Where do you buy your torque wrench? Torque wrench tips.

#4

Nice post! The parts about about where you hold the wrench and using extensions and crow's feet were demonstrated well.

We have an analog tester at work and I've taken mine in a few times to check em out. My torque wrenches are from Snap-on, Craftsman, and Kobalt. I also still have the first torque wench I ever bought, a no-name beam type. A couple of years ago, I bought a short handled "made in Taiwan" torque wrench from the parts store. Very cheap. It tested all over the place (low on the bottom end-high on the top) almost useless.

Just a few observations on the subject though. Sometimes it's more important that all the fasteners on the same part be the same tightness than what that tightness actually is. Meaning even a known inaccurate torque wrench can have some value. On my job, if a torque wrench is dropped more than two feet it's tagged and sent to the calibration lab. Take care with yours and try not to bang them around. If you're using self-locking fasteners, you have to measure the run-down torque and add that to the specified value. And don't forget, any lube can make big changes the working torque, be sure to install fasteners as per the instructions.

We have an analog tester at work and I've taken mine in a few times to check em out. My torque wrenches are from Snap-on, Craftsman, and Kobalt. I also still have the first torque wench I ever bought, a no-name beam type. A couple of years ago, I bought a short handled "made in Taiwan" torque wrench from the parts store. Very cheap. It tested all over the place (low on the bottom end-high on the top) almost useless.

Just a few observations on the subject though. Sometimes it's more important that all the fasteners on the same part be the same tightness than what that tightness actually is. Meaning even a known inaccurate torque wrench can have some value. On my job, if a torque wrench is dropped more than two feet it's tagged and sent to the calibration lab. Take care with yours and try not to bang them around. If you're using self-locking fasteners, you have to measure the run-down torque and add that to the specified value. And don't forget, any lube can make big changes the working torque, be sure to install fasteners as per the instructions.

#5

Nice post! The parts about about where you hold the wrench and using extensions and crow's feet were demonstrated well.

We have an analog tester at work and I've taken mine in a few times to check em out. My torque wrenches are from Snap-on, Craftsman, and Kobalt. I also still have the first torque wench I ever bought, a no-name beam type. A couple of years ago, I bought a short handled "made in Taiwan" torque wrench from the parts store. Very cheap. It tested all over the place (low on the bottom end-high on the top) almost useless.

Just a few observations on the subject though. Sometimes it's more important that all the fasteners on the same part be the same tightness than what that tightness actually is. Meaning even a known inaccurate torque wrench can have some value. On my job, if a torque wrench is dropped more than two feet it's tagged and sent to the calibration lab. Take care with yours and try not to bang them around. If you're using self-locking fasteners, you have to measure the run-down torque and add that to the specified value. And don't forget, any lube can make big changes the working torque, be sure to install fasteners as per the instructions.

We have an analog tester at work and I've taken mine in a few times to check em out. My torque wrenches are from Snap-on, Craftsman, and Kobalt. I also still have the first torque wench I ever bought, a no-name beam type. A couple of years ago, I bought a short handled "made in Taiwan" torque wrench from the parts store. Very cheap. It tested all over the place (low on the bottom end-high on the top) almost useless.

Just a few observations on the subject though. Sometimes it's more important that all the fasteners on the same part be the same tightness than what that tightness actually is. Meaning even a known inaccurate torque wrench can have some value. On my job, if a torque wrench is dropped more than two feet it's tagged and sent to the calibration lab. Take care with yours and try not to bang them around. If you're using self-locking fasteners, you have to measure the run-down torque and add that to the specified value. And don't forget, any lube can make big changes the working torque, be sure to install fasteners as per the instructions.

Your very correct about dropped torque wrenches. Engine turbine cases are a good

example on the final torque of a lock fitting. You have to know what the drag of the

faster is and account for that in the final torque. Always fun when you have 20 little

nuts to put on all the way around the case. Nothing worse that R&R a hot section

installed in the aircraft. Man is not built like Gumby. Some times it just has to come

out and that is where getting paid by the Hour is nice. Nothing like dropping parts.

They must be found. It's not an option.

I take mine back to the school every now and then to verify the calibration on the tester.

It's one of the beam weight type and is calibrated at least once a year.

And it a good one from Mac tools if I recall correctly.

Sean <BR>

6.0L Tech Folder

#7

I just bought two torque wrenches last month doing the turbo cleaning and such. I bought them from Home Depot. The Husky brand. One is a 1/4" 40-200 In/Lbs and the other is a 3/8" drive 20-100 Ft/Lbs.

I know they are not the best, but I have heard good things about them not being far off from spec. I paid around $70-$75 for each one.

I handle them like carrying eggs, very csrefully. And I always reset back to zero when done.

I know they are not the best, but I have heard good things about them not being far off from spec. I paid around $70-$75 for each one.

I handle them like carrying eggs, very csrefully. And I always reset back to zero when done.

