Ford F-Series: What are the Symptoms of a Bad DPFE Sensor?

There are a lot of small components that work together in order to make a vehicle operate efficiently. One of the more modern parts is the DPFE sensor, which is included to help reduce the amount of pollutants emitted by an engine. When this component begins to go, it can impact the performance of your Ford F-Series truck. There are warning signs to look out for and ways to go about diagnosing the problem. And if the DPFE Sensor does, in fact, need to be replaced, it’s a fairly easy thing to do at home.

This article applies to the Ford F-Series Truck.

There are a lot of small components that work together in order to make a vehicle operate efficiently. One of the more modern parts is the DPFE sensor, which is included to help reduce the number of pollutants emitted by an engine. When this component begins to go, it can impact the performance of your Ford F-Series truck. There are warning signs to look out for and ways to go about diagnosing the problem. And if the DPFE Sensor does, in fact, need to be replaced, it’s a fairly easy thing to do at home.

Key Information

- DIY Cost: Start as little $30 but can go for as much as $100. It depends on which model of the Ford F-Series truck you own.

- Professional Cost: Between $150 to $500 – depending on where you live and which model of Ford F-Series truck you own.

- DIY Time: Less than 30 minutes.

- Req. Skill Level: This is a fairly easy component to replace.

Materials Needed

- Vacuum line splitter

- New DPFE sensor

- Socket wrench set; typically, a 10mm socket is required

Step 1: What is a DPFE Sensor?

