460 engine stumbling under load

#31

My ECM is under the heater core. I did a how-to thread here on replacing mine.

My bracket is intact and my ground cable was correctly installed. I should do an ohm test to verify.

I hooked up a vacuum gauge tonight - I'm getting steady and good vacuum at idle. I haven't tried driving with it. Maybe tomorrow.

Since I'm getting such good fuel pressure, even while stumbling, I tend to doubt the fuel pump.

I guess tomorrow I'll replace the TPS, but I doubt that is the issue.

At this point I'm ready to call the Ford dealership on Monday and see if they will look at it even though it's an RV. I'm hoping they have a computer intercept connector they can plug in between the computer connector and the ECM and log the sensor inputs and computer outputs while driving.

There is a guy who sells one (tweecer.com) but it is like $400.

Steve

My bracket is intact and my ground cable was correctly installed. I should do an ohm test to verify.

I hooked up a vacuum gauge tonight - I'm getting steady and good vacuum at idle. I haven't tried driving with it. Maybe tomorrow.

Since I'm getting such good fuel pressure, even while stumbling, I tend to doubt the fuel pump.

I guess tomorrow I'll replace the TPS, but I doubt that is the issue.

At this point I'm ready to call the Ford dealership on Monday and see if they will look at it even though it's an RV. I'm hoping they have a computer intercept connector they can plug in between the computer connector and the ECM and log the sensor inputs and computer outputs while driving.

There is a guy who sells one (tweecer.com) but it is like $400.

Steve

#32

Good idea to ohm the gorund. I remember being told that its a good idea to clean all the grounds from time to time. I was just hoping connecting the ground properly would by some miracle fix mine!

Good on the vacuum gauge. you can rule out a lot of possible mechanical problems.

TPS,,, have you checked it with a ohm meter? Mine is on the bottom of the throttle body and I have to take the throttle body off to change it.. since mine is fairly new, i will just check mine with a meter.

I understand the frustration. The problem with the dealer and most shops is that often the mechanics were in diapers when of vans/motor-homes were built. You have to hope that you get an older mechanic who was good with the older ones. 2 different shops and 2 trips to each one before I had to get in the bay with the last guy and help him get the alignment right on my van. He couldn't understand that there was only 1 adjustment for the toe in and the caster/camber readings varied with ride height.

I am not sure just how much live data Ford can read. I had a guy to use a Snap On MT2500 on mine right after I got it but he couldn't read much more then the O2 sensor I don't think.. I will check my code reader and see what it can read on mine. I bought the Actron CP9145 to use on my sons 94 regal.It has a obd1-1/2. it was a transition year for that car and only a few scanners would work. It came with a Ford OBD1 cable and I ran it on my van. On the Buick we could read the coolant temp, rpm's, o2 sensor, cylinder balance test, and a few components. on the van it pretty much ran its program and told me when to turn the steering wheel and hit the brake peddle and I believe it gave me live o2 data, I am not positive about that but think it did. I'll check again tomorrow.

Have you checked the timing chain slack? I have been meaning to do that on mine and will when I tune it up in the next week or two. I will have to look it up again but i believe it is as follows. Take the distributor cap off. Clean the timing marks and and bracket off so you can clearly read them. turn the crank clockwise till you line up on 0 = TDC. turn the crank back counter clockwise very carefully just until the rotor starts to move. If it takes more then 7 degrees then there is excessive slack in the timing chain.

You said the vacuum at idle was good though. I believe that if your timing is retarded due to slack in the chain and gears, the vacuum will be low at idle.

Anna

Good on the vacuum gauge. you can rule out a lot of possible mechanical problems.

TPS,,, have you checked it with a ohm meter? Mine is on the bottom of the throttle body and I have to take the throttle body off to change it.. since mine is fairly new, i will just check mine with a meter.

I understand the frustration. The problem with the dealer and most shops is that often the mechanics were in diapers when of vans/motor-homes were built. You have to hope that you get an older mechanic who was good with the older ones. 2 different shops and 2 trips to each one before I had to get in the bay with the last guy and help him get the alignment right on my van. He couldn't understand that there was only 1 adjustment for the toe in and the caster/camber readings varied with ride height.

