generator repair

#1

generator repair

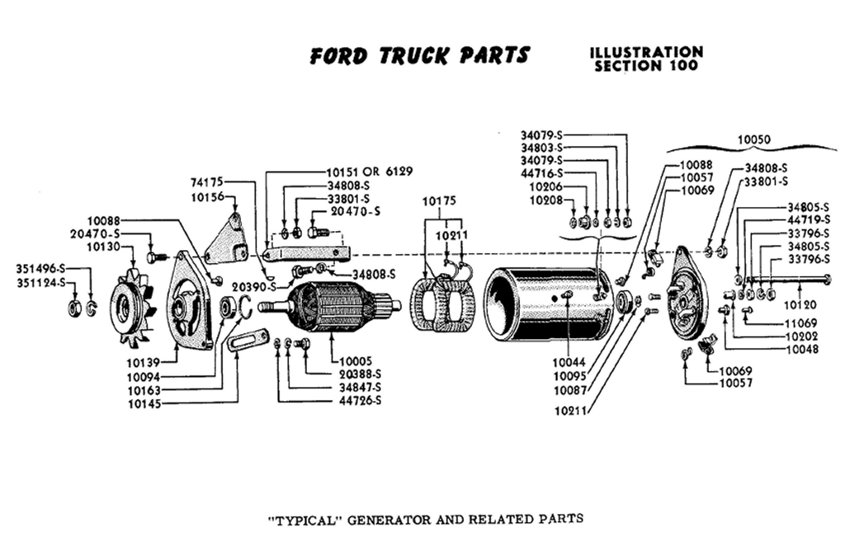

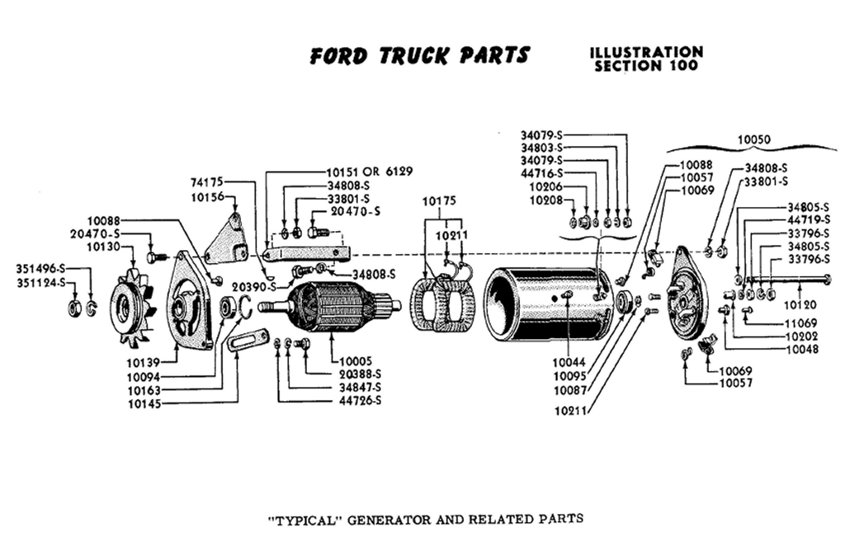

I have opened up the generator of my 52 F-3 (239 v8) and need some info regarding the brushes. The generator was packed with mud nests etc. While cleaning it out I noticed that there are two small circular springs that attach to the brush mounting ears that don't seem to do anything. The brushes don't have any tension on them and it appears that something is missing. Does anyone have a picture if the inside of one or even a microfiche exploded view?

Thanks,

w

Thanks,

w

#2

Are you referring to part #10057? Those are springs that supply pressure on the back side of the brushes so they ring on the armature commutator. You install the brushes and springs after you have the generator bolted together. You have to leave them loose until you have the generator together then you insert the brushes and use a hook to hook the springs, pull them back and swing them into the brush socket. It's been a while since I worked on a generator, I might be wrong about leaving the brushes out, it might work to insert the brushes into the socket but I know you have to leave the spring out or else they'll push the brushes in the path of the armature. The same procedure is used on starter brushes.

#3

.... It's been a while since I worked on a generator, I might be wrong about leaving the brushes out, it might work to insert the brushes into the socket but I know you have to leave the spring out or else they'll push the brushes in the path of the armature. The same procedure is used on starter brushes.

#4

Ross, you're probably correct, you can install the brushes before installing the armature but you have to wait until last to pull out the springs and swing them over. At least that's the my dad taught me to do, he was a pretty smart guy when it came to working on cars. It's been a while since I've had my generator or starter apart.

#5

#7

Thread

Thread Starter

Forum

Replies

Last Post

62 ford owner

1961 - 1966 F-100 & Larger F-Series Trucks

5

04-26-2015 07:52 PM

pops_91710

FE & FT Big Block V8 (332, 352, 360, 390, 406, 410, 427, 428)

2

03-25-2015 11:25 AM