300ci timing problem

#1

#6

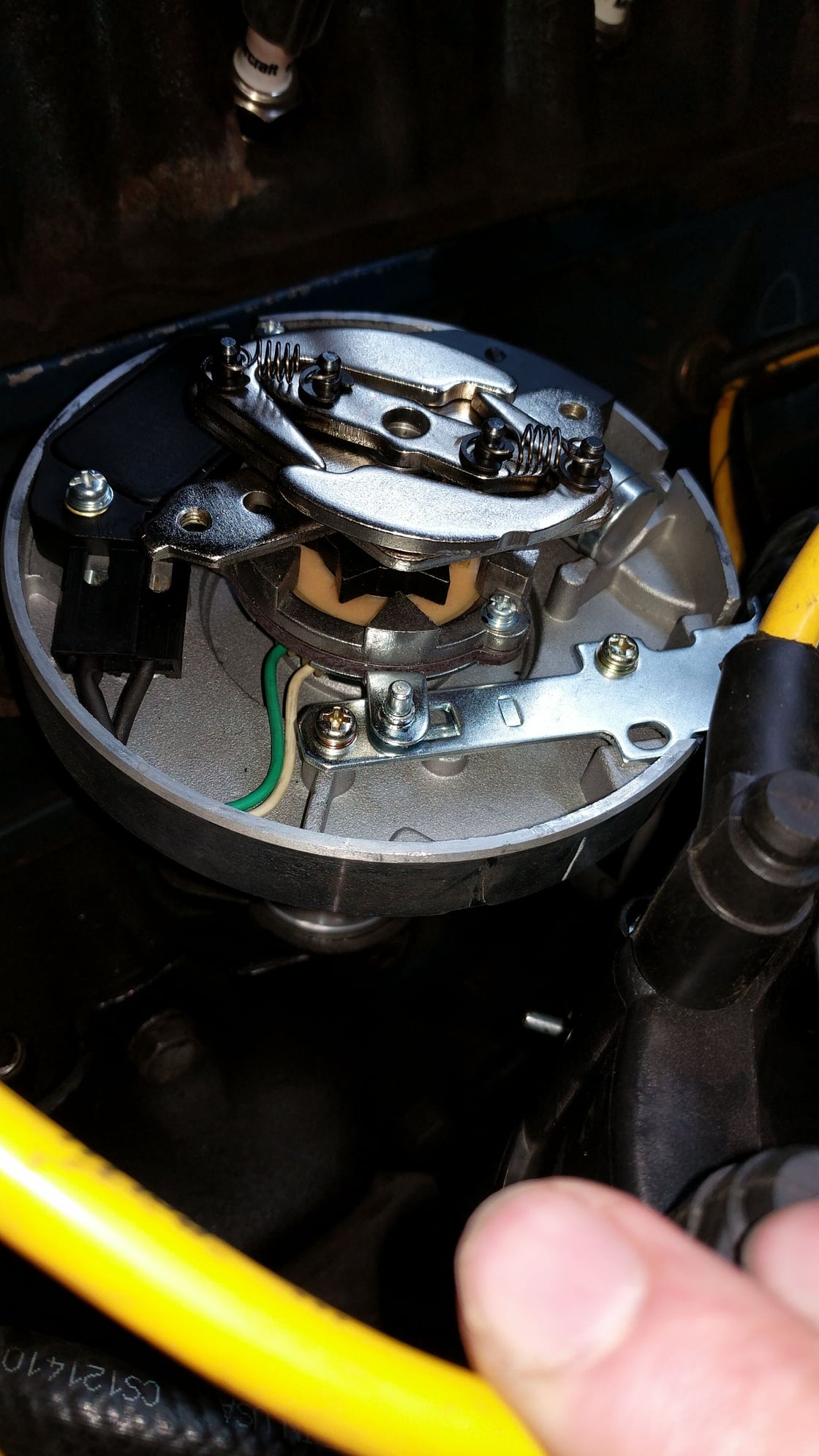

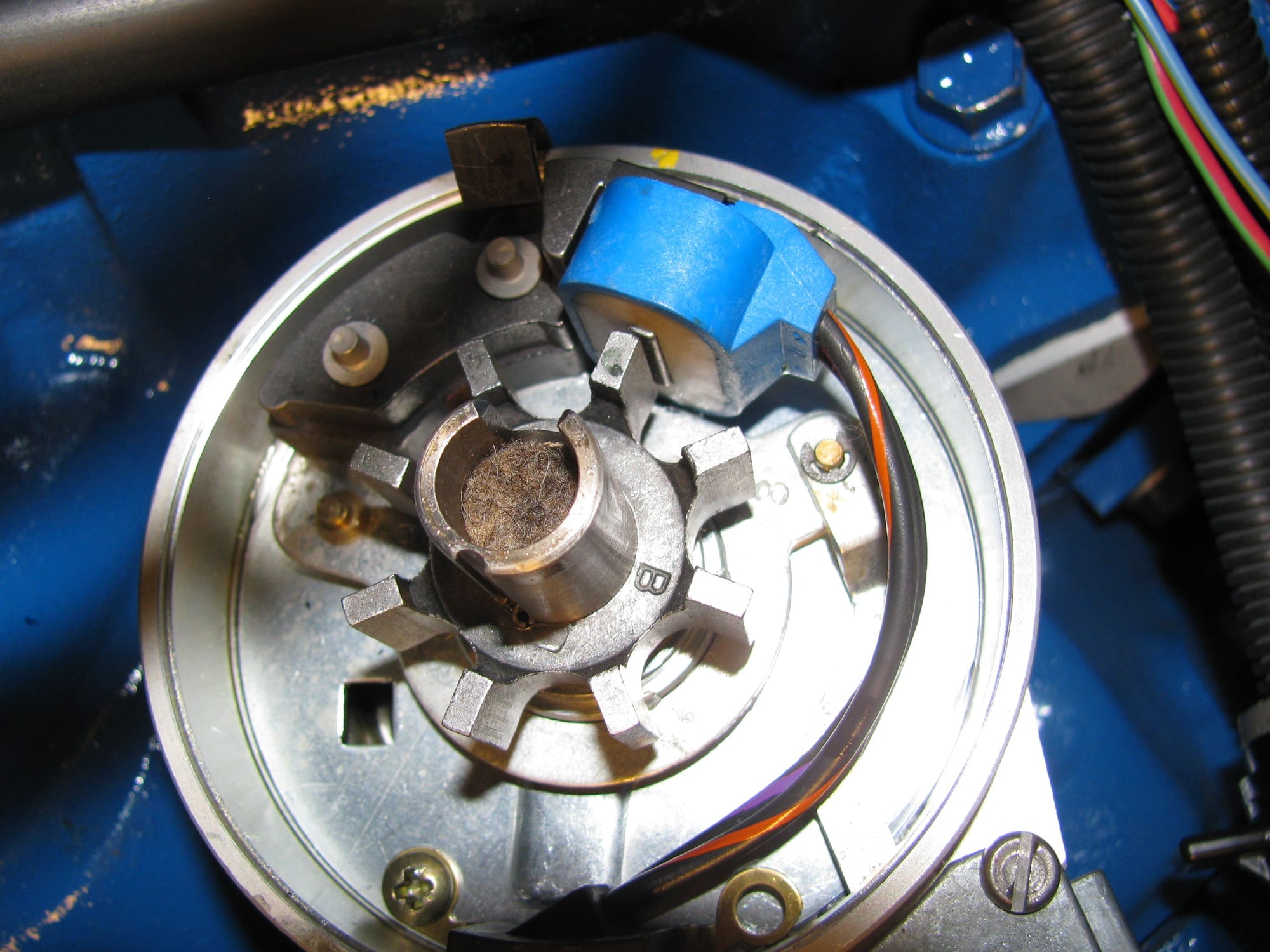

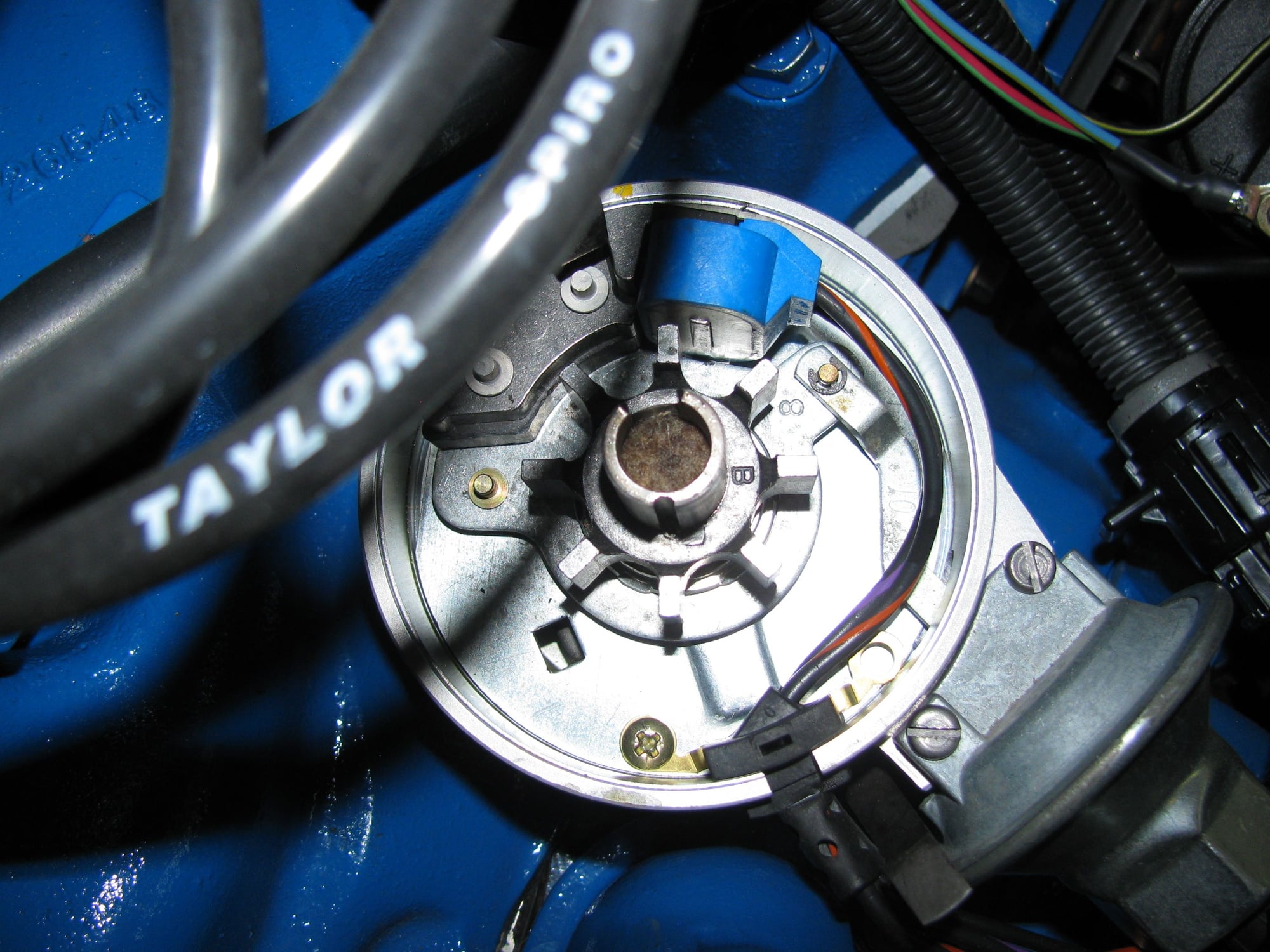

Distributor

#7

Originally Posted by RMystique

So I have an HEI distributor on my engine and when I set the timing to 12 degrees BTDC with the vacuum line off it idles good and revs good, but when I put my vacuum line back on and open up the throttle a bit it sputters and backfires and runs like crap?????

Assuming crank balancer is OK, it sounds a little like it could be a vacuum leak (maybe bad vacuum can diaphragm?) or something related. Or, maybe it's just way out of adjustment. Check with vacuum gauge for obvious leaks.

Originally Posted by RMystique

With the initial 12 degres and the mechanical looks about 18 or so when reved up, about 30 defrees without the vacuum hooked up

