Input Needed: Inverter/Amp install

#1

Input Needed: Inverter/Amp install

This all applies to a 2000 Excursion V10...

So I am getting ready to install a few amps and an invereter (2300 watt). I built a storage box with a pull out drawer for the back (removed the third row seat: Ford Truck Enthusiasts Forums - View Single Post - Input needed - rear storage box) and I would like to mount the inverter to the front face of the box (and maybe the amps as well).

I have a Phoenix Gold 200w circuit breaker that I was going to mount under the hood near the battery, the try to run my power cable through the passenger side floorboards to behind the 2nd row seats. I have a Kinetic 600 cap batt from my old Expedition that I used to keep the lights from dimming while the stereo was on.

Now, in my Expy I didn't have a large inverter (it was only a 300 watt). I need some input as to wiring sequence and anything to look out for.

The amps I have are a Phoenix Gold Ryval 2 channel (800w I think) and two older Kenwood 2 x 100 amps (for front and rear doors).

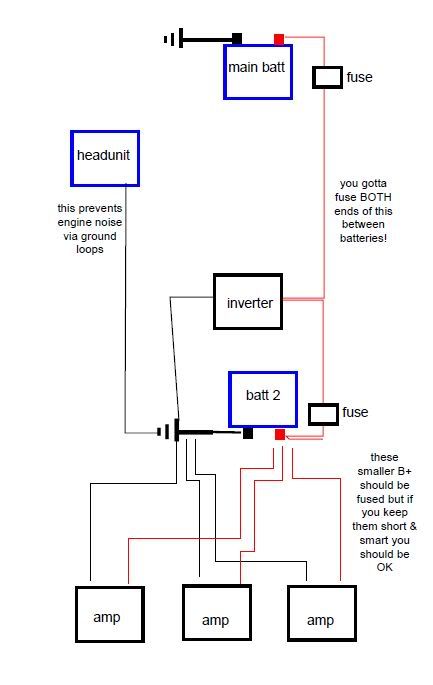

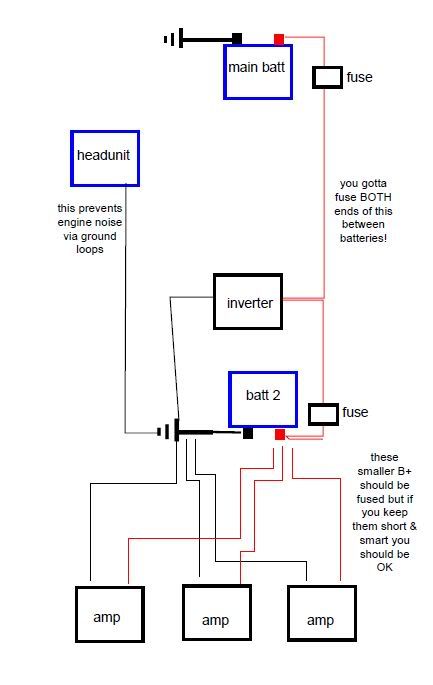

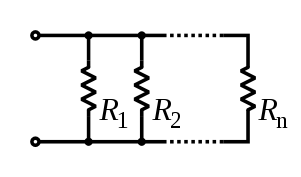

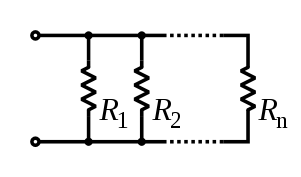

I was thinking I should put in a junction and run only the amps through the Kinetic since they will be the items requiring power "right now" and the inverter will only be needed when I'm at a scene (the truck pulls a FD search and rescue trailer). I will put up a rough sketch later, but does anyone have any thoughts on how they would do something like this?

So I am getting ready to install a few amps and an invereter (2300 watt). I built a storage box with a pull out drawer for the back (removed the third row seat: Ford Truck Enthusiasts Forums - View Single Post - Input needed - rear storage box) and I would like to mount the inverter to the front face of the box (and maybe the amps as well).

