Broken bolts in rear hub (axle shaft) '85 F250

#1

Broken bolts in rear hub (axle shaft) '85 F250

Truck is a '85 F-250 with Sterling 10.25 full-float rear. For as long as I can remember I've had some slop in the drivetrain that would manifest itself as a light clunk sound whenever I started forward or reverse from a stop. I checked everything I know to check, everything seemed nice and tight. I figured to drive it until it got worse and the problem become more obvious, but it never did.

Last night I was looking again, rotating the rear wheels back and forth with the rear end in the air when I noticed what was making the noise. The axle shaft where it bolts to the rear hub was rocking back and forth, as if it weren't tightened down enough. It was doing this on both sides. Basically the axle shaft would rotate until it contacted the bolts on either side, which was about 1/8" of play. Common sense says tighten the bolts, but they won't tighten, they seem bottomed out, and not putting any clamping force on the axle shaft, therefore letting it rotate back and forth slightly.

I tried to coax the bolts out as gently as I could for a closer look, but many were completely frozen and no amount of penetrating oil would help. Out of the eight (?) five broke, and I haven't even gotten to the other side yet. Judging by the amount of rust I can see, it's highly unlikely that I'll have much luck drilling and removing with a bolt extractor. So quite possibly looking at replacing both hubs.

What I'm most curious about is how it ended up this way-- the bolts went in far enough that they looked tight to the naked eye, so the PO or whoever put them in last, it would have been easy to miss that they weren't clamping down. The bolts look original, but something is definitely awry. Am I missing a washer or something that would keep the bolts from bottoming out? Thoroughly scratching my head over this.

How is the procedure of replacing the rear hubs? Any ideas where to find them, and am I lucky enough that these are the same as the '87-96 trucks? (would make junkyard shopping a whole lot easier). Hoping it's not a total nightmare. Curious what you guys think the problem is that caused this.

Last night I was looking again, rotating the rear wheels back and forth with the rear end in the air when I noticed what was making the noise. The axle shaft where it bolts to the rear hub was rocking back and forth, as if it weren't tightened down enough. It was doing this on both sides. Basically the axle shaft would rotate until it contacted the bolts on either side, which was about 1/8" of play. Common sense says tighten the bolts, but they won't tighten, they seem bottomed out, and not putting any clamping force on the axle shaft, therefore letting it rotate back and forth slightly.

I tried to coax the bolts out as gently as I could for a closer look, but many were completely frozen and no amount of penetrating oil would help. Out of the eight (?) five broke, and I haven't even gotten to the other side yet. Judging by the amount of rust I can see, it's highly unlikely that I'll have much luck drilling and removing with a bolt extractor. So quite possibly looking at replacing both hubs.

What I'm most curious about is how it ended up this way-- the bolts went in far enough that they looked tight to the naked eye, so the PO or whoever put them in last, it would have been easy to miss that they weren't clamping down. The bolts look original, but something is definitely awry. Am I missing a washer or something that would keep the bolts from bottoming out? Thoroughly scratching my head over this.

How is the procedure of replacing the rear hubs? Any ideas where to find them, and am I lucky enough that these are the same as the '87-96 trucks? (would make junkyard shopping a whole lot easier). Hoping it's not a total nightmare. Curious what you guys think the problem is that caused this.

#4

So I'm fairly certain I'm not supposed to have washers on the bolt (can anyone with a 10.25 rear end confirm?), therefore I'm a little perplexed why the bolts never tightened up-- unless the PO just forgot to tighten them and then they rusted solid in there, which is why I could neither tighten or remove them. It's all a guess at this point, now I just gotta fix it!

#5

Ok I am lost????

You are talking / posting about the axle bolts to the hub that show all 8 in place and no signs of them being loose and moving.

If loose you would / should / better see gear oil leaking from between the axle flange & hub as the gasket would not be compressed.

You would see bare clean metal around the bolts & axle flange.

Also you are holding a broken wheel stud, Is that what you broke 5 of the 8 of?

If so what were you using to undo them what and was it CW or CCW?

Dave ----

You are talking / posting about the axle bolts to the hub that show all 8 in place and no signs of them being loose and moving.

If loose you would / should / better see gear oil leaking from between the axle flange & hub as the gasket would not be compressed.

You would see bare clean metal around the bolts & axle flange.

Also you are holding a broken wheel stud, Is that what you broke 5 of the 8 of?

If so what were you using to undo them what and was it CW or CCW?

Dave ----

#6

You need to be careful, but I think you can drill the old bolts out. The first thing is to carefully center punch the broken bolt, getting it as close to center as possible. Punch it, and then eyeball it. If it looks off, hold the punch at a severe angle and move the punch mark the direction it needs to go. Get it as centered as you can.

