Stock Headlight Upgrade

#31

That's similar to what I did. Here are some pictures of the modifications I made to my 1987 Mustang to replace the stock flush mount headlights with some Bosch E-code headlights (they're cheaper than Cibie'). These lights are now on my Aerostar, but you can see the pattern that they make is far superior than the DOT headlights. If you can find and afford the Cibie' lights, go for it!

#32

Yeah, the only downside to the E-code headlights is that they do not light overhead signs. Which isn't really a downside, because its stupid for the USDOT to require that overhead signs be light by a cars headlights. Its mostly a demonstration on how cheap they were to not want to install lights on road signs, which in the end most of them did anyway. Most overhead lights in the US are now illuminated, so you would never have a problem with reading overhead lights with ecode lamps.

Ecode headlights put more of the light where it needs to be, which means you get better output for any given wattage. With an Aerostar, too much of the output is wasted shining where it doesn't need to be.

Ecode headlights put more of the light where it needs to be, which means you get better output for any given wattage. With an Aerostar, too much of the output is wasted shining where it doesn't need to be.

#33

#34

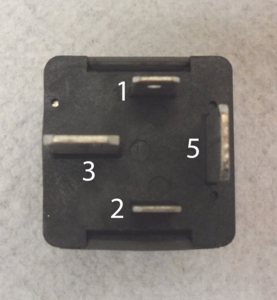

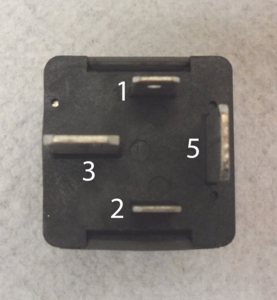

I was looking for some heavier type relays last week, and ran across a reference to Ford fan relays that are 70A, so . . . I was in the JY today, found these cute little 70 ampere relays in a pair of '98 Windstars. Ford No. F80B-14B192-AA. This is a SPST (four terminal) relay, with the load terminals 3/8" wide rather than the common <30A relay's 1/4" terminals all around. A cursory Google check seems to link this relay to several fords (Crown Vic/Grand Marquis) and a Freightliner FL70 (funny, I used to work on those). There are several available on eBay right now (all used ones). I gave a buck for this pair.

(click on any image for larger)

I think these 70 amp relays might be a good, heavy-duty, cheap relay to use here. No socket, though.

(click on any image for larger)

I think these 70 amp relays might be a good, heavy-duty, cheap relay to use here. No socket, though.

#35

#36

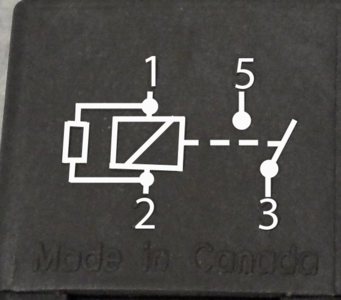

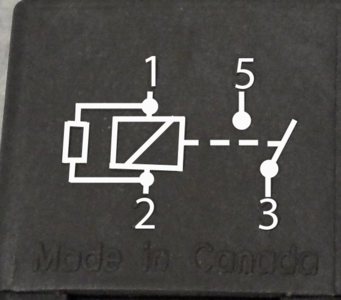

Good catch, and I was going to mention that when I added the pics, but didn't remember to.

My assumption is that it's showing a diode. But with no cathode marking. I don't have my variable power supply unpacked, and my Variac is back in Washington. I'll try to determine if a diode is present using some other supply. Maybe I can find a resistor around here somewhere and do a current test.

The forward bias of the clamping diode (if present) is more than the coil resistance.

I picked up some .375" female quick disconnect terminals today. Made in USA, 60 cents each. Labelled "NAPA Wire Products", Part No. 723118, not Balkamp or Echlin. Bought a box of ten.

I'll be cutting off the insulating PVC and soldering, using heat-shrink to cover the end, but this is what the warehouse had in stock, and the price is nearly the same from NAPA.

My assumption is that it's showing a diode. But with no cathode marking. I don't have my variable power supply unpacked, and my Variac is back in Washington. I'll try to determine if a diode is present using some other supply. Maybe I can find a resistor around here somewhere and do a current test.