Trending Topics

#10

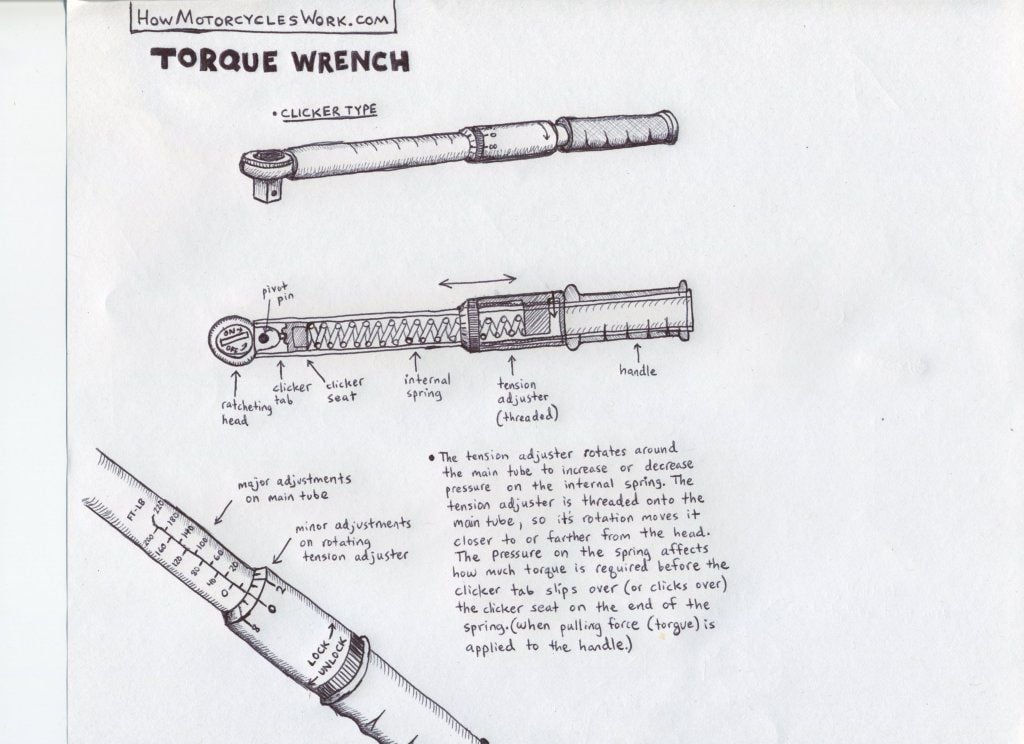

BTW here are some how they work images

Here are the guts of a click type

Here is a short description on how they work.

Two words to keep in mind when dealing with any tool that measures and they are Accuracy and Repeatability and that can lead

you off onto other tangents like error factor.

I also looked to see if I could find a drawing of an electronic torque wrench and did not really find much worth posting.

To put is simply you have a load cell and some display/control circuitry. They can be simpler with less things like springs

and pivots to create errors with. But they can still be made just too cheap to be reliable and they may not like getting

wet with solvents,oils,water and other chemicals.

If you stick to name brands then you are fairly safe.

Things I would trust are Snap On, CDI, Bluepoint, Mac, Matco, Armstrong, Proto/Stanley, Craftsman and that is just the SHORT list.

There are other good ones out there. It's the dirt cheap stuff that no ones ever heard of that I would avoid. If in doubt

google it and see what you can find that way.

Sean <BR>

6.0L Tech Folder

#11

Funny you brought this up Sean. Good timing I would say.

I recently tested my Craftsman 1/2" Made in USA wrench and it is right on the money. Allowable factor is within 3%. It is several years old and always reset to zero. I have a 3/8" Craftsman that I need to retest as the tester was off.

I recently tested my Craftsman 1/2" Made in USA wrench and it is right on the money. Allowable factor is within 3%. It is several years old and always reset to zero. I have a 3/8" Craftsman that I need to retest as the tester was off.

#12

For $10 what could go wrong.

1/2" Torque Wrench

Anybody here willing to admit they used one of these when studding a 6.0 and then have the head gaskets fail again? Torque accuracy is critical on the 6.0 due to the number bolts to keep the load spread evenly across all the bolts.

1/2" Torque Wrench

Anybody here willing to admit they used one of these when studding a 6.0 and then have the head gaskets fail again? Torque accuracy is critical on the 6.0 due to the number bolts to keep the load spread evenly across all the bolts.

#13

I bought the $10 Harbor Freight wrench. But to tell you the truth, I never used a torque in my life until the 6.0. I figured the $10 version was better than guessing all these years. I don't do any major repairs. However, I am going to shell out some good coin and get a real torque wrench as I want to start going deeper inside my 6.0.

Most of my repairs are preventative maintenance like brakes, wheel bearings, ball joints, starters.

Most of my repairs are preventative maintenance like brakes, wheel bearings, ball joints, starters.

#14

The quality of the torque wrench is important, but friction will throw that actual amount of faster load more than a faulty touque wrench. Good quality lubrication can drop the amount of torque required by 50% to achieve the same faster load. That is where torque then turn tightening works better. Same thing when using a stretch gage.

There are so meny variables when using a torque wrench , and as the torque goes up the amount of the twisting motion used up by friction to where over 70% of it is needed to overcome friction.

There are so meny variables when using a torque wrench , and as the torque goes up the amount of the twisting motion used up by friction to where over 70% of it is needed to overcome friction.

#15

I've not tested my torque wrenches since purchasing, but I always promptly put them back to the lowest settings after use and they have relatively few cycles on them as a DIY'er. I have one Craftsman for the inch-lb ranges and three Proto torque wrenches covering from low settings all the way up to 250 lb-ft. Those are some nice diagrams/pics Yahiko. Thanks for posting them. It seems like most write-ups on DIY calibration are really only calibration checks, but omit any actual calibration adjustments if the checks turn out to be too far off.