Wire size ????

#1

Wire size ????

What size wire should be used for wiring the gauges,and other comp. Would this work from EBAY

eBay Motors: 16 Gauge Wire Assortment - Auto Electrical Truck RV (item 200317441754 end time Mar-09-09 16:47:43 PDT)

eBay Motors: 16 Gauge Wire Assortment - Auto Electrical Truck RV (item 200317441754 end time Mar-09-09 16:47:43 PDT)

#2

#3

For the gauges, I would have to recommend the painless gauge harness. I used it and work flawless and looks neat. Saves alot of time, wires are marked, neat and clean for any troubleshooting, and not that exspensive. It can be used with OEM guages if that is what you are using. I got mine through Parr Automotive.

#4

I looked at the ebay listing. It claims the wire is made in the USA but I sort of doubt it. This looks like one of the deals you can get through HF or some of the other foreign vendors. It may just be packaged in the USA. Bob mentions the use of heavier wire, which is a good idea for 6 volt systems as they run at twice the current in amps as theire 12 volt counterparts. However, that said, I do not totally agree with the sbsolute need for heavier than 16 GA wire in all applications. Go to a junk yard and take a look at the wire being used in cars built in the last ten years. I doubt if you will find much 14 GA. wire in them. The issues here is not one size for all applications. It is a matter of matching the wire size to the current load required.

Another thing I have a problem with is the insulation on the wire. 50 volt insulation rating makes for a very thin and therefore not very durable covering for the wire. In other words, there is very little mechanical protection for the conductors. Put another way, it would take very little to break through the insulation sheath by processes of vibration or rubbing edges and surfaces. Even thirty-million dollar fighter planes have been brought dowm by by this and they use the best wire money can buy.

I don't like pre-made harness kits. They use the cheapest stuff they can get by with. However, I do understand the need for simplicity when people either do not know anything about electrical systems or they just want to get it done quickly.

I use either THHN or MTW wire. Either is intended for industrial applications in harsh environments. The common insulation value is 600 volts. You can get the stuff at Lowe's or Home Depot. I have an account with a local industrial electrical supplier and I can usually beat Lowe's prices. I buy the single conductor wire in 250' rolls.

Another point is the connector devices you use. Don't skimp on that stuff by buying the foreign junk sold by HF. Get a good quality brand like T&B or equivilent. Use the right tools for crimping. I have seen more than one good looking job fail due to bad crimping. If you don't do it right it will pull right out with a minimum of tension.

I hope I have not discouraged you with your project. I just thing doing it right trumps saving a buck or a little time.

Later Man...

Another thing I have a problem with is the insulation on the wire. 50 volt insulation rating makes for a very thin and therefore not very durable covering for the wire. In other words, there is very little mechanical protection for the conductors. Put another way, it would take very little to break through the insulation sheath by processes of vibration or rubbing edges and surfaces. Even thirty-million dollar fighter planes have been brought dowm by by this and they use the best wire money can buy.

I don't like pre-made harness kits. They use the cheapest stuff they can get by with. However, I do understand the need for simplicity when people either do not know anything about electrical systems or they just want to get it done quickly.

I use either THHN or MTW wire. Either is intended for industrial applications in harsh environments. The common insulation value is 600 volts. You can get the stuff at Lowe's or Home Depot. I have an account with a local industrial electrical supplier and I can usually beat Lowe's prices. I buy the single conductor wire in 250' rolls.

Another point is the connector devices you use. Don't skimp on that stuff by buying the foreign junk sold by HF. Get a good quality brand like T&B or equivilent. Use the right tools for crimping. I have seen more than one good looking job fail due to bad crimping. If you don't do it right it will pull right out with a minimum of tension.

I hope I have not discouraged you with your project. I just thing doing it right trumps saving a buck or a little time.

Later Man...

