Lug nut torque

#91

#92

As you wish.... See highlighted.

MARCH 18, 1998

FORD:

1972-97 THUNDERBIRD

1976-86 LTD

1976-97 MUSTANG

1981-97 CROWN VICTORIA

1982-88 EXP

1982-98 ESCORT

1984-94 TEMPO

1986-97 TAURUS

1988-93 FESTIVA

1989-97 PROBE

1994-97 ASPIRE

1995-98 CONTOUR

LINCOLN-MERCURY:

1979-83 MONARCH, ZEPHYR

1979-97 COUGAR

1980-83 MARK VI

1980-98 CONTINENTAL, TOWN CAR

1981-86 LYNX

1983-86 MARQUIS

1984-92 MARK VII

1984-94 TOPAZ

1986-97 SABLE

1987-89 TRACER

1987-97 GRAND MARQUIS

1991-94 CAPRI

1991-97 TRACER

1993-98 MARK VIII

1995-98 MYSTIQUE

LIGHT TRUCK:

1979-96 BRONCO

1979-97 ECONOLINE, F-150-350 SERIES

1984-90 BRONCO II

1984-97 RANGER

1986-97 AEROSTAR

1988-97 F SUPER DUTY

1991-97 EXPLORER

1993-97 VILLAGER

1995-98 WINDSTAR

1997 EXPEDITION

1998 NAVIGATOR

ISSUE:

The use of air impact tools to tighten wheel lug nuts can lead to overtightened and/or unevenly tightened wheel lug nuts. Air impact tools typically used for wheel lug nut removal and installation can generate up to 475 N-m (350 lb-ft) of torque. Overtightened and/or unevenly torqued wheel lug nuts may cause:

- Brake vibration

- Distortion of the wheel hub

- Distortion of the brake rotor

- Brake rotor runout

- Damage to the wheel

- Damage to the wheel nuts and studs

ACTION:

All wheel lug nuts should only be tightened to specification using a torque wrench or by using the Rotunda ACCUTORQ 164-R0314 or equivalent on a 1/2" drive air impact tool. The "ACCUTORQ" lug nut sockets limit the torque of the air impact tool, preventing overtightening or uneven tightening of the wheel lug nuts. The torque limiting devices (regulators) on air impact tools will not reduce the output torque enough to prevent overtightening of the wheel lug nuts.

NOTE:

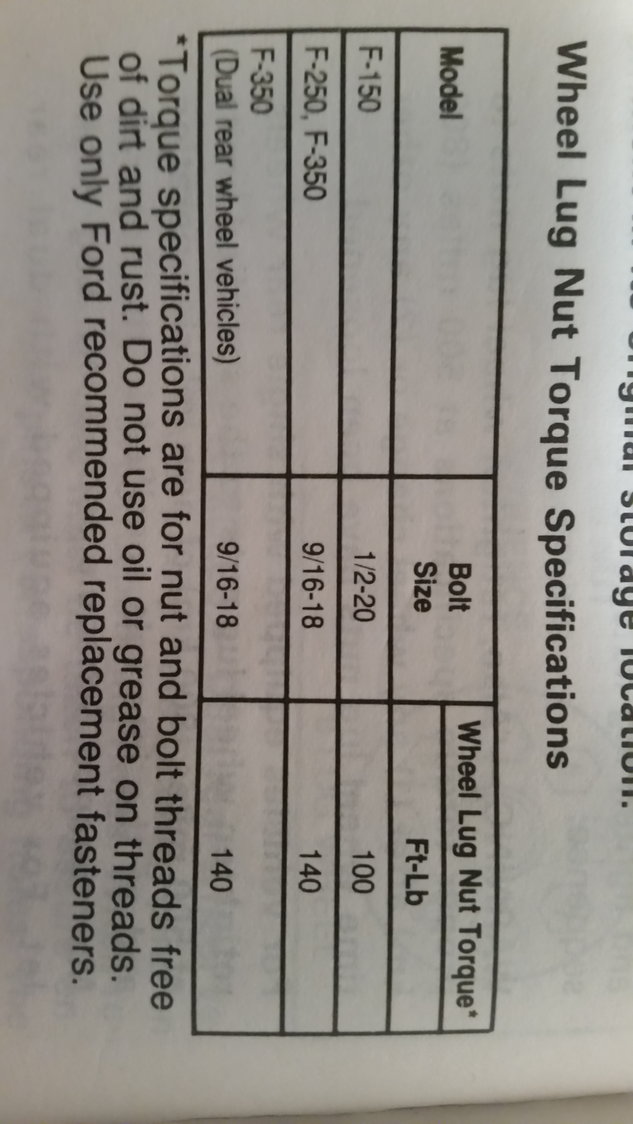

REFER TO THE APPROPRIATE SERVICE MANUAL OR THE CHART IN «FIGURE 1» FOR THE CORRECT WHEEL LUG NUT TORQUE SPECIFICATION. THE CHART IN «FIGURE 1» ALSO PROVIDES THE CORRECT "ACCUTORQ" LUG NUT SOCKET TO USE.

Figure 1 - Article 98-5A-4

The "ACCUTORQ" socket is intended for lug nut installation, not removal. When using the "ACCUTORQ" socket, the output torque of the air impact tool must be set to 217-339 N-m (160-250 lb-ft), usually this will be the lowest setting on the air impact tool.

The "ACCUTORQ" lug nut sockets are available through Rotunda Equipment. The four-piece set (164-R0314) fits most Ford Motor Company cars and light trucks. The tool set consists of four (4) lug nut sockets and a storage case. The set can be ordered by calling Rotunda Equipment at 1-800-ROT-UNDA (768-8632).

CAUTION:

AIR IMPACT TOOLS SHOULD NOT BE USED TO TIGHTEN WHEEL LUG NUTS UNLESS THE "ACCUTORQ" LUG NUT SOCKET OF THE CORRECT SPECIFICATION IS USED.

NOTE:

DO NOT USE AIR IMPACT TOOLS ON LOCKING WHEEL LUG NUTS. THEY ARE TO BE HAND-TORQUED ONLY WITH CLEAN RUST FREE LUBRICATED THREADS..

OTHER APPLICABLE ARTICLES: NONE

SUPERSEDES: 97-17-6

WARRANTY STATUS: INFORMATION ONLY

OASIS CODES: 301000, 303000, 306000"

MARCH 18, 1998

FORD:

1972-97 THUNDERBIRD

1976-86 LTD

1976-97 MUSTANG

1981-97 CROWN VICTORIA

1982-88 EXP

1982-98 ESCORT

1984-94 TEMPO

1986-97 TAURUS

1988-93 FESTIVA

1989-97 PROBE

1994-97 ASPIRE

1995-98 CONTOUR

LINCOLN-MERCURY:

1979-83 MONARCH, ZEPHYR

1979-97 COUGAR

1980-83 MARK VI

1980-98 CONTINENTAL, TOWN CAR

1981-86 LYNX

1983-86 MARQUIS

1984-92 MARK VII

1984-94 TOPAZ

1986-97 SABLE

1987-89 TRACER

1987-97 GRAND MARQUIS

1991-94 CAPRI

1991-97 TRACER

1993-98 MARK VIII

1995-98 MYSTIQUE

LIGHT TRUCK:

1979-96 BRONCO

1979-97 ECONOLINE, F-150-350 SERIES

1984-90 BRONCO II

1984-97 RANGER

1986-97 AEROSTAR

1988-97 F SUPER DUTY

1991-97 EXPLORER

1993-97 VILLAGER

1995-98 WINDSTAR

1997 EXPEDITION

1998 NAVIGATOR

ISSUE:

The use of air impact tools to tighten wheel lug nuts can lead to overtightened and/or unevenly tightened wheel lug nuts. Air impact tools typically used for wheel lug nut removal and installation can generate up to 475 N-m (350 lb-ft) of torque. Overtightened and/or unevenly torqued wheel lug nuts may cause:

- Brake vibration

- Distortion of the wheel hub

- Distortion of the brake rotor

- Brake rotor runout

- Damage to the wheel

- Damage to the wheel nuts and studs

ACTION:

All wheel lug nuts should only be tightened to specification using a torque wrench or by using the Rotunda ACCUTORQ 164-R0314 or equivalent on a 1/2" drive air impact tool. The "ACCUTORQ" lug nut sockets limit the torque of the air impact tool, preventing overtightening or uneven tightening of the wheel lug nuts. The torque limiting devices (regulators) on air impact tools will not reduce the output torque enough to prevent overtightening of the wheel lug nuts.

