Alternator and bracket from hell....

#1

Alternator and bracket from hell....

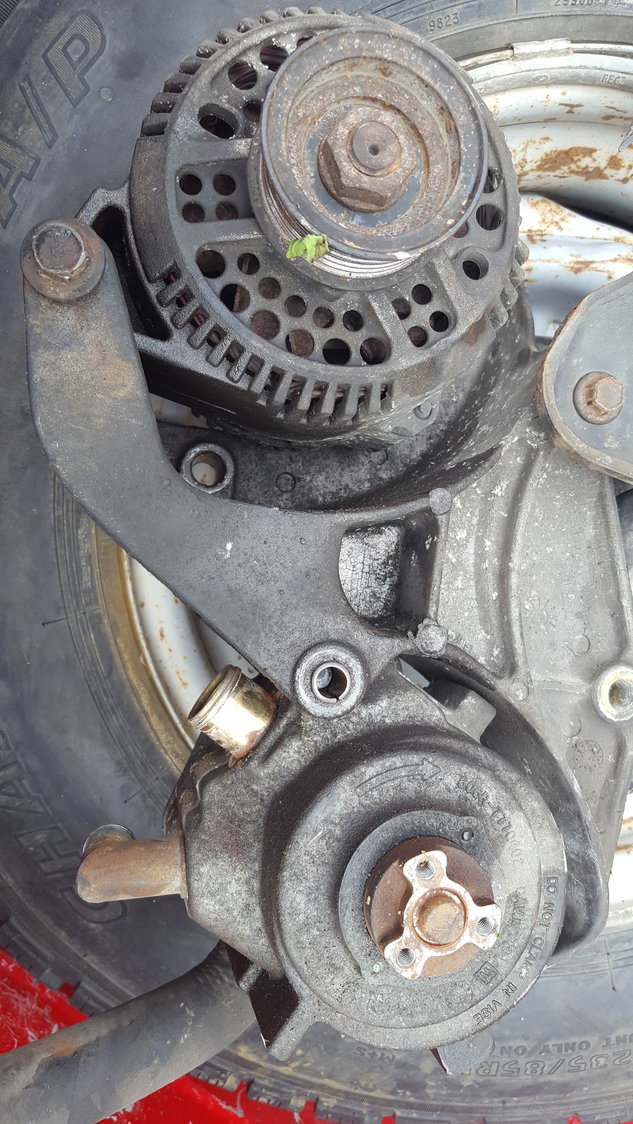

Sooooooo....I went to change my timing cover gasket on my 96 F250 460 and the water pump. I go to start removing the alternator and all its junk. Except the pivot bolt on the alternator has become.....frozen up into the bracket. After letting it sit with Penetrating for a day, then applying some heat, and getting the breaker bar on it....the most I did was bend. I figured, no big deal and I was able to move the alternator enough to remove the belt.

Here comes the fun part. Upon putting it all back together, I get to tightening the hold down bolt at the top of the alternator and SNAP! That butthole of an alternator decided to have the whole casing shatter. So I've got alternator casing everywhere now. I would like to just drop the whole bracket, do a smog delete while I am at it, get a new alternator and bracket, and put it all on. My issue is finding the darn bracket. Anyone know where to get one? I already checked eBay and I don't see any. Maybe someone knows someone who would have this laying around perhaps? And then what would be the best course of action for a new pivot bolt since my current one is frozen up into the bracket. I can't exactly take it off and have Fastenal make one in this scenario.

Here comes the fun part. Upon putting it all back together, I get to tightening the hold down bolt at the top of the alternator and SNAP! That butthole of an alternator decided to have the whole casing shatter. So I've got alternator casing everywhere now. I would like to just drop the whole bracket, do a smog delete while I am at it, get a new alternator and bracket, and put it all on. My issue is finding the darn bracket. Anyone know where to get one? I already checked eBay and I don't see any. Maybe someone knows someone who would have this laying around perhaps? And then what would be the best course of action for a new pivot bolt since my current one is frozen up into the bracket. I can't exactly take it off and have Fastenal make one in this scenario.

#2

#4

When you go to put it all back together, load everything up good with anti-seize so it won't be so bad if you have to do this job again for some reason..

Edit: you might give car-part.com a look see..

Edit: you might give car-part.com a look see..

#5

#6

Problem is that bracket is cast aluminum throughout the entire pathway of the pivot bolt, and a casting seam exists at a point that obstructs the bore slightly.

Chevy for example has a precision bore sleeve that is dropped into a partial casting in their version.