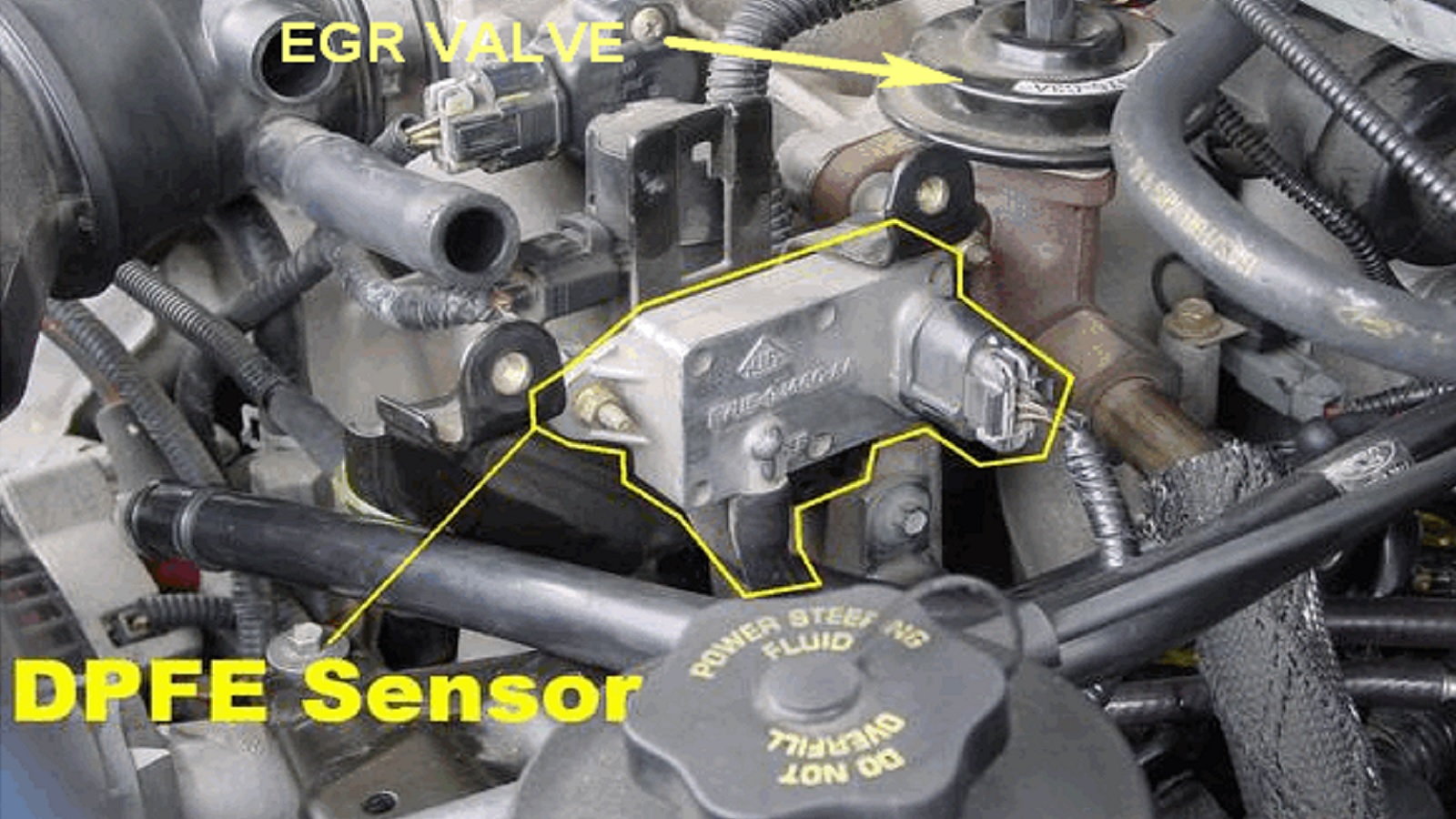

“DPFE” means “Differential Pressure Feedback of EGR”. It’s also referred to as "Delta Pressure Feedback of EGR", with ‘Delta’ meaning "difference" or "change". Regardless of the acronym’s definition, the DPFE Sensor reads changes in the pressure of the EGR system. For those unfamiliar, “EGR” means "Exhaust Gas Recirculation", and this refers to the process of the system actually sucking exhaust gases back into the engine for re-burn purposes. It’s a fairly modern technology designed to help reduce the total amount of pollutants emitted by an engine. By all accounts, though, the DPFE sensor is a critical component of the exhaust gas recirculation system.

Step 2: Understanding the DFPE system

For many modern vehicles, including Ford’s F-Series of trucks, there is a vacuum line coming off the intake manifold to the EGR actuator. Now, the actuator is an electric device controlled by the PCM that controls how much vacuum pressure gets past it. Generally speaking, it is located on the car’s firewall. There’s another hose in there that goes to the EGR Valve. Now, the aforementioned vacuum pressure is used to open the EGR Valve which, in turn, allows exhaust gases to be pulled from the exhaust, past the DPFE tubes, and back into the intake manifold.

So where does the DPFE sensor come in? Well, when gas passes through the EGR tube, the two tubes leading to the DPFE Sensor get pressurized. As this happens, a difference in pressure is created, wherein one tube has more pressure than the other one. The DPFE sensor registers this difference in pressure and can tell how much exhaust gas is flowing through the EGR system. It then tells the PCM, if you will, how much gas is flowing through the system, and the PCM uses this data to control the actuator.

Step 3: How to tell when a DPFE sensor is failing

When a DPFE sensor begins to fail, it provides the PCM with bad/inaccurate data. This is because it is less sensitive and the PCM thinks less recirculated gas is being burned than is actually so. When this happens, the PCM adjusts the flow of the gas as a means of compensation and winds up opening the actuator too much. This results in too much EGR coming in and combing with the air which, in turn, leans out the fuel mixture. The result is the truck misfiring, stumbling, or hesitating. This system typically degrades over time and so is often hard to diagnose right away. It might start failing weeks ahead of the “check engine” light actually going on.

Step 4: Diagnosing a DPFE sensor failure – Trick 1

If your truck is misfiring, one thing you can do is stop your DPFE sensor from opening up. This can be accomplished using a vacuum line splitter. Once you’ve split the line, insert anything that fits snugly within the line to stop the circulation of the EGR (a screw bit often works well). If the car no longer hesitates, you’ve diagnosed the problem.

Step 5: Diagnosing a DPFE sensor failure – Trick 2

Remove both hoses from the DPFE sensor then re-attach the hose that used to go to the EGR Valve, to the "Ref" hose port on the DPFE Sensor. Doing this sort of tricks the system so that instead of opening the EGR valve when the PCM sends the signal, it will now apply vacuum to the "Reference" sensor for the DPFE. The result: the "Hi" sensor will see more pressure than the reference sensor sees, so the PCM is tricked into thinking that the EGR valve is working properly. Going this route will help you tell if the DPFE Sensor is completely fried – you’ll wind up seeing an “Insufficient EGR flow” notification on your dashboard.

Step 6: You’re sure the DPFE sensor is shot – what should you do?

Replace it. These things do degrade over time, so you’re likely to be faced with this scenario at some point of owning your car. While you can take the truck in to have the DPFE sensor replaced, it’s a fairly easy component to update yourself. Simply disconnect the negative battery cable, unbolt the DPFE sensor from the firewall using a 10mm socket and pull it off the rubber hoses. As you do this, take care to also disconnect the wire harness holding it place. No sense in having to replace additional components by yanking the sensor out of the system. Now put the new DPFE sensor in its place, re-attach the wire harness and bolt it back to the firewall. If you did it wrong, you’ll get a notification on your dashboard. But if you did it right, your truck won’t misfire anymore.

Pro Tip:

Remember to pay attention to the wire harness as you remove the DPFE sensor. If you are too rough with it, you can snap the harness. Which will require another fix.

Related Discussions

- How to test your DPFE sensor. - Ford Trucks.com

- What is a DPFE sensor, what does it do? - Ford Trucks.com