Wanting to put batteries in the bed, need help with wire selection

#1

Wanting to put batteries in the bed, need help with wire selection

Hey all,

I'm in the process of redoing an 88 f250 where I'm going to put the batteries in the bed and I need some help selecting battery cable size. It's a cclb, and I have estimated measurements of:

10' positive to starter

13' positive to fender relay

14' negative to motor ground

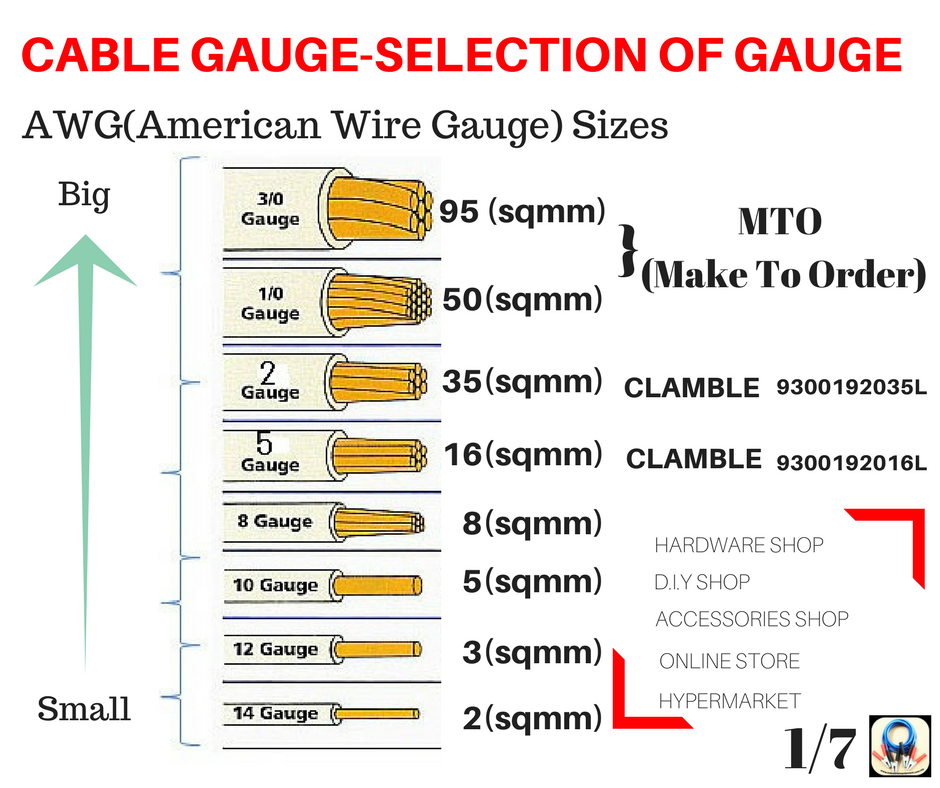

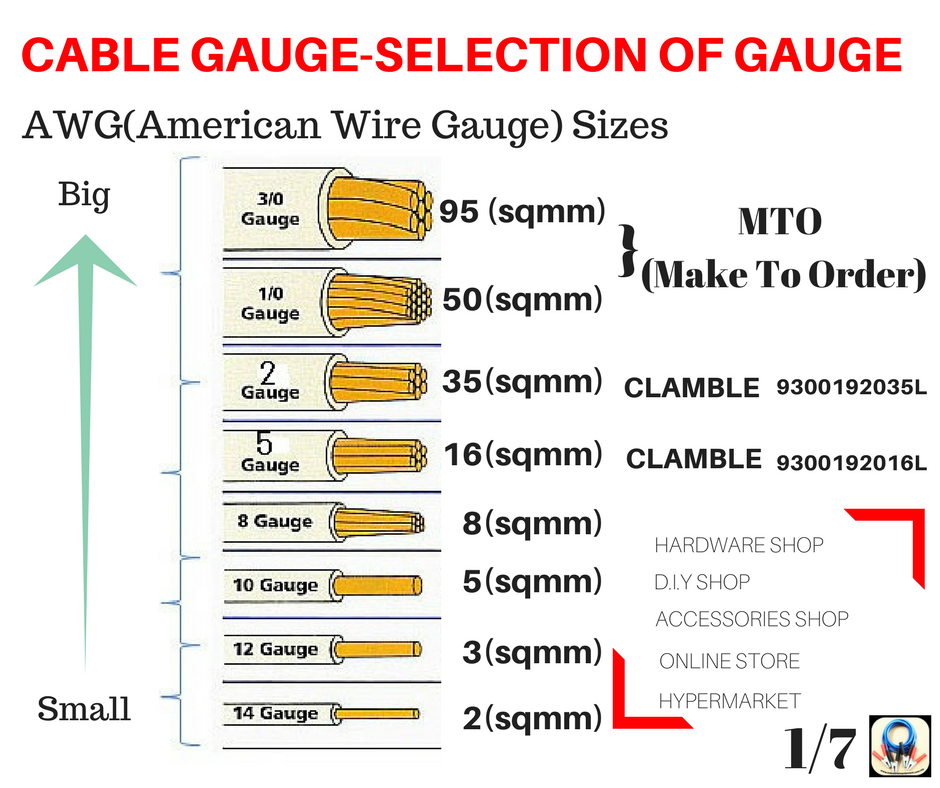

I was thinking 3/0 for + to starter, 1/0 + to fender relay, and 2/0 negative to motor ground.

Do these sizes sound about right? I wasn't sure if I should do 4/0 for the positive to the starter. Also, can I get away with taking the ground wire straight to the motor? Or do I need to ground it to the frame somewhere as well? And can I get away with running the ground only to the passenger side of the motor?

Thanks

I'm in the process of redoing an 88 f250 where I'm going to put the batteries in the bed and I need some help selecting battery cable size. It's a cclb, and I have estimated measurements of:

10' positive to starter

13' positive to fender relay

14' negative to motor ground

I was thinking 3/0 for + to starter, 1/0 + to fender relay, and 2/0 negative to motor ground.

Do these sizes sound about right? I wasn't sure if I should do 4/0 for the positive to the starter. Also, can I get away with taking the ground wire straight to the motor? Or do I need to ground it to the frame somewhere as well? And can I get away with running the ground only to the passenger side of the motor?

Thanks

#2

I would go with 3/0 welding wire to the starter and motor ground. Sure, grounding will go through the mounts, buy that starter pulls just as much from positive as negative and better to have more ground than less.

