manifolds to block studs and bolts

#1

#2

I switched to all studs on mine. It works very well, and most here recommend it.

It's much easier to install everything because you can install the studs, and then hang the manifolds on them.

The biggest issue you may or may not run into is the thick washers on the stock bolts. May or may not because on some years the washers can be slid off the original bolt, and some years they can't.

If you need new washers, get some grade 8 hardened washers around the same diameter, and double stack them. I also like to put a split washer under the nut to give a little extra holding power.

The Mr. Gasket #260 is the recommended intake/exhaust manifold gasket. A lot of parts stores don't carry it, but it's easily orderable on line.

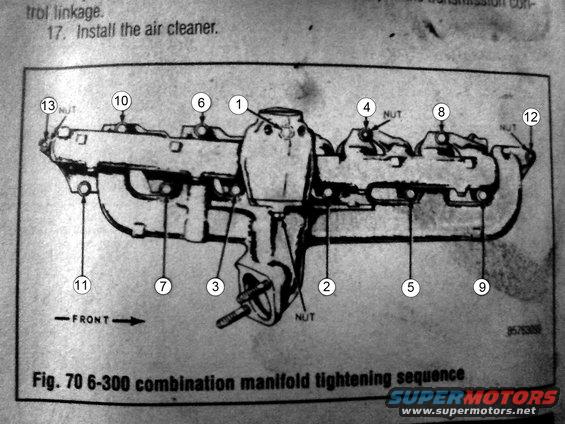

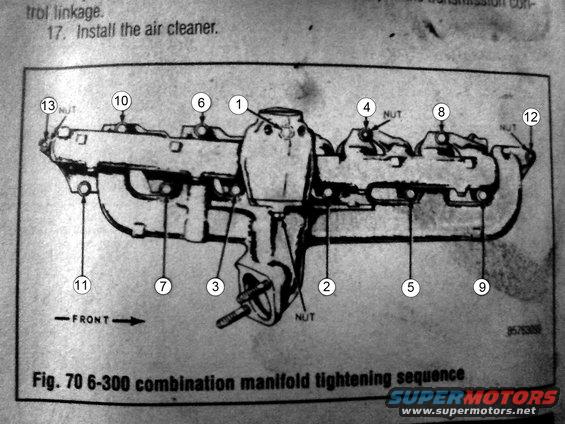

Also, be sure to torque them in the proper sequence. And if you haven't already, check to make sure they haven't warped (common). If so, take the manifolds to a machine shop to have them planed (and be sure to have them already bolted together when you do.)

It's much easier to install everything because you can install the studs, and then hang the manifolds on them.

The biggest issue you may or may not run into is the thick washers on the stock bolts. May or may not because on some years the washers can be slid off the original bolt, and some years they can't.

If you need new washers, get some grade 8 hardened washers around the same diameter, and double stack them. I also like to put a split washer under the nut to give a little extra holding power.

The Mr. Gasket #260 is the recommended intake/exhaust manifold gasket. A lot of parts stores don't carry it, but it's easily orderable on line.

Also, be sure to torque them in the proper sequence. And if you haven't already, check to make sure they haven't warped (common). If so, take the manifolds to a machine shop to have them planed (and be sure to have them already bolted together when you do.)

#4

#7

I'm getting ready to do the same thang! What is the torque specs? The reason I asked is because my Haynes Manual says "Upper intake manifold-to-lower intake manifold bolts: 12 to 18". I assume that is 12 to 18 in-lbs. but that seems a little low. Plus I hate how the manuals give you this wide range of torque numbers. Why can't they publish what it should be?

Trending Topics

#9

#11

Thread

Thread Starter

Forum

Replies

Last Post