Cut bolt out carefully with Dremel tool.

Look on internet for complete engines for sale with all the attachments.

Use a rat-tail file or similar to get the slight burr out of your replacement.

Chevy for example has a precision bore sleeve that is dropped into a partial casting in their version.

Cut bolt out carefully with Dremel tool.

Look on internet for complete engines for sale with all the attachments.

Use a rat-tail file or similar to get the slight burr out of your replacement.

#7

1996 F250 460

I just looked up these 460 alternator brackets for another member with a 1996 E350 Club Wagon 460.

Lower picture: The mounting bracket (E7TZ-10A313-C - Obsolete) is the same 1988/89 E250/350; 1988/97 F250/350 & F(Super Duty) & F53 Stripped Chassis / 1990/97 E350.

There are two different 10145 adjustment brackets. Same applications as above.

E7TZ-10145-A .. Use with 60/75 & 95 amp alternators / Obsolete ~ 2 available NOS

E7TZ-10145-B .. Use with 100 & 135 amp alternators / Obsolete

Lower picture: The mounting bracket (E7TZ-10A313-C - Obsolete) is the same 1988/89 E250/350; 1988/97 F250/350 & F(Super Duty) & F53 Stripped Chassis / 1990/97 E350.

There are two different 10145 adjustment brackets. Same applications as above.

E7TZ-10145-A .. Use with 60/75 & 95 amp alternators / Obsolete ~ 2 available NOS

E7TZ-10145-B .. Use with 100 & 135 amp alternators / Obsolete

Trending Topics

#8

After reviewing bracket 1013 it refreshed my memory as what I've run into twice with the original alternators.

It's the alternators that have the casting seam in the pivot bolt's bore.

For example the Chevy's used 'outside ears' on the alternator's, then used the steel, bored, removable sleeve, where Ford cast the sleeve into the alternator itself.

If the entire bracket and alternator are removed together, and the fragile aluminum end ears on the bracket are firmly supported against flex, the bolt can be pounded out.

My earlier post was inaccurate, sorry.

It's the alternators that have the casting seam in the pivot bolt's bore.

For example the Chevy's used 'outside ears' on the alternator's, then used the steel, bored, removable sleeve, where Ford cast the sleeve into the alternator itself.

If the entire bracket and alternator are removed together, and the fragile aluminum end ears on the bracket are firmly supported against flex, the bolt can be pounded out.

My earlier post was inaccurate, sorry.

#11

If I get what you are saying....pounding the bolt out will strip the threads the bolt screws into in the aluminum bracket that holds the alternator and air pump. So that still leaves me with getting a new bracket.

As for the summit racing one, that bracket is worth the price when build the motor into a powerhouse. Its too shiny and nice to stick on my daily rode hard truck. Lol. I do plan on using that setup though for when I rebuild the motor in a few months.

On super bright side....I went junkyarding to my 11 yards, got to the third yard and found a 7.3 powerstroke, 96 year. I was like....SWEET! Injectors for my Powerstroke! Since she sits with two bad ones in my driveway. I step one vehicle over and wam! 96 E350 with a 460 in it! Bracket and alternator still in it. So I snatched that **** all in one piece. I plan on soaking it over night in some penetrating oil and removing the alternator to have it tested. If its good(looks good) I will slap it on, if not I'll buy another. Also when I pulled the valve covers on the Powerstroke, the injectors have already been replaced with rebuilt ones and look like they've barely seen any miles! The o-rings look fantastic. I scored a damn good price too at $6 a piece. Hahaha! So tomorrow I will get the bracket replaced and the alternator put on. Woowoo! If anyone needs some 460 parts give me a holler. There are a dozen here thought the 3 yards I went to with good parts on em. 460's are hard to find at yards as it is.

460's are hard to find at yards as it is.

As for the summit racing one, that bracket is worth the price when build the motor into a powerhouse. Its too shiny and nice to stick on my daily rode hard truck. Lol. I do plan on using that setup though for when I rebuild the motor in a few months.

On super bright side....I went junkyarding to my 11 yards, got to the third yard and found a 7.3 powerstroke, 96 year. I was like....SWEET! Injectors for my Powerstroke! Since she sits with two bad ones in my driveway. I step one vehicle over and wam! 96 E350 with a 460 in it! Bracket and alternator still in it. So I snatched that **** all in one piece. I plan on soaking it over night in some penetrating oil and removing the alternator to have it tested. If its good(looks good) I will slap it on, if not I'll buy another. Also when I pulled the valve covers on the Powerstroke, the injectors have already been replaced with rebuilt ones and look like they've barely seen any miles! The o-rings look fantastic. I scored a damn good price too at $6 a piece. Hahaha! So tomorrow I will get the bracket replaced and the alternator put on. Woowoo! If anyone needs some 460 parts give me a holler. There are a dozen here thought the 3 yards I went to with good parts on em.

