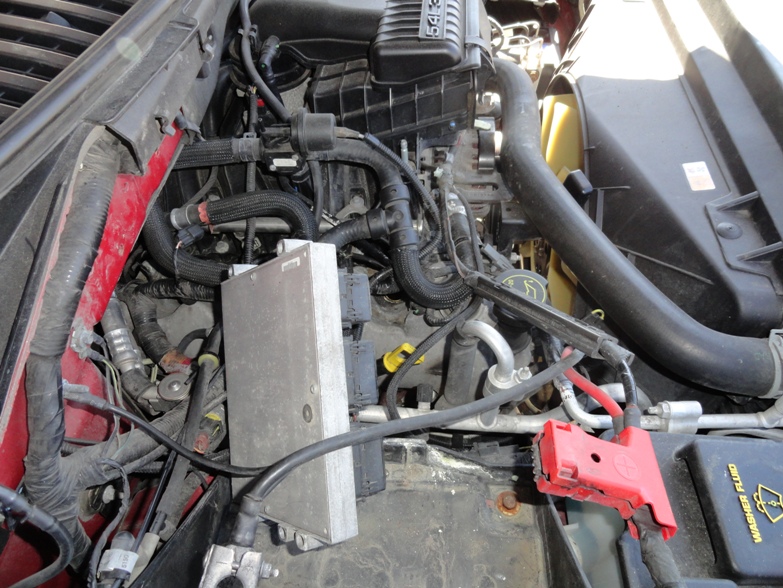

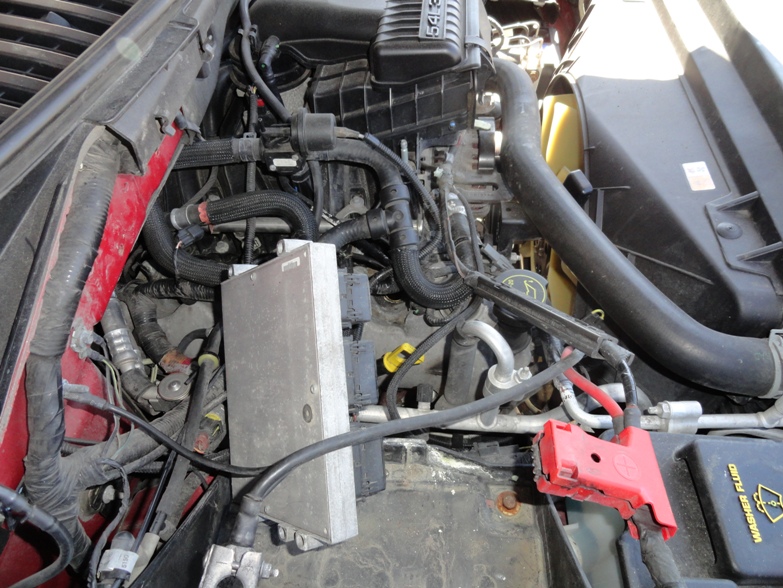

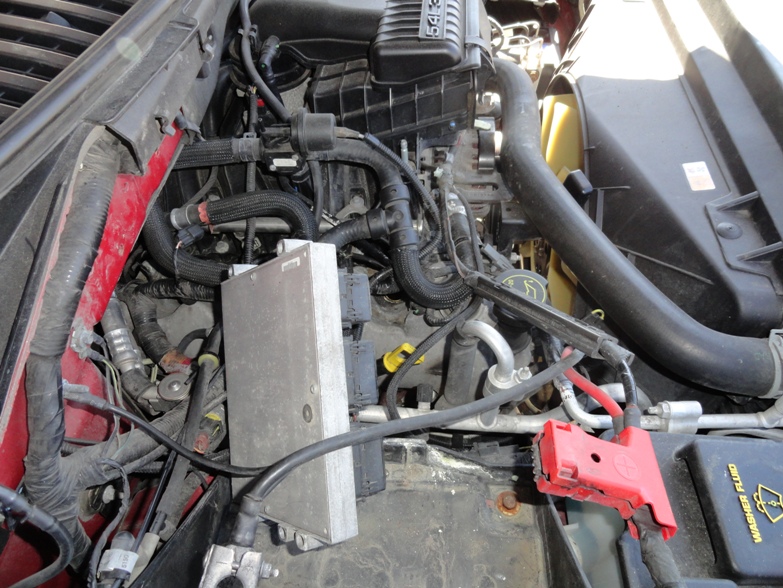

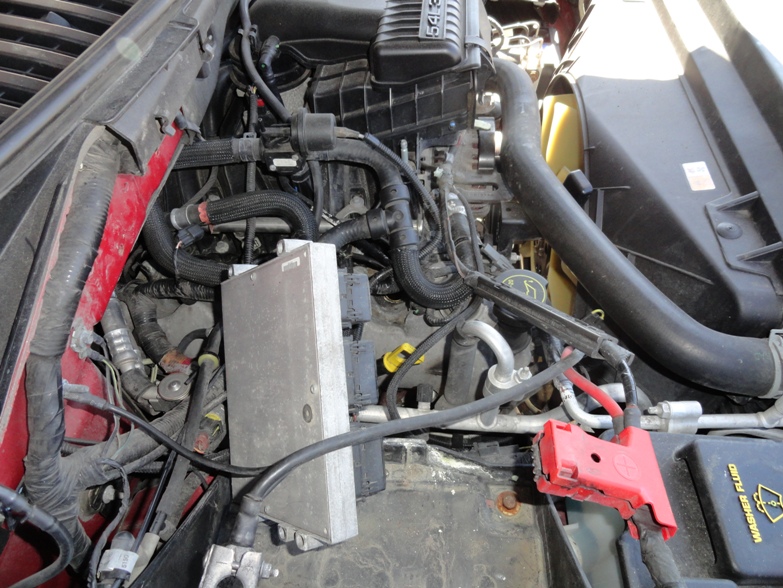

Passenger's side. I had to remove the ECM and the battery. No biggie.

Removal of the ECM is essential for reaching the plugs on the passenger side rear. It is only 4 bolts to remove the ECM and three to remove the support bracket for the ECU. I did not find removal of the battery necessary. I simply moved the ECM forward in the engine bay and tucked it under an A/C hose next to the battery which secured it from moving upward.

Below are some of the tools I used to get this job done...

I used the exact same tools, although I did not need to use a wobble at all. I did not have to remove any items on the driver's side to get to the coils, although a little creative wrangling is needed to extract them from the wires and hoses in the area.

I think it is very important to use an impact tool. In my case, i cleaned off all the spark plug well with air, removed the bolt and electrical connector and then removed the Coil on plug. I then used a 9/16 spark plug socket ($4.99 at Autozone) and a set of locking 3/8 in drive extensions in 3, 6, 12" lengths depending (available from Sears..) on the plug location. The most important item for getting an impact in to the back plugs is depth of the impact tool. I started on the drivers side, and I was able to get the front plugs with my 1/2" drive impact which has a depth of about 7.5" Had it been more compact, (it could suffice, however I was also using a 1/2 to 3/8" reducer, which added to the depth. I stopped and went to Sears and purchased a Craftsman 3/8 " drive impact for $69.99. It is quoted at 140 foot lbs of force which was plenty of headroom over the 30-50 ft lbs needed. The depth of the entire tool is 6" and it easily fit under the cowl and into the proper extension, which was placed down into the holes first, particularly for the rear most plugs. The engine was still warm when I got back from the store, and I was still able to get the plugs out, so one can get the motor up to temp and still have as much as 1-3 hours to work on it while it is still warm.