NOTE:

REFER TO THE APPROPRIATE SERVICE MANUAL OR THE CHART IN «FIGURE 1» FOR THE CORRECT WHEEL LUG NUT TORQUE SPECIFICATION. THE CHART IN «FIGURE 1» ALSO PROVIDES THE CORRECT "ACCUTORQ" LUG NUT SOCKET TO USE.

Figure 1 - Article 98-5A-4

The "ACCUTORQ" socket is intended for lug nut installation, not removal. When using the "ACCUTORQ" socket, the output torque of the air impact tool must be set to 217-339 N-m (160-250 lb-ft), usually this will be the lowest setting on the air impact tool.

The "ACCUTORQ" lug nut sockets are available through Rotunda Equipment. The four-piece set (164-R0314) fits most Ford Motor Company cars and light trucks. The tool set consists of four (4) lug nut sockets and a storage case. The set can be ordered by calling Rotunda Equipment at 1-800-ROT-UNDA (768-8632).

CAUTION:

AIR IMPACT TOOLS SHOULD NOT BE USED TO TIGHTEN WHEEL LUG NUTS UNLESS THE "ACCUTORQ" LUG NUT SOCKET OF THE CORRECT SPECIFICATION IS USED.

NOTE:

DO NOT USE AIR IMPACT TOOLS ON LOCKING WHEEL LUG NUTS. THEY ARE TO BE HAND-TORQUED ONLY WITH CLEAN RUST FREE LUBRICATED THREADS..

OTHER APPLICABLE ARTICLES: NONE

SUPERSEDES: 97-17-6

WARRANTY STATUS: INFORMATION ONLY

OASIS CODES: 301000, 303000, 306000"

#93

Excerpt from the bulletin you posted. Note highlighted portions:

ACTION:

All wheel lug nuts should only be tightened to specification using a torque wrench or by using the Rotunda ACCUTORQ 164-R0314 or equivalent on a 1/2" drive air impact tool. The "ACCUTORQ" lug nut sockets limit the torque of the air impact tool, preventing overtightening or uneven tightening of the wheel lug nuts. The torque limiting devices (regulators) on air impact tools will not reduce the output torque enough to prevent overtightening of the wheel lug nuts.

NOTE:

REFER TO THE APPROPRIATE SERVICE MANUAL OR THE CHART IN «FIGURE 1» FOR THE CORRECT WHEEL LUG NUT TORQUE SPECIFICATION. THE CHART IN «FIGURE 1» ALSO PROVIDES THE CORRECT "ACCUTORQ" LUG NUT SOCKET TO USE.

Figure 1 - Article 98-5A-4

The "ACCUTORQ" socket is intended for lug nut installation, not removal. When using the "ACCUTORQ" socket, the output torque of the air impact tool must be set to 217-339 N-m (160-250 lb-ft), usually this will be the lowest setting on the air impact tool.

The "ACCUTORQ" lug nut sockets are available through Rotunda Equipment. The four-piece set (164-R0314) fits most Ford Motor Company cars and light trucks. The tool set consists of four (4) lug nut sockets and a storage case. The set can be ordered by calling Rotunda Equipment at 1-800-ROT-UNDA (768-8632).

CAUTION:

AIR IMPACT TOOLS SHOULD NOT BE USED TO TIGHTEN WHEEL LUG NUTS UNLESS THE "ACCUTORQ" LUG NUT SOCKET OF THE CORRECT SPECIFICATION IS USED.

NOTE:

DO NOT USE AIR IMPACT TOOLS ON LOCKING WHEEL LUG NUTS. THEY ARE TO BE HAND-TORQUED ONLY WITH CLEAN RUST FREE LUBRICATED THREADS..

OTHER APPLICABLE ARTICLES: NONE

ACTION:

All wheel lug nuts should only be tightened to specification using a torque wrench or by using the Rotunda ACCUTORQ 164-R0314 or equivalent on a 1/2" drive air impact tool. The "ACCUTORQ" lug nut sockets limit the torque of the air impact tool, preventing overtightening or uneven tightening of the wheel lug nuts. The torque limiting devices (regulators) on air impact tools will not reduce the output torque enough to prevent overtightening of the wheel lug nuts.

