Time for a rebuild

#16

Well got all the accessories off the front of the motor, but I can not get the fan clutch knocked loose. no matter how tight I put a ratchet strap on the pulley it slips. I've tried using a cheater, beating on the wrench nothing budges the nut without the strap slipping on the pulley. Yes I am going the correct direction, I've double and triple checked myself on that. Any suggestions?

#17

Well got all the accessories off the front of the motor, but I can not get the fan clutch knocked loose. no matter how tight I put a ratchet strap on the pulley it slips. I've tried using a cheater, beating on the wrench nothing budges the nut without the strap slipping on the pulley. Yes I am going the correct direction, I've double and triple checked myself on that. Any suggestions?

It can ding the pulley up a little, but it /works/. I /barely/ got mine around it, loosened up all the way; this was on a V-belt setup by the way.

#18

I finally got it off, I build a wrench that fit bolted onto 3 of the pulley bolts to hold a back up. Still could not get it loose for nothing with a wrench. I ended up having to beat on it as hard as I could with a chisel for about 10 min before it finally let loose. I guess that means a new water pump on this motor, but hey at least its done. Got the motor pulled going in with the new-to-me one in the morning. Unfortunately I put a nice hole in the radiator pulling the old motor out.

One the transmission end, of course I can't tell anything about the torque converter other than 2 of the bolts to the flywheel where loose. Fluid looks brand new. It's not burnt or slipping. Maybe it's the torque converter, maybe it was the bottom end of the motor making the noise. I'm not sure.

On the new motor it has a hose coming from the back of the head on the passenger side that my motor didn't have. do I plug it off or where do I need to tie it into?

One the transmission end, of course I can't tell anything about the torque converter other than 2 of the bolts to the flywheel where loose. Fluid looks brand new. It's not burnt or slipping. Maybe it's the torque converter, maybe it was the bottom end of the motor making the noise. I'm not sure.

On the new motor it has a hose coming from the back of the head on the passenger side that my motor didn't have. do I plug it off or where do I need to tie it into?

#19

#20

so Doing a little research, I'm thinking maybe this is a 94 IDI, and the extra line is an oil line for the turbo??? My question is if this assumption is correct then will it perform fine if I plug the line and run it without a turbo, or are there tuning differences between the two?

