oil in coolant - AGAIN

#1

oil in coolant - AGAIN

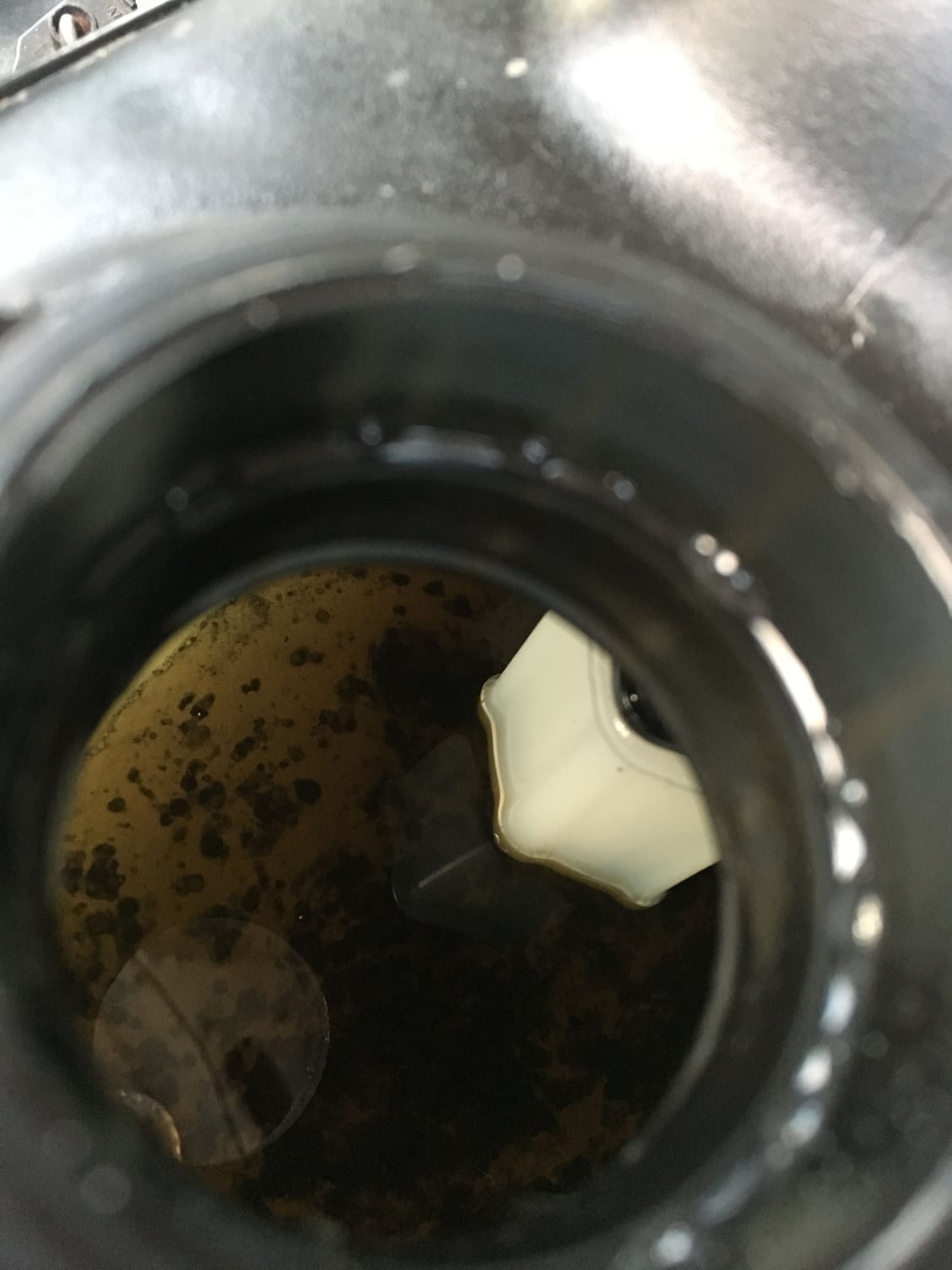

So, this past December I noticed oil in my coolant so I went ahead and flushed the system, replaced the oil cooler, and all was good. Didn't see any oil in the coolant for a long time. In the past month or so, I started to see a little of black specks in my coolant bottle. Note at the same time I also noticed the dried white coolant particles around the cap, looking like it had been puking a little. Kept checking it, didn't see any more puking, and the oil didn't seem to get any worse, so chalked it up as small particles gathering over time from the last time oil had infiltrated the system. As far as the puking, chalked it up to a faulty cap or freak one-off thing.

Replaced coolant bottle and cap last week, since the last one developed a small crack. Just checked my coolant bottle today, and there is a GOOD amount of oil in the bottle... Way more oil in the bottle than what I had described seeing around a month ago.

What in the world am I doing wrong?? From what I've gathered, oil in the coolant is basically 100% a failed oil cooler. Which means the oil cooler i put in this past winter has only lasted about 7 months. That just doesn't seem right. I bought the cooler from autonation ford white bear lake, factory ford motorcraft OEM part.