NOTE:

REFER TO THE APPROPRIATE SERVICE MANUAL OR THE CHART IN «FIGURE 1» FOR THE CORRECT WHEEL LUG NUT TORQUE SPECIFICATION. THE CHART IN «FIGURE 1» ALSO PROVIDES THE CORRECT "ACCUTORQ" LUG NUT SOCKET TO USE.

Figure 1 - Article 98-5A-4

The "ACCUTORQ" socket is intended for lug nut installation, not removal. When using the "ACCUTORQ" socket, the output torque of the air impact tool must be set to 217-339 N-m (160-250 lb-ft), usually this will be the lowest setting on the air impact tool.

The "ACCUTORQ" lug nut sockets are available through Rotunda Equipment. The four-piece set (164-R0314) fits most Ford Motor Company cars and light trucks. The tool set consists of four (4) lug nut sockets and a storage case. The set can be ordered by calling Rotunda Equipment at 1-800-ROT-UNDA (768-8632).

CAUTION:

AIR IMPACT TOOLS SHOULD NOT BE USED TO TIGHTEN WHEEL LUG NUTS UNLESS THE "ACCUTORQ" LUG NUT SOCKET OF THE CORRECT SPECIFICATION IS USED.

NOTE:

DO NOT USE AIR IMPACT TOOLS ON LOCKING WHEEL LUG NUTS. THEY ARE TO BE HAND-TORQUED ONLY WITH CLEAN RUST FREE LUBRICATED THREADS..

OTHER APPLICABLE ARTICLES: NONE

#94

ALL torque values for lug nuts are with lubricated threads this was updated years ago, as non-lubricated threads will give wildly inconsistent clamping forces. This how wheel nuts/bolts end up backing off. You really think Ford would only spec lubricating locking nuts.... All Ford shop manuals state ALL torque values are with lubricated threads. Of course these are written techs who understand that lubricated threads does not mean gob it on like a drunken sailor...

I have not spent 40 plus years as an engineer who just happen to have worked at Ford engineering the stuff YOU are working on, so I just might know a thing or two that is NOT covered in the manuals.

But hey if you think you know better.,....

Sort of like the torque wrench thing you have no idea why it says do not go past the lowest setting just that it does with out understanding why.. Where as I do know the why. It is a compromise to minimize spring compression set and the chances of the stupid from backing the handle right off/out and potentially having the guts fall to bits on the floor. The best practice is to fully unload the spring regardless what the instructions say. You seemed to think that if you did this it would negate the wrench from ever being calibrated. torque wrenches should be re-calibrated every 5000 cycles. If it is found to be out spec at any time this should be shortened to 2500 cycles these are the ISO standards.

I have not spent 40 plus years as an engineer who just happen to have worked at Ford engineering the stuff YOU are working on, so I just might know a thing or two that is NOT covered in the manuals.

But hey if you think you know better.,....

Sort of like the torque wrench thing you have no idea why it says do not go past the lowest setting just that it does with out understanding why.. Where as I do know the why. It is a compromise to minimize spring compression set and the chances of the stupid from backing the handle right off/out and potentially having the guts fall to bits on the floor. The best practice is to fully unload the spring regardless what the instructions say. You seemed to think that if you did this it would negate the wrench from ever being calibrated. torque wrenches should be re-calibrated every 5000 cycles. If it is found to be out spec at any time this should be shortened to 2500 cycles these are the ISO standards.

#95

ALL torque values for lug nuts are with lubricated threads this was updated years ago, as non-lubricated threads will give wildly inconsistent clamping forces. This how wheel nuts/bolts end up backing off. You really think Ford would only spec lubricating locking nuts.... All Ford shop manuals state ALL torque values are with lubricated threads. Of course these are written techs who understand that lubricated threads does not mean gob it on like a drunken sailor...

I have not spent 40 plus years as an engineer who just happen to have worked at Ford engineering the stuff YOU are working on, so I just might know a thing or two that is NOT covered in the manuals.

But hey if you think you know better.,....