I am not sure just how much live data Ford can read. I had a guy to use a Snap On MT2500 on mine right after I got it but he couldn't read much more then the O2 sensor I don't think.. I will check my code reader and see what it can read on mine. I bought the Actron CP9145 to use on my sons 94 regal.It has a obd1-1/2. it was a transition year for that car and only a few scanners would work. It came with a Ford OBD1 cable and I ran it on my van. On the Buick we could read the coolant temp, rpm's, o2 sensor, cylinder balance test, and a few components. on the van it pretty much ran its program and told me when to turn the steering wheel and hit the brake peddle and I believe it gave me live o2 data, I am not positive about that but think it did. I'll check again tomorrow.

Have you checked the timing chain slack? I have been meaning to do that on mine and will when I tune it up in the next week or two. I will have to look it up again but i believe it is as follows. Take the distributor cap off. Clean the timing marks and and bracket off so you can clearly read them. turn the crank clockwise till you line up on 0 = TDC. turn the crank back counter clockwise very carefully just until the rotor starts to move. If it takes more then 7 degrees then there is excessive slack in the timing chain.

You said the vacuum at idle was good though. I believe that if your timing is retarded due to slack in the chain and gears, the vacuum will be low at idle.

Anna

#33

I understand the frustration. The problem with the dealer and most shops is that often the mechanics were in diapers when of vans/motor-homes were built. You have to hope that you get an older mechanic who was good with the older ones. 2 different shops and 2 trips to each one before I had to get in the bay with the last guy and help him get the alignment right on my van. He couldn't understand that there was only 1 adjustment for the toe in and the caster/camber readings varied with ride height.

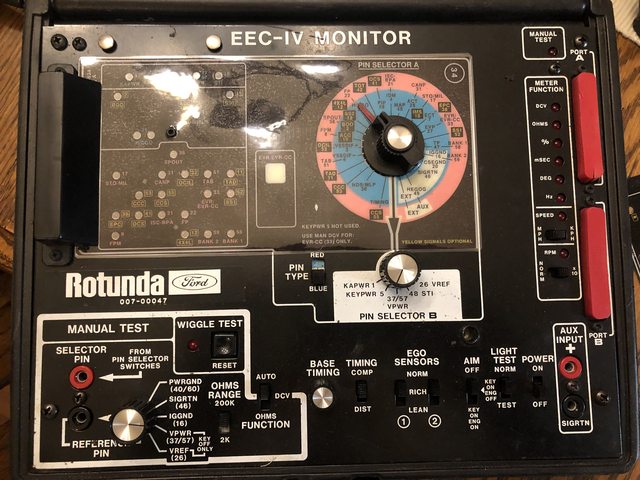

I know Rotunda made break-out box tools to plug in between the harness and the ECM. This lets you hook up meters to the leads easily. There are other EEC-IV diagnostic tools made by Rotunda also - you can see them on ebay from time to time. Here is one, but I don't know if it is the right one or how to use one:

https://www.ebay.com/itm/Rotunda-007...t/274087820573

Here is another that is cheap enough I would bite but again I don't know if it will work with my van or how to use it:

https://www.ebay.com/itm/Ford-Rotund...2/163924434911

The Tweecer.com guys have made an in-line device that intercepts all of the inputs and outputs and lets you modify the outputs and do real-time datalogging of the inputs. But the data logging version is $450. I have sent the guy an email explaining my situation and asking if I can rent one. I doubt it but figured I'd ask.

But, I figure the dealership should have the above kinds of tools and know how use them. They should, hopefully, be able to use such a tool while driving to see if there are sensor drop-outs while the condition repeats.

Steve

#34

I just found this product called the snEEC:

The SnEEC

Basically it was a custom connector inline with the OEM connector and the computer that hooked up to some electronics that let you tap into the system and monitor all the inputs and outputs in real time on a PC.

Sadly, it seems they do not make them anymore. It would be super cool to have real-time access to the computer inputs and outputs.

Only if you can back-probe the connector easily and have some way to monitor the output while driving.

Steve

The SnEEC

Basically it was a custom connector inline with the OEM connector and the computer that hooked up to some electronics that let you tap into the system and monitor all the inputs and outputs in real time on a PC.

Sadly, it seems they do not make them anymore. It would be super cool to have real-time access to the computer inputs and outputs.

Only if you can back-probe the connector easily and have some way to monitor the output while driving.

Steve

#35

You can see your coolant temperature change at a standstill from a cold start, your TPS while stationary as you advance the throttle with the key on, engine off. The MAF sensor while rocking the throttle of a running engine in park. As long as you see expected change you'll know if the sensor is on track or not. The 5V reference should be clean of noise and stable in all conditions of course. Think it through and don't make it any harder than you have to.

1) Finding a way to tap into the lead to make the measurement.

2) Knowing which leads to measure, and what kind of value.