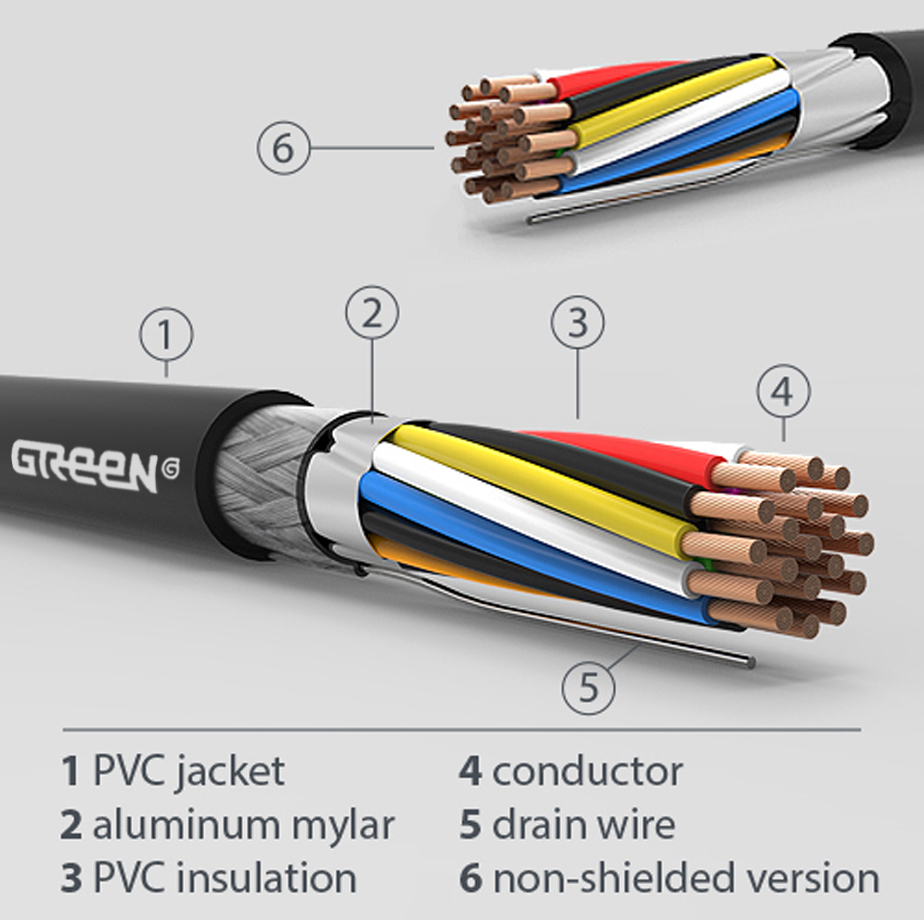

Welding cable will give you flexibility to run the bends, and I would wrap any potential chafe point with large fuel hose sliced lengthwise and zip tied to protect any positive wire. Use good connecters with a solid crimp and use lead solder and seal it well with liquid electric tape and shrink tube. Oxygen will cause corrosion. Yes also ground the chassis.

Welding cable will give you flexibility to run the bends, and I would wrap any potential chafe point with large fuel hose sliced lengthwise and zip tied to protect any positive wire. Use good connecters with a solid crimp and use lead solder and seal it well with liquid electric tape and shrink tube. Oxygen will cause corrosion. Yes also ground the chassis.

