If you had 30 minutes with a body design engineer what would you ask?

#1

#3

#4

With me I can understand the primary benefit (or at least the one they like to publicly push) on weight savings. Others include cost savings by sharing common cab production with the F150 and more importantly to me reducing or eliminating corrosion.

My current truck is a rust bucket and I'm not alone in struggling with this problem. My questions would be how much thought did they give corrosion prevention in the design and selection of materials? Did they did give a thought to how those choices hold up 10, 15, 20 years down the line?

I know aluminum will hold up way better than the steel but it's not infallible if bad designs and/or materials are used.

My current truck is a rust bucket and I'm not alone in struggling with this problem. My questions would be how much thought did they give corrosion prevention in the design and selection of materials? Did they did give a thought to how those choices hold up 10, 15, 20 years down the line?

I know aluminum will hold up way better than the steel but it's not infallible if bad designs and/or materials are used.

#7

I would ask if, and how, the new cabs were designed for occupant protection in rollovers, where the weight of the heavier Super Duty frame and drivetrain is disproportionately heavier than the cab greenhouse... in a ratio that is quite different than aluminum space frame cars.

Cab crush kills.

Evidence abounds of this fact, and independent testing has shown that strategic reinforcements at the window sill and roof joints of the A, B, and C pillars can greatly reduce the severity of pillar joint deformation on rollovers, and thereby increase the chance of survivability in those type of bottom heavy crashes.

I'd ask the designers to explain if, and how, the new cab, regardless of what material it is made with, was engineered to improve cab crush performance over the current Super Duty cab. For example, I might ask if inlaid doors (doors that nest into the cab, as opposed to doors that close over the cab) augment the rigidity of the green house under the weight of the chassis. I would ask how the self piercing rivets and the adhesive bonding attachment methods used for aluminum keep the cab together during a rollover, as opposed to the current robotic welded cabs. That kind of thing.

And, I'd ask the designers if they've grown bored with 45 degree angle themed design details yet.

Cab crush kills.

Evidence abounds of this fact, and independent testing has shown that strategic reinforcements at the window sill and roof joints of the A, B, and C pillars can greatly reduce the severity of pillar joint deformation on rollovers, and thereby increase the chance of survivability in those type of bottom heavy crashes.

I'd ask the designers to explain if, and how, the new cab, regardless of what material it is made with, was engineered to improve cab crush performance over the current Super Duty cab. For example, I might ask if inlaid doors (doors that nest into the cab, as opposed to doors that close over the cab) augment the rigidity of the green house under the weight of the chassis. I would ask how the self piercing rivets and the adhesive bonding attachment methods used for aluminum keep the cab together during a rollover, as opposed to the current robotic welded cabs. That kind of thing.

And, I'd ask the designers if they've grown bored with 45 degree angle themed design details yet.

Trending Topics

#9

#11

If Ford addresses the perceived concern, that would certainly help counter propagandize GM's recent big-bear-pick-a-safety-cage video.

(GM released a big bear into a room that had a regular joe truck customer inside. There were two safety cages in the room, one made of aluminum, one made of steel, and they filmed the regular joe's knee jerk reaction picking the cage he wanted to remain safe from the bear in. In this manner, GM promotes their current trucks by propagating the suggestion that aluminum is weaker, without creating a history of being a hypocritical marketer when and if GM eventually switches to aluminum, because the regular joe is the one who picked the cage. The age old trick of making a suggestion... without suggesting).

If Ford achieves better actual cab safety cage performance in roof crush protection, plastic and all, when the Super Duty rolls or lands upside down, then that would help allay the real concerns.

The Super Duty's frame, diesel engine, 6R140 transmission, Sterling and Dana axles, brake rotors and hubs... all weigh significantly more than the chassis equipment under the F150. So while the F150's testing results might be indicative, they are not definitive as to how the Super Duty might perform under the same testing conditions.

78_f800crewcab4x4... now you have a crew cab '60 dually? What a fleet! If a bear rumbled into a room, I'm jumping into one of YOUR trucks!

(GM released a big bear into a room that had a regular joe truck customer inside. There were two safety cages in the room, one made of aluminum, one made of steel, and they filmed the regular joe's knee jerk reaction picking the cage he wanted to remain safe from the bear in. In this manner, GM promotes their current trucks by propagating the suggestion that aluminum is weaker, without creating a history of being a hypocritical marketer when and if GM eventually switches to aluminum, because the regular joe is the one who picked the cage. The age old trick of making a suggestion... without suggesting).

If Ford achieves better actual cab safety cage performance in roof crush protection, plastic and all, when the Super Duty rolls or lands upside down, then that would help allay the real concerns.