The forward bias of the clamping diode (if present) is more than the coil resistance.

I picked up some .375" female quick disconnect terminals today. Made in USA, 60 cents each. Labelled "NAPA Wire Products", Part No. 723118, not Balkamp or Echlin. Bought a box of ten.

I'll be cutting off the insulating PVC and soldering, using heat-shrink to cover the end, but this is what the warehouse had in stock, and the price is nearly the same from NAPA.

#37

If you have a good soldering iron, you can probably heat up the connector enough to flow solder into the wire contact area without stripping the insulation. I did this with my connections, after first crimping it around the wires first. Then I put some rtv into the end of a heat shrink tube and shrunk it around the connector/wire end.

#38

Thats why using the relays that come with harnesses is a good idea instead of building your own with spade connectors. The Ford relays are better, but you don't need a 70 amp relay. A 40 amp will do. A 40 amp relay will support 240 watts, you headlight bulbs are only 110 watts for the pair. You can find them for cheap on Amazon and eBay complete with the 5 pin plug in harness pigtail. They also come with the mounting tab so that you can secure them somewhere. The stock Ford ones are meant to plug into a relay block. They are excellent relays, but in my opinion, they are majorly overkill and are lacking in features from a versatility standpoint. Using a prefabricated relay harness pigtail sure beats trying to reinvent the wheel. The only problem with the relay and harness kits is they come in a 5 pack. Thats fine cause you need at least two anyway. Again, they are inexpensive.

Amazon.com: AGT (5 Pack) 30/40 AMP Relay Harness Spdt 12V Bosch Style (40AMP-HRNS): Automotive

Amazon.com: AGT (5 Pack) 30/40 AMP Relay Harness Spdt 12V Bosch Style (40AMP-HRNS): Automotive

#40

I was going to let this slide, being as it's your thread and all, but there's just too much wrong here.

As someone whose done more than the average amount of low-voltage wire harness work, I've seen some very poorly constructed plug-n-play retrofit harnesses, and as I'm pretty well stocked to build my own and roll it my way, that's what I'll likely do.

I am 100% certain that I can do better work and use better materials at an equivalent cost, or less, than a pre-built harness under $100. At least, the ones I've seen so far.

Next, those quick disconnect pigtails? Here's what AGT is saying about them:

16 gauge? That's no better than OEM. Why go to all the expense of putting more 16 gauge wire in place? If I'm going to the trouble to do anything about a problem with the OEM system (and, I think that the replacement HL switch connector is beefed up enough that no add'l work is needed at all, using stock wattage lamps), I want at least 14 gauge on the load lines.

Put 30A on a 16 gauge stranded wire for a half-hour, then try to put your hand on it. You won't, because it'll be melted. The ampacity of 16 gauge solid wire is about 13A, and stranded wire will be even less (link to Wikipedia).

Are these sub-$1 pigtails going to be soldered? I thought not. A properly-crimped solderless connector can be a very good connection, but the dies in the line crimper have to be in good condition. Dice, anyone? Give me a soldered connection any time it's practical.

And, why introduce add'l splices in your harness? Using those (or any) socket/pigtails, you'll have at least four more splice points for each relay: eight add'l potential points of failure. I hate splices. I do them, of course, but I don't design in splices.

Regarding that Amazon link to five relays plus five pigtails for $5, I believe that that's a get-what-u-pay-for deal.

I believe the stock 9007 lamp is 65W on high-beam. At 13.8V nominal, that's around 10A for both headlamps on high-beam.

Those aren't 40A relays. They're rated at 30A. The 40A part is BS. It's supposed to be a surge rating. But there's damn little surge on a filament (the inrush current on a cold filament is for so brief a period as to be ignored for this application). If you want to talk inductive loads, then a surge rating is relevant, but not for headlamps.

I'd be reluctant to use a single $5 30A relay, much less a five-pack for $5. When even Potter & Brumfield relays are being sourced from China these days, I'm very picky about mission-critical relays -- and headlights are that. They run continuously for hours.