#5

#6

wiring

Have you thought about calling EZ for extra wiring? Behind the seat seems like alot of splicing. Unless you spread out the splices, the bundle size including heat shielding will grow. All those wires and splices on the floor is a potential problem, especially if someone spills a liquid or leaves the window open in the rain. Shoot happens. Unless air-cond or other installation mod, I would consider mounting in the glove box. Easy to access fuses,etc. or if not using original radio, mount behind dash speaker grille. chuck

#7

Dave, three reasons I suggested not going smaller than 14 ga wire are the following:

I would also like to add if you don't do control wiring on a regular basis, like Dave and I do, I strongly suggest going with an aftermarket wire harness. Wiring from scratch isn't easy unless you're used to reading wiring schematics. I also strongly suggest going with a non- stock reproduction harness unless you're going for show quality originality, where originality counts. I bought reproduction clothe covered harness for my F-2 25+ years ago and it looks almost as bad now as the original wire harness that I yanked out of the truck. For my panel I rewired the entire truck with modern MTW wire. I will eventually redo the F-2 with MTW wire.

- I didn't know what voltage he was running, going with a heavier wire usually never hurts. <br>

- Instead of buying numerous gages of wires and only using a little of each I like to look at the gages needed and buy just a couple of gages, using 14 gage for all the circuits calling for 18ga, 16g and 14ga. Same with using 10ga for all of the 12ga and 10ga circuits. We're lucky, our jobs call for all kinds of wire and we have everything at our disposal. The average guy doesn't have our stock.<br>

- I just like going with a heavier gage because it doesn't cost all that much more to step up a gage. I think the car manufacturers use the minimum gage wire to save on weight and money. There have been plenty of recalls and warnings about inferior wire being using and causing problems. I was sent a warning after I bought my daily driver not to use the headlight circuit to power axillary driving lights or trailer lights, it said I needed a relay adapter kit to do so.<br>

I would also like to add if you don't do control wiring on a regular basis, like Dave and I do, I strongly suggest going with an aftermarket wire harness. Wiring from scratch isn't easy unless you're used to reading wiring schematics. I also strongly suggest going with a non- stock reproduction harness unless you're going for show quality originality, where originality counts. I bought reproduction clothe covered harness for my F-2 25+ years ago and it looks almost as bad now as the original wire harness that I yanked out of the truck. For my panel I rewired the entire truck with modern MTW wire. I will eventually redo the F-2 with MTW wire.

Trending Topics

#8

Voltage doesn't matter when selecting wire gauge. (Assuming vehicle, dc voltages. AC is another ball of wax). What matters

is the current in the wire. General rule of thumb:

18 AWG --4 amps or less

16 AWG --10

14 AWG --15

12 AWG --20

10 AWG --25

8 AWG --30

This is for general use, go up one gauge for extremely long runs or overkill,

and try to use wire rated for 300 volts or better, as it has the thicker insulation.

Most permanent splice is a soldered connection covered with heatshrink tubing (the kind with the inner

adhesive that melts). The wire tap stuff is a less permanent connection, though insulated crimp splices

work pretty good inside the vehicle if installed correctly. Use a good crimp tool, not the cheapie that comes

with the splice assortment. Don't use crimp connectors where exposed to the weather unless heat shrink covered.

I stay away from Liberals because I'm allergic to nuts.

is the current in the wire. General rule of thumb:

18 AWG --4 amps or less

16 AWG --10

14 AWG --15

12 AWG --20

10 AWG --25

8 AWG --30

This is for general use, go up one gauge for extremely long runs or overkill,

and try to use wire rated for 300 volts or better, as it has the thicker insulation.

Most permanent splice is a soldered connection covered with heatshrink tubing (the kind with the inner

adhesive that melts). The wire tap stuff is a less permanent connection, though insulated crimp splices

work pretty good inside the vehicle if installed correctly. Use a good crimp tool, not the cheapie that comes

with the splice assortment. Don't use crimp connectors where exposed to the weather unless heat shrink covered.

I stay away from Liberals because I'm allergic to nuts.

#9

I do not normally use butt type crimp connections in my shop, only as a last resort like in a field installation when I didn't expect to connect two wires. I don't like the way they look. I always try to solder the wire together and use two layers of shrink tubing, top one slightly longer that first one. If a component has sealed leads coming out of it I normally use crimp on wire connectors: I leave extra wire available in case the component has to be replaced a person could cut both wires and recrimp the wire together again.

I leave extra wire available in case the component has to be replaced a person could cut both wires and recrimp the wire together again.