#3

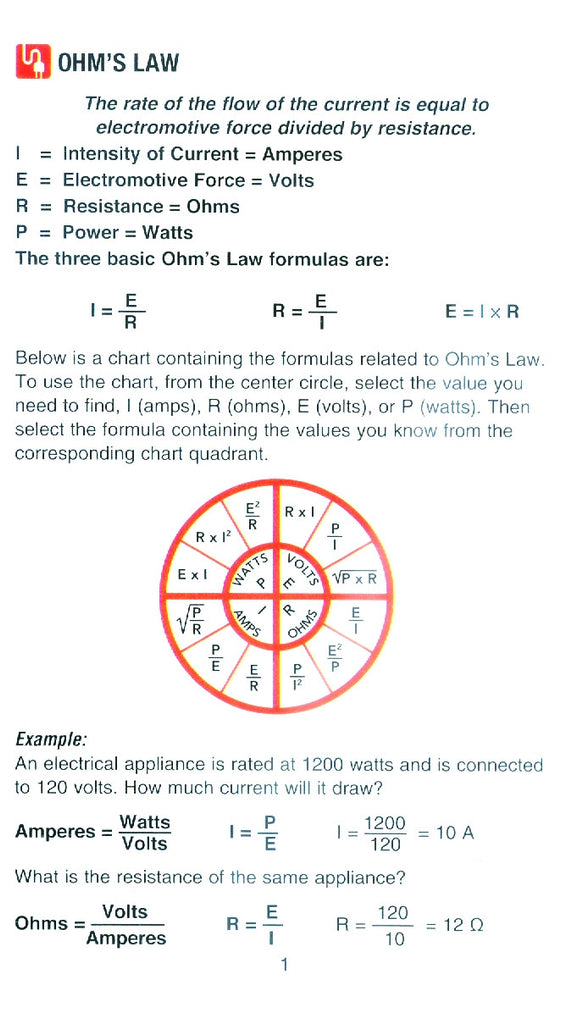

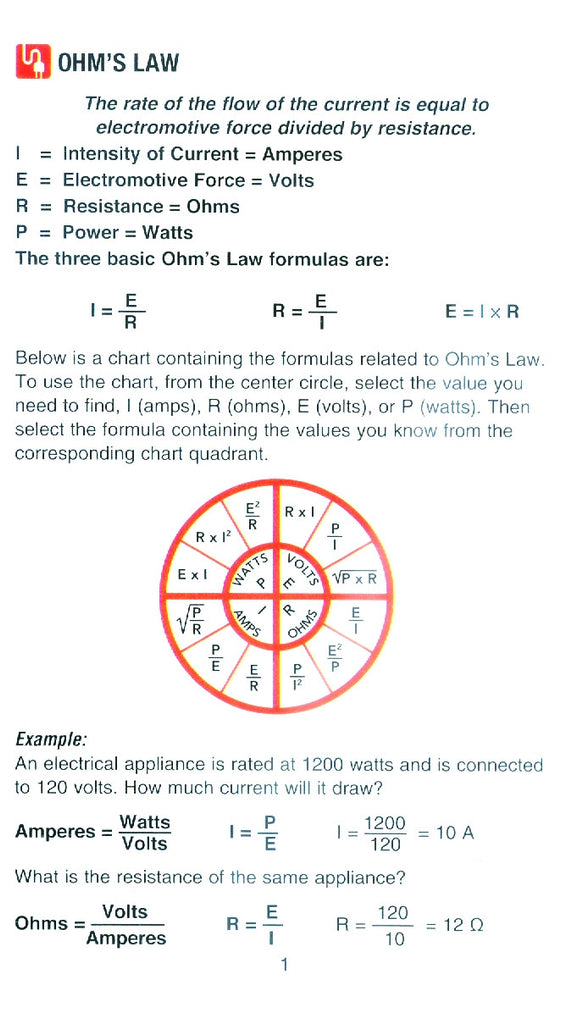

With electrical work, wire selection is critical. There are formulas for selecting the proper wire for what you intend, based upon amperage, voltage, the length of the wire run......much more complicated than can be answered in an online forum post. Electricians apprentice for years. A lot of electricians use reference charts.

