Oil on exhaust, fuel tank skid & rear end squeak

#1

Oil on exhaust, fuel tank skid & rear end squeak

The squeaking I've experienced is coming from the rear end. I took a ride in the bed and definitely heard it in the rear. It sounds like it's more prevalent on the driver's side, but maybe that's because there's a rot stripe above the wheel and the sound comes out up higher. I don't know.

I took a good look around under there and this is what I found:

On underside of exhaust:

On underside of fuel tank skid:

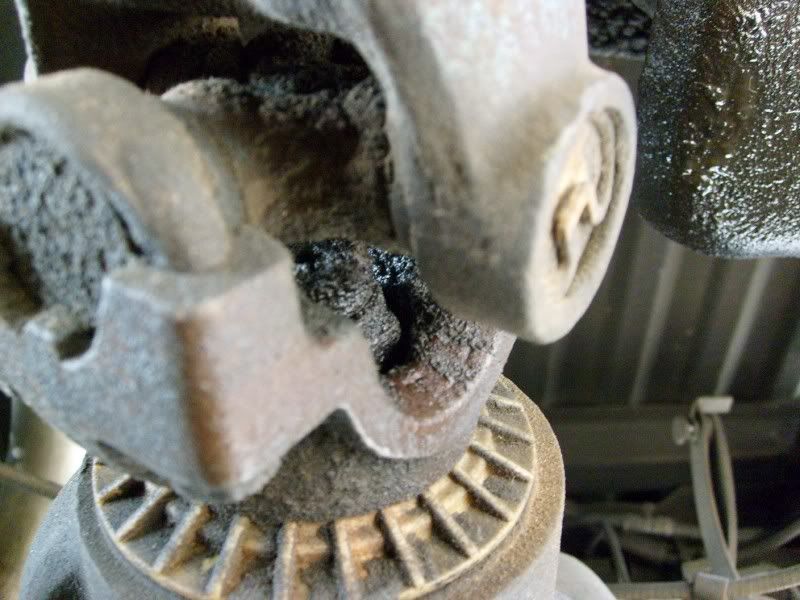

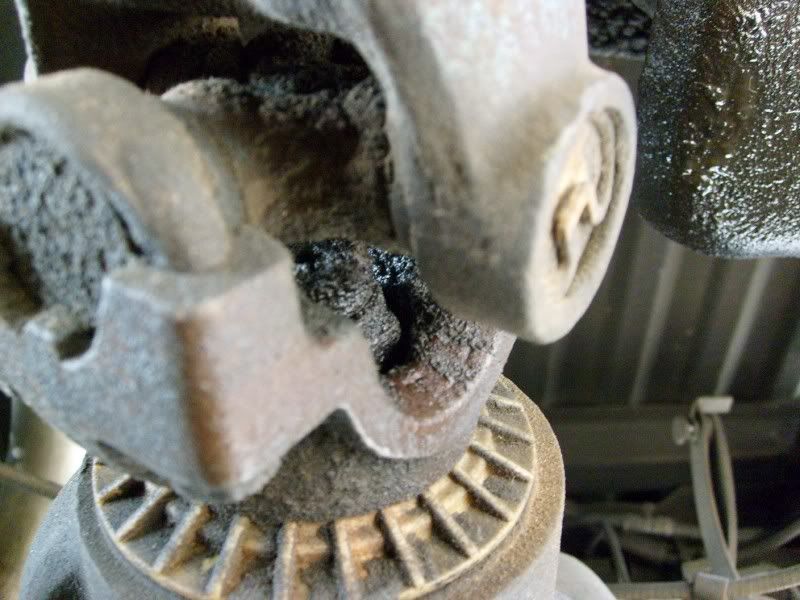

Rear yolk:

Under yolk - you can see the wet tank skid:

I knocked on the muffler pretty good to see if it was full of oil and it doesn't appear to be because it rings when knocked. I tried smelling the oil from both the exhaust and tank skid and it doesn't appear to have a strong odor like gear oil. It appears as though the pinion seal is leaking and possibly slinging gear oil up onto the exhaust and skid. I've read that some folks actually have that nut walk off on them. That's a Sterling 10.25 rear end w/ 4.10's.

