Ford Is Going Futuristic with 3D Printing and So Can You

FTE SPECIAL REPORT: Ford thinks 3D printing is the future, but can the technology benefit you today?

Ford just announced that it was starting testing of large-scale 3D printing for use in its passenger cars and trucks. But Ford isn’t the only one using 3D printing in the automotive sector. Lots of people are turning to the revolutionary printing technology to make custom parts or recreate hard-to-find pieces for restoring older cars. But just how hard is it to 3D-print things? Is it actually useful? And how much will it cost you? Basically, what we all want to know is: Can 3D printing be usable for everyday people? Ford Truck Enthusiasts spent a few weeks digging, diving, buying, printing and testing to find out.

But first, let’s break some of this down to make it a little easier to parse through.

What is 3D Printing, and why should I care?

On its surface, 3D printing is exactly what it sounds like: a machine that shares a lot of similarities with your home ink-and-paper printer but produces an object in three dimensions. A print head takes a material, usually plastic, and draws it onto a hard surface. Then the printer head raises a fraction of an inch and does it over again until an object is made. What makes this new technology so amazing is that you can make really complicated things that really couldn’t be made using standard casting or molding techniques for plastic.

Since this also means that you don’t need molds or castings, you can create one-off or custom items for much cheaper than previously possible. That makes it perfect for restoring old cars or adding some custom flair.

But does it actually work?

Well, this is where things reach a yes/no/maybe stage. Just like normal parts you find made of plastic and metal, everything has its place and use. If you print something out of cheap and weak plastic, it won’t stand up to any use. If you use a cheap printer with poor quality, your parts won’t fit or look right. But if you take the time to do some research and get the right materials and printer, you could have parts that are even better than OEM.

If you want to restore a car, a 3D printer is your best friend. Rather than searching for an expensive specialty part, just print one. It won’t get you top points at a concourse event, but you also won’t have to spend $500 for that obscure speaker grille.

In the last year or so, companies have been creating some amazing materials that are suitable for 3D printing. Carbon-infused nylon plastics have immense strength, and there are new plastics that are incredibly temperature resistant. A company called 3DXTech has a product called Ultem 1010 that can withstand temps up to 217 C. That’s more than 400-degrees Fahrenheit, meaning you can print pieces for cooling systems and more. In theory, you could even make something like a throttle-body from this plastic.

Plus, we can’t forget that Local Motors printed an entire car once. So yeah, it can definitely work if you pay attention.

What can I make?