I Used the angle of my driveway to make the Expy a little lower, easier to get to the back plugs.

A great suggestion, thank you!

The excellent youtube video by the Mechanic made this job a breeze. I first had gone to a Firestone service center and was quoted a worst case of $1377.... $325 basic labor... $27 per spark plug, $96 per ignition coil, with a recommendation to replace all 8) and then charges could go up if any of the plugs broke. I figured I can break the plugs as easily as any other mechanic, and if the extraction was bad I would happily tow it to a mechanic knowing which plugs were broken, not wondering if they decided to inflate the labor.

ALL 8 of my plugs came out with no drama and no muss and no fuss. I finished the drivers side first and then did the passenger side a second day. Working on the engine warm was not too bad, even in 100 degree TX shade. My truck has 136,500 miles and had been hesitating badly at part throttle. These symptoms occured for months before every throwing a trouble code... Eventually Mine was 0308 which was cyl 8 misfire. I opted to the plugs alone. Removing the Coil on plug setup is not difficult at all and I figured I would replace later if needed or if the misfire situation continued.

I replaced the plugs with factory plugs at $13.99 and liberally applied anti-seize. Since my plugs came out easily I was not concerned with an upgrade, nor do I expect the truck and I together do the work at 200K more beyond, however if we are still together, I am sure they will come out very easily.

hopefully the instructions here convince others to do the work themselves. A person with an air compressor and just a few tools can do this job in their driveway or garage for far less than the costs of the labor at a dealer.