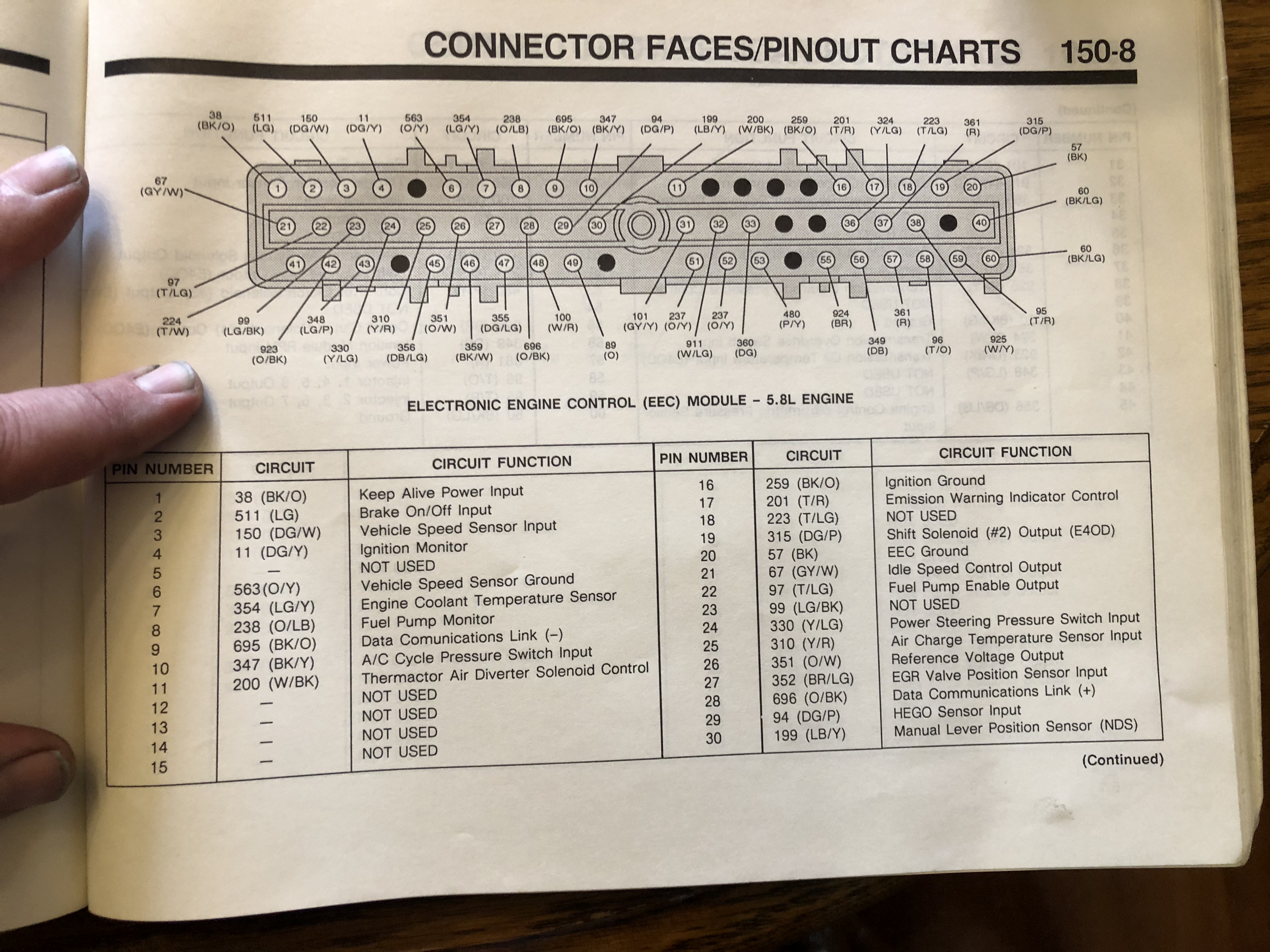

A break-out box like this would make the job a lot easier:

https://www.ebay.com/itm/Thexton-Bre...6/184080732881

But then you have to hunt down the pinouts for your EEC and you still have to figure out what to measure and what values are good.

Anyway.

Today I replaced the Throttle Position Sensor. As expected at this point, no change in the stumbling.

I will say though that today the stumbling seems much better than it ever has. In fact if it were this way to begin with I never would have started trouble shooting it. It is no longer bucking as it had done previously. Now, it basically has to be running in top gear at almost exactly 45 MPH with the engine lugging right at the cusp of transmission step-down, and it will stumble/miss. If the transmission downshifts, the problem goes away. Engine pulls strong from a stoplight through all gears.