This is the crimp tool I use on a daily basis. I have three pair in my shop and will only allow my employees to use these to crimp connectors. When I first started building control systems the place I worked at provided the manual type, a little better than the type you get with a connector kit. We used them until one day we had a customer come into the shop to inspect the job we were doing for him. As he was looking over the control panel he started tugging on the wires and one came out of the crimp. My boss told me to find something better and these are what I found. They aren't cheap, about $130-150 but I've never had a wire come out of a connection since I started using them, almost 20 years. They show up on the 'Bay every so often, new and used.

Ideal #83-001

I leave extra wire available in case the component has to be replaced a person could cut both wires and recrimp the wire together again.

I leave extra wire available in case the component has to be replaced a person could cut both wires and recrimp the wire together again.This is the crimp tool I use on a daily basis. I have three pair in my shop and will only allow my employees to use these to crimp connectors. When I first started building control systems the place I worked at provided the manual type, a little better than the type you get with a connector kit. We used them until one day we had a customer come into the shop to inspect the job we were doing for him. As he was looking over the control panel he started tugging on the wires and one came out of the crimp. My boss told me to find something better and these are what I found. They aren't cheap, about $130-150 but I've never had a wire come out of a connection since I started using them, almost 20 years. They show up on the 'Bay every so often, new and used.

Ideal #83-001

#10

The gauges draw almost nothing; 6 or 12v, 20 ga will work. The "other comp." in the opening post would be a long list, with wire sizes based on the guidelines above and their individual current draws.

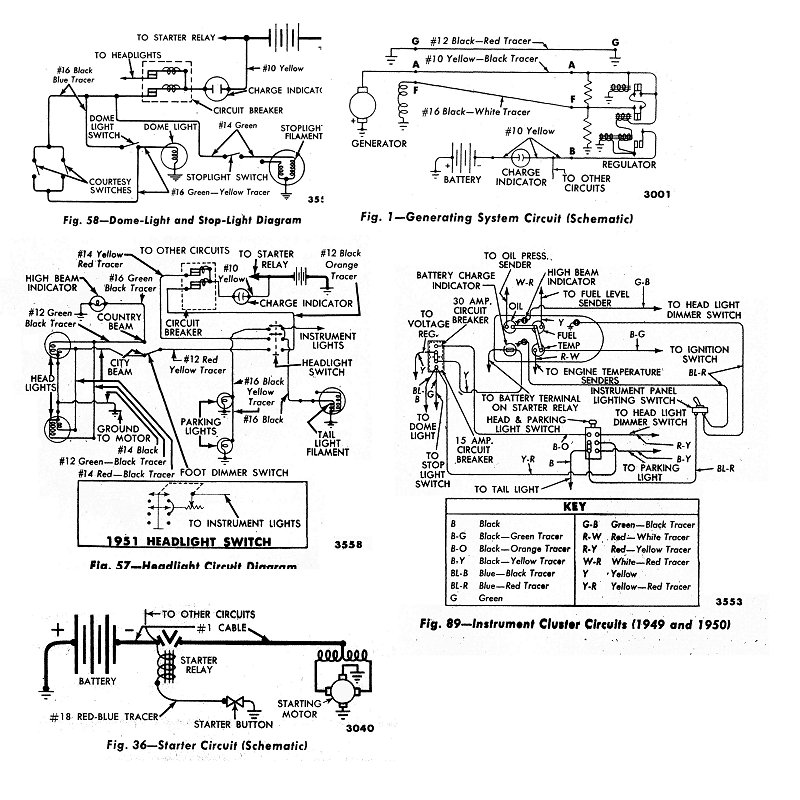

Bob, I've never seen a Bonus Built wiring diagram that gives wire gauges like you posted; is that out of the 48 - 51 WSM? It appears only the critical sizes are called out.

Dave, I started out using THHN, that is some miserable stuff to make into a loom! Great for straight stuff along the frame, tho.

Bob, I've never seen a Bonus Built wiring diagram that gives wire gauges like you posted; is that out of the 48 - 51 WSM? It appears only the critical sizes are called out.

