F1 horn button.

#1

F1 horn button.

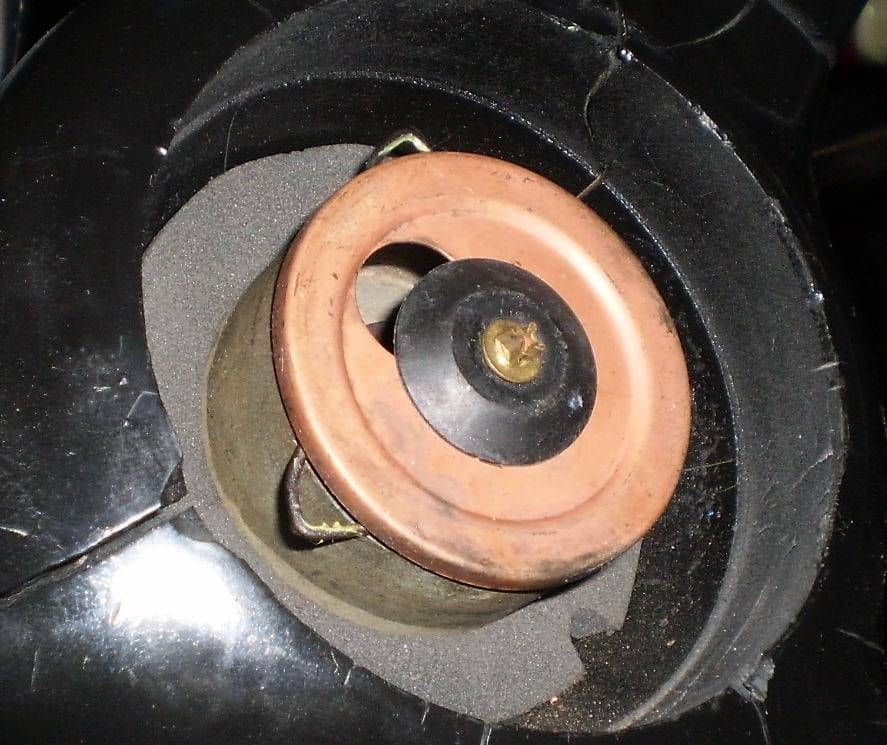

Trying to get the horn working on my brothers 49 F1. I replaced the horn wire and spring. Now I can not get the horn button to set back in place. It was on the column previously but had no "give" to it. I am lost as to why it will not set back on the wheel except that the spring is tighter, not as flat as the one I took off.. Is it possible that it is not the correct button?

#5

#6

#7

Trending Topics

#8

#9

#10

horn button

l had this problem with all new horn button parts. Take the assembly off the sreering wheel including button index plate, assemble all peices together on bench, you can place horn button over and twist and see the spring clip if it engages horn button. I had to bend spring slightly to engage horn button, it must lock to button index plate.

#11

#12

I would love to see a completely original horn button assemble. The only way I can get the repro [second one] cap seated is to put the little isolator below the plate it sets in then there is no play for the button to push the spring. Obviously the horn will always be grounded that way. If I ground the button areas that the metal clip goes in enough there will be nothing left. At a loss. Sure more fun to deal with the late model column in my 53.

#14

#15

I just used a few small pieces of electrical tape to isolate it. just to kind of prevent unwanted beeps. My repro horn button had a big booger on the bottom in the middle that had to be ground down. furthermore I felt the contact plate fit too tight inside the button, it was preventing the spring action. so I took a dremel and ground half a freckle around the inside way up towards to top. I also smoothed it out where the springs slip into the groove. just a hair.. That wire spring has to be sticking out pretty even on all 3 places about the same for it to slip in. Once I got it in I knew where it had to be. But I was surprised that it didn't have much spring action up and down.

Hope this helps.

Hope this helps.