Sort of like the torque wrench thing you have no idea why it says do not go past the lowest setting just that it does with out understanding why.. Where as I do know the why. It is a compromise to minimize spring compression set and the chances of the stupid from backing the handle right off/out and potentially having the guts fall to bits on the floor. The best practice is to fully unload the spring regardless what the instructions say. You seemed to think that if you did this it would negate the wrench from ever being calibrated. torque wrenches should be re-calibrated every 5000 cycles. If it is found to be out spec at any time this should be shortened to 2500 cycles these are the ISO standards.

I have not spent 40 plus years as an engineer who just happen to have worked at Ford engineering the stuff YOU are working on, so I just might know a thing or two that is NOT covered in the manuals.

But hey if you think you know better.,....

Sort of like the torque wrench thing you have no idea why it says do not go past the lowest setting just that it does with out understanding why.. Where as I do know the why. It is a compromise to minimize spring compression set and the chances of the stupid from backing the handle right off/out and potentially having the guts fall to bits on the floor. The best practice is to fully unload the spring regardless what the instructions say. You seemed to think that if you did this it would negate the wrench from ever being calibrated. torque wrenches should be re-calibrated every 5000 cycles. If it is found to be out spec at any time this should be shortened to 2500 cycles these are the ISO standards.

This is not a "I think I know better" situation at all. Stop being so defensive. I'm only going on the information I have at hand in quadruplicate in four different publications one of them published by Ford. Beyond that I have been implementing the specified torque on clean rust free threads with no oil or grease like the spec says for 400,000 miles 10 sets of tires and 2 winter tire to summer tire change out annually for 33 years with no problems of a nut falling off or a stud being over tightened or any difficulty getting a nut off either. So it's going to take more than a guy who says he is a Ford engineer on a website with so far no proof to get me to consider changing the M&O on my truck.

As for the Torque wrench...I'm following the recommendations of the manufacturer on specifically this question which was asked directly to the mfgr. Do you think you know more than the manufacturer of these tools? What are you a torque wrench engineer too?

BB2

#96

#97

ALL torque values for lug nuts are with lubricated threads this was updated years ago, as non-lubricated threads will give wildly inconsistent clamping forces. This how wheel nuts/bolts end up backing off. You really think Ford would only spec lubricating locking nuts.... All Ford shop manuals state ALL torque values are with lubricated threads. Of course these are written techs who understand that lubricated threads does not mean gob it on like a drunken sailor...

I have not spent 40 plus years as an engineer who just happen to have worked at Ford engineering the stuff YOU are working on, so I just might know a thing or two that is NOT covered in the manuals.

But hey if you think you know better.,....

Sort of like the torque wrench thing you have no idea why it says do not go past the lowest setting just that it does with out understanding why.. Where as I do know the why. It is a compromise to minimize spring compression set and the chances of the stupid from backing the handle right off/out and potentially having the guts fall to bits on the floor. The best practice is to fully unload the spring regardless what the instructions say. You seemed to think that if you did this it would negate the wrench from ever being calibrated. torque wrenches should be re-calibrated every 5000 cycles. If it is found to be out spec at any time this should be shortened to 2500 cycles these are the ISO standards.

I have not spent 40 plus years as an engineer who just happen to have worked at Ford engineering the stuff YOU are working on, so I just might know a thing or two that is NOT covered in the manuals.

But hey if you think you know better.,....

Sort of like the torque wrench thing you have no idea why it says do not go past the lowest setting just that it does with out understanding why.. Where as I do know the why. It is a compromise to minimize spring compression set and the chances of the stupid from backing the handle right off/out and potentially having the guts fall to bits on the floor. The best practice is to fully unload the spring regardless what the instructions say. You seemed to think that if you did this it would negate the wrench from ever being calibrated. torque wrenches should be re-calibrated every 5000 cycles. If it is found to be out spec at any time this should be shortened to 2500 cycles these are the ISO standards.

#98

#99

Double checked with my torque wrench manufacturer on the lowest setting. They recommend never to go below the the lowest setting. Yes it does put some pressure on the spring. But they have done long term testing on that setting and have found no effects on the torque readings. Also the mechanism used on this torque wrench is not as you described. There are two ball bearings involved in this one and going below the lowest setting could put it out of phase...so the amount to go below the lowest setting ever is ZERO. Moral of the story: Always refer to the manufacturer's recommendations on your torque wrench use! Do your own due diligence!

BB2

#100

Do you know the K factor for the lubricant or anti-seize you are using on your studs?