Dave, I started out using THHN, that is some miserable stuff to make into a loom! Great for straight stuff along the frame, tho.

#11

The gauges draw almost nothing; 6 or 12v, 20 ga will work. The "other comp." in the opening post would be a long list, with wire sizes based on the guidelines above and their individual current draws.

Bob, I've never seen a Bonus Built wiring diagram that gives wire gauges like you posted; is that out of the 48 - 51 WSM? It appears only the critical sizes are called out.

Bob, I've never seen a Bonus Built wiring diagram that gives wire gauges like you posted; is that out of the 48 - 51 WSM? It appears only the critical sizes are called out.

I don't like using THHN wire because of the memory it has. It likes to find it's way back to being a coil. Some shops I have worked in used THHN in their panels, it's very stiff stuff to use when you don't have a lot of room. I use only MTW in panels, unless the customer specs out something else. I use all MTW wire in the panel. I have a wide variety of colors and gauges to use so I followed the color coding in the manual. For the wires with colored leads I use a paint pen to add the stripe.

#12

Yep, those crimpers are a step up, and from a price/performance standpoint are hard to beat. On the other hand here's a cadillac style-

Thomas & Betts, rather pricey, but, they last forever. I've had mine for almost 30 years..... (sorry about the picture quality, only image I can find).

Isn't carrying a gun a little overkill? Paranoid? When you need it, and don't have it, you sing a different tune.

Thomas & Betts, rather pricey, but, they last forever. I've had mine for almost 30 years..... (sorry about the picture quality, only image I can find).

Isn't carrying a gun a little overkill? Paranoid? When you need it, and don't have it, you sing a different tune.

#13

Those are OK but I've found them hard to use in close quarters. I sometimes find myself wiring in small restricted areas and with the type I use I can reach in and crimp a wire from the side. I don't have to try to thread the tool over the wire and crimp end. I've had my oldest pair over 15 years with a problem. It's all comes down to personal preference. I've tried almost every kind of wire stripper and have always come back to the manual type, the ones that are small and have the knotches in the front:

These are the worse:

This type is great for stripping the outer jacket off of cable, they also work pretty good at stripping regular wire:

These are the worse:

This type is great for stripping the outer jacket off of cable, they also work pretty good at stripping regular wire:

#14

Further clarification on wire size and amp capacity. Electrons move along the surface layer of the conductor, so the more surface area you have the less resistance and more carrying capacity before it starts heating up. A multi stranded wire of the same ga size will have more amp capacity than the same ga size with only a few to one conductor. Beware of cheap stranded wire with just a few larger strands in the bundle.

Dave, I'll have to disagree with you that the premade harness makers use the cheapest materials available. I have an EZ Wire harness and have to say they did not cut any corners on quality of materials IMHO.

Rusty, I'd look at your situation as an opportunity to add a disconnect plug under the seat or under the dash and then add the necessary wire length from the plug to the gauges. See how many conductors you need to extend then pick up a male and female automotive grade plug and socket. They are available from auto supply stores and some electronic parts supply stores. I prefer that they have removable connectors to solder to rather than pigtails attached. I bought a quantity of them a while back they were dirt cheap in industrial quantities, so I may be able to supply you with what you need.

If you are extending an EZ wire harness, I'd just match the wire ga of the wires you are extending. I'd give EZWire a call to see if you can get the wire from them. I have talked to them several times and find them very friendly and helpful, unlike that other big name company that should use -in the a##, rather than -less.

Dave, I'll have to disagree with you that the premade harness makers use the cheapest materials available. I have an EZ Wire harness and have to say they did not cut any corners on quality of materials IMHO.

Rusty, I'd look at your situation as an opportunity to add a disconnect plug under the seat or under the dash and then add the necessary wire length from the plug to the gauges. See how many conductors you need to extend then pick up a male and female automotive grade plug and socket. They are available from auto supply stores and some electronic parts supply stores. I prefer that they have removable connectors to solder to rather than pigtails attached. I bought a quantity of them a while back they were dirt cheap in industrial quantities, so I may be able to supply you with what you need.

If you are extending an EZ wire harness, I'd just match the wire ga of the wires you are extending. I'd give EZWire a call to see if you can get the wire from them. I have talked to them several times and find them very friendly and helpful, unlike that other big name company that should use -in the a##, rather than -less.

