My head is "supper glued" to the block!

#61

#62

Yea, I may not have mentioned it, but we were talking about the hard plastic wedges, NOT the metal ones.

I didn't think adding heat to the exhaust port area would cause any damage since it is probably designed for that kind of thing. I also got the suggestion of filling the hole with PB Blaster, and driving a punch down the hole into the top of the broken bolt. Not to deform it, but to "shock" it so maybe the lube can work it's way in.

I didn't think adding heat to the exhaust port area would cause any damage since it is probably designed for that kind of thing. I also got the suggestion of filling the hole with PB Blaster, and driving a punch down the hole into the top of the broken bolt. Not to deform it, but to "shock" it so maybe the lube can work it's way in.

#63

#65

#66

This is my first post on this site, so hello to everyone.

First, make sure when you are spraying the penetrating fluid that you are also spraying it in the exhaust manifold bolt hole that intersects with the broken bolt hole. That way it will work away at the carbon from both ends. After soaking for a day try prying the head off by using a long pipe through the lift-bracket on the head. This probably won't work since the head needs to come straight up, but it might break it loose so you can work it off by hand.

The best solution I have heard so far is to drill out the bolt. If you are concerned about metal shavings getting into the motor, don't worry about it. You are going to have the head cleaned at the machine shop and you can vacuum/blow/wash out any shaving that fall into the motor once you get the head off. Use a shop vac to suck the shaving out of the hole, rather than blowing them all over the place with compressed air. Make sure to keep oil in the hole and to use a drill bit that is as big as the bolt. Keep the drill slow and steady with plenty of pressure. If shavings are not coming you have the drill rpm's too fast or the bit is dulled. The bit should not scream, but have a nice hum to it. And be sure to keep the drill at the right angle so you don't drill into the head. As was mentioned, use tape to mark the drill bit so you don't drill into the threads in the block. Every inch or so try prying the head off. If you stop for the day, spray it down with the penetrating spray and try prying it off the next day.

Good luck and keep us updated.

First, make sure when you are spraying the penetrating fluid that you are also spraying it in the exhaust manifold bolt hole that intersects with the broken bolt hole. That way it will work away at the carbon from both ends. After soaking for a day try prying the head off by using a long pipe through the lift-bracket on the head. This probably won't work since the head needs to come straight up, but it might break it loose so you can work it off by hand.

The best solution I have heard so far is to drill out the bolt. If you are concerned about metal shavings getting into the motor, don't worry about it. You are going to have the head cleaned at the machine shop and you can vacuum/blow/wash out any shaving that fall into the motor once you get the head off. Use a shop vac to suck the shaving out of the hole, rather than blowing them all over the place with compressed air. Make sure to keep oil in the hole and to use a drill bit that is as big as the bolt. Keep the drill slow and steady with plenty of pressure. If shavings are not coming you have the drill rpm's too fast or the bit is dulled. The bit should not scream, but have a nice hum to it. And be sure to keep the drill at the right angle so you don't drill into the head. As was mentioned, use tape to mark the drill bit so you don't drill into the threads in the block. Every inch or so try prying the head off. If you stop for the day, spray it down with the penetrating spray and try prying it off the next day.

Good luck and keep us updated.

#68

pawpaw - In post #11 & 31 I tried using compression to pop it. Both from the pistons and from an air compressor. There is too much air escaping to build pressure.

Ken00 - Don't sweat it, I was considering it myself. I guess the professional words of wisdom just saved me some time. (since we don't have an icon for a dunce hat. lol)

(since we don't have an icon for a dunce hat. lol)

RangerPilot - I will be trying just about anything. Oh, I have been getting around via "Flinstone" power. In all seriousness though we have a few cars in the family, 77' T/A (project car), 92' Integra, 97' Civic, 05' CR-V and the 88' Ranger which is intended to be my "beater". The secret is in the username:

In all seriousness though we have a few cars in the family, 77' T/A (project car), 92' Integra, 97' Civic, 05' CR-V and the 88' Ranger which is intended to be my "beater". The secret is in the username:

Generation

2

Integra

Club

scuba69diver - Welcome, and thanks for the suggestions. Updates to follow.

handyman43358 -

Ken00 - Don't sweat it, I was considering it myself. I guess the professional words of wisdom just saved me some time.

(since we don't have an icon for a dunce hat. lol)

(since we don't have an icon for a dunce hat. lol)RangerPilot - I will be trying just about anything. Oh, I have been getting around via "Flinstone" power.

In all seriousness though we have a few cars in the family, 77' T/A (project car), 92' Integra, 97' Civic, 05' CR-V and the 88' Ranger which is intended to be my "beater". The secret is in the username:

In all seriousness though we have a few cars in the family, 77' T/A (project car), 92' Integra, 97' Civic, 05' CR-V and the 88' Ranger which is intended to be my "beater". The secret is in the username:Generation

2

Integra

Club

scuba69diver - Welcome, and thanks for the suggestions. Updates to follow.

handyman43358 -

#70

Wow G2, it was X-mas when you first posted about this and still haven't got it resolved! What a pain.

I just had to pull the head off my 95 2.3 with 145k and it came right off. My bolts were much cleaner than yours coming out too.

I feel for ya. Sorry I don't have any ideas.....just had to post. I'm curious to find out what happens.

I just had to pull the head off my 95 2.3 with 145k and it came right off. My bolts were much cleaner than yours coming out too.

I feel for ya. Sorry I don't have any ideas.....just had to post. I'm curious to find out what happens.

#71

This has nothing to do with the Ranger head.....

