Studs vs. Bolts - General Strength

#17

I would say you could theoretically weaken the material by over torquing and then have a pulling failure later due to that. But you could do the same thing to a stud by weakening the threads if you over torque them.

Either way it would be a failure do to improper installation not strength of one verses the other.

#18

Wow, that is excellent info guys!!

It's awesome to have such a broad range of knowledge that everyone brings to the forum from different backgrounds they've experienced in their past. I truly appreciate you guy sharing your knowledge!

S.P. - I think I know what you're trying to say. You're comparing Grade 8 bolt and a Grade 8 Stud strength difference right?

From the information I've read, a Grade 8 stud will be stronger than a Grade 8 bolt because a stud has the nut on the other end. The nut provides 3 more of the crucial threads that provide clamping force.

The Grade 8 bolt has the "weak link" area at the base of the head.

The bolt has 3 threads doing the work, while a stud has 6 threads doing the work.

How much weaker? I don't know. How much of a strength difference is there between a Grade 8 bolt and a Grade 8 stud?

Warozz - If a bolt is machined from equivalent-sized bar stock, is all-thread/theaded-rod machined the same way? That would make them the same strength if that's the case. The advantage of a stud over a bolt would then only be the slightly greater clamping force created by using a nut on the stud, in place of the bolt head.

As a side note, to add important information to a great thread - How would someone install studs in general? Not specifically a Cylinder Head application, but in general.

You could thread the stud in by hand, then thread one nut onto the stud, then thread another nut onto the stud, double-nut them and tighten them agaist each other, then tighten the stud down by tightening on the top nut. Sound about right?

It's awesome to have such a broad range of knowledge that everyone brings to the forum from different backgrounds they've experienced in their past. I truly appreciate you guy sharing your knowledge!

S.P. - I think I know what you're trying to say. You're comparing Grade 8 bolt and a Grade 8 Stud strength difference right?

From the information I've read, a Grade 8 stud will be stronger than a Grade 8 bolt because a stud has the nut on the other end. The nut provides 3 more of the crucial threads that provide clamping force.

The Grade 8 bolt has the "weak link" area at the base of the head.

The bolt has 3 threads doing the work, while a stud has 6 threads doing the work.

How much weaker? I don't know. How much of a strength difference is there between a Grade 8 bolt and a Grade 8 stud?

Warozz - If a bolt is machined from equivalent-sized bar stock, is all-thread/theaded-rod machined the same way? That would make them the same strength if that's the case. The advantage of a stud over a bolt would then only be the slightly greater clamping force created by using a nut on the stud, in place of the bolt head.

As a side note, to add important information to a great thread - How would someone install studs in general? Not specifically a Cylinder Head application, but in general.

You could thread the stud in by hand, then thread one nut onto the stud, then thread another nut onto the stud, double-nut them and tighten them agaist each other, then tighten the stud down by tightening on the top nut. Sound about right?

#22

Warozz - If a bolt is machined from equivalent-sized bar stock, is all-thread/theaded-rod machined the same way? That would make them the same strength if that's the case. The advantage of a stud over a bolt would then only be the slightly greater clamping force created by using a nut on the stud, in place of the bolt head.

Yes the advantage is the greater clamping force caused by the threads. But remember since you are not machining up to a corner (the bolt head) you are not making a weak spot so that gives a slight advantage as well.