#15

Follow up...

I have a few pouints to Make. alchymist, Yes it's true that it doesn't matter if it's 6 or 12 volts in respect to wire size. The point was, that in 6 volt systems the current for any given similar device is twice as much. That means the guage of the wire has to be larger to handle the current difference. It's Basic Electricity 101 and ninth grade General Science. As for using the crimpers that come with the splice assortmet is concerned, you might as well because if you bought a splice assortment, it's probably junk anyway.

Moving on, Yes Bobj, you are right, THHN is a lot harder to work with than the softer and more pliable MTW. I too would prefer MTW to work with and it is a lot easier to make a good looking job. However, over the years working on so many jobs that require and use it, I have amassed quite a collection of the stuff. So I use it because I don't like to mix types of wire. Also, if you go to places like Lowe's, that is what they have. If you want MTW you pretty much have to get it from an industrial supplier. More on the crimpers... Those cycled crimpers were designed to be used by people who do not apply enough pressure to make a good crimp. They will not allow you to release until you have gone through the complete crimp cycle. It is another idiot proof tool. It's made that way so you can't screw up the crimp.

Pre-wire kits... As I said before, don't like 'em and I won't use 'em. This is because they cut corners by using minimal wire sizes and lower quality material. However, I do understand there are a lot of people that do for various reasons that are justifiable. In Rusty's case, a custom wiring job would have been a whole lot better because there would no be a big ball of splices.

ALBUQ F-1, yes, in most cases guage wiring does not pull much current but there is one exception. The ammeters in the old sytems, pass all the current being used in the vehicle with exception of the starter. It has to be of suffeceint size to handle the total ouput of your generator or alternator. If you have the minimum 30 amp charging system then you need at least 10 GA wire. Yes, you're right, they don't always do it but that is because they figure your charging system won't be demanding that much current on a steady basis. if you start adding stuff like big driving lights and A/C, then you will need bigger wire in the ammeter circuit.

bobj, I don't do control wiring on a regular basis anymore since I retired two years ago. I only do vehicle wiring now. I will be posting some of the work on my website in the next few months and then everyone can judge for themselves. I am about to do some work on a project I am trying to wind up. I will be posting that job when complete and I have two trucks I'll be doing soon.

Later Folks...

Moving on, Yes Bobj, you are right, THHN is a lot harder to work with than the softer and more pliable MTW. I too would prefer MTW to work with and it is a lot easier to make a good looking job. However, over the years working on so many jobs that require and use it, I have amassed quite a collection of the stuff. So I use it because I don't like to mix types of wire. Also, if you go to places like Lowe's, that is what they have. If you want MTW you pretty much have to get it from an industrial supplier. More on the crimpers... Those cycled crimpers were designed to be used by people who do not apply enough pressure to make a good crimp. They will not allow you to release until you have gone through the complete crimp cycle. It is another idiot proof tool. It's made that way so you can't screw up the crimp.

Pre-wire kits... As I said before, don't like 'em and I won't use 'em. This is because they cut corners by using minimal wire sizes and lower quality material. However, I do understand there are a lot of people that do for various reasons that are justifiable. In Rusty's case, a custom wiring job would have been a whole lot better because there would no be a big ball of splices.

ALBUQ F-1, yes, in most cases guage wiring does not pull much current but there is one exception. The ammeters in the old sytems, pass all the current being used in the vehicle with exception of the starter. It has to be of suffeceint size to handle the total ouput of your generator or alternator. If you have the minimum 30 amp charging system then you need at least 10 GA wire. Yes, you're right, they don't always do it but that is because they figure your charging system won't be demanding that much current on a steady basis. if you start adding stuff like big driving lights and A/C, then you will need bigger wire in the ammeter circuit.

bobj, I don't do control wiring on a regular basis anymore since I retired two years ago. I only do vehicle wiring now. I will be posting some of the work on my website in the next few months and then everyone can judge for themselves. I am about to do some work on a project I am trying to wind up. I will be posting that job when complete and I have two trucks I'll be doing soon.

Later Folks...