Do you have the 400 in the T/A or the 455?? I'm interested to find out, bc my 22yr old brother has a 78 T/A with the 400 that's been recently built and the 3spd auto which has also been built. Do you know how the two motors compare to each other? He was trying to find a 455 to put in there when he had it rebuilt. Btw, he had it rebuilt bc his motor locked up as he was doing 85 down the interstate and the car nearly killed him. It's black with the "BANDIT1" license plate. I'm in love with this car. The power is amazing.

Do you have the 400 in the T/A or the 455?? I'm interested to find out, bc my 22yr old brother has a 78 T/A with the 400 that's been recently built and the 3spd auto which has also been built. Do you know how the two motors compare to each other? He was trying to find a 455 to put in there when he had it rebuilt. Btw, he had it rebuilt bc his motor locked up as he was doing 85 down the interstate and the car nearly killed him. It's black with the "BANDIT1" license plate. I'm in love with this car. The power is amazing.

#72

Go figure, I went to the hardware store trying to find the plastic wedges, and they just look at me like I have 3 heads. The search is on, so if anyone knows just were to get some with a very thin egde please let me know.

RangerPilot - Thanks.

chelmer - Yes it is one royal pain. I have never had anything stuck like this before. Lucky me.

natebaker - It kind of depends on what car the 400 and 455 came out of. For the most part (the best I can remember) all 389 to 455 Pontiac engines are the same block with different bore and stroke and different heads. It has been quite a while since I have been able to spend some time on it. I love that car and yes the power is scary. Pontiacs had descent HP, but it was usually the Torque that would twist you like a pretzel. When it came to the 400 there were several variations of it that came in different cars. The nastiest 400ci Pontiac that I know of was the RamAir IV (and very rare). For my current power plant I found a 1969 GTO 400ci RamAir III that has been just waiting to fire up. I hope it is everything I want. If not I will have to win the lottery so I can do a super killer Twin Turbo LS-1 (or LT-5)

When it came to the 400 there were several variations of it that came in different cars. The nastiest 400ci Pontiac that I know of was the RamAir IV (and very rare). For my current power plant I found a 1969 GTO 400ci RamAir III that has been just waiting to fire up. I hope it is everything I want. If not I will have to win the lottery so I can do a super killer Twin Turbo LS-1 (or LT-5)  . I think a built LS-1TT could push 1000whp/1000wtq. But that is just dreaming for now.

. I think a built LS-1TT could push 1000whp/1000wtq. But that is just dreaming for now.

RangerPilot - Thanks.

chelmer - Yes it is one royal pain. I have never had anything stuck like this before. Lucky me.

natebaker - It kind of depends on what car the 400 and 455 came out of. For the most part (the best I can remember) all 389 to 455 Pontiac engines are the same block with different bore and stroke and different heads. It has been quite a while since I have been able to spend some time on it. I love that car and yes the power is scary. Pontiacs had descent HP, but it was usually the Torque that would twist you like a pretzel.

When it came to the 400 there were several variations of it that came in different cars. The nastiest 400ci Pontiac that I know of was the RamAir IV (and very rare). For my current power plant I found a 1969 GTO 400ci RamAir III that has been just waiting to fire up. I hope it is everything I want. If not I will have to win the lottery so I can do a super killer Twin Turbo LS-1 (or LT-5)

When it came to the 400 there were several variations of it that came in different cars. The nastiest 400ci Pontiac that I know of was the RamAir IV (and very rare). For my current power plant I found a 1969 GTO 400ci RamAir III that has been just waiting to fire up. I hope it is everything I want. If not I will have to win the lottery so I can do a super killer Twin Turbo LS-1 (or LT-5)  . I think a built LS-1TT could push 1000whp/1000wtq. But that is just dreaming for now.

. I think a built LS-1TT could push 1000whp/1000wtq. But that is just dreaming for now.

Last edited by Ken00; 03-10-2006 at 07:15 PM.

#73

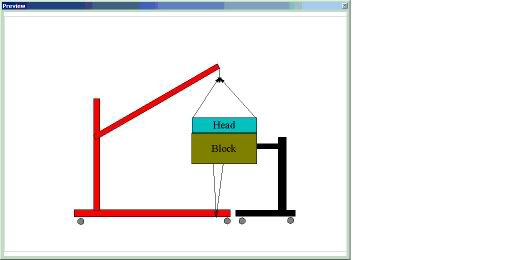

Ok guys, this thing is really getting to me. The engine is out, all the bolts are removed (the broken piece is still in there), and the engine is mounted to a stand. I tried soaking the hole, I remove all the other accessories on the head and engine, and there is just nowhere to get leverage to pry up. I tried the only hard plastic wedge I could find (a tent stake that I ground a flat edge into), I'll let you guess what happened.  I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.

I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.

So now I have a new idea. I have never tried this but I think it could work, see what you think. Take a look at this simple pic I made to describe what I want to do. The black arrows are supposed to be chains. The crane has an 8 ton ram on it and I will use the strongest chain I can find. I was thinking of using the biggest bolts on the block like maybe where the mounts bolt to. What do you think????? Am I just crazy?

I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.

I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.So now I have a new idea. I have never tried this but I think it could work, see what you think. Take a look at this simple pic I made to describe what I want to do. The black arrows are supposed to be chains. The crane has an 8 ton ram on it and I will use the strongest chain I can find. I was thinking of using the biggest bolts on the block like maybe where the mounts bolt to. What do you think????? Am I just crazy?

#74

#75

So you're going to use the crane to pry up on the head while you do your best to anchor the block. Sounds good in theory at least. I say give it whirl.

You might want to use a rubber hammer to (reasonably) bang on the head and block while using the crane to try and pull them apart.

Good luck.

You might want to use a rubber hammer to (reasonably) bang on the head and block while using the crane to try and pull them apart.

Good luck.