need advice on dashpot install

#1

need advice on dashpot install

I found a new motorcraft Dashpot & SOLENOID ASSEMBLY for 11bucks..

Since I did the DSII conversion on my 85 e150, I have not swapped the carb out yet. My feedback carb has an electric high idle solenoid and no dashpot... When I do swap out the carb should I use a dashpot or the electric solenoid?

Thanks Anna

Since I did the DSII conversion on my 85 e150, I have not swapped the carb out yet. My feedback carb has an electric high idle solenoid and no dashpot... When I do swap out the carb should I use a dashpot or the electric solenoid?

Thanks Anna

#2

#3

I looked up both the 300 six and the 5.0, and both throttle actuators are controlled by the computer. So they are not going to work if you take the computer system out.

You really don't need one at all unless you have a stalling problem when goosing the throttle with it in drive. If you have A/C you can fudge the idle speed up a little bit if it becomes a problem with the A/C on and the idle is a little too slow.

You really don't need one at all unless you have a stalling problem when goosing the throttle with it in drive. If you have A/C you can fudge the idle speed up a little bit if it becomes a problem with the A/C on and the idle is a little too slow.

#4

I found a new motorcraft Dashpot & SOLENOID ASSEMBLY for 11bucks..

Since I did the DSII conversion on my 85 e150, I have not swapped the carb out yet. My feedback carb has an electric high idle solenoid and no dashpot... When I do swap out the carb should I use a dashpot or the electric solenoid?

Thanks Anna

Since I did the DSII conversion on my 85 e150, I have not swapped the carb out yet. My feedback carb has an electric high idle solenoid and no dashpot... When I do swap out the carb should I use a dashpot or the electric solenoid?

Thanks Anna

A lot of people throw these away but they do serve a useful purpose. Although they are not totally necessary, having a solepot in place and working will prevent your engine from stalling under certain conditions and will allow you to run a lower idle speed if you have air conditioning.

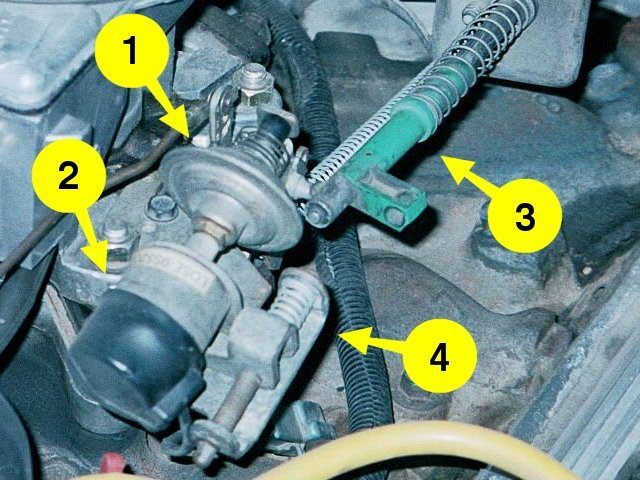

The purpose of the dashpot (1) function is to make the throttle plates close slowly instead of slamming shut. This is better for emissions and will prevent the engine from stalling if you have an automatic transmission and you suddenly let your foot off the gas.

The idle solenoid (2) function is typically used as a throttle kicker to increase the engine idle when the load of the air conditioning compressor slows the idle down. The idle solenoid is wired into the air conditioning switch on the accumulator. When the compressor turns on, it also activates the idle solenoid. A little plunger will extend to chock the throttle lever on the carburetor just enough to keep your idle at the same RPM as it was previously set without the extra load of the compressor.

Capiche?

#5

Thanks

Yes I do have AC (not working at the moment) so I don't know how it will work right now.. I was hoping to keep the idle down ( i guess really not so important though).

I was looking at the one for the 1983 5.0..

When I reworked my DSII harness I left a couple of extra wires in the harness, one has the matching male connector that matches this dashpot solenoid connector and it has constant power whenever the ignition switch is in the run position.

If I decide to install this dashpot I was thinking i could install a relay switched by the compressor clutch circuit and use the extra constant power lead in the DSII harness to power the dashpot..