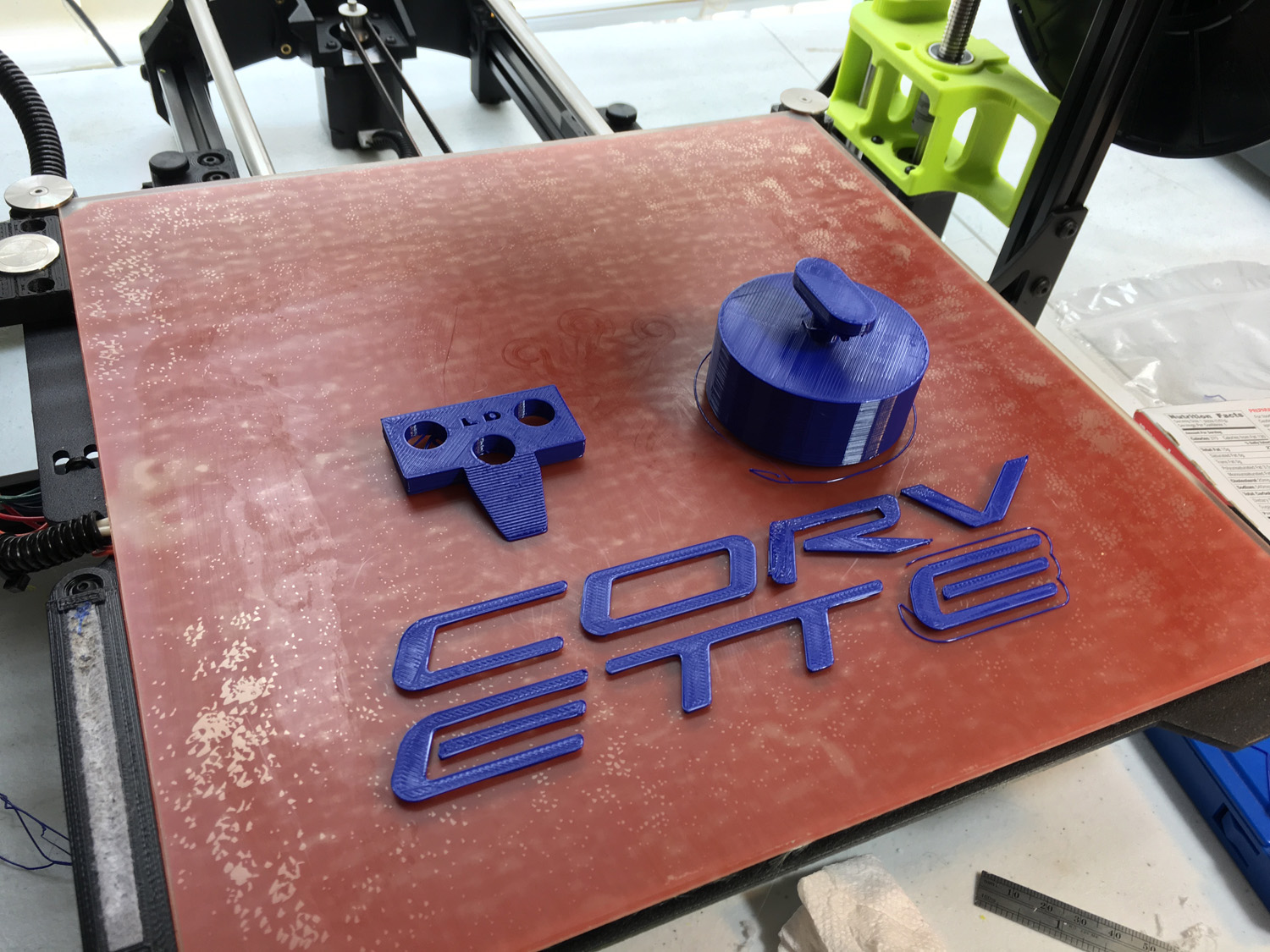

Well, basically, you can make anything. Within a slight margin of reason, if you can dream it up, you can print it. Spare parts, custom badges, interior trim, special holders and brackets. Some of the parts we have already found and printed include a new fuel door hinge for the twelfth gen Ford F-150, speaker adapter plates for eleventh gen trucks, and a new wiper gear motor for a Ford Fiesta.

Things get even better for enthusiasts. Want to add some extra gauges to your car? Print one that fits exactly where you want that holds the exact gauge you want. Stop paying for poor-quality aftermarket a-pillar pods. If you own a Ford Fiesta ST and hate how the throttle is deeper towards the firewall compared to the brake, print this extension plate we found. Now heel-toe shifting is easier than ever.

If you want to restore a car, a 3D printer could actually be your best friend. Rather than searching for an expensive and slightly broken specialty part, you can just print one. It won’t get you top points at a concourse event, but you also won’t have to spend $500 for that obscure speaker grille.

Sounds great! What’s the catch?

Ah… Yeah. Well, for starters, 3D printing isn’t fool-proof or painless. Thanks to a lack of standards in printer filament quality and production, there is a learning curve. Each different brand and material will require a little bit of tweaking to get working perfectly. And occasionally, something is just going to go wrong and you are going to get a failed print.

Then there is the issue of time. Most 3D printers are not exactly fast. A large and complicated part can take upwards of an entire day to produce. Thankfully, you can mostly just start the printer and then come back and retrieve it after it’s done. You don’t have to watch and monitor it.

Also, that lack of standardization means that certain printers can’t use certain materials. Our first printer was a very cheap model called the M3D, and while it was a great way to learn about 3D printers, the quality is so poor that nothing we made was usable, and it can only print in the weakest form of plastic available, a material called PLA.

If you spend a bit of time doing your research though, there isn’t much to worry about.

How much money are we looking at here?

Just like everything else, that kind of depends. There are good basic plastics that run about $30 for a roll. On our roll, we have already printed two pairs of brake-cooling ducts for a 350Z; the Fiesta wiper gear; a T-Top bracket for a C3 Corvette; engine badges and a jacking puck for a C6 Corvette; two camera card cases; a business card holder; and a phone mount for our car. We are about 2/3 the way through our roll. So it goes a long way. If you want some of the stronger materials, you may be looking at as much as $90 per roll, but crafting a pair of CFRP brake-cooling ducts for $30 sounds like a pretty great deal to us.

Just make sure to try and order in bulk. These rolls of plastic weigh a few pounds each, and you can save a lot on shipping if you order several rolls at once. When you realize that shipping on one $40 roll is $9, but its only $12 for three rolls, you tend to start ordering in larger shipments.

Can’t you just do the hard work for us and pick a printer?

Well, we figured that would come up, so yes. Rather than make you sort through the dozens of printers and technologies out there, we did most of the legwork for you. We already talked about the M3D printer. It is one of the cheapest printers out there, and it’s so easy to use that a monkey could do it, but it falls so far down the scale of usability, that we can’t recommend it.

When we went searching for printers, we wanted something that was incredibly easy to use, had a big build capacity and was compatible with as many different types of material as possible. Quality and speed were also hugely important, but we didn’t want to spend $10k on a professional-level printer. So, it needs to be good, cheap, fast and capable.