Maybe you know all this already - not trying to beat up on you. This is always checked and set with vacuum advance disconnected and plugged Also when you do this make sure it's done advancing all the way. Stock OEM are pretty tight and may not reach full advance till 4000 RPM. Get in the manuals and find out what specification is for your engine. With a "modern" V8 it's always 34° or 36° BTDC, right in there, it's probably similar for a six. Point being it's a whole lot more mechanical timing advance than people might think.

It's important to test drive and see how it runs, especially without vacuum advance. Check for ping or detonation upon full throttle high RPM acceleration from a dead stop or near enough. When you are satisfied with how it runs, then re-connect vacuum advance.

These are usually adjustable with an allen wrench. Most instructions have you start out testing with the vacuum can pulling in maximum (fully clockwise). The Crane Cam type has something like 16 turns from stop to stop. Hook it back up and go for a ride. Here you're testing steady cruise and part throttle acceleration. Back off 1 or 2 turns at a time as required, bring your Allen wrench with you. When you get it dialed in pretty close you'll notice seasonal variations or even a bad tank of juice. Adjust the timing for the "worst" type of fuel you plan to use.

What you're doing is adjusting when (at what manifold vacuum level, inches Hg) the vacuum can pulls in the extra timing needed. A stock engine pulls maybe 18" of vacuum at idle and almost as much cruising at 60 miles an hour on level ground. This manifold engine vacuum goes away instantly when accelerator is pressed but returns as the engine load levels off. This only takes a split second. The distributor is a very busy kind of fellow!