Is there any troubleshooting I can do? I have to make a 16 hour drive in about two weeks, so I need to start ordering parts if I am going to go through this again.

For reference, the truck has 365k miles, EGR delete (welded shut), and studs.

Oh, and my A/C stopped working the other day. Compressor isn't kicking on. Tried jumping the low pressure switch on the A/C with no luck.

Replaced coolant bottle and cap last week, since the last one developed a small crack. Just checked my coolant bottle today, and there is a GOOD amount of oil in the bottle... Way more oil in the bottle than what I had described seeing around a month ago.

What in the world am I doing wrong?? From what I've gathered, oil in the coolant is basically 100% a failed oil cooler. Which means the oil cooler i put in this past winter has only lasted about 7 months. That just doesn't seem right. I bought the cooler from autonation ford white bear lake, factory ford motorcraft OEM part.

Is there any troubleshooting I can do? I have to make a 16 hour drive in about two weeks, so I need to start ordering parts if I am going to go through this again.

For reference, the truck has 365k miles, EGR delete (welded shut), and studs.

Oh, and my A/C stopped working the other day. Compressor isn't kicking on. Tried jumping the low pressure switch on the A/C with no luck.

#2

#3

#4

#5

#7

it wasn't. I toyed with the idea, but didn't have the resources or the time to go about it... But, I'm certain it fixed the problem, since I drove plenty of miles (although not nearly as much as I'd have liked) without ever seeing oil in the coolant again.

Trending Topics

#8

There are multiple things altered with a cooler installed. In my past work I had to hunt for the cause.

The easy way to check for an internal failure on something like this ..... since it's oil moving to coolant, use a hose to fit over one port from the oil side (high pressure). The other port can have an expandable plug, threaded internally for a NPT plug, or another hose that can be plugged. Hoses should be secured with worm clamps. You then can use a garden hose to supply pressure and flow, or an air line. The oil side can get to 75psi so you can moderate below that to that pressure level. Anything pressured should be contained with the possibility of explosive failure. The other side (coolant) should see water or air flow if the cooler is indeed ruptured.

The easy way to check for an internal failure on something like this ..... since it's oil moving to coolant, use a hose to fit over one port from the oil side (high pressure). The other port can have an expandable plug, threaded internally for a NPT plug, or another hose that can be plugged. Hoses should be secured with worm clamps. You then can use a garden hose to supply pressure and flow, or an air line. The oil side can get to 75psi so you can moderate below that to that pressure level. Anything pressured should be contained with the possibility of explosive failure. The other side (coolant) should see water or air flow if the cooler is indeed ruptured.

#9

There are multiple things altered with a cooler installed. In my past work I had to hunt for the cause.

The easy way to check for an internal failure on something like this ..... since it's oil moving to coolant, use a hose to fit over one port from the oil side (high pressure). The other port can have an expandable plug, threaded internally for a NPT plug, or another hose that can be plugged. Hoses should be secured with worm clamps. You then can use a garden hose to supply pressure and flow, or an air line. The oil side can get to 75psi so you can moderate below that to that pressure level. Anything pressured should be contained with the possibility of explosive failure. The other side (coolant) should see water or air flow if the cooler is indeed ruptured.

The easy way to check for an internal failure on something like this ..... since it's oil moving to coolant, use a hose to fit over one port from the oil side (high pressure). The other port can have an expandable plug, threaded internally for a NPT plug, or another hose that can be plugged. Hoses should be secured with worm clamps. You then can use a garden hose to supply pressure and flow, or an air line. The oil side can get to 75psi so you can moderate below that to that pressure level. Anything pressured should be contained with the possibility of explosive failure. The other side (coolant) should see water or air flow if the cooler is indeed ruptured.

From my understanding, the oil infiltrates the coolant only because the oil is at a higher pressure than the coolant. So if you pressurized the coolant side with air, it still wouldn't hold pressure.

#12

Also.. the coolant system is still holding pressure. Even after truck sits for a long time, when I pull the degas bottle cap, a good amount of pressure is released. So, the oil cooler must only be leaking at pressures > 15 psi, or else the coolant would be leaking into the oil when the truck is turned off. Unless the oil side of the oil cooler stays pressurized with the truck turned off.

#13

Would it be easier to just plug one side (either oil or coolant), supply air pressure, and see if it holds?

From my understanding, the oil infiltrates the coolant only because the oil is at a higher pressure than the coolant. So if you pressurized the coolant side with air, it still wouldn't hold pressure.

From my understanding, the oil infiltrates the coolant only because the oil is at a higher pressure than the coolant. So if you pressurized the coolant side with air, it still wouldn't hold pressure.

In my old test world you would want the flow to go in the same direction as the flow failure. If you go in the opposite direction and it doesn’t show failure the question would be did it somehow seal, so howdo you answer that concern. It’s the problem we would see with brake hoses, a torn inner layer that sealsin one direction only. It’s a procedural thing, remove possibilities no matter how remote.

#15