Then get a pretty small drill bit, and gently start drilling the bolt out. Lean the drill if it gets off center, and don't press too hard and make the bit wander off. Move up to a larger drill bit and hog out some more of the old bolt. Find out what size bolt you are dealing with, and what size drill bit is required to tap the hole. That will be your final size drill, and then get a tap and tap the holes out. Hopefully you will just be tapping rust and thread slivers, if you are a little bit off the bolt will still hold.

Then get a pretty small drill bit, and gently start drilling the bolt out. Lean the drill if it gets off center, and don't press too hard and make the bit wander off. Move up to a larger drill bit and hog out some more of the old bolt. Find out what size bolt you are dealing with, and what size drill bit is required to tap the hole. That will be your final size drill, and then get a tap and tap the holes out. Hopefully you will just be tapping rust and thread slivers, if you are a little bit off the bolt will still hold.

#7

You need to be careful, but I think you can drill the old bolts out. The first thing is to carefully center punch the broken bolt, getting it as close to center as possible. Punch it, and then eyeball it. If it looks off, hold the punch at a severe angle and move the punch mark the direction it needs to go. Get it as centered as you can.

Then get a pretty small drill bit, and gently start drilling the bolt out. Lean the drill if it gets off center, and don't press too hard and make the bit wander off. Move up to a larger drill bit and hog out some more of the old bolt. Find out what size bolt you are dealing with, and what size drill bit is required to tap the hole. That will be your final size drill, and then get a tap and tap the holes out. Hopefully you will just be tapping rust and thread slivers, if you are a little bit off the bolt will still hold.

Then get a pretty small drill bit, and gently start drilling the bolt out. Lean the drill if it gets off center, and don't press too hard and make the bit wander off. Move up to a larger drill bit and hog out some more of the old bolt. Find out what size bolt you are dealing with, and what size drill bit is required to tap the hole. That will be your final size drill, and then get a tap and tap the holes out. Hopefully you will just be tapping rust and thread slivers, if you are a little bit off the bolt will still hold.

If the AXLE bolts did break off are they flush with the axle flange? If so pull the axle out and you now have a little bit sticking out.

Find nuts that fit over the part sticking out, now weld the nut to the stud sticking out and let it cool.

This will do 2 things: it will give you something solid to grab to unscrew it and the heating and cooling will help break the rust so it will come out.

If you don't have a welder pull the hubs and take them and the nuts to a local welder, cant be much $ to do.

Dave ----

Trending Topics

#8

Ok I am lost????

You are talking / posting about the axle bolts to the hub that show all 8 in place and no signs of them being loose and moving.

If loose you would / should / better see gear oil leaking from between the axle flange & hub as the gasket would not be compressed.

You would see bare clean metal around the bolts & axle flange.

Also you are holding a broken wheel stud, Is that what you broke 5 of the 8 of?

If so what were you using to undo them what and was it CW or CCW?

Dave ----

You are talking / posting about the axle bolts to the hub that show all 8 in place and no signs of them being loose and moving.

If loose you would / should / better see gear oil leaking from between the axle flange & hub as the gasket would not be compressed.

You would see bare clean metal around the bolts & axle flange.

Also you are holding a broken wheel stud, Is that what you broke 5 of the 8 of?

If so what were you using to undo them what and was it CW or CCW?

Dave ----

If you're familiar with the hubs on these, the gasket is a radial gasket that goes around the circumference of the axle shaft flange. Once you insert the axle, it does not require any compression to create a seal. If the bolts are inserted but not torqued down all the way (or at all), it will still seal provided the axle shaft does not actually pull out of the hub.

I'll post some pictures in a moment. Unfortunately most of the broken bolts are broke at least 1/2" inside the hub where it is not possible to weld a nut on like was suggested.

#9

My bad on the picture I should look closer at who posted it

It has been a long time since I messed with that type of axle and thought it had a thin gasket that looked like the end of the hub?

As for the broken bolts it might be best to pull the hubs and take them to a machine shop to have them drill and tap them, unless you can find used ones cheap.

Dave ----

It has been a long time since I messed with that type of axle and thought it had a thin gasket that looked like the end of the hub?

As for the broken bolts it might be best to pull the hubs and take them to a machine shop to have them drill and tap them, unless you can find used ones cheap.

Dave ----

#10

#11

Ok I am going out on a limb here but them bolts do not look factory as least for the axle flange.

They look more for fly wheel or flex plate bolts.

When you put it back together again I would look at maybe using grade 8 studs and nuts this way you know the nuts will tighten down on the flange.

Bolts can bottom out and still look like they are tight and not be.