I have a "test track" that I run from my neighborhood where I can reproduce this stumbling. On one surface street there is a very deep "gulley/ravine" that the road goes down into and then back up. If I keep the speed at 45 MPH through the bottom of the hill, when climbing out of the valley and lug the engine at 45 MPH it will stumble a bit. Then, I take the interstate and get off onto a bypass. As I get off the off ramp, I'm going about 35 MPH. As I accelerate from 35 to hit the bypass if I just ease up the speed without the transmission downshifting, as it goes through 45 MPH it will stumble.

At this point I have replaced:

- In-tank fuel pump (about 5 years ago when OEM unit burned up. When it burned up it took out the Inertia Switch also).

- Fuel Filter

- Distributor

- Spark Plugs

- Spark Plug Wires

- Coil

- Engine Temperature Sensor

- Air Charge Temperature Sensor

- Throttle Position Sensor

- Idle Air Valve

- MAP Sensor

- EGR Valve

- EGR Position Sensor

- EGR Vacuum Solenoid (this was the problem with the code 33 - shop broke the solenoid when replacing fuel pressure regulator - I replaced all EGR components because of this.)

- Fuel Pressure Regulator (I put OEM unit back in though.)

- Catalytic Converter (OEM unit started clanging internally at idle - indicative of broken matrix).

- O2 Sensor

- Ignition Control Module

At this point the vehicle is running well enough that I'm probably going to leave it alone. I've got a 1200-mile round trip coming up Jan 9th so we'll see how it does after 20 hours of continuous interstate driving. Assuming it doesn't die on me.

Steve

#36

Well, a couple of days ago I verified the routing of my spark plug wires, and I set them up with spacers.

The stumble is now barely noticeable. Still happens when lugging the engine in top gear 45-55 MPH. But it is so slight now that if it was this way all along I probably would not have bothered over it.

I don't know if it is some combination of all the things I replaced, or simply putting 2 tanks of Top Tier detergent, 93 octane gasoline through it, along with 2 bottles of Gumout and a bottle of Lucas.

I'll be driving it on an 8-hour round trip on Monday, and a 22-hour round trip in 2 weeks. We'll see how it does.

Steve

The stumble is now barely noticeable. Still happens when lugging the engine in top gear 45-55 MPH. But it is so slight now that if it was this way all along I probably would not have bothered over it.

I don't know if it is some combination of all the things I replaced, or simply putting 2 tanks of Top Tier detergent, 93 octane gasoline through it, along with 2 bottles of Gumout and a bottle of Lucas.

I'll be driving it on an 8-hour round trip on Monday, and a 22-hour round trip in 2 weeks. We'll see how it does.

Steve

#37

Thanks for the update. I also put a bottle of Tectron injector cleaner in my tank with only 1/2 a tank of gas in it. I ran the 1/2 tank out around town. I filled the tank up with premium gas and went on a 130 mile round trip on Christmas day. On the 75 miles down there were a few jerks here and there when pulling hills. on the way back there were none. I could still hear a tick like a plug wire snap sound when really pressing the gas peddle way down while pulling a grade, but this time there was no misfire/jerk.

Now on the way down it was late and I had the defroster on which caused the AC compressor to run and I didn't use it on the way back

I have heard pros and cons on using injector cleaners as to if they really work or not. Maybe it depends on how much and how often along with just how much cleaning needs to be done.

When you took your injectors out to clean them, did you flow test each of them by using a measuring device to see how much fuel flows through each one in a given time?

What type of temp gauge do you have? Have you noticed any temperature changes during the time the engine might normally misfire/buck?

I hope your tripe goes well and you make it back trouble free. I was hesitant to go off in mine this week but it did ok and I

would do it again...

Now on the way down it was late and I had the defroster on which caused the AC compressor to run and I didn't use it on the way back

I have heard pros and cons on using injector cleaners as to if they really work or not. Maybe it depends on how much and how often along with just how much cleaning needs to be done.

When you took your injectors out to clean them, did you flow test each of them by using a measuring device to see how much fuel flows through each one in a given time?

What type of temp gauge do you have? Have you noticed any temperature changes during the time the engine might normally misfire/buck?

I hope your tripe goes well and you make it back trouble free. I was hesitant to go off in mine this week but it did ok and I

would do it again...

#38

When you took your injectors out to clean them, did you flow test each of them by using a measuring device to see how much fuel flows through each one in a given time?