It took about four hours for me to do the work. If you just have a few hours of time in the evening you can do one side and then the other, starting when you arrive home from work as the motor is warm. If you have a full day, then go run an errand to warm up the engine or buy plugs etc and then do the work.

Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.

Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.I have been contemplating the replacement of my plugs ( 06 Expy EB ) since before It had reached 100K miles.

My idea was to remove the plugs with the engine hot. Ford states it should be room temperature. But if they new better they would not caused this issue on the first place.

I followed the instructions from this guy on You tube ( watch video below )

Within 40 minutes I had all 8 of my plugs on my hands. None broke.

Thanks for posting this most excellent procedure! I think the idea to remove the plugs when hot is absolutely Brilliant. I very much agree that clearly Ford came up with a horrible design, and their procedures in the TSB for extraction are also incredibly wrong.

Passenger's side. I had to remove the ECM and the battery. No biggie.

Removal of the ECM is essential for reaching the plugs on the passenger side rear. It is only 4 bolts to remove the ECM and three to remove the support bracket for the ECU. I did not find removal of the battery necessary. I simply moved the ECM forward in the engine bay and tucked it under an A/C hose next to the battery which secured it from moving upward.

Below are some of the tools I used to get this job done...

I used the exact same tools, although I did not need to use a wobble at all. I did not have to remove any items on the driver's side to get to the coils, although a little creative wrangling is needed to extract them from the wires and hoses in the area.

I think it is very important to use an impact tool. In my case, i cleaned off all the spark plug well with air, removed the bolt and electrical connector and then removed the Coil on plug. I then used a 9/16 spark plug socket ($4.99 at Autozone) and a set of locking 3/8 in drive extensions in 3, 6, 12" lengths depending (available from Sears..) on the plug location. The most important item for getting an impact in to the back plugs is depth of the impact tool. I started on the drivers side, and I was able to get the front plugs with my 1/2" drive impact which has a depth of about 7.5" Had it been more compact, (it could suffice, however I was also using a 1/2 to 3/8" reducer, which added to the depth. I stopped and went to Sears and purchased a Craftsman 3/8 " drive impact for $69.99. It is quoted at 140 foot lbs of force which was plenty of headroom over the 30-50 ft lbs needed. The depth of the entire tool is 6" and it easily fit under the cowl and into the proper extension, which was placed down into the holes first, particularly for the rear most plugs. The engine was still warm when I got back from the store, and I was still able to get the plugs out, so one can get the motor up to temp and still have as much as 1-3 hours to work on it while it is still warm.

I Used the angle of my driveway to make the Expy a little lower, easier to get to the back plugs.

A great suggestion, thank you!

The excellent youtube video by the Mechanic made this job a breeze. I first had gone to a Firestone service center and was quoted a worst case of $1377.... $325 basic labor... $27 per spark plug, $96 per ignition coil, with a recommendation to replace all 8) and then charges could go up if any of the plugs broke. I figured I can break the plugs as easily as any other mechanic, and if the extraction was bad I would happily tow it to a mechanic knowing which plugs were broken, not wondering if they decided to inflate the labor.

ALL 8 of my plugs came out with no drama and no muss and no fuss. I finished the drivers side first and then did the passenger side a second day. Working on the engine warm was not too bad, even in 100 degree TX shade. My truck has 136,500 miles and had been hesitating badly at part throttle. These symptoms occured for months before every throwing a trouble code... Eventually Mine was 0308 which was cyl 8 misfire. I opted to the plugs alone. Removing the Coil on plug setup is not difficult at all and I figured I would replace later if needed or if the misfire situation continued.

I replaced the plugs with factory plugs at $13.99 and liberally applied anti-seize. Since my plugs came out easily I was not concerned with an upgrade, nor do I expect the truck and I together do the work at 200K more beyond, however if we are still together, I am sure they will come out very easily.

hopefully the instructions here convince others to do the work themselves. A person with an air compressor and just a few tools can do this job in their driveway or garage for far less than the costs of the labor at a dealer.

It took about four hours for me to do the work. If you just have a few hours of time in the evening you can do one side and then the other, starting when you arrive home from work as the motor is warm. If you have a full day, then go run an errand to warm up the engine or buy plugs etc and then do the work.