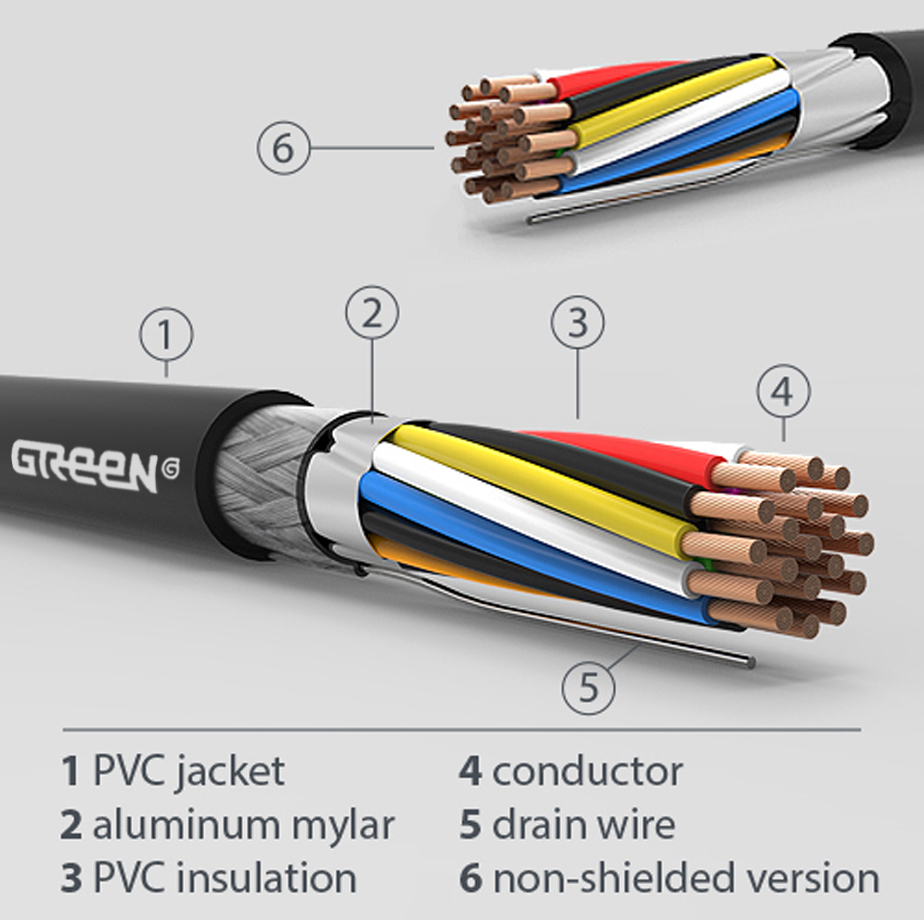

Another consideration is what type of wire. Solid? Stranded? How many strands? Copper? Aluminum? Did you know that you don't always have to use copper wire, and that aluminum wire is a less expensive option? Yes, it will make a difference when it comes to current flow & resistance. Best case scenario is that you do not get the results you were hoping to achieve. Worst case scenario is that you have a fire.

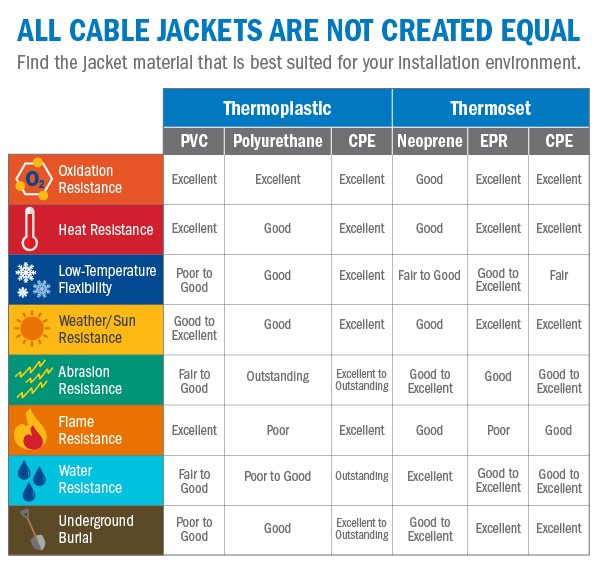

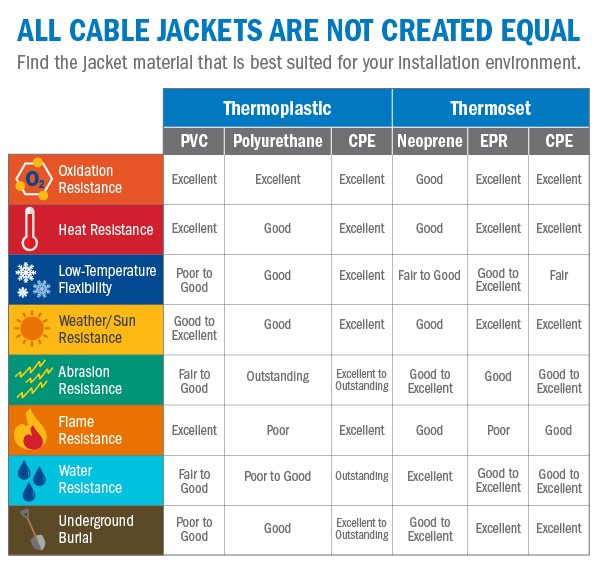

Which also brings us to insulation and jacketing. A lot to choose from. Consider heat, elements, exposure to moisture, rigidity........having the correct wrap around your wire will protect the wire, and insulate the electrical current. Best case scenario for failure may be just radio interference, and getting nothing but static on your 8-track tape deck. Worst case may be the electrical current interfering with your car's computer and it's sensors. And again, fire.