I back-flushed each injector into a clear peanut butter jar (well, I forward-flushed also) and there were a few tiny black specks in the jar when finished. But nothing that I would point to and go, "Ahah!" They all seemed to forward-flush fine and produced a cone-like spray of carb cleaner.

What type of temp gauge do you have? Have you noticed any temperature changes during the time the engine might normally misfire/buck?

#39

Drove the RV to Atlanta and back this weekend, about an 8 hour round trip. Same old same old. Stumbles under load at about 45 MPH. But it doesn't always do it, and, sometimes it will do it at other speeds.

I am pretty sure that what triggers it is driving in 4th gear (top gear, E40D transmission), and lugging the engine at 45 MPH, right on the cusp of the transmission stepping down. This makes it stumble. If the transmission downshifts, the stumble is mostly gone, but it could also be that it's just racing so the miss is not so noticeable. Sometimes it sounds like a slight "buzzing" while revving and then it will even out and run fine. I almost wonder if a spark plug is not firing. I may pull the plugs tomorrow and inspect. It would not be the first time my usual shop has screwed up.

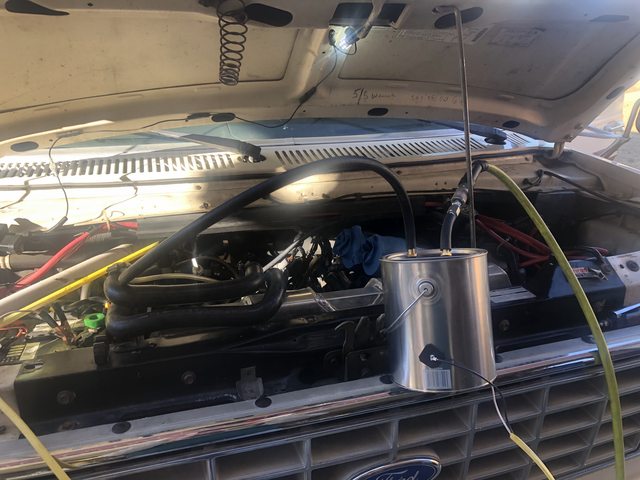

Got home, tried out my home-made smoke can. I followed this guy's video:

I plugged up the two intake pipes by stretching some nitrile gloves over them. Fed the smoke in from the MAP fitting on the back of the upper intake.

The good news is I did not find any smoke leaks indicating a vacuum leak. Since I had already replaced most easy-to-get-to rubber vacuum line, I did not expect any.

I did spot one leak - the "T" fitting that routes from the middle of the two main intake tubes to the inlet for the Idle Air Valve. But this is a leak up-stream of the manifold so it's not a vacuum leak. Worst case is the engine may be pulling it a little unfiltered air. But it's not unmetered air.

However, when I went under the car to look for any smoke leaks there, I went and looked at the Vapor Canisters, and I noticed that the tubing that runs from the hard line to the first canister was broken. No smoke though, because the engine was off (and so I guess the solenoid is closed).

I replaced the rubber hose from the solenoid hard line to the first canister, the hose from the first canister to the second canister, and the rubber hose from the fuel tank hard line to the first canister.

I did notice that when the engine was running I got no suction from the solenoid line. From reaching my Chilton's I think this solenoid should be open when the engine is running, so that it is sucking vapor from the canisters and the fuel tank all the time the engine is running?

So it may not be functioning. I don't know if this would cause stumbling under load. I kind of doubt it.

I'm going to play with the EEC-IV monitor tomorrow. I used my wife's laminator to make an almost factory-looking overlay with a color printout:

But to be honest the manual for this thing is 256 pages long and it's pretty intimidating to me. Maybe I'll figure it out tomorrow. But I'm running out of hope for fixing this myself. I called our local Ford place today and they will work on an RV. So if I don't find out something revealing tomorrow, on Thursday I'm going to take it in to the pros.

Steve

I am pretty sure that what triggers it is driving in 4th gear (top gear, E40D transmission), and lugging the engine at 45 MPH, right on the cusp of the transmission stepping down. This makes it stumble. If the transmission downshifts, the stumble is mostly gone, but it could also be that it's just racing so the miss is not so noticeable. Sometimes it sounds like a slight "buzzing" while revving and then it will even out and run fine. I almost wonder if a spark plug is not firing. I may pull the plugs tomorrow and inspect. It would not be the first time my usual shop has screwed up.