If I needed a relay for, say, power door locks, I might take a chance on a Chinese "Bosch style" relay (as AGT advertises at Amazon), but not for my headlights, nope. I've replaced bunches of crappy relays over the years.

A digression:

The ampere rating on these is one of those things like the Harbor Frieight appliance dollies.

They're one of only a handful of things I'll buy from HF. They're rated for a half-ton: 1000 lbs. They run $10. I have a half-dozen of them around at home. They're great for storing a 200 lb transmission under a workbench, or moving a bookshelf.

We put an 800 lb safe on one once. Guess what happened

Like the HF dollies, you have got to take the ratings and multiply by a service factor. I know a used Ford 70A Omron-sourced relay isn't going to fail with a 25A load for a good, long time. I'd bet money that a $1 30A relay from a no-name outfit will have a 80% load life measured in under a thousand hours. And that's not good enough.

In summary:

a) Cheap relays in a HL system aren't worth the money you save;

b) Building your own upgrade harness is a worthwhile investment of your time & money, if you have the skills & inclination;

c) Opinions are like armpits: everyone has a couple.

Originally Posted by Khan

Thats why using the relays that come with harnesses is a good idea instead of building your own with spade connectors

I am 100% certain that I can do better work and use better materials at an equivalent cost, or less, than a pre-built harness under $100. At least, the ones I've seen so far.

Next, those quick disconnect pigtails? Here's what AGT is saying about them:

Originally Posted by AGT/Amazon

Heavy Duty Wire and construction 16 Gauge 1ft Long

Put 30A on a 16 gauge stranded wire for a half-hour, then try to put your hand on it. You won't, because it'll be melted. The ampacity of 16 gauge solid wire is about 13A, and stranded wire will be even less (link to Wikipedia).

Are these sub-$1 pigtails going to be soldered? I thought not. A properly-crimped solderless connector can be a very good connection, but the dies in the line crimper have to be in good condition. Dice, anyone? Give me a soldered connection any time it's practical.

And, why introduce add'l splices in your harness? Using those (or any) socket/pigtails, you'll have at least four more splice points for each relay: eight add'l potential points of failure. I hate splices. I do them, of course, but I don't design in splices.

Regarding that Amazon link to five relays plus five pigtails for $5, I believe that that's a get-what-u-pay-for deal.

Originally Posted by Khan

you headlight bulbs are only 110 watts for the pair.

Originally Posted by Khan

A 40 amp will do.

I'd be reluctant to use a single $5 30A relay, much less a five-pack for $5. When even Potter & Brumfield relays are being sourced from China these days, I'm very picky about mission-critical relays -- and headlights are that. They run continuously for hours.

If I needed a relay for, say, power door locks, I might take a chance on a Chinese "Bosch style" relay (as AGT advertises at Amazon), but not for my headlights, nope. I've replaced bunches of crappy relays over the years.

A digression:

The ampere rating on these is one of those things like the Harbor Frieight appliance dollies.

They're one of only a handful of things I'll buy from HF. They're rated for a half-ton: 1000 lbs. They run $10. I have a half-dozen of them around at home. They're great for storing a 200 lb transmission under a workbench, or moving a bookshelf.

We put an 800 lb safe on one once. Guess what happened

Originally Posted by Khan

The Ford relays are better, but you don't need a 70 amp relay.

In summary:

a) Cheap relays in a HL system aren't worth the money you save;

b) Building your own upgrade harness is a worthwhile investment of your time & money, if you have the skills & inclination;

c) Opinions are like armpits: everyone has a couple.

#41

always believed in using relays and switches rated for 2X the run load for hot switched apps like headlights.

voltage drop on too small gauge wiring, low quality switch and relay contacts only makes a marginal headlight system like the Aero even worse. suppose if my only night driving was no rain, clear weather, no fog well lighted freeway, I wouldn't care.