In a building, the wire run is suppose to be in some sort of conduit. Aluminum, steel, various metal pipes, PVC pipe. Under the hood of most cars, you will see the wiring encased in flex loom. Except for battery cables, which you can see, are just big battery cables. But you are running the wires away from that location, to a remote location, and it may be important to add a little more protection to that wire run.

A lot more to think about than just what size to get. Usually, when you shop from a battery distributor, they should have a counter guy with a little more knowledge, who can help you pick out that correct wire, and whatever else you will need to perform your installation. In my area, most of the guys setting up extra batteries will go to Interstate Battery. The counter guy there is very good. He's been working there for who knows how long, and has the knowledge to help you do it safely. In your area, you should also have a battery supplier who can set you up with the correct wire, terminals, specialty tools, and even the battery tray, box, & securement hardware.

The advantage to shopping at specialty stores, is that they have more in depth knowledge. Same way it's better to go to a place that only sells brakes, and can advise you properly on whether to resurface your rotors or replace them. They can also advise on upgrade kits, better or bigger rotors, or using a different caliper. Something an O'Reilly's or Auto Zone clerk can't help you with.

Try a battery distributor store first. Just remember that they charge a lot more for the same thing, because you are paying for what they know. And the fact that they are selling wiring a few feet at a time, as opposed to an electrical supply distributor who sells thousands of feet at a time, their cost on wire will be significantly higher. As I have tried going to regular electrical supply houses, where the wiring and terminals are a lot less expensive; and the 1st thing that they tell you is that even though it's all wire, they do not have any knowledge on what you need for 12V direct current.

Another consideration is what type of wire. Solid? Stranded? How many strands? Copper? Aluminum? Did you know that you don't always have to use copper wire, and that aluminum wire is a less expensive option? Yes, it will make a difference when it comes to current flow & resistance. Best case scenario is that you do not get the results you were hoping to achieve. Worst case scenario is that you have a fire.

Which also brings us to insulation and jacketing. A lot to choose from. Consider heat, elements, exposure to moisture, rigidity........having the correct wrap around your wire will protect the wire, and insulate the electrical current. Best case scenario for failure may be just radio interference, and getting nothing but static on your 8-track tape deck. Worst case may be the electrical current interfering with your car's computer and it's sensors. And again, fire.

In a building, the wire run is suppose to be in some sort of conduit. Aluminum, steel, various metal pipes, PVC pipe. Under the hood of most cars, you will see the wiring encased in flex loom. Except for battery cables, which you can see, are just big battery cables. But you are running the wires away from that location, to a remote location, and it may be important to add a little more protection to that wire run.

A lot more to think about than just what size to get. Usually, when you shop from a battery distributor, they should have a counter guy with a little more knowledge, who can help you pick out that correct wire, and whatever else you will need to perform your installation. In my area, most of the guys setting up extra batteries will go to Interstate Battery. The counter guy there is very good. He's been working there for who knows how long, and has the knowledge to help you do it safely. In your area, you should also have a battery supplier who can set you up with the correct wire, terminals, specialty tools, and even the battery tray, box, & securement hardware.

The advantage to shopping at specialty stores, is that they have more in depth knowledge. Same way it's better to go to a place that only sells brakes, and can advise you properly on whether to resurface your rotors or replace them. They can also advise on upgrade kits, better or bigger rotors, or using a different caliper. Something an O'Reilly's or Auto Zone clerk can't help you with.