#21

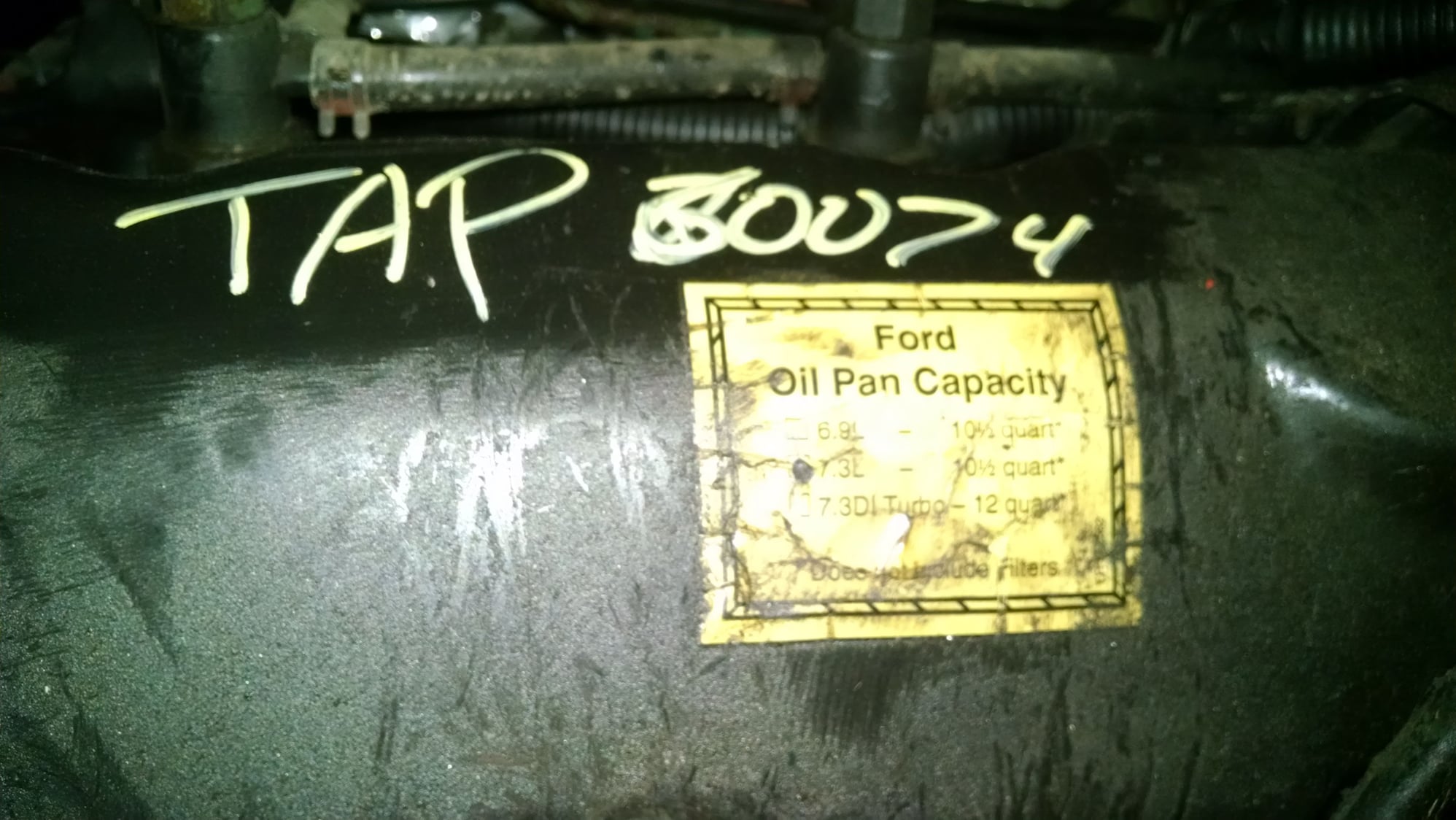

First picture is the mysterious line, others are any markings I could find on the motor other than the firing order which if needed i can go take a picture of that as well. The fuel return lines are also ran different than my 90 model motor. if I had the original motor here I would post pics for comparison, but it's in my buddies truck bed at the moment

#22

Looks like that was an oil /return/ line, off a bypass filter perhaps?

There is no oil pressure in the heads, and I believe those ports go into the oil return galleries.

Just remove the whole line and install a plug.

Um, any more info on this motor?

It's definitely a rebuild, and I have the same yellow sticker(and black rattle-can paint job) on the motor in my '92. That yellow sticker is *not* factory.

While you are at it, can you put a socket on one of the head bolts? Let me know what (12-point) socket fits.

The sticker says it's a 7.3, but for some reason I get the 'feeling' that it could be a 6.9, just looking at the head bolt.

Of course, I can't really see scale, so I'm probably wrong...

There is no oil pressure in the heads, and I believe those ports go into the oil return galleries.

Just remove the whole line and install a plug.

Um, any more info on this motor?

It's definitely a rebuild, and I have the same yellow sticker(and black rattle-can paint job) on the motor in my '92. That yellow sticker is *not* factory.

While you are at it, can you put a socket on one of the head bolts? Let me know what (12-point) socket fits.

The sticker says it's a 7.3, but for some reason I get the 'feeling' that it could be a 6.9, just looking at the head bolt.

Of course, I can't really see scale, so I'm probably wrong...

#23

Head bolts are the same as my old motor. It also had another oil hose coming off the filter. Both holes were plugged in my motor so I took the plugs out and plugged them on this one. I also had to swap out vacuum lines on the injection pump to the electronic one on my motor (throttle position sensor maybe?) Anyway got that done and the motor dropped in the truck. Going to try and put everything back together tonight after dinner. Hopefully pick up a radiator tomorrow. Turning the motor over feels like it has more compression than my old one.

#24

You don't happen to have a picture of where the line coming off the oil filter head was, do you?

See, that was obviously a bypass filter setup on there. I'm going to do one myself at some point, so seeing what someone else did(successfully) is always good.

Mind you... as those plugs were put in by you(and therefor not rusted in), you might think about adding a bypass oil filter setup as well. Probably wouldn't be too expensive, and would probably make the engine last longer(due to fewer sub-20 micron particles floating around between oil changes)

See, that was obviously a bypass filter setup on there. I'm going to do one myself at some point, so seeing what someone else did(successfully) is always good.

Mind you... as those plugs were put in by you(and therefor not rusted in), you might think about adding a bypass oil filter setup as well. Probably wouldn't be too expensive, and would probably make the engine last longer(due to fewer sub-20 micron particles floating around between oil changes)

#25

No picture, It was a plug on the front of the oil filter housing.(toward the front of the motor) removed and then a connection screwed in its place, the hose had a 90 degree hard line bend and fitting then went to hose, bigger than the one off the back of the motor. 3/8" was the size of the plug in the head. Not sure about the one on the oil filter, but to remove it you use a 3/8" ratchet.

#26

I also got most of the stuff back together still have an alternator, fan, and radiator to install. I JB welded the radiator maybe it will seal till payday. But there's a 90% chance I have to drop the transmission now. I didn't know you had to spin the converter to seat it back on, and I just wiggled and pushed it on. My buddy who is a mechanic instead of just a parts swapper like me let me in on that little tid bit after we got the transmission bolted back to the motor. I guess that gives me a good opportunity to clean all the electrical connections real good and make sure they are making good contact.

#27

#28

well I got everything back on except the radiator and tried to fire the motor. Nothing. 1st my old starter doesn't like compression. It started smoking very quickly. but it would still turn it over just not quite as quick as I would have liked. Then I got fuel past the filter, and nothing at the injectors. So I'll check for plugged lines, but I think I'm going to have to cannibalize the pump off my other motor. How is the easiest way to set timing of the pump swapping it to a new motor?

#29

#30