NOT fun having both headlights go out on a long night drive.

the wet climate we have here in the Pac NW and as much as I like to drive on the beach chasing razor clams and Japanese drift, I use marine Coast Guard approved copper with tin coating stranded wiring and HD moisture resistance insulation

Genuinedealz > Marine Wire, Boat Wire, Boat Cable, Marine Grade

certified tested copper content, not like the cheap Chinese pot metal god knows what metals junk at the auto parts store.

I like screw or solder terminal relays, not the easily pulled off or corrosion head ache push on crimp connectors. if I can't do the above, I crimp with HD industrial crimps and then solder the wire connection and the relay pushon then slide self sealing heat shrink up over all.

prevents problems with my mountain logging road photography trips and beach salt water ingress.

http://shop.genuinedealz.com/Marine%...rink%20Tubing/

only takes one trip out on the Pacific Ocean in a boat with defective low quality wiring to ruins one's life.

nice find on the relays Al, darn things are getting so expensive. will have to prowl the JR for some next trip.

My two, the wife says they stink

voltage drop on too small gauge wiring, low quality switch and relay contacts only makes a marginal headlight system like the Aero even worse. suppose if my only night driving was no rain, clear weather, no fog well lighted freeway, I wouldn't care.

NOT fun having both headlights go out on a long night drive.

the wet climate we have here in the Pac NW and as much as I like to drive on the beach chasing razor clams and Japanese drift, I use marine Coast Guard approved copper with tin coating stranded wiring and HD moisture resistance insulation

Genuinedealz > Marine Wire, Boat Wire, Boat Cable, Marine Grade

certified tested copper content, not like the cheap Chinese pot metal god knows what metals junk at the auto parts store.

I like screw or solder terminal relays, not the easily pulled off or corrosion head ache push on crimp connectors. if I can't do the above, I crimp with HD industrial crimps and then solder the wire connection and the relay pushon then slide self sealing heat shrink up over all.

prevents problems with my mountain logging road photography trips and beach salt water ingress.

http://shop.genuinedealz.com/Marine%...rink%20Tubing/

only takes one trip out on the Pacific Ocean in a boat with defective low quality wiring to ruins one's life.

nice find on the relays Al, darn things are getting so expensive. will have to prowl the JR for some next trip.

My two, the wife says they stink

#42

Al, you've written down all the thoughts I considered when I put my system together, and came up with the same conclusions. I've not seen a pre-made harness that I've been satisfied with; they all used very thin wires, and most of them exposed the electrical connectors to the elements. That's why I chose to make my own.

For what it's worth, I had no trouble flowing solder into the crimped connectors. Put the solder iron tip on one side of the wire "tunnel", and touch the solder onto the other end. When the solder starts melting, it will slowly flow toward the hot iron tip. You know you've flowed enough when it starts dripping out of the connector. In my case, the plastic insulator softened and molded itself to the outside of the connector.

I used those 1 cubic inch relays, rated at 30A, from Radio Shack. They're most likely China sourced. They weren't the cheapest, nor the most expensive, but they've been working for almost 15 years on the Mustang, and at least 12 years on the Aerostar. As you noted, a typical pair of 65W high beams will draw only about 10A, so that's plenty of margin. By the way, 40A at 12V is 480W, not 240W.

I used 10 gauge wires for the high current side of the relay, which are also rated for 30A, like the relays and fuses I used. The additional current rating isn't all about how much current the parts can support, but more a matter of built up resistance. Any amount will cause the lights to be dimmer. The only resistive elements I could not get around were the fuses, which work based on resistance generating enough heat to melt it when the current flow exceeds its rating.

For what it's worth, I had no trouble flowing solder into the crimped connectors. Put the solder iron tip on one side of the wire "tunnel", and touch the solder onto the other end. When the solder starts melting, it will slowly flow toward the hot iron tip. You know you've flowed enough when it starts dripping out of the connector. In my case, the plastic insulator softened and molded itself to the outside of the connector.

I used those 1 cubic inch relays, rated at 30A, from Radio Shack. They're most likely China sourced. They weren't the cheapest, nor the most expensive, but they've been working for almost 15 years on the Mustang, and at least 12 years on the Aerostar. As you noted, a typical pair of 65W high beams will draw only about 10A, so that's plenty of margin. By the way, 40A at 12V is 480W, not 240W.