#23

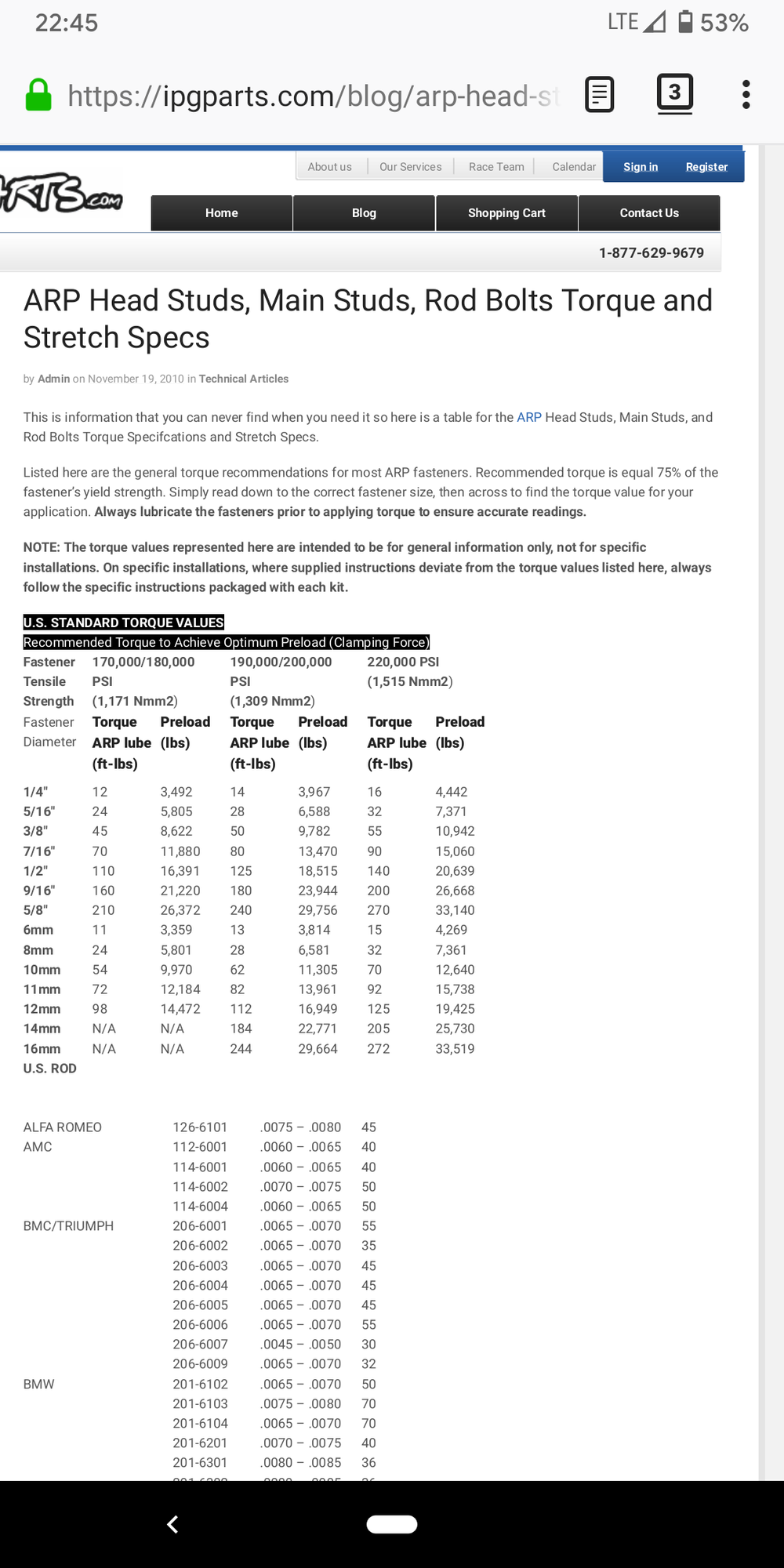

ARP head studs have course thread on the block end, and can be screwed to the bottom of the hole in the block.

There is an Allen wrench socket in the top end used to screw them in.

The middle of the stud is plain round stock, no threads.

The top has fine threads where the parallel ground washers are installed between the head and nut.

And since the top has fine threads, the same torque value used on the nuts results in much higher clamping force.

Back when I bought my studs, the actually had three grades of studs.

180,000 PSI yield strength

200,000 PSI yield strength

220,000 PSI yield strength

Price increased from lower strength to higher strength.

Looking at a grade to yield strength chart, grade 8 yield strength is 130,000 PSI.

From memory, which is not so good anymore, stock head bolts on the 6.9 was only around 160,000.

So stock head bolts would be slightly better than grade 8 studs, but much lower than ARP head studs.

40,000 PSI stronger times 17 studs per head, 680,000 PSI stronger.

There is an Allen wrench socket in the top end used to screw them in.

The middle of the stud is plain round stock, no threads.

The top has fine threads where the parallel ground washers are installed between the head and nut.

And since the top has fine threads, the same torque value used on the nuts results in much higher clamping force.

Back when I bought my studs, the actually had three grades of studs.

180,000 PSI yield strength

200,000 PSI yield strength

220,000 PSI yield strength

Price increased from lower strength to higher strength.

Looking at a grade to yield strength chart, grade 8 yield strength is 130,000 PSI.

From memory, which is not so good anymore, stock head bolts on the 6.9 was only around 160,000.

So stock head bolts would be slightly better than grade 8 studs, but much lower than ARP head studs.

40,000 PSI stronger times 17 studs per head, 680,000 PSI stronger.

#24

#25

Wow, that is excellent info guys!!

It's awesome to have such a broad range of knowledge that everyone brings to the forum from different backgrounds they've experienced in their past. I truly appreciate you guy sharing your knowledge!

S.P. - I think I know what you're trying to say. You're comparing Grade 8 bolt and a Grade 8 Stud strength difference right?

From the information I've read, a Grade 8 stud will be stronger than a Grade 8 bolt because a stud has the nut on the other end. The nut provides 3 more of the crucial threads that provide clamping force.