#48

Join Date: Mar 2009

Location: Chicago and Mt Carroll IL

Posts: 6,243

Likes: 0

Received 2 Likes

on

2 Posts

I personally would feel safer with the lower torque of a cordless impact but I've still not done my plugs so I have nothing but intuition to back that up. The thought of a 1/2" impact vs. aluminum head casting scares the pants off me. However, I've watched that video at least 20 times and it sure seems to work.

#51

Great timing. I was going to the track this weekend and pulled out my own 18v dewalt and realized i potentially could have used it. I think it does provide enough torque for the task. My only concern is that it takes a good 10-20 seconds to get then to unscrew, mine were squeaking as they came out because of rust on the plugs. Most impacts are used for short bursts and for this use is possibly a little longer than what one would normally keep the trigger wide open on a cordless but shouldn't be an issue.

As far as using an impact at all, the quick application of torque in the initial break free of the plug is what is needed. Note how the factory method recommends an initial half turn and then time and soak. This seems to be exactly wrong. One wants to break these free *quickly*. As far as I am concerned , if it breaks off with an impact then it definitely would have broken off using conventional hand tools, so just use the impact.

#53

You are simply a blogger who is completely unfamiliar or choosing to ignore the MC SP 515's (the spec'd replacement) which are a 1 piece (welded), double platinum design....and have been out for about 1+ years now.

I wish you the best with the champions and I am glad you were in good shape regarding the removal.

BTW...the "Hot Engine' is not the "key"...a little thing called physics here....as an engine heats things expand not contract....so the tolerances actually reduce. The heat can soften the carbon but I doubt if you had much build-up in the 1st place (a good thing which is actually what causes the OEM 2-piece plugs to break).

There is also a technique presently taught in the MSE brieifings, crack the plug open 9unscrew) about 1/8 to 1/4 of a turn, fire the engine, let run for 1 minutes....this creates venting (leakage) ever so slight as to allow the flame in the cylinder to promogate up and burn off the carbon, agin reducing/eliminating the binding action that occurs breaking the oem 2-piece plug.

I wish you the best with the champions and I am glad you were in good shape regarding the removal.

BTW...the "Hot Engine' is not the "key"...a little thing called physics here....as an engine heats things expand not contract....so the tolerances actually reduce. The heat can soften the carbon but I doubt if you had much build-up in the 1st place (a good thing which is actually what causes the OEM 2-piece plugs to break).

There is also a technique presently taught in the MSE brieifings, crack the plug open 9unscrew) about 1/8 to 1/4 of a turn, fire the engine, let run for 1 minutes....this creates venting (leakage) ever so slight as to allow the flame in the cylinder to promogate up and burn off the carbon, agin reducing/eliminating the binding action that occurs breaking the oem 2-piece plug.

I say this after spending considerable number of year's working as railroad section hand and using torch to heat rusted track bolt's that could more easily be removed with track wrench,impact gun.

Without the heat,,you could be out there till the cow's come home twisting on track bolt's that have been in place since Moses came down from the mountain.

Popular television show now featuring restoration of all manner of rusted, bolted metal item's to be restored also uses heat or torch to loosen bolt's if one has seen very many episodes of this show.

Just sayin.

#54

You are of course heating up the nut not the bolt correct? By heating the nut and causing it to expand more than the bolt, it in turn loosens it's grip on the bolt and allows for easier removal. If you heat up the bolt instead of the nut, then it expands into the nut resulting in the threads binding all that much tighter. That method works well if you have access to the nut, but in the case of the spark plugs in the 5.4 engine, you cannot get heat on just the cylinder head threads without also heating up the spark plug. Because of that, heat won't help with the removal of the plugs.

#55

You are of course heating up the nut not the bolt correct? By heating the nut and causing it to expand more than the bolt, it in turn loosens it's grip on the bolt and allows for easier removal. If you heat up the bolt instead of the nut, then it expands into the nut resulting in the threads binding all that much tighter. That method works well if you have access to the nut, but in the case of the spark plugs in the 5.4 engine, you cannot get heat on just the cylinder head threads without also heating up the spark plug. Because of that, heat won't help with the removal of the plugs.

Had to get track nut's nearly cherry red to get the nut's to loosen from the bolt's. End of bolt also got cherry red.

Doubt the heat from letting truck get to operating temp is anywhere near the heat we applied to said track nut's.

In any event I'm much more willing to try the impact and operating temp.

either way,,worst that can happen is broken plug.