The most popular name in 3D printing is Makerbot. Their Replicator+ ticks the boxes for quality, speed and ease of use, but the build volume is kind of small, and the filament choices are less than stellar. The price is fair at $2,500, but ultimately it was a pass. Other big names like Dremel and Polaroid are offering 3D Printers, but they all fall into that category of slightly too small to be usable for car parts.

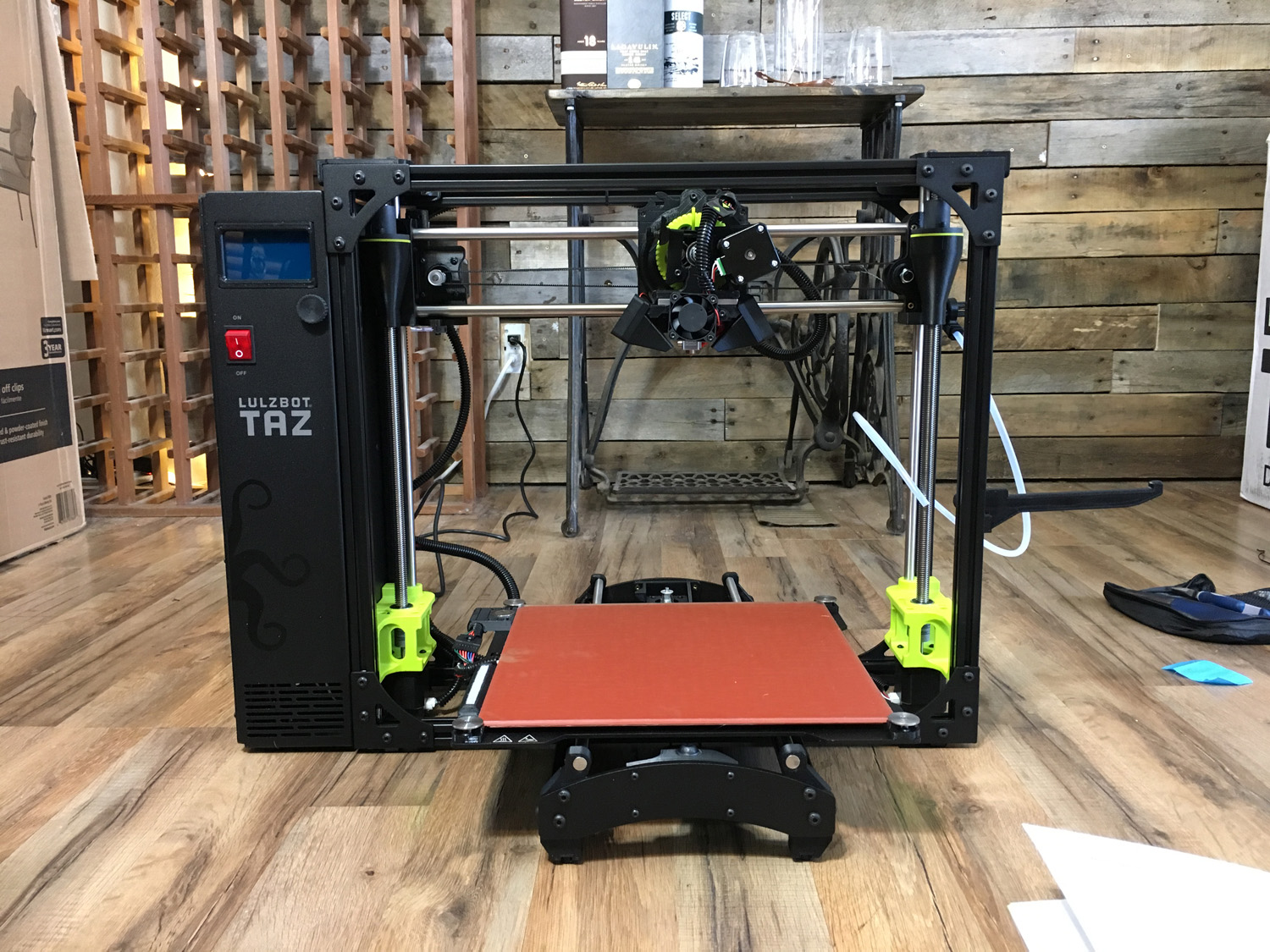

But then, a colleague who operates a 3D print and prototyping lab at a local university told us what printers the college uses: The Lulzbot TAZ6 — the best printer with the silliest name.

It sounded great on paper, so we called Lulzbot and had one shipped over ASAP.