I have a Phoenix Gold 200w circuit breaker that I was going to mount under the hood near the battery, the try to run my power cable through the passenger side floorboards to behind the 2nd row seats. I have a Kinetic 600 cap batt from my old Expedition that I used to keep the lights from dimming while the stereo was on.

Now, in my Expy I didn't have a large inverter (it was only a 300 watt). I need some input as to wiring sequence and anything to look out for.

The amps I have are a Phoenix Gold Ryval 2 channel (800w I think) and two older Kenwood 2 x 100 amps (for front and rear doors).

I was thinking I should put in a junction and run only the amps through the Kinetic since they will be the items requiring power "right now" and the inverter will only be needed when I'm at a scene (the truck pulls a FD search and rescue trailer). I will put up a rough sketch later, but does anyone have any thoughts on how they would do something like this?

#3

What's that, about 400# of gear you're hauling around? Reminds me of my SAR days, 'cept it was all ultralight backcountry stuff usually. I imagine things are a little different in Sacremento than in CO. Still the trunk was always jammed full with rubbermaid bins

The space between the spare & the box, mounted to the side of the box looks good to me. Two big issues are cable management & cooling. Those PG's will kick out some heat if you puch them for sure. So will that big inverter.

If it were me I'd extend the top of the box towards the left & mount electronics on the left side of the box beneath the overhanging top. That keeps crap from falling down in there but it's still open enough to vent.

The wiring scheme looks fine assuming you're using at least 1/0 for the big run. You'll want to fuse after distro 1 if the inverter B+ wires are smaller, also fusing next to battery 2 since current could flow either way.

You'll want a switch for the inverter if it doesn't have on/off, it'll draw current with nothing plugged in otherwise.

How's your alternator? Might have to upgrade.

The space between the spare & the box, mounted to the side of the box looks good to me. Two big issues are cable management & cooling. Those PG's will kick out some heat if you puch them for sure. So will that big inverter.

If it were me I'd extend the top of the box towards the left & mount electronics on the left side of the box beneath the overhanging top. That keeps crap from falling down in there but it's still open enough to vent.

The wiring scheme looks fine assuming you're using at least 1/0 for the big run. You'll want to fuse after distro 1 if the inverter B+ wires are smaller, also fusing next to battery 2 since current could flow either way.

You'll want a switch for the inverter if it doesn't have on/off, it'll draw current with nothing plugged in otherwise.

How's your alternator? Might have to upgrade.

#5

It's a new main batt 1000 CCA, but methinks a new HO alternator is on the "to-do" list.

#6

Yes, bought out a local welding supply store today (25' of 0/1 - might not be enough). After reading the inverter specs, (suggests 2ga up to 6 feet, bigger if farther) I think I need to run both the hot and ground of the inverter to the main battery direct...I don't think my OEM battery ground can handle all of the inverter ground and the engine ground. The inverter is 2300 watts run, 4600 peak, so that dinky 200watt circuit breaker isn't going to work. I'll use that between the Kinetic and the sub amps I think.

I had the same thought about a flip-top deck above amps on left. If they're mounted closer to the bottom I bet there'd be sufficient room to angle the tire inward & lift up. Or just deflate it, perfect

I think you'll really want the inverter mounted for access when standing at the rear, it's dummy-proof for anyone needing a plug during an incident. Where's the battery go? And the big question, what are you powering with the 2 big sub amps? 1600w of subs take up much more space than the equipment.

About wiring, you're looking at 160a run & 320a peak at 14v for the inverter alone. distance to battery is important here so let's figure that out first: Dx from battery to battery & Dx from inverter to battery. Wiring the inverter to the aux battery is fine as long as it's linked to the charging system sufficiently & I think a 25' run of 1/0 might be enough. A 250a breaker between batteries should be enough, it can pulse substantially higher before tripping. Check RV stores for big breakers, or Darvex.com maybe.

The big ?? tho is what's the rest of the audio system plan? That's going to determine the trunk layout more than anything else. I personally think you should use a single PG amp driving a single 12" or 15" sub glassed into the spare tire area (yes, lose the spare completely in favor of a tire repair kit, a small compressor & 2 cans of Slime). Then build the flip-top cover, mount all electronics under it on the left with inverter being in the rear for easy access. There'd be plenty of ventilation so no need for fans.