460's are hard to find at yards as it is.

460's are hard to find at yards as it is.

#12

When I broke the front 'ear' off my bracket for the alternator it went down like this.

The pivot bolt would not even budge. Used a 1/2in. breaker bar, bolt had plenty of penetrating oil.

Got the bolt to move somewhat with a 3/4in.x36in. breaker bar with a 1/2x3/4 adapter and a 1/2in. drive black socket.

Started to move the alternator back-and-forth as much as possible in the arc allowed.

Was finally able to thread the bolt out of it's mount, fighting it every single

revolution.

Then the bolt was just stuck, in the hole, no longer threaded, but still at the edge of the threads in back hole.

Took bracket and alternator off together, laid them on floor, and supported the stress points, except...

Using a long punch started to pound the bolt out, alternator facing up, as the bolt moved out of the rear hole the rest of the way, of course the alternator, which is heavy, leaned to the side, and the front ear of the bracket snapped off.

The bolt was still stuck in the alternator hole, because of the casting seam it is galled, not rusted (aluminum doesn't rust, just oxidizes).

Got the bolt out, reamed the hole in the alternator and re-used it.

Luckily I had another bracket.

The pivot bolt would not even budge. Used a 1/2in. breaker bar, bolt had plenty of penetrating oil.

Got the bolt to move somewhat with a 3/4in.x36in. breaker bar with a 1/2x3/4 adapter and a 1/2in. drive black socket.

Started to move the alternator back-and-forth as much as possible in the arc allowed.

Was finally able to thread the bolt out of it's mount, fighting it every single

revolution.

Then the bolt was just stuck, in the hole, no longer threaded, but still at the edge of the threads in back hole.

Took bracket and alternator off together, laid them on floor, and supported the stress points, except...

Using a long punch started to pound the bolt out, alternator facing up, as the bolt moved out of the rear hole the rest of the way, of course the alternator, which is heavy, leaned to the side, and the front ear of the bracket snapped off.

The bolt was still stuck in the alternator hole, because of the casting seam it is galled, not rusted (aluminum doesn't rust, just oxidizes).

Got the bolt out, reamed the hole in the alternator and re-used it.

Luckily I had another bracket.

#13

Got the bolt to move somewhat with a 3/4in.x36in. breaker bar with a 1/2x3/4 adapter and a 1/2in. drive black socket.

Started to move the alternator back-and-forth as much as possible in the arc allowed.

Was finally able to thread the bolt out of it's mount, fighting it every single

revolution.

Then the bolt was just stuck, in the hole, no longer threaded, but still at the edge of the threads in back hole.

Took bracket and alternator off together, laid them on floor, and supported the stress points, except...

Using a long punch started to pound the bolt out, alternator facing up, as the bolt moved out of the rear hole the rest of the way, of course the alternator, which is heavy, leaned to the side, and the front ear of the bracket snapped off.

The bolt was still stuck in the alternator hole, because of the casting seam it is galled, not rusted (aluminum doesn't rust, just oxidizes).

Got the bolt out, reamed the hole in the alternator and re-used it.

Luckily I had another bracket.

Started to move the alternator back-and-forth as much as possible in the arc allowed.

Was finally able to thread the bolt out of it's mount, fighting it every single

revolution.

Then the bolt was just stuck, in the hole, no longer threaded, but still at the edge of the threads in back hole.

Took bracket and alternator off together, laid them on floor, and supported the stress points, except...

Using a long punch started to pound the bolt out, alternator facing up, as the bolt moved out of the rear hole the rest of the way, of course the alternator, which is heavy, leaned to the side, and the front ear of the bracket snapped off.

The bolt was still stuck in the alternator hole, because of the casting seam it is galled, not rusted (aluminum doesn't rust, just oxidizes).

Got the bolt out, reamed the hole in the alternator and re-used it.

Luckily I had another bracket.

#14

#15

Thread

Thread Starter

Forum

Replies

Last Post

Duramaxfanatic1

1987 - 1996 F150 & Larger F-Series Trucks

1

01-01-2011 11:15 AM

JoeTaco1

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

2

06-21-2010 09:06 PM

So I have to rely on being able to purchase one another way.

So I have to rely on being able to purchase one another way.