Taking all fastener surface conditions into account, the value of "K" ranges from approximately 0.06 to 0.35.

As per above clean rust free studs and lug nuts would be a K value of 0.20

It does appear that K values vary wildly depending on the type of lubricant or anti-seize used. Of course if you have rusty equipment that can increase the K value as well, leading to reduced clamping load.

No torque spec is a valid one with out stating both the torque to be applied and the thread condition. T= K*D*P and from that P=T/K*D

In my opinion using clean rust free condition in conjunction with 140 ft-lbs of torque is easily reproduced time after time. If you are using other products find out the appropriate K factor for your product and adjust your torque appropriately. Many companies test for K factors and supply that information on-line.

After assembly I coat my threads and lugs with Fluid Film. Prevents rust, seals out water and penetrates through any rust to the metal surface. The beauty of Fluid Film is that it can be easily washed off with hot soapy water prior to disassembly so you don't have to worry about the K factor being affected when you re-assemble your wheels. I further clean the studs with a clean dry rag. One turn around the stud and a few back and forth motions thoroughly cleans the stud. I also inspect and clean the nuts with a clean dry rag. This only takes a few minutes per wheel. This is the best way I have found to have consistent results.

It's been great to hear from all you FTE folks on this important element on our trucks for safety and peace of mind when rolling down the road! All input is appreciated.

BB2

Examples of "K" Value

- For non-plated carbon steel bolts in their as-received condition, "K" is 0.20.

- For cadmium-plated bolts, "K" drops to 0.17 because cadmium offers good lubrication.

- For zinc-plated bolts, "K" may be as high as 0.22 for zinc electroplated fasteners and 0.25 if they are hot-dipped galvanized. Zinc plating roughens the fasteners surface.

- For bare steel fasteners exposed to severe elements and beginning to oxidize, "K" may be 0.30 or higher.

- For fasteners using extreme pressure waxes, as in prevailing torque nuts, "K" is reduced to 0.10.

Taking all fastener surface conditions into account, the value of "K" ranges from approximately 0.06 to 0.35.

As per above clean rust free studs and lug nuts would be a K value of 0.20

It does appear that K values vary wildly depending on the type of lubricant or anti-seize used. Of course if you have rusty equipment that can increase the K value as well, leading to reduced clamping load.

No torque spec is a valid one with out stating both the torque to be applied and the thread condition. T= K*D*P and from that P=T/K*D

In my opinion using clean rust free condition in conjunction with 140 ft-lbs of torque is easily reproduced time after time. If you are using other products find out the appropriate K factor for your product and adjust your torque appropriately. Many companies test for K factors and supply that information on-line.

After assembly I coat my threads and lugs with Fluid Film. Prevents rust, seals out water and penetrates through any rust to the metal surface. The beauty of Fluid Film is that it can be easily washed off with hot soapy water prior to disassembly so you don't have to worry about the K factor being affected when you re-assemble your wheels. I further clean the studs with a clean dry rag. One turn around the stud and a few back and forth motions thoroughly cleans the stud. I also inspect and clean the nuts with a clean dry rag. This only takes a few minutes per wheel. This is the best way I have found to have consistent results.

It's been great to hear from all you FTE folks on this important element on our trucks for safety and peace of mind when rolling down the road! All input is appreciated.

BB2

#101

#102

#103

#104

#105

The formula for the clamping load on the stud:

P= T/ (K*D) shows the relationship. P is the clamping load or tension load in the stud, T is the torque, K is the friction factor, D is the diameter of the Stud.

When the friction factor gets smaller due to lubrication the clamping force gets bigger even when the Torque stays the same. D stays the same for a given diameter stud. So for dry clean steel the K factor is 0.2 and for lubricated it's generally taken as 0.1, half as large. So the clamping force doubles when you lubricate with the same torque. If you know basic math and a bit of algebra it makes sense. Damage can and does occur when too much torque is applied and/or when more lubricity is applied to the threads. You stretch the stud out and then it's rubbish.

BB2

Thread

Thread Starter

Forum

Replies

Last Post

Connecticut Calvin

1948 - 1956 F1, F100 & Larger F-Series Trucks

12

09-29-2015 08:47 AM

packrat56

Garage & Workshop

9

01-02-2008 03:02 PM