But that's just me

#7

I'll try to answer your questions, but probably not in the same order.

The idea was to run one of those short power strips to the inverter behind the passenger side bulkhead. During an incident I'd probably need it for laptop charging and radio charging...a tiny chance for spotlights (but we carry both rechargable LED floodlights on our trailers as well as generators). It would mostly be for the laptops/radio chargers, so running a short power strip shouldn't tax it too much.

I initially did want stuff on the left, but between the tire issue and the additional power lead run I'd need, I thought the area behind the 2nd row was best...ventilation, shorter power lead runs and I could deal with the spare later. Plus, if I put that stuff on the side, my maps would go to the footwell area - further away from operations out of the rear of the truck. I'd still also need to run something to get the 110 to the 2nd row, so either way I'd have to run a short power strip or the like. Figured I'd save the $3 a foot to run the extra power lead when the power strips are so much cheaper.

I'm starting to re-think it a little bit...mainly because of your statement about using the inverter separate from the amps. That will be the case 90% of the time, and when I do use both - it wouldn't be on a call, it would be when say driving to Tucson to visit family. The types of things I'd use it for would be laptops or the like. I don't think powering up a laptop or recharging it would push anything over the limit - with Sgt. Major Wifee in the truck the amps would be down low (I only rock out when driving solo).

My rethink is with that big of an inverter, I don't think I should split the leads. I bought another 25' of 1/0 today. When I ran the ground run yesterday, I'd say I have about 6 feet of the 25 left over, so say the run was 19 feet from negative terminal, over the passenger side fenderwell to the passenger footwell area, following the rear heating/ac lines back, then into the truck just behind the 2nd row rear seat mount, then up to the inverter that sits right where the front of the third row seating area is.

With that much of a run, and knowing I wouldn't be running my amp during a deployment. My truck carries myself and a crew of 4, and with the design of the box I can fit a backboarded patient on the driver side, so I'd remove the speakers would be removed for space and weight. So, couldn't I just put additional leads on the inverter for the amps?

The sub amp would wire to the inverter, but I'd flip the cutoff switch (the remote wire) and that should prevent the amp from powering up (but it would be connected to the hot/ground leads). The 1/0 should be more than enough to rock out when I'm rolling around town, and during a call the amp remote would be cut (and in all liklihood the stereo would be turned off alltogether so I could hear the VHF/UHF).

The plan is to upgrade the front and rear door speakers...no more than 100w per. If I can find a good set of separates that will let me put the tweets up on the flat part of the doors I may go that route, but I'm not sure I can aim them right.

I heard there may be speakers at the third row...but not sure if that was an option on the limited. I have the two 100w Kendwoods that will power the front vs rear doors. I currently have the PG Ryval that will push the two 10's in a sealed box. I may upgrade the speakers to 12's but that won't be for a while. I'm not looking for a pounding system, just one that sounds good. I have a Kenwood Excelon deck with a pretty good DSP, so I think that will do me just fine.

So, with the diagram above and the narrative of how I'd be using everything, could I just run leads from the inverter terminals to run the amps off of if I put the Kinetic between the inverter and amps as a 'buffer' against spikes?

I initially did want stuff on the left, but between the tire issue and the additional power lead run I'd need, I thought the area behind the 2nd row was best...ventilation, shorter power lead runs and I could deal with the spare later. Plus, if I put that stuff on the side, my maps would go to the footwell area - further away from operations out of the rear of the truck. I'd still also need to run something to get the 110 to the 2nd row, so either way I'd have to run a short power strip or the like. Figured I'd save the $3 a foot to run the extra power lead when the power strips are so much cheaper.

I'm starting to re-think it a little bit...mainly because of your statement about using the inverter separate from the amps. That will be the case 90% of the time, and when I do use both - it wouldn't be on a call, it would be when say driving to Tucson to visit family. The types of things I'd use it for would be laptops or the like. I don't think powering up a laptop or recharging it would push anything over the limit - with Sgt. Major Wifee in the truck the amps would be down low (I only rock out when driving solo).