What are your thoughts about that?

I could probably use the existing idle solenoid to do that.. The one in the RA link if i am correct ha the electric solenoid and (not sure what the proper name is,,, dashpot duh,, ) If i understand correctly the dashpot, when you let off the throttle, keeps it from instantly dropping to the lowest idle?

https://www.rockauto.com/catalog/raf...ktemplate=true

Yes I do have AC (not working at the moment) so I don't know how it will work right now.. I was hoping to keep the idle down ( i guess really not so important though).

I was looking at the one for the 1983 5.0..

When I reworked my DSII harness I left a couple of extra wires in the harness, one has the matching male connector that matches this dashpot solenoid connector and it has constant power whenever the ignition switch is in the run position.

If I decide to install this dashpot I was thinking i could install a relay switched by the compressor clutch circuit and use the extra constant power lead in the DSII harness to power the dashpot..

What are your thoughts about that?

I could probably use the existing idle solenoid to do that.. The one in the RA link if i am correct ha the electric solenoid and (not sure what the proper name is,,, dashpot duh,, ) If i understand correctly the dashpot, when you let off the throttle, keeps it from instantly dropping to the lowest idle?

https://www.rockauto.com/catalog/raf...ktemplate=true

#6

Just saw your post after i posted my reply..

Thank you Lariat! yes I Capiche!

The existing kicker on my feedback carb, if I remember correctly, does not have the dashpot, only the kicker solenoid..

So if i wire in the kicker, i need to just switch it off the AC accumulator.. Do you think I should put in a relay or run it directly off the accumulator switch?

Thanks Anna

Thank you Lariat! yes I Capiche!

The existing kicker on my feedback carb, if I remember correctly, does not have the dashpot, only the kicker solenoid..

So if i wire in the kicker, i need to just switch it off the AC accumulator.. Do you think I should put in a relay or run it directly off the accumulator switch?

Thanks Anna

#7

Originally Posted by annaleigh

So if i wire in the kicker, i need to just switch it off the AC accumulator.. Do you think I should put in a relay or run it directly off the accumulator switch?

The dashpot is strictly a mechanical device; no power is needed. You adjust it by turning the screw (4) in the diagram I posted above.

Trending Topics

#8

Now i am confused... (nothing new)

Franklin said: “I looked up both the 300 six and the 5.0, and both throttle actuators are controlled by the computer. So they are not going to work if you take the computer system out.”

You say: “Run the solepot directly off the A/C accumulator, just like Ford did it. You should have a wire already there.”

I guessed like Franklin said, the computer activates the throttle actuator.. When you shift to drive the engine throttle kicker raises the idle. I know when you turn on the AC it is supposed to also, but since the AC is not working I have never noticed.

Are you saying that the wiring should already be in the harness regardless of wither it has a eec or not?

Thanks Anna

Franklin said: “I looked up both the 300 six and the 5.0, and both throttle actuators are controlled by the computer. So they are not going to work if you take the computer system out.”

You say: “Run the solepot directly off the A/C accumulator, just like Ford did it. You should have a wire already there.”

I guessed like Franklin said, the computer activates the throttle actuator.. When you shift to drive the engine throttle kicker raises the idle. I know when you turn on the AC it is supposed to also, but since the AC is not working I have never noticed.

Are you saying that the wiring should already be in the harness regardless of wither it has a eec or not?

Thanks Anna

#9

There may be a plug in the A/C wiring where the different non-EEC engine harness plugs in. So you will have to run the wire, you just may find a spot already there to put the end of the wire(you probably won't have the official ford plug-in for it).

As they put more computerized stuff on the trucks, they were able to do more things. I am not sure if they had it on these EEC trucks, but at some time they also added a relay in series with the A/C clutch circuit. With the computer they now know when the throttle is wide open. So they let the computer signal a relay to turn the A/C clutch off to give you a little more oomph when the throttle goes wide open.

That would all the part of the different EEC harness.