Got home, tried out my home-made smoke can. I followed this guy's video:

I plugged up the two intake pipes by stretching some nitrile gloves over them. Fed the smoke in from the MAP fitting on the back of the upper intake.

The good news is I did not find any smoke leaks indicating a vacuum leak. Since I had already replaced most easy-to-get-to rubber vacuum line, I did not expect any.

I did spot one leak - the "T" fitting that routes from the middle of the two main intake tubes to the inlet for the Idle Air Valve. But this is a leak up-stream of the manifold so it's not a vacuum leak. Worst case is the engine may be pulling it a little unfiltered air. But it's not unmetered air.

However, when I went under the car to look for any smoke leaks there, I went and looked at the Vapor Canisters, and I noticed that the tubing that runs from the hard line to the first canister was broken. No smoke though, because the engine was off (and so I guess the solenoid is closed).

I replaced the rubber hose from the solenoid hard line to the first canister, the hose from the first canister to the second canister, and the rubber hose from the fuel tank hard line to the first canister.

I did notice that when the engine was running I got no suction from the solenoid line. From reaching my Chilton's I think this solenoid should be open when the engine is running, so that it is sucking vapor from the canisters and the fuel tank all the time the engine is running?

So it may not be functioning. I don't know if this would cause stumbling under load. I kind of doubt it.

I'm going to play with the EEC-IV monitor tomorrow. I used my wife's laminator to make an almost factory-looking overlay with a color printout:

But to be honest the manual for this thing is 256 pages long and it's pretty intimidating to me. Maybe I'll figure it out tomorrow. But I'm running out of hope for fixing this myself. I called our local Ford place today and they will work on an RV. So if I don't find out something revealing tomorrow, on Thursday I'm going to take it in to the pros.

Steve

#40

Well I've been reading tonight about the EEC-IV monitor, and I think I understand basically how to use it.

It is a pretty ingenious tool, actually, for 1980s technology. Essentially, you set the dial to the input or output you want to monitor, and the device automatically knows what kind of measurement to take (volts, ohms, %, Hz, etc.), and it tells you what it is measuring, and presents you the results on a remote display. Of course today you'd get a computer display screen that would give you the state of ALL of the inputs and outputs simultaneously. Here we have to look at them one at a time.

But, with the Recorder device (which I also have), we can monitor and record the state of up to 8 things simultaneously.

So I think I know enough now so that tomorrow I can hook up the device and start monitoring some inputs and outputs.

Of course the real meat and potatoes is going to be if I can catch some input or output going haywire when it stumbles.

Steve

It is a pretty ingenious tool, actually, for 1980s technology. Essentially, you set the dial to the input or output you want to monitor, and the device automatically knows what kind of measurement to take (volts, ohms, %, Hz, etc.), and it tells you what it is measuring, and presents you the results on a remote display. Of course today you'd get a computer display screen that would give you the state of ALL of the inputs and outputs simultaneously. Here we have to look at them one at a time.

But, with the Recorder device (which I also have), we can monitor and record the state of up to 8 things simultaneously.

So I think I know enough now so that tomorrow I can hook up the device and start monitoring some inputs and outputs.

Of course the real meat and potatoes is going to be if I can catch some input or output going haywire when it stumbles.

Steve

#42

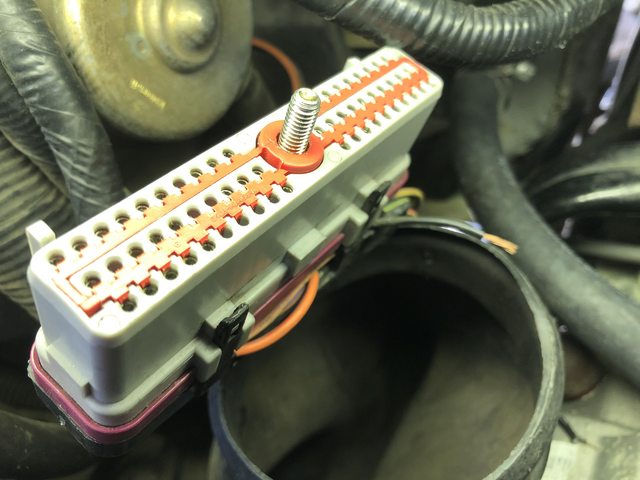

Well, bad news. The nose of the plug on the Monitor is not long enough to reach through the firewall and plug into the computer.

The problem is the harness that attaches to the Monitor plug has a plastic protrusion that stands too far forward.

