Setting Pinion Angle

#1

Setting Pinion Angle

I've always read that you should set your axle pinion angle at the same degree as the transmission - actually to clarify, the pinion should be aiming up the same degree as the trans is pointing down.

A shop that set up my '56 didn't do this and after 15K I had some abnormal wear showing on my u-joints. So I set out to get this right.

Here is my current scenario after my FIX: 5.0 / AOD at a 4 1/2 degree downward angle and a Lincoln Versaille on the stock '56 leaf springs on 4 1/2 upward angle. The truck is low - axle on top of leafs with one leaf removed so the driveshaft is at an incline going up from the trans to the rear end.

After doing this reset I ate the u-joints in 20 miles and the axle torqued enough to hit a crossmember above it. So I'm looking for guidance on what to reset the pinion angle while allowing for spring wrap.

A shop that set up my '56 didn't do this and after 15K I had some abnormal wear showing on my u-joints. So I set out to get this right.

Here is my current scenario after my FIX: 5.0 / AOD at a 4 1/2 degree downward angle and a Lincoln Versaille on the stock '56 leaf springs on 4 1/2 upward angle. The truck is low - axle on top of leafs with one leaf removed so the driveshaft is at an incline going up from the trans to the rear end.

After doing this reset I ate the u-joints in 20 miles and the axle torqued enough to hit a crossmember above it. So I'm looking for guidance on what to reset the pinion angle while allowing for spring wrap.

Last edited by 2losteve; 05-14-2009 at 02:05 PM. Reason: bold

#2

theres a certain point you hit in low-ness and horse power where leaf springs just wont cut it anymore, you may have hit that point and need a 4 link. but other than that you can buy 2 degree pinion shims if that might help. your running stock leaf springs with one missing so, look into aftermarket ones if you dont want to go the 4 link route, they will be stronger and will be able to hold up to the torque your motor is putting out.

shouldnt the pinion angle of the axle be pointing the other way? or am i reading that wrong.

oh, that noise that the drive shaft makes when it hits a cross member is scary as s*** lol. i'll never forget it....

check this out too http://restomod.us/PinionAnglePage.htm

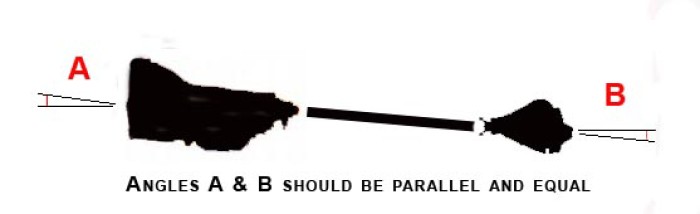

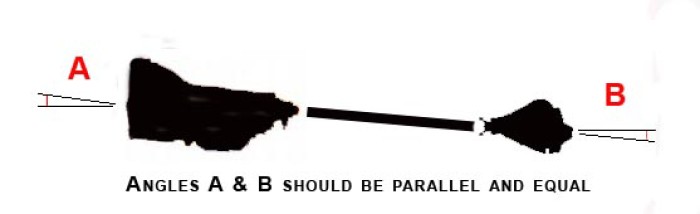

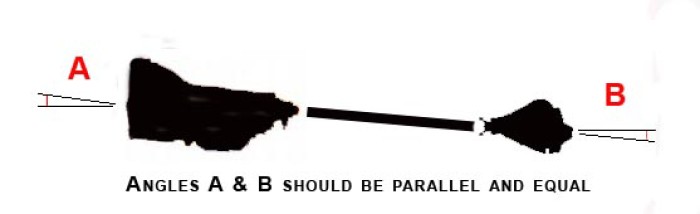

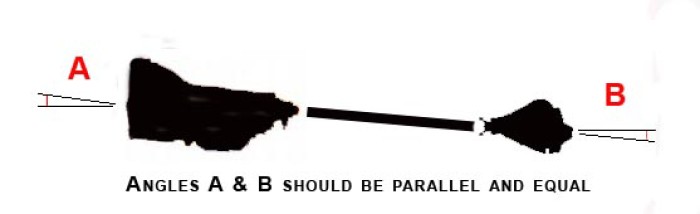

simple pinion diagram

heres a pic of the axle shim, probably easier to just make.

shouldnt the pinion angle of the axle be pointing the other way? or am i reading that wrong.

oh, that noise that the drive shaft makes when it hits a cross member is scary as s*** lol. i'll never forget it....

check this out too http://restomod.us/PinionAnglePage.htm

simple pinion diagram

heres a pic of the axle shim, probably easier to just make.

#4

Pinion angle

I've always read that you should set your axle pinion angle at the same degree as the transmission - actually to clarify, the pinion should be aiming up the same degree as the trans is pointing down.

A shop that set up my '56 didn't do this and after 15K I had some abnormal wear showing on my u-joints. So I set out to get this right.

Here is my current scenario after my FIX: 5.0 / AOD at a 4 1/2 degree downward angle and a Lincoln Versaille on the stock '56 leaf springs on 4 1/2 upward angle. The truck is low - axle on top of leafs with one leaf removed so the driveshaft is at an incline going up from the trans to the rear end.

After doing this reset I ate the u-joints in 20 miles and the axle torqued enough to hit a crossmember above it. So I'm looking for guidance on what to reset the pinion angle while allowing for spring wrap.

A shop that set up my '56 didn't do this and after 15K I had some abnormal wear showing on my u-joints. So I set out to get this right.