Earlier this summer I did pressure wash that yolk until there was zero grime on it.

What says the FTE collective?

I took a good look around under there and this is what I found:

On underside of exhaust:

On underside of fuel tank skid:

Rear yolk:

Under yolk - you can see the wet tank skid:

I knocked on the muffler pretty good to see if it was full of oil and it doesn't appear to be because it rings when knocked. I tried smelling the oil from both the exhaust and tank skid and it doesn't appear to have a strong odor like gear oil. It appears as though the pinion seal is leaking and possibly slinging gear oil up onto the exhaust and skid. I've read that some folks actually have that nut walk off on them. That's a Sterling 10.25 rear end w/ 4.10's.

Earlier this summer I did pressure wash that yolk until there was zero grime on it.

What says the FTE collective?

#2

#3

#4

just replaced mine bro, dont be scared of it, it is a snap. oil seal was cheap and easiest way to replace, use a nail to get the seal off the surface, screwdriver from there. The nail....just gently tap it in between the seal and housing to "break" it loose. Then the screwdriver will fit nicely and pry right out. Replace with new and done. For the pinion nut, just clean every thing off really well and then use a paint marker to line it up and count the threads for depth. It is how the ford techs do it so rest easy.

#5

#6

Join Date: Mar 2009

Location: Maine (NorCal Native)

Posts: 6,442

Likes: 0

Received 5 Likes

on

5 Posts

Yes, there is a crush collar, Technically pulling the yoke requires the replacement of the Crush collar and a complete setup of the gears ...

However this technique has been being done for years and years without issue.

If it's already loose, there is a problem and it should be addressed appropriately.

-Enjoy

fh : )_~

However this technique has been being done for years and years without issue.

If it's already loose, there is a problem and it should be addressed appropriately.

-Enjoy

fh : )_~

#7

if it has backed off, then you can move the yoke in and out a bit or a lot. If it is seated properly which it appears to be then it should be fine. If in doubt take it to ford, they will charge about 200 i believe for the labor and parts to replace with new nut, crush collar and set the torque. I did it the way i did for a test purpose. I am going to take the other rear end i have and let a mech rebuild it with all new seals and bearings, then i will take it into ford when i get it installed and make sure it is all good to go.

Trending Topics

#8

So it's safe to pull the yoke after you mark everything and count # of turns on the pinion nut and there's no need to replace the crush sleeve when reassembling? My axle work is quite limited to bearings, seals & joints from the differential sides out. I've never replaced gears before.

I watched a video on youtube of a guy using a typical seal puller to remove the pinion shaft oil seal. Then he found it fishy that the pinion seal was leaking and diagnosed the issue - the axle tube vent was completely clogged. Maybe that's where my odd noise sporadically comes from.

I watched a video on youtube of a guy using a typical seal puller to remove the pinion shaft oil seal. Then he found it fishy that the pinion seal was leaking and diagnosed the issue - the axle tube vent was completely clogged. Maybe that's where my odd noise sporadically comes from.

#9

doubt the noise is from that but yes you can do the yoke that way, ford does it all the time. You just have to get it back to where it was so i lined it up like a clock and made marks on the pinion, and the nut, with numbers you can be more precise but lines work too, i would use numbers though so you dont get lost.

#10

Join Date: Mar 2009

Location: Maine (NorCal Native)

Posts: 6,442

Likes: 0

Received 5 Likes

on

5 Posts

Actually, you don't need to count the turns off ... Run the nut down till it touches then align your marks between pinion and nut ...

Remember to mark it with something that will not get wiped off ... like a center punch (lightly) and align the dots.

Whatever you do, if you go beyond your marks DO NOT BACK IT UP!

In fact a little beyond is not a bad idea.

Of course this whole procedure only applies if you are not changing anything other then the seal!

-Enjoy

fh : )_~

Remember to mark it with something that will not get wiped off ... like a center punch (lightly) and align the dots.

Whatever you do, if you go beyond your marks DO NOT BACK IT UP!

In fact a little beyond is not a bad idea.

Of course this whole procedure only applies if you are not changing anything other then the seal!

-Enjoy

fh : )_~