Here is the stock harness plug:

Looks like what I need is an extension cable, but holy **** they are like $200!

https://www.ebay.com/itm/Ford-60-Pin...s/290528552854

However, while I was playing around with the harness, I noticed some damaged wires!

This yellowish wire has a slight nick in it, probably no big deal:

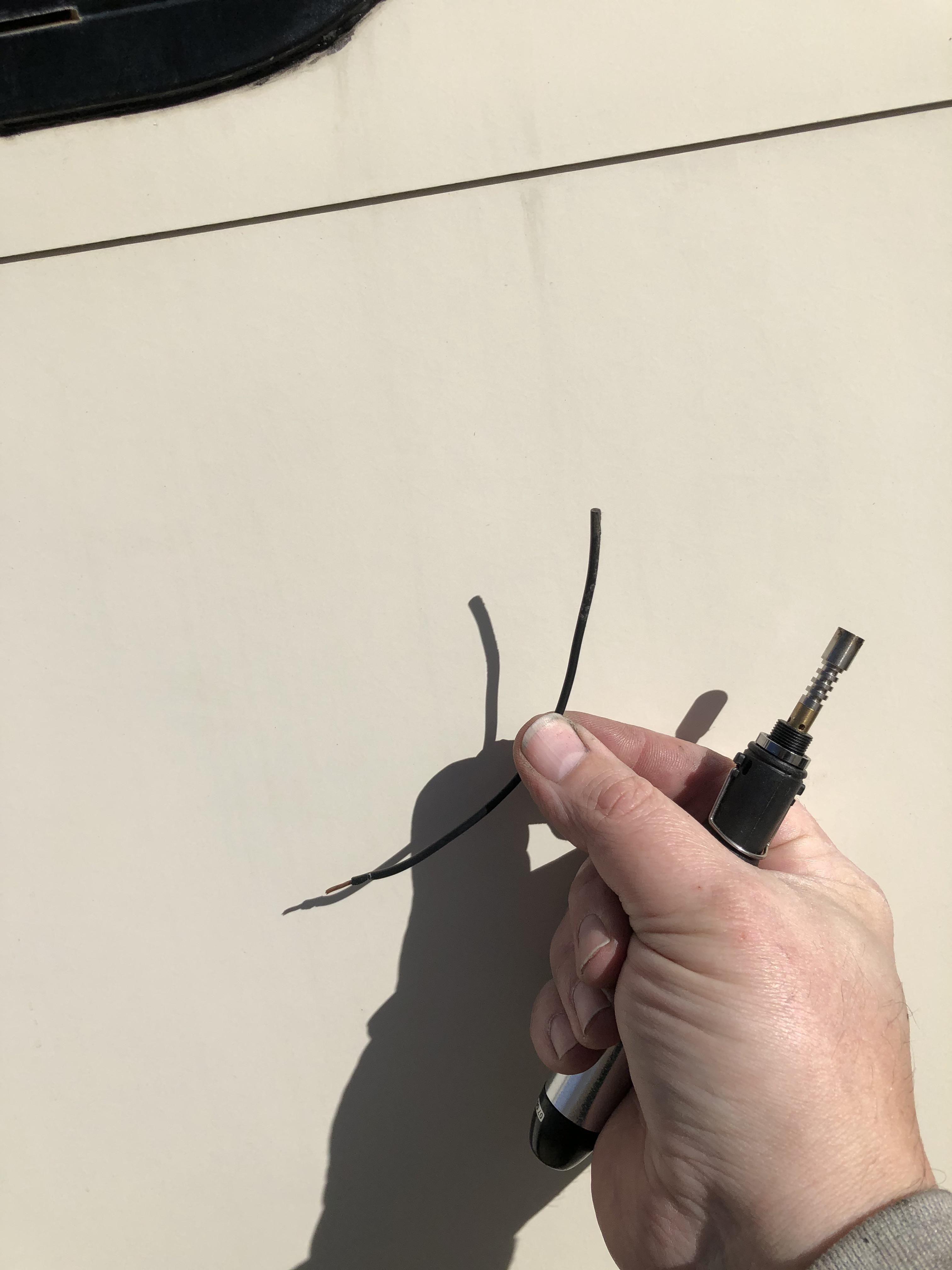

But this black wire looks almost completely severed!

According to this pinout, the black wire is EEC Ground.

I imagine it would be a bad thing to have an intermittent ground contact for the computer. Although since the case itself is grounded, maybe not. Although sometimes chassis ground and signal ground are isolated from each other. I don't know about on this computer.