I used 10 gauge wires for the high current side of the relay, which are also rated for 30A, like the relays and fuses I used. The additional current rating isn't all about how much current the parts can support, but more a matter of built up resistance. Any amount will cause the lights to be dimmer. The only resistive elements I could not get around were the fuses, which work based on resistance generating enough heat to melt it when the current flow exceeds its rating.

#43

Thought I might chip in with an update since technology is always changing.

HIDs:

As I expressed before, HIDs are severely lacking technologically. They inherently produce too much blue spectrum light, which then has to be filtered out. 45k bulbs work well and have less glare, but the color rendering problems persist. Many EU countries have banned automakers from selling HID equipped vehicles after numerous safety tests showed that they are inferior to halogen technology. Now HIDs can work fine if they are used with a properly designed projector housing. But they are not suitable to retrofit into a halogen reflector. They never have been and never will be.

LED technology:

This has some real promise when designed correctly. While LEDs still have a ways to go to be perfected, they do have some genuine advantages. If they are designed properly they can be used with a halogen reflector, though using an LED reflector is better. The color rendering can be pretty good, especially on warm spectrum bulbs. While not as even as halogens, the color of light the LEDs produce is better than HIDs. The manufacturer of the bulb can produce almost any color. There are different options and solutions. It is up to the individual to do their own research to find the best products and not get caught up in gimmicks.

Obviously the pros and cons of the different options must be considered.

HIDs:

As I expressed before, HIDs are severely lacking technologically. They inherently produce too much blue spectrum light, which then has to be filtered out. 45k bulbs work well and have less glare, but the color rendering problems persist. Many EU countries have banned automakers from selling HID equipped vehicles after numerous safety tests showed that they are inferior to halogen technology. Now HIDs can work fine if they are used with a properly designed projector housing. But they are not suitable to retrofit into a halogen reflector. They never have been and never will be.

LED technology:

This has some real promise when designed correctly. While LEDs still have a ways to go to be perfected, they do have some genuine advantages. If they are designed properly they can be used with a halogen reflector, though using an LED reflector is better. The color rendering can be pretty good, especially on warm spectrum bulbs. While not as even as halogens, the color of light the LEDs produce is better than HIDs. The manufacturer of the bulb can produce almost any color. There are different options and solutions. It is up to the individual to do their own research to find the best products and not get caught up in gimmicks.

Obviously the pros and cons of the different options must be considered.