The Super Duty's frame, diesel engine, 6R140 transmission, Sterling and Dana axles, brake rotors and hubs... all weigh significantly more than the chassis equipment under the F150. So while the F150's testing results might be indicative, they are not definitive as to how the Super Duty might perform under the same testing conditions.

78_f800crewcab4x4... now you have a crew cab '60 dually? What a fleet! If a bear rumbled into a room, I'm jumping into one of YOUR trucks!

#12

I watched that commercial. I thought that Ford will need to counteract the propaganda. When most people think of when they hear aluminum is a soda/pop/beer can, weak, flexible, easily crushable; not something that can be made stronger and lighter than steel. It's good marketing by GM, for now.

As far as the roll-over that is a good subject. I hope manufacturers consider this when designing Class II and up trucks now a days.

As far as the roll-over that is a good subject. I hope manufacturers consider this when designing Class II and up trucks now a days.

#13

Another question I would put to the body designers, if they didn't kick me out of the room after 3 minutes, let alone 30, is this:

If the new Super Duty boxed frame is "24 times stiffer" than the outgoing frame it replaces, how does that increased stiffness impact the body structure?

From mild but constant cyclical stress such when jiggling down the road, to wild single event dramatic stress, such as when undulating through a ditch where the amplitude of the suspension has reached it's limit.

What "gives" then?

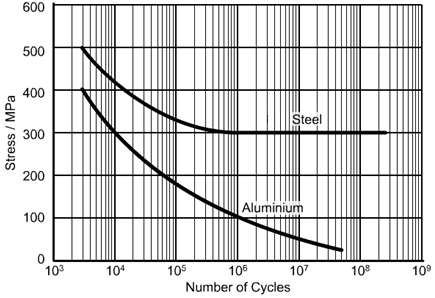

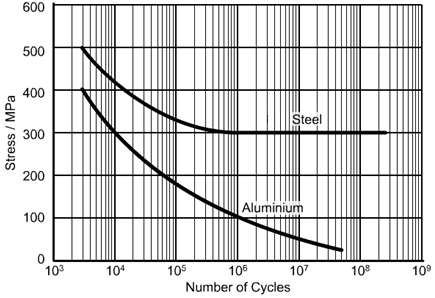

Here's a quick collection of similar diagrams from a variety of sources that illustrate the commonly known difference in fatigue endurance between steel and aluminum:

A is steel. B is aluminum.

You get the idea. Aluminum does not level at a fatigue limit plateau. Each cycle of bending stress continues to tear away at it's ability to stay together.

This is NOT to argue that aluminum is a poor choice of material to make a truck cab out of. This is simply part of the question that I'd ask of the designers, which is how does the stiffer frame impact the body structure.

Does the stiffer frame help insulate the aluminum body from cyclical road jiggling? Or does the stiffer frame transmit the road jiggling to the body?

I once had a chance to have a conversation with the designer of my utility body. He made a very big deal about how the body was skip welded, rather than seam welded, in order to allow for some ductility in the body without inducing stress risers or fatigue to the panels. And this is a comparatively heavy gauge steel body.

From that perspective, I would want to know more about how Ford's design team considered these issues (because of course they did), and I'd want to know more details about these considerations so that any concerns I might have about long term durability could be put to bed.

If the new Super Duty boxed frame is "24 times stiffer" than the outgoing frame it replaces, how does that increased stiffness impact the body structure?

From mild but constant cyclical stress such when jiggling down the road, to wild single event dramatic stress, such as when undulating through a ditch where the amplitude of the suspension has reached it's limit.

What "gives" then?

Here's a quick collection of similar diagrams from a variety of sources that illustrate the commonly known difference in fatigue endurance between steel and aluminum:

A is steel. B is aluminum.

You get the idea. Aluminum does not level at a fatigue limit plateau. Each cycle of bending stress continues to tear away at it's ability to stay together.

This is NOT to argue that aluminum is a poor choice of material to make a truck cab out of. This is simply part of the question that I'd ask of the designers, which is how does the stiffer frame impact the body structure.

Does the stiffer frame help insulate the aluminum body from cyclical road jiggling? Or does the stiffer frame transmit the road jiggling to the body?

I once had a chance to have a conversation with the designer of my utility body. He made a very big deal about how the body was skip welded, rather than seam welded, in order to allow for some ductility in the body without inducing stress risers or fatigue to the panels. And this is a comparatively heavy gauge steel body.

From that perspective, I would want to know more about how Ford's design team considered these issues (because of course they did), and I'd want to know more details about these considerations so that any concerns I might have about long term durability could be put to bed.

#14

That's the only part of the question I can answer.

#15