Of course, as is usual, I can't seem to work on something without breaking something, and this time I broke the EEC-IV support bracket. The bracket is important in that not only does it support the weight of the computer, but it also provides chassis ground (case ground) for the computer.

So, I fabricated a new one out of sheet metal. I was never thrilled about the simple "contact" method of grounding the original clamp had, so I punched a hole in it that corresponds to the screw for the access cover on the back of the EEC-IV, so now my bracket not only "pinches" the case and grounds but also has a screw going through it.

Full size pictures here:

https://imgur.com/a/1QCyPWu

This bracket should have been a simple sheet metal part to begin with. Not sure why Ford went with the plastic/pressed-in-sheet-metal part here.

I'm kind of annoyed with Ford and this computer. There is already some kind of programming/diagnostic port on the back side of the computer. Didn't Ford anticipate that someone might need to do this kind of diagnostics at some point? There should have been a diagnostic plug-in right on the computer. I guess that is what ODB-II did later on.

Anyway now I have to figure out how to splice this black wire. Maybe it was the culprit all along. But I won't get that lucky.

Steve

The problem is the harness that attaches to the Monitor plug has a plastic protrusion that stands too far forward.

Here is the stock harness plug:

Looks like what I need is an extension cable, but holy **** they are like $200!

https://www.ebay.com/itm/Ford-60-Pin...s/290528552854

However, while I was playing around with the harness, I noticed some damaged wires!

This yellowish wire has a slight nick in it, probably no big deal:

But this black wire looks almost completely severed!

According to this pinout, the black wire is EEC Ground.

I imagine it would be a bad thing to have an intermittent ground contact for the computer. Although since the case itself is grounded, maybe not. Although sometimes chassis ground and signal ground are isolated from each other. I don't know about on this computer.

Of course, as is usual, I can't seem to work on something without breaking something, and this time I broke the EEC-IV support bracket. The bracket is important in that not only does it support the weight of the computer, but it also provides chassis ground (case ground) for the computer.

So, I fabricated a new one out of sheet metal. I was never thrilled about the simple "contact" method of grounding the original clamp had, so I punched a hole in it that corresponds to the screw for the access cover on the back of the EEC-IV, so now my bracket not only "pinches" the case and grounds but also has a screw going through it.

Full size pictures here:

https://imgur.com/a/1QCyPWu

This bracket should have been a simple sheet metal part to begin with. Not sure why Ford went with the plastic/pressed-in-sheet-metal part here.

I'm kind of annoyed with Ford and this computer. There is already some kind of programming/diagnostic port on the back side of the computer. Didn't Ford anticipate that someone might need to do this kind of diagnostics at some point? There should have been a diagnostic plug-in right on the computer. I guess that is what ODB-II did later on.

Anyway now I have to figure out how to splice this black wire. Maybe it was the culprit all along. But I won't get that lucky.

Steve

#43

Well, a complete goose chase.

I snipped the black wire at the frayed point, and then stripped the ends.

I noticed the black wire was unusual as unlike the rest of the wires that neatly disappeared into the harness trunk, this one seemed longer and was wrapped around the wire bundle before it went into the trunk.

Anyway I stripped it and unwound it from the bundle to get some length to work with and gave it a tug and it just pulled right out of the harness trunk! The end of the wire is shear-cut so I don't think this wire was ever used - it was just tucked into the harness trunk.

Full size images here: https://imgur.com/a/8aBRAFA

I put everything back together and the engine seems to run fine, so I guess this wire was not used.

Anyway since I can't make the monitor talk to the computer tomorrow I'm taking it in to the Ford dealership.

Steve

I snipped the black wire at the frayed point, and then stripped the ends.

I noticed the black wire was unusual as unlike the rest of the wires that neatly disappeared into the harness trunk, this one seemed longer and was wrapped around the wire bundle before it went into the trunk.

Anyway I stripped it and unwound it from the bundle to get some length to work with and gave it a tug and it just pulled right out of the harness trunk! The end of the wire is shear-cut so I don't think this wire was ever used - it was just tucked into the harness trunk.

Full size images here: https://imgur.com/a/8aBRAFA

I put everything back together and the engine seems to run fine, so I guess this wire was not used.

Anyway since I can't make the monitor talk to the computer tomorrow I'm taking it in to the Ford dealership.

Steve

#44

I have gone ahead and purchased a cheap $15 ODBI computer for a Taurus or something, and found a $25 ODB1 pigtail also. I've got them on order - I will use them to make my own extension cable. I should be able to make one for less than $50. I'll have to juggle the pins around of course but that will be easy enough.

Steve

Steve