The Grade 8 bolt has the "weak link" area at the base of the head.

The bolt has 3 threads doing the work, while a stud has 6 threads doing the work.

How much weaker? I don't know. How much of a strength difference is there between a Grade 8 bolt and a Grade 8 stud?

Warozz - If a bolt is machined from equivalent-sized bar stock, is all-thread/theaded-rod machined the same way? That would make them the same strength if that's the case. The advantage of a stud over a bolt would then only be the slightly greater clamping force created by using a nut on the stud, in place of the bolt head.

As a side note, to add important information to a great thread - How would someone install studs in general? Not specifically a Cylinder Head application, but in general.

You could thread the stud in by hand, then thread one nut onto the stud, then thread another nut onto the stud, double-nut them and tighten them agaist each other, then tighten the stud down by tightening on the top nut. Sound about right?

It's awesome to have such a broad range of knowledge that everyone brings to the forum from different backgrounds they've experienced in their past. I truly appreciate you guy sharing your knowledge!

S.P. - I think I know what you're trying to say. You're comparing Grade 8 bolt and a Grade 8 Stud strength difference right?

From the information I've read, a Grade 8 stud will be stronger than a Grade 8 bolt because a stud has the nut on the other end. The nut provides 3 more of the crucial threads that provide clamping force.

The Grade 8 bolt has the "weak link" area at the base of the head.

The bolt has 3 threads doing the work, while a stud has 6 threads doing the work.

How much weaker? I don't know. How much of a strength difference is there between a Grade 8 bolt and a Grade 8 stud?

Warozz - If a bolt is machined from equivalent-sized bar stock, is all-thread/theaded-rod machined the same way? That would make them the same strength if that's the case. The advantage of a stud over a bolt would then only be the slightly greater clamping force created by using a nut on the stud, in place of the bolt head.

As a side note, to add important information to a great thread - How would someone install studs in general? Not specifically a Cylinder Head application, but in general.

You could thread the stud in by hand, then thread one nut onto the stud, then thread another nut onto the stud, double-nut them and tighten them agaist each other, then tighten the stud down by tightening on the top nut. Sound about right?

#26

Hilarious! The guy posts time after time giving the rest of us "clinics" on head studs, then at the very end the expert says he doesn't even have a clue how to install one. I worked all my adult life full time in diesel shops and working on everything from a Buda diesel (Google it), to Cummins, Detroits of all sizes on down and never came across an engine with factory head studs. As competitive as the diesel engine market is, seems like if they were needed for longevity the mfgrs would be using them.

#27

The reason it doesn't seem necessary to you is in the medium and heavy duty world they OVERBUILT stuff, because they knew it was going to see maximum load day in and day out. There's sled pullers out the running 100psi of boost on dt360's with factory bolts just overtorqued. Try that on an idi and you'll be sorry...

I imagine the head would blow off and you'd be buying a new head, hood and windshield!

To add to the topic here's a handy little chart I screenshot the other night on arp studs and the clamp load they make at thier rated torque

#28

But I think you'll find most all the IDI owners use their trucks for trips to Walmart and back, unlike what few old time owners are left who bought their IDI's new. We all bought them for heavy towing. Can't see where studs are needed in either case. And then of course there's the bunch that own one just to run around town to make smoke and noise, stacks are required of course.

#29

Your right, I ran up to 15psi daily on stock 6.9 headbolts, probably could have ran a little more if I over torqued them

But for anybody chasing power, you need studs, head gasket jobs aren't fun...

If youve been reading my cracked piston thread, you'll see I blew a head gasket even with studs, and I'm just running a stock pump turned up all the way. There are guys here running bigger pumps than me, and they're all pretty much studded or plan to be.

I know studs are costly, but the money you'll save in premature gasket replacement will pay for itself...

My truck isn't exactly your grandpa's idi

But for anybody chasing power, you need studs, head gasket jobs aren't fun...

If youve been reading my cracked piston thread, you'll see I blew a head gasket even with studs, and I'm just running a stock pump turned up all the way. There are guys here running bigger pumps than me, and they're all pretty much studded or plan to be.

I know studs are costly, but the money you'll save in premature gasket replacement will pay for itself...

My truck isn't exactly your grandpa's idi

The following users liked this post:

Thread

Thread Starter

Forum

Replies

Last Post

tanagerhills

1997-2006 Expedition & Navigator

2

05-11-2017 09:41 AM

dulockdrumheller

1973 - 1979 F-100 & Larger F-Series Trucks

6

04-13-2011 02:42 AM

46yblock

Y-Block V8 (239, 272, 292, 312, 317, 341, 368)

8

07-19-2007 11:28 AM