#44

Halogen Pros

Factory equipment

low cost

can be improved and optimized through better wiring

lots of options

Halogen cons

Heat

high wattage for light output

requires better than factory wiring for optimal light output

HID pros

high levels of light output

excellent output in space constrained applications

more light per watt than halogen

HID cons

tends to produce high levels of glare

often has blue shifted color spectrum

has to warm up to produce full light output

not compatible with halogen reflectors

some produce UV light which can burn plastic lenses

some produce concentrated heat which can burn lenses

poor color rendering

LED pros

Wide degree of color spectrum options

instant brightness

resistant to vibration

long life

low power consumption

when correctly designed has excellent beam pattern

can be compatible with halogen reflector

LED cons

new technology. Unproven long term

high cost

lots of poorly designed and gimmicky products

cheaper products use blue shift to create increased perceived brightness

LEDs may require good cooling

if LEDs overheat they may fail prematurely

Factory equipment

low cost

can be improved and optimized through better wiring

lots of options

Halogen cons

Heat

high wattage for light output

requires better than factory wiring for optimal light output

HID pros

high levels of light output

excellent output in space constrained applications

more light per watt than halogen

HID cons

tends to produce high levels of glare

often has blue shifted color spectrum

has to warm up to produce full light output

not compatible with halogen reflectors

some produce UV light which can burn plastic lenses

some produce concentrated heat which can burn lenses

poor color rendering

LED pros

Wide degree of color spectrum options

instant brightness

resistant to vibration

long life

low power consumption

when correctly designed has excellent beam pattern

can be compatible with halogen reflector

LED cons

new technology. Unproven long term

high cost

lots of poorly designed and gimmicky products

cheaper products use blue shift to create increased perceived brightness

LEDs may require good cooling

if LEDs overheat they may fail prematurely

#45

I've been using HID headlights in the Mustang for almost 15 years, and they've been great. They're the 4300K types, so once they warm up (in the same time it takes other HID lights to warm up), they look almost like bright halogen lights, with excellent color rendering. Their spectral output is broader than LEDs, so their illumination doesn't appear as harsh. These lower temperature HID bulbs are readily available, but most cars come with the 6000K version, which have that bluish cast, and do not have as good of color rendering, though still better than most LEDs with the same color rating.

I've been riding in the mountains at night for about 20 years, with enough experience using halogen, HID, and LED lights and I really prefer the HID for visibility. Maybe it was the HID bulbs that were made by Welch-Allyn, originally for medial devices, but they just got the color right. The LED lights were always too blue, providing poor color rendition, and making it difficult to discern different textures of the trails.

LED makers can make the colors warmer to get better color rendition, but that also reduces their luminous output, losing some of the efficacy advantage. The new cars coming out with LED headlights still have too high of apparent color temperature, due mainly to their too sharp of spectral outputs. That becomes a big problem in foggy conditions, where the light really scatters. Even without fog, I've found that passing road signs at night, the reflections from signs on the side of the road are intense enough to slightly blind you to the road in front of you.

The other problem with LED lights is that they still produce a lot of heat; they're about as efficient at turning electrons into visible photons as HID lights at their respective designed operating points. But where HID efficacy increases with increasing power, LED efficacy decreases with increasing power. LEDs start generating more heat than visible light when you crank up the power. All that heat must be carried away, or the LED will burn out fast, like any other overheated semiconductor device.

The biggest problem with HID lights is their 30-60 second warm up time. This is where both halogen and LED have the advantage, near instant on/off.

The second biggest problem with HID lights is their heavy ballast. My helmet mounted HID light has the ballast built into the housing, making it a lot heavier than a halogen or LED light. However, LED lights also need a regulator, which is a ballast of sorts, but that operates at much lower voltages, so it can be much smaller. But it still needs to have proper heat sinking, or the regulator can also fail, again like an overheated solid state device.

The third big problem with HID lights is their glass envelop; it's fragile like a halogen bulb.

LED is probably the future of lighting, but the current versions can still be improved upon.

I've been riding in the mountains at night for about 20 years, with enough experience using halogen, HID, and LED lights and I really prefer the HID for visibility. Maybe it was the HID bulbs that were made by Welch-Allyn, originally for medial devices, but they just got the color right. The LED lights were always too blue, providing poor color rendition, and making it difficult to discern different textures of the trails.

LED makers can make the colors warmer to get better color rendition, but that also reduces their luminous output, losing some of the efficacy advantage. The new cars coming out with LED headlights still have too high of apparent color temperature, due mainly to their too sharp of spectral outputs. That becomes a big problem in foggy conditions, where the light really scatters. Even without fog, I've found that passing road signs at night, the reflections from signs on the side of the road are intense enough to slightly blind you to the road in front of you.

The other problem with LED lights is that they still produce a lot of heat; they're about as efficient at turning electrons into visible photons as HID lights at their respective designed operating points. But where HID efficacy increases with increasing power, LED efficacy decreases with increasing power. LEDs start generating more heat than visible light when you crank up the power. All that heat must be carried away, or the LED will burn out fast, like any other overheated semiconductor device.

The biggest problem with HID lights is their 30-60 second warm up time. This is where both halogen and LED have the advantage, near instant on/off.

The second biggest problem with HID lights is their heavy ballast. My helmet mounted HID light has the ballast built into the housing, making it a lot heavier than a halogen or LED light. However, LED lights also need a regulator, which is a ballast of sorts, but that operates at much lower voltages, so it can be much smaller. But it still needs to have proper heat sinking, or the regulator can also fail, again like an overheated solid state device.

The third big problem with HID lights is their glass envelop; it's fragile like a halogen bulb.

LED is probably the future of lighting, but the current versions can still be improved upon.