Remember mechanical advance is strictly RPM dependent, with centrifugal weights and springs. Vacuum advance on the other hand, doesn't care about any of that, it is strictly dependent on engine load. The two advance mechanisms are completely independent of yet complement each other, one is generally advancing while the other is retarding. The goal is to have any gasoline engine operate with the maximum possible ignition advance at all times under all conditions, just short of any damaging detonation or spark knock. Vacuum advance helps greatly with this under street driving conditions.

When cruising at a steady speed (any speed) on level road, you're likely in high gear. RPM is low. So at this point we're nowhere near the maximum possible mechanical timing advance the distributor is capable, when we first set it on the far end at 34° BTDC or whatever.

The ignition advance isn't really optimal under these lightly loaded cruise conditions. Engine load is at its lowest though and engine vacuum at its highest - so engineers figured out a way to get more timing pulled in under those specific conditions. It's all done by sensors and computer today. 100 years ago it was pretty ingenious.

Check for ping or rattle during steady cruise and part throttle acceleration. This is different than earlier, when checking for full throttle or high RPM heavy load ping conditions. If you go too far with vacuum advance it will knock continuously or rattle at steady highway cruise, though not during acceleration. Keep in mind any timing changes at this point are necessary in your tuning, adjust only the vacuum advance can, the initial and mechanical has already been optomized. Sorry for the novel. It growed.

Trending Topics

#8

#9

So if I'm getting this right I need to set my initial rotor to cap so that the contacts are at the trailing Edge to begin to with so that when it advances it has plenty of contact to still make the connection. And start off with about six degrees advance. And yes my distributor is from a country where English is a second language to Mandarin, it's the type that has the coil in the cap.

#10

Rotor

So if I'm getting this right I need to set my initial rotor to cap so that the contacts are at the trailing Edge to begin to with so that when it advances it has plenty of contact to still make the connection. And start off with about six degrees advance. And yes my distributor is from a country where English is a second language to Mandarin, it's the type that has the coil in the cap.

As far as rotor to cap alignment, that is built into 99% of the distributors out there and there isn't anything you can do to change it short of major surgery on the distributor. And the only way to see if that is the problem is to have a cap with a hole in it so you can use your timing light to see where that rotor is when it fires.

Here is the one I use for the Durasparks.

#12

#14

I was hoping to see your rotor. But that's OK. That distributor is basically a General Motors made to fit a Ford. Look at your rotor and see if it has slotted holes in it, if it does turn it counter clockwise a little and tighten it up. If the rotor phasing is out I believe that MSD sells a rotor that is slotted so it can be adjusted.

Eric, I'm not sure about the Motors manuals but the Ford shop manuals generally express those numbers in camshaft degrees which means you have to double them to get crankshaft degrees. I don't have my 65 book here but the 71 shop manual shows a total of 18 degrees of vacuum advance at 25 inches and 22 degrees of centrifugal at 2600 rpm for a 240. And that is at the crankshaft.

Eric, I'm not sure about the Motors manuals but the Ford shop manuals generally express those numbers in camshaft degrees which means you have to double them to get crankshaft degrees. I don't have my 65 book here but the 71 shop manual shows a total of 18 degrees of vacuum advance at 25 inches and 22 degrees of centrifugal at 2600 rpm for a 240. And that is at the crankshaft.

#15

Originally Posted by EricJ

Hey guys I just checked my Motors manual and it claims the initial advance on the 240-300 in '66 varies between TDC and 6 degrees depending on the model, and max centrifugal is 11, and vacuum is 12, so total max advance is between 23 and 29.

When the book says 11° distributor degrees they mean 22° at the crank.

The initial timing number doesn't really matter that much. Set it wherever it needs to fall to reach your target ignition timing at the far end.

Yes it's confusing at first.

Run about 28° BTDC or thereabouts (more if she'll take it without ping) without vacuum advance connected and take it for a spin. Try full throttle accelerations from a dead stop. Bring your 1/2" box end wrench with you. Try a little more or a little less till it pings anyway and back off and see how it performs. This is the optimum setting for YOUR engine. A few degrees one way or another can make a big difference. Just a slight turn - about the width of a pencil line - of the distributor equals 2° on the crank.

When you're certain it is to your liking, then re-connect vacuum advance and priceed with tuning the can itself. Don't mess with the initial timing again. If you're thinking all of this is a pain in the *** - you're right. But the distributor is the heart of any engine. It has to be working perfectly, and setup correctly, or it will never run right and exhibit lousy performance, and worse economy. Take the time to set it up right yourself (or get it curved on a machine, you're just curving using the engine) you'll be glad you did.