Try a battery distributor store first. Just remember that they charge a lot more for the same thing, because you are paying for what they know. And the fact that they are selling wiring a few feet at a time, as opposed to an electrical supply distributor who sells thousands of feet at a time, their cost on wire will be significantly higher. As I have tried going to regular electrical supply houses, where the wiring and terminals are a lot less expensive; and the 1st thing that they tell you is that even though it's all wire, they do not have any knowledge on what you need for 12V direct current.

#5

And by the way, you do not have crimp your connections. As a crimping tool large enough to handle 4/0 wire would cost about as much as the battery you are installing. I have used NSI Polaris terminals with great success, on all sized of wiring. Simply strip the wire, insert, and turn the bolt to tighten down onto the wire. The connectors come are available for all sizes of large and small wiring, are available in a variety of angles for different installations, and are fully insulated. The below style connector will work just fine for your application.

#7

Trending Topics

#9

See if you can rent this tool before you buy it.

Greenlee K09-2GL K-Series Crimping Tool, 8-4/0 AWG

Greenlee K09-2GL K-Series Crimping Tool, 8-4/0 AWG

Greenlee

Price + Shipping

Condition ( )

Delivery

Seller Information

Buying Options$427.00+ $8.49 shipping

New

new in box with factory warranty

Add to cart

Greenlee K09-2GL K-Series Crimping Tool, 8-4/0 AWG

Greenlee K09-2GL K-Series Crimping Tool, 8-4/0 AWGGreenlee

- Compare:

- Offers for this product

Price + Shipping

Condition ( )

Delivery

Seller Information

Buying Options$427.00+ $8.49 shipping

New

new in box with factory warranty

- Arrives between Mar. 19 - April 3.

- Want it delivered Friday, March 22? Choose Expedited Shipping at checkout.

- and .

4.5 out of 5 stars (75 total ratings)

Add to cart

#10

That's excellent advice that Fifty150 gave. Reps given! FWIW, I happen to be an FAA electronics tech (hate the single strand AC stuff).

You may be able to find an electrical supply distributor or battery store that will make the cables for you. I had battery cables made for my 86 f250 recently and used 00 and 000 gauge welding cable. Also, don't solder battery cables. They carry so much current that the solder would fail pretty quickly. Battery cables need to be crimped to be done the right way. If you can't find someone to do the crimping for you then see about renting that crimper mentioned above.

You may be able to find an electrical supply distributor or battery store that will make the cables for you. I had battery cables made for my 86 f250 recently and used 00 and 000 gauge welding cable. Also, don't solder battery cables. They carry so much current that the solder would fail pretty quickly. Battery cables need to be crimped to be done the right way. If you can't find someone to do the crimping for you then see about renting that crimper mentioned above.

#11

Join Date: Mar 2005

Location: Marlboro Mental Hospital.

Posts: 61,125

Received 3,186 Likes

on

2,221 Posts

#12

Find a tractor trailer junk yard nearby and you can get all the 4/0 battery cables you can carry usually for a dollar a foot. I bought several 15 foot sections recently at a local yard for 100 bucks and it already was covered with protective wire sleeves and had all the little plastic brackets to hang and separate it. Just a thought!

#13

I would use 4/0. I don't like dealing with slow crank or no start when it's really cold out.

Why the bed? You lose utility and make a longer run. What are you putting in the factory location of the batteries that cannot go anywhere else? If you absolutely must move the batteries why not mount a box to the frame rail and keep them conveniently out of the way rather than waste bed space? I've seen a few clean mounting solutions for a frame rail mounter battery box.

Why the bed? You lose utility and make a longer run. What are you putting in the factory location of the batteries that cannot go anywhere else? If you absolutely must move the batteries why not mount a box to the frame rail and keep them conveniently out of the way rather than waste bed space? I've seen a few clean mounting solutions for a frame rail mounter battery box.

#14

#15