Here is my current scenario after my FIX: 5.0 / AOD at a 4 1/2 degree downward angle and a Lincoln Versaille on the stock '56 leaf springs on 4 1/2 upward angle. The truck is low - axle on top of leafs with one leaf removed so the driveshaft is at an incline going up from the trans to the rear end.

After doing this reset I ate the u-joints in 20 miles and the axle torqued enough to hit a crossmember above it. So I'm looking for guidance on what to reset the pinion angle while allowing for spring wrap.

mostly52f1 has it right.

Alan

#6

#7

I'm trying to figure this out also. Alanco: seems like the downward pinion angle would apply to drag vehicles appling a tremendous amount of power causing the axle to rotate upwards. 2losteve: If i understand your picture you should draw a line completely across the page thru the centerline of the tranny. Then a second line all across the page thru the centerline of the pinion. The distance between the two lines on the left side of the page should be the same a the distance between the two lines on the right side of the page. That would parallel the tranny and pinion. A and B doesn't do this. Some one jump on this in clearer terms. chuck

Last edited by 49fordpickumup; 05-14-2009 at 10:47 PM. Reason: correction

Trending Topics

#8

it sounds like your pinion angle is as good as its gonna get, but someone else might have to give a better explanation. so if the problem is the u-joints someone else might have to chim in (ahummm julie anybody?!!... i'm outta ideas at the moment

if its the torque on the rear end, you'll have to either make/modify a new cross member or buy a drive shaft safety loop, or look into changing your suspension... 4 link, ladder bars, or aftermarket leafs. your old leafs have to much give in them causing the awwwwful noise.

if its the torque on the rear end, you'll have to either make/modify a new cross member or buy a drive shaft safety loop, or look into changing your suspension... 4 link, ladder bars, or aftermarket leafs. your old leafs have to much give in them causing the awwwwful noise.

#9

4.5 is too much. It should be between 1 and 2 degrees. THe u-joint needs some movement to keep the needles moving.

Just put a lift in my '76 bronco. Pinion angle was 12 degrees. you could feel the ujoint binding while turning. The installed 6 degree shims, got to 4 degrees off, still lightly binding. got 8 degree shims, now the pinion angle is at 1.5 degrees, runs beautifully.

Just put a lift in my '76 bronco. Pinion angle was 12 degrees. you could feel the ujoint binding while turning. The installed 6 degree shims, got to 4 degrees off, still lightly binding. got 8 degree shims, now the pinion angle is at 1.5 degrees, runs beautifully.

#10

Okay, looking at the simple diagram my 'A'(engine) is 4 1/2 downward angle and my 'B' is the on the same angle(to me, upward). The only difference is that my axle sets a bit higher than the rear of the trans. so the driveshaft angle is going up from the tip of the trans to the rear axle.

A line drawn thru the centerline of the tranny output shaft and one drawn thru the pinion gear shaft should be parallel to each other with the vehicle at rest supported by the suspension.

The person that originally set it up didn't angle the engine relative to the frame by any chance? Even if the pinion is offset to one side, or the engine is off set to one side, the engine-tranny centerline should still be parallel to the frame centerline.

If you use the tapered shims be sure the spring centerbolt head is long enough with the shim(s) in place that it still solidly engages the hole in the axle mount.

If you are getting that much spring wrap up/wheel hop, you need some sort of traction bars to prevent it, ladder bars, trailing arms, slapper bars, or pinion snubber.

Are you sure the sound you heard was the driveshaft hitting to crossmember or are the U joints binding from running at too severe an angle when the chassis squats?

#11

Join Date: May 2004

Location: MN - NW of Twin Cities

Posts: 553

Likes: 0

Received 2 Likes

on

2 Posts

I think everyone is correct in that the centerline of the transmission and the centerline of the pinion should be basically parallel or the pinion should be tilted slightly downward to allow for some amount of rotation of the axle under hard acceleration. What is being forgotten is that the driveshaft should be about 3 degrees offset from the parallel lines of the trans and pinion centerline this is what allows the u-joints to work.

It sounds like the trans is tilted too far down. You don't want the transmission to be pointing directly at the rearend. Yea the centerlines will be parallel but you aren't getting the driveshaft offset angle. Well that's my take on it!

It sounds like the trans is tilted too far down. You don't want the transmission to be pointing directly at the rearend. Yea the centerlines will be parallel but you aren't getting the driveshaft offset angle. Well that's my take on it!

#12

average pinion angle is between 2 and 7 degrees, depending on your suspension, 4 link is 2, leafs are between 4 and 6. rear coil springs are different too, but i dont remember the degree.

Lets say that your driveshaft had 3 deg to the left of the zero and your pinion yoke had 3 deg to the right of the zero. You would add the numbers together and your pinion angle would be 6 degrees.

Lets say that your driveshaft had 3 deg to the left of the zero and your pinion yoke had 3 deg to the right of the zero. You would add the numbers together and your pinion angle would be 6 degrees.

#13

Chuck, what I'm trying to say is that my trans angle & pinion angle do run on a paralel. I am tending towards 52f1 in that my leafs must be too weak to keep from torqueing (is that a word?). I also have that teflon type strips between the leaves to help the spring work (from Mid-Fifties). I think I'll try shimming the rearend down a couple degrees to compensate for the wrap.

I didn't actually hear any noise from the rear end, I found the smoked u-joints and saw a fresh wear mark (paint gone) above the joint.

I didn't actually hear any noise from the rear end, I found the smoked u-joints and saw a fresh wear mark (paint gone) above the joint.

#15