The 3D printer features a build-size much bigger than the Makerbot Replicator+, nearly a full cubic foot in total, and out of the box it can print nylon, polyester, ABS, polycarbonate, PLA and most any variation of those with wood, metal or carbon fills. The TAZ6 is also completely open source and modifiable so it’s easy to change, upgrade and modify to suit your needs. They even sell a second printer head that will allow you print in flexible materials, so you can make sound- or vibration-absorbing materials, which is perfect for interior trim and speaker mounting. Best of all, it costs about the same as the Makerbot: $2,500.

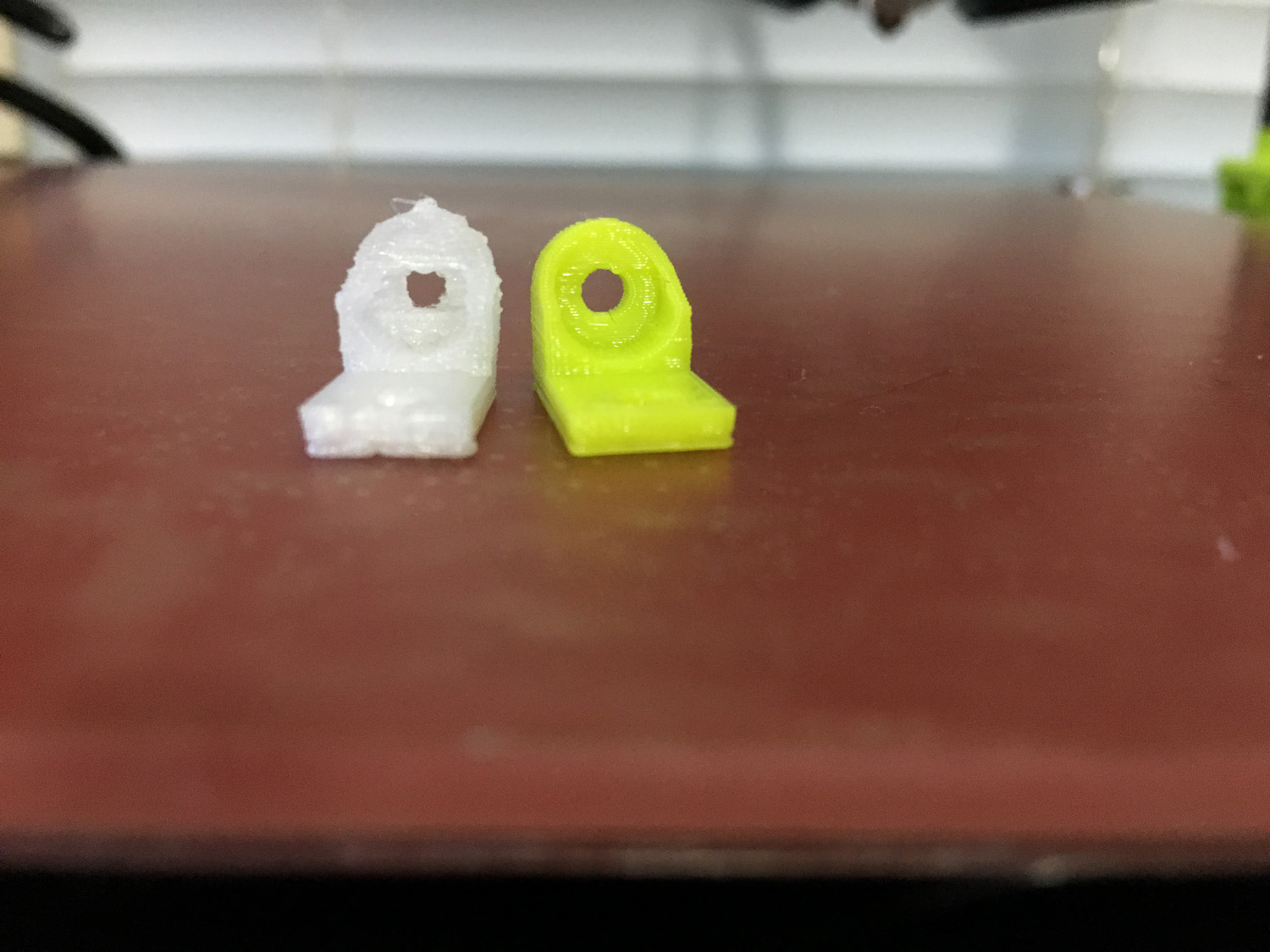

As for speed and quality, it excels on both fronts. The photo here shows a small mounting bracket that we printed on both the cheap M3D and the TAZ6. You can very obviously see which of those two is the higher quality. We were also able to print 12 of these brackets on the TAZ6 in the same time it took to print the one on the M3D.

We still have to do some testing with printing carbon plastics and we don’t yet have the second print head for flexible materials, but overall we have been extremely impressed with the Lulzbot TAZ6.

Reporting, photos and video: Christian Moe