My rethink is with that big of an inverter, I don't think I should split the leads. I bought another 25' of 1/0 today. When I ran the ground run yesterday, I'd say I have about 6 feet of the 25 left over, so say the run was 19 feet from negative terminal, over the passenger side fenderwell to the passenger footwell area, following the rear heating/ac lines back, then into the truck just behind the 2nd row rear seat mount, then up to the inverter that sits right where the front of the third row seating area is.

With that much of a run, and knowing I wouldn't be running my amp during a deployment. My truck carries myself and a crew of 4, and with the design of the box I can fit a backboarded patient on the driver side, so I'd remove the speakers would be removed for space and weight. So, couldn't I just put additional leads on the inverter for the amps?

The sub amp would wire to the inverter, but I'd flip the cutoff switch (the remote wire) and that should prevent the amp from powering up (but it would be connected to the hot/ground leads). The 1/0 should be more than enough to rock out when I'm rolling around town, and during a call the amp remote would be cut (and in all liklihood the stereo would be turned off alltogether so I could hear the VHF/UHF).

The plan is to upgrade the front and rear door speakers...no more than 100w per. If I can find a good set of separates that will let me put the tweets up on the flat part of the doors I may go that route, but I'm not sure I can aim them right.

I heard there may be speakers at the third row...but not sure if that was an option on the limited. I have the two 100w Kendwoods that will power the front vs rear doors. I currently have the PG Ryval that will push the two 10's in a sealed box. I may upgrade the speakers to 12's but that won't be for a while. I'm not looking for a pounding system, just one that sounds good. I have a Kenwood Excelon deck with a pretty good DSP, so I think that will do me just fine.

So, with the diagram above and the narrative of how I'd be using everything, could I just run leads from the inverter terminals to run the amps off of if I put the Kinetic between the inverter and amps as a 'buffer' against spikes?

Trending Topics

#9

#10

OK, so let's back way up. I thought you were building some kind of ERV capable of powering extraction tools or something. A 2300w inverter is larger than a 20a home outlet, it's a massive thing that could power an RV. If it's just laptops & radio chargers we're killing flies with a cannon. Which sounds fun except you'll basically have to rebuild the whole electrical system around it. $$$$$

A simple plug-in 400w deal will serve you fine & be so much simpler. Plus you can forget about the extra battery & new alternator. If you really need all this juice, OK, but if y'all have generators on those calls, why bother?

Rethink that piece & we'll figure the wiring from there. If you still want the big inverter it's totally possible.

Either way, running a 1/0 ground from battery to battery doesn't get you anything significant, you're fine with a good chassis ground which you'll have to do anyway with battery 2. And doing a big 3 upgrade should be on your list if it isn't already.

Where are you putting 2 10's without blocking your rearview? In a sealed box it'll be around 1.5 cubic ft. And using both those PG's will result in some serious boom which it doesn't sound like you're after. How about a single 12" with one PG amp? Still, where would that go? What if you slam on the brakes, will it be a missile?

Thoughts on front soundstage - components are great but if you use the upper tweeter mount you'll need time alignment or they'll sound like crap. Does your Kenwood DSP do this? What model? If no, simple solution is to mount tweeter close to woofer or as a coaxial, will sound a world better.

Unless you're going for a quadraphenia-style sound I wouldn't use the other Alpine on the rear spks, just go off the headunit for them - plenty of power there for rear fill. If you really want that surround feel the amp is a good choice. But since the front spks are the audio focal point most people prefer to dial down the rears quite a bit. Personal choice.

Do you use a hardwired mobile radio? Can you run it into a headunit aux input? That sounds like fun

A simple plug-in 400w deal will serve you fine & be so much simpler. Plus you can forget about the extra battery & new alternator. If you really need all this juice, OK, but if y'all have generators on those calls, why bother?

Rethink that piece & we'll figure the wiring from there. If you still want the big inverter it's totally possible.