As they put more computerized stuff on the trucks, they were able to do more things. I am not sure if they had it on these EEC trucks, but at some time they also added a relay in series with the A/C clutch circuit. With the computer they now know when the throttle is wide open. So they let the computer signal a relay to turn the A/C clutch off to give you a little more oomph when the throttle goes wide open.

That would all the part of the different EEC harness.

#10

Thanks for the help.. I have a pretty good understanding now ,, I think!!

I have a lot of ford connectors laying around now since I pulled out 3 different harnesses trying to find a DSII harness for my van. One of them has connectors all the way to the headlights!

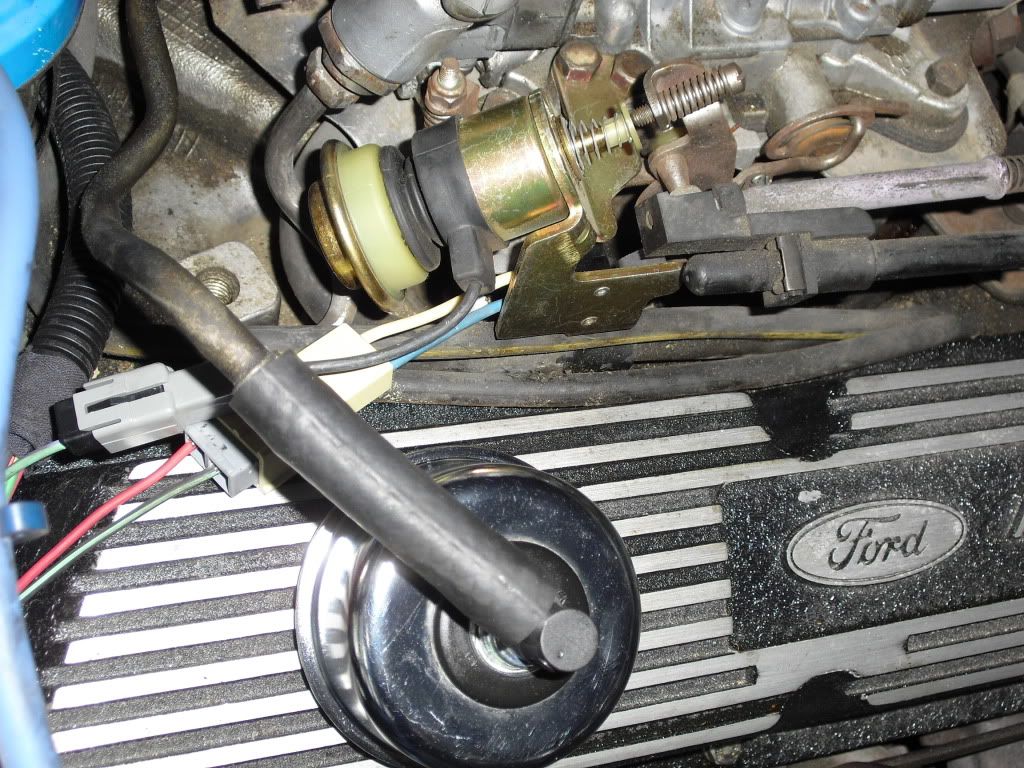

SO now i am thinking about a WOT AC cutout. The pic below shows one mounted on the side of the dashpot/throttle kicker.. one would need a AC cutout relay and switch to break the circuit when you were at WOT

thats a project for another day though!!

<a href="http://s451.photobucket.com/user/escogt/media/Parts/Motorsportparts019.jpg.html" target="_blank"><img src="http://i451.photobucket.com/albums/qq231/escogt/Parts/Motorsportparts019.jpg" border="0" alt=" photo Motorsportparts019.jpg"/></a>

I have a lot of ford connectors laying around now since I pulled out 3 different harnesses trying to find a DSII harness for my van. One of them has connectors all the way to the headlights!

SO now i am thinking about a WOT AC cutout. The pic below shows one mounted on the side of the dashpot/throttle kicker.. one would need a AC cutout relay and switch to break the circuit when you were at WOT

thats a project for another day though!!

