NP435 Rebuild

#1

NP435 Rebuild

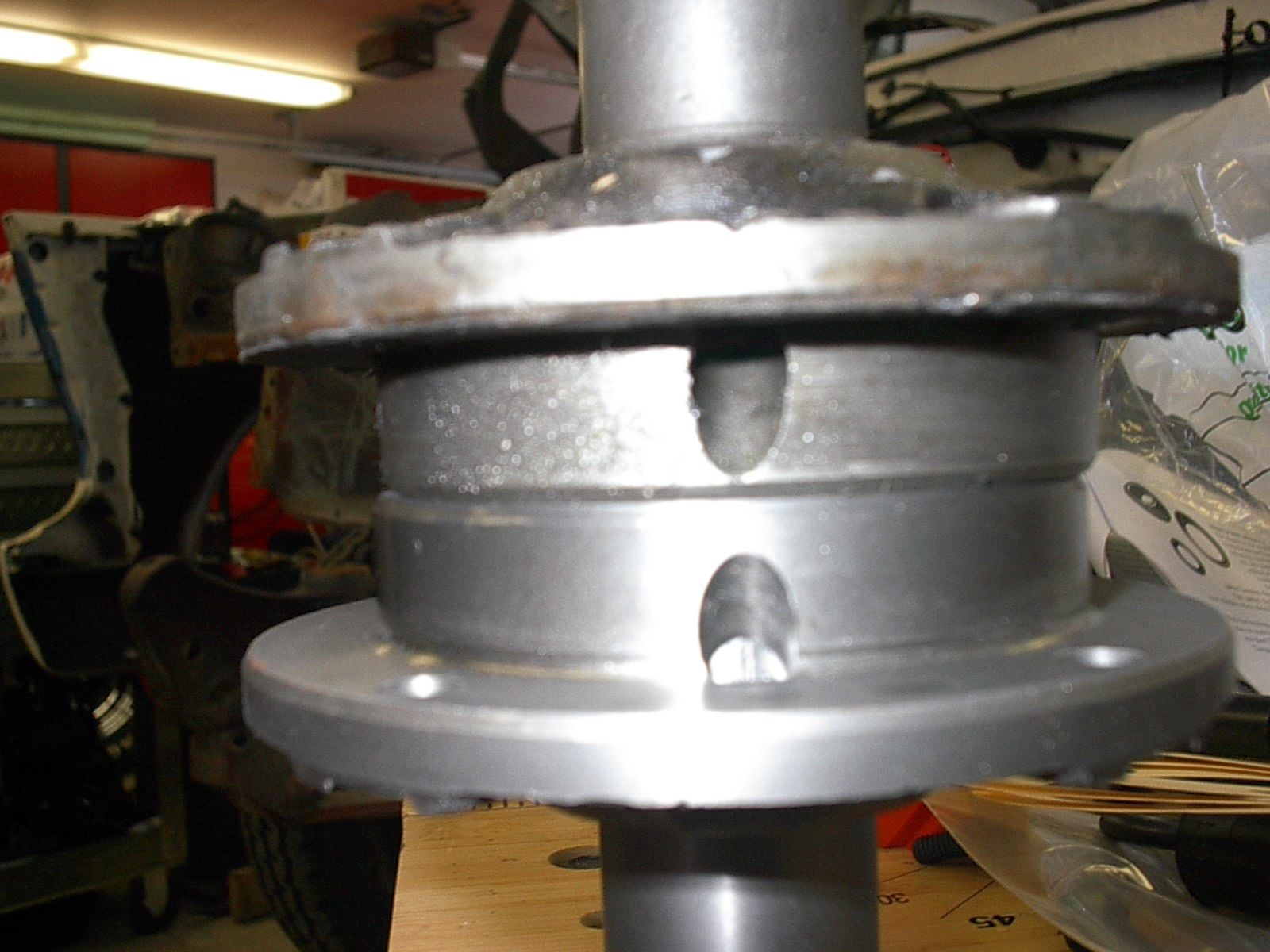

top retainer is original, bottom is replacement. Note slot on original comes out to flange edge.

Just finished a rebuild of my NP435 trans, and thought I would post some things I learned doing it for others who plan to rebuild theirs.

- When I took my trans out, it had a fairly new clutch in it and I could see some fresh RTV sealant on the input bearing retainer. When I removed the retainer, it had a new seal installed I'm guessing when they put the clutch in. The retainer was also chipped and cracked on the open end where the shaft comes thru. I'm also guessing it got cracked during the seal install, they probably set it open end down on a steel surface. I had to replace the retainer because of the damage, and when I put the seal in I placed the large flange in my open vise so the strain was spread to the large flange surface rather than the end of the hollow tube.

- I got the replacement retainer from JBG, and the oiling slot in it is not machined like the original. See the pic. I had to open up the slot with a small Carbide tree burr so that it extended to the edge of the flange. If you don't open up the slot, the case blocks the oil feed to the input shaft bearing.

- Before you remove the race in the this bearing retainer, measure how far it is seated into the bore. It is important to get the new race seated at the same depth, or you won't be able to accurately set your shaft endplay.

- Leave the input shaft seal out of the retainer until you have your endplay and synchro clearance set. No sense dragging the seal over the shaft half a dozen times while you remove and install the gasket shims to set the endplay.

- I used this puller to get the output bearing off:

13-Ton Grip-O-Matic Puller | OTC Tools

- I used a 1.5" black iron pipe, 12" long to install the output shaft bearing. I wrapped the end of the pipe that bears against the inner bearing race many times with duct tape, and folded the wraps inside the pipe so that an errant splinter from the softer pipe would not find its way into the bearing, it would just stick to the tape.

- I used a 1/16" carbide burr to slot the counter shaft rear bearing cage to remove it. I located the cut inline with one of the oiling grooves machined in the cap. I then just peeled it out.

Overall its a fairly easy rebuild.

Thread

Thread Starter

Forum

Replies

Last Post

FordPerf300

Clutch, Transmission, Differential, Axle & Transfer Case

4

09-12-2002 12:16 PM