Either way, running a 1/0 ground from battery to battery doesn't get you anything significant, you're fine with a good chassis ground which you'll have to do anyway with battery 2. And doing a big 3 upgrade should be on your list if it isn't already.

Where are you putting 2 10's without blocking your rearview? In a sealed box it'll be around 1.5 cubic ft. And using both those PG's will result in some serious boom which it doesn't sound like you're after. How about a single 12" with one PG amp? Still, where would that go? What if you slam on the brakes, will it be a missile?

Thoughts on front soundstage - components are great but if you use the upper tweeter mount you'll need time alignment or they'll sound like crap. Does your Kenwood DSP do this? What model? If no, simple solution is to mount tweeter close to woofer or as a coaxial, will sound a world better.

Unless you're going for a quadraphenia-style sound I wouldn't use the other Alpine on the rear spks, just go off the headunit for them - plenty of power there for rear fill. If you really want that surround feel the amp is a good choice. But since the front spks are the audio focal point most people prefer to dial down the rears quite a bit. Personal choice.

Do you use a hardwired mobile radio? Can you run it into a headunit aux input? That sounds like fun

#11

OK, so let's back way up. I thought you were building some kind of ERV capable of powering extraction tools or something. A 2300w inverter is larger than a 20a home outlet, it's a massive thing that could power an RV. If it's just laptops & radio chargers we're killing flies with a cannon. Which sounds fun except you'll basically have to rebuild the whole electrical system around it. $$$$$

When NOT on a call, yes, I'll be running laptop and radio chargers, etc. etc. When on a call I'll run that and more...spotlights, etc...up to compressors.

LOL, You are hooked on battery 2 - battery 2 is a capacitor in the shape of a battery, not a true battery. It's there only to keep the lights from dimming when the amps hit, nothing more. I took my Expedition to a pro shop when I first installed everything in it to ask how to fix the lights. They said a cap would work, but the new Kinetic "battery style" ones seemed to be less sensitive to summer heat and had a lower fail rate than the "can style" caps.

Unless you're going for a quadraphenia-style sound I wouldn't use the other Alpine on the rear spks, just go off the headunit for them - plenty of power there for rear fill. If you really want that surround feel the amp is a good choice. But since the front spks are the audio focal point most people prefer to dial down the rears quite a bit. Personal choice.

Back to the original question about the power wiring...can I run the power source for the amps right from the terminals of the inverter without issue?

#12

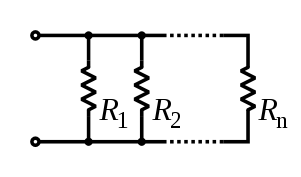

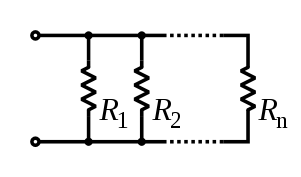

Chassis ground has more metal than any wire. Conductivity rates are a bit different but no real matter. The idea with big B+ cables for long runs isn't about current capacity so much as low resistance. A 4g wire over 20' can carry 130a all day but it'll lose voltage thru resistance, 1/0 won't until you're up to 300a. That's not an issue with your ground since they're much shorter. Once connected to vehicle chassis there's effectively zero resistance simply 'cos there's so much metal.

Some great wire calculators.

I re-read your OP & see you're using a small Kinetik battery - still a battery, just a different design. You can use the inverter as a distro block - as long as everything's wired parallel you can do it any way you want - but you brought up an interesting point about shutdown spikes that I don't know the answer to.

Personally I'd prefer to use the cap as the distro block (using a simple battery terminal, easy to add wires) as it might provide a buffer but it all depends on electron flow at that instant. To truly protect against spikes the inverter would need to be diode-protected (some big diodes like from an alternator housing) but I'd also assume the manufacturer would have that in the design. This is a good question for the inverter maker. Or test with a DMM.

Back to the Kinetik - a cap is connected to B- in order to attract B+, it's a little different than a lead acid battery. I'd chassis ground it in the same place the amps are grounded. Would it make a difference if the amps were grounded to it over the chassis? Probably not but the physics are different & I may missing something. Since you already ran the dedicated ground cable to battery 1, might as well use it, the point I was making is there's no advantage over a chassis ground really. Or yank that cable back out & use it for the big 3.