#56

have been reading this thread and figuring out best way to remove plugs in 2000 5.4L e-250 van that now has some 80K on it.

it appears when the plug were removed warm, no problem. When the plugs were cold even with PB Blaster used they broke. So to me it seem the correct way to remove the plug is with impact tool on warm engine as evidenced by post #32 of this thread..

"Ok, did plugs over Thanksgiving (the wife was thrilled). Did the hours of soaking with PB Blaster after cracking the plugs a quarter turn and all, but it was to no avail. All eight plugs broke, and the porcelain at the tip broke and fell into the cylinders. I did have the broken plug removal tool made by the Lisle company on hand, and boy did it get a workout. Thought I was going to have to take it in and have the heads pulled, (and time may tell that I should have). However, I Google searched and found a video of a guy who retrieved porcelain chunks as well as the whole electrode from a cylinder using a borescope with a piece of tape on it. Awesome, but I don't have a borescope."

So it seem to me if you do it the way the video show you will not have a problem.. let them get cold and they break.

it appears when the plug were removed warm, no problem. When the plugs were cold even with PB Blaster used they broke. So to me it seem the correct way to remove the plug is with impact tool on warm engine as evidenced by post #32 of this thread..

"Ok, did plugs over Thanksgiving (the wife was thrilled). Did the hours of soaking with PB Blaster after cracking the plugs a quarter turn and all, but it was to no avail. All eight plugs broke, and the porcelain at the tip broke and fell into the cylinders. I did have the broken plug removal tool made by the Lisle company on hand, and boy did it get a workout. Thought I was going to have to take it in and have the heads pulled, (and time may tell that I should have). However, I Google searched and found a video of a guy who retrieved porcelain chunks as well as the whole electrode from a cylinder using a borescope with a piece of tape on it. Awesome, but I don't have a borescope."

So it seem to me if you do it the way the video show you will not have a problem.. let them get cold and they break.

#57

In no way, shape or form are the SP-515 or SP-514 plugs "welded" or otherwise "one piece". the only modifications that were done over the original plugs was that the upper shell is made of a new steel that Autolite claims is 50% stronger, and they made the lower ground strap out of a nickel alloy which supposedly will not bind to carbon like the previous copper-based ground straps. The SP 515 and SP 514 plugs are very much indeed two-piece plugs. The only real one-piece plugs out there are the Champion 7989, E3.70 and Brisk Racing plugs. Autolite used to be part of Fram (honeywell), but was sold in 2011 to a Rank, a New Zealand-based investment group. the plugs have been changed three times on my 2007 Exploder, once by the dealer for $480.00 even though none broke, and then I replaced them twice myself after that. Given that Autolite HT1's can be had for $8.00 a plug, doing it every 40K and using nickel antisieze is cheap insurance against plugs breaking off in the head. The design is simply dumb as a bag of hammers.

#58

You are now talking 30 years ago. The new redesigned Champion plug above is platinum, actually double platinum.

If Motor-craft was any good this problem would not exist to begin with.

My advise to folks out there DO NOT USE a plug you know will brake next time you do a tune up.

Don't take my word for it. Do as search on the web as well as here on these forum about spark plugs. You will be horrified of the stories of broken plugs head removal thousands of dollar job just because Motorcraft did not design a good plug.

I did all my plugs within 1 hour . None broke, my truck is now doing about 17 MPG on the new double platinum Champions.

If Motor-craft was any good this problem would not exist to begin with.

My advise to folks out there DO NOT USE a plug you know will brake next time you do a tune up.

Don't take my word for it. Do as search on the web as well as here on these forum about spark plugs. You will be horrified of the stories of broken plugs head removal thousands of dollar job just because Motorcraft did not design a good plug.

I did all my plugs within 1 hour . None broke, my truck is now doing about 17 MPG on the new double platinum Champions.

#60

Dreadful spark plug

[QUOTE=mig25;11552379][SIZE=3][COLOR=navy] Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.

Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.

Hello, I am new to this forum and I know you posted this 2 years ago but I have a question. Was just wondering if an Electric/Cordless impact wrench would do the trick as well. The only reason i ask is I don't have an air compressor. Thank you so much for the post.

Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.

Hello, Ford folks, I have posted about this issue before, but I decided to share my recent experience on this issue with you guys.Hello, I am new to this forum and I know you posted this 2 years ago but I have a question. Was just wondering if an Electric/Cordless impact wrench would do the trick as well. The only reason i ask is I don't have an air compressor. Thank you so much for the post.

Last edited by Low n Brass; 06-13-2014 at 02:55 AM. Reason: spell check