<a href="http://s451.photobucket.com/user/escogt/media/Parts/Motorsportparts019.jpg.html" target="_blank"><img src="http://i451.photobucket.com/albums/qq231/escogt/Parts/Motorsportparts019.jpg" border="0" alt=" photo Motorsportparts019.jpg"/></a>

#11

Originally Posted by annaleigh

I guessed like Franklin said, the computer activates the throttle actuator.. When you shift to drive the engine throttle kicker raises the idle. I know when you turn on the AC it is supposed to also, but since the AC is not working I have never noticed.

Originally Posted by annaleigh

Are you saying that the wiring should already be in the harness regardless of wither it has a eec or not?

My own EEC-IV equipped truck was pretty hacked up when I took possession of it, but I don't *think* the engine computer activated the throttle kicker. I found a cut black wire that was part of the A/C accumulator and spliced the solepot directly into that. This is how it was hooked up on the older Duraspark trucks. This will make the throttle solenoid kick up the throttle lever when the compressor is turned on to raise the RPMs a little to compensate for the load of the A/C compressor. My EEC-IV computer is long gone, and the solepot works perfectly fine like this.

Originally Posted by Franklin2

As they put more computerized stuff on the trucks, they were able to do more things. I am not sure if they had it on these EEC trucks, but at some time they also added a relay in series with the A/C clutch circuit. With the computer they now know when the throttle is wide open. So they let the computer signal a relay to turn the A/C clutch off to give you a little more oomph when the throttle goes wide open.

This looks like a Ford Mustang Motorcraft/Holley 4180 with the Mustang solepot. Notice there are two extra wires that the solepot in the picture I posted above doesn't have. That is the wiring for the WOT cutoff switch.

#12

here's a pic where you can see the switch

Airtex 3H1069 Idle Air Shutoff Solenoid

#13

Do you think having a WOT relay would help with my van? As it is quite heavy and not a race car, I seldom wold be mashing the gas down all the way.. What I am thinking about is like when on the interstate and going up long uphill grades in even without the AC working now, I find it is better to pull the shifter down into drive. If I keep it in OD I have to keep the peddle mashed all the way down to maintain speed. If I drop it into drive I have to let off the gas and can maintain speed or pick up speed if needed. Perhaps that will change once I get it all set up correct. But what if I installed a AC cutout used when the throttle is over 3/4 way opened?

Re-gearing your rear axle to a lower (higher numerically) gear will definitely help.

What is your current rear axle gear?

#14

302 engine with AOD transmission.

The brief time i have driven it when not down for maintenance, I filled it up and drove about 100 miles on the interstate and once back home filled it up again. I was getting 18MPG when dropping it down in drive going up hills.

A while back when checking the engine compression it was 165 on all cylinders give or take a couple of points. That was dry, or without any oil in the cylinders and the engine was cold..

Right now it is down due to fuel problems. I am going to replace the tank, sending unit, rubber hoses, and what ever else I find old or bad in the fuel system. IT has been too hot for me to work outside the last month or so..

Speaking of the rear axle.., It is a 9" and I had removed the axles to replace bearings. I also removed the differential itself from the housing without taking the yoke off or any disassembly of the differential so I could clean the housing. Before I did that work there was a vibration and after the work there was still a vibration around 45 maybe 50 mph to 60 mph then it goes away. The vibration feels like it is coming from the front between the seats and into the floorboard, not in the steering wheel.

All U-joints and the center bearing carrier were replaced. Could a pinion bearing vibration travel up front an not be felt in the rear of the van?

I remember while I had it up on stands that revving it all the way up to 70 or 80mph the only vibration seemed to be when letting off the gas but I didnt pay attention to what speed that was.. i will have it up again soon to do the fuel tank and will pay closer attention... When driving the vibration happens wither giving it gas or not...

I was going to check it out more when driving but only drove it a very short time after the DSII swap before it acted like it was out of gas. We got it home using a gas can and hose inside the van. We were only 3 miles from home!

Thread

Thread Starter

Forum

Replies

Last Post

Trubl4U83

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

2

07-25-2003 01:21 PM