If you even think of using a compressor on this system you gotta do the alternator upgrade. And the big 3 upgrade.

The kinetik can start fires if shorted, it has to be fused on both ends between the main battery.

I agree that 2-10's @ 400wpc are appropriate for the cabin volume in a 100w front stage system, it's just a big space commitment for your already crowded trunk. To equal that with a single driver you'd need a 15". The really graceful solution is to glass that into the spare tire well & lose the spare, it'd fit so nicely & you'd never have to remove it. Probably not realistic for you tho.

Your fronts, without active time alignment (which you don't have) it'll sound really annoying if the tweeters are moved away from your mids. This is such a common mistake when using components, then people fall into the "emporer's new clothes" syndrome & assume that's what good sound is supposed to be since it's good equipment. I hope you don't fall into that trap.

Some great wire calculators.

I re-read your OP & see you're using a small Kinetik battery - still a battery, just a different design. You can use the inverter as a distro block - as long as everything's wired parallel you can do it any way you want - but you brought up an interesting point about shutdown spikes that I don't know the answer to.

Personally I'd prefer to use the cap as the distro block (using a simple battery terminal, easy to add wires) as it might provide a buffer but it all depends on electron flow at that instant. To truly protect against spikes the inverter would need to be diode-protected (some big diodes like from an alternator housing) but I'd also assume the manufacturer would have that in the design. This is a good question for the inverter maker. Or test with a DMM.

Back to the Kinetik - a cap is connected to B- in order to attract B+, it's a little different than a lead acid battery. I'd chassis ground it in the same place the amps are grounded. Would it make a difference if the amps were grounded to it over the chassis? Probably not but the physics are different & I may missing something. Since you already ran the dedicated ground cable to battery 1, might as well use it, the point I was making is there's no advantage over a chassis ground really. Or yank that cable back out & use it for the big 3.

If you even think of using a compressor on this system you gotta do the alternator upgrade. And the big 3 upgrade.

The kinetik can start fires if shorted, it has to be fused on both ends between the main battery.

I agree that 2-10's @ 400wpc are appropriate for the cabin volume in a 100w front stage system, it's just a big space commitment for your already crowded trunk. To equal that with a single driver you'd need a 15". The really graceful solution is to glass that into the spare tire well & lose the spare, it'd fit so nicely & you'd never have to remove it. Probably not realistic for you tho.

Your fronts, without active time alignment (which you don't have) it'll sound really annoying if the tweeters are moved away from your mids. This is such a common mistake when using components, then people fall into the "emporer's new clothes" syndrome & assume that's what good sound is supposed to be since it's good equipment. I hope you don't fall into that trap.

#13

Well anyway, to boil that down & answer your ?, as long as everything's wired parallel it doesn't matter the order or where your branches are, it's really a question of efficiency. The one exception is grounding your headunit, run this to the amp's ground or you'll very likely have alternator noise.

#14

Well anyway, to boil that down & answer your ?, as long as everything's wired parallel it doesn't matter the order or where your branches are, it's really a question of efficiency. The one exception is grounding your headunit, run this to the amp's ground or you'll very likely have alternator noise.

And the head unit ground...so the factory adapter harness isn't a good ground? I have never grounded a head unit with anything other than the harness adapters. Never noticed any whine, but then again I guess I could have just been lucky?

If everything is grounded to good metal, what causes the whine?

I have to get behind the dash again for some wiring mods to my 650 dash panel...I can redo the ground then...just wondering what would cause the whine if everything has good ground and the comment you made about so much metal any ground is good?

#15

Kinetik High Current Car Audio Power Cells #KHC600 : soundfixers.com, Where you can find all sorts of car audio equipment

Great for ring terminals, but those nifty aftermarket terminals won't work on them.

My solution in the past was to just get longer bolts and cut them down when I add more leads. Should work just fine for this application, but I need to find a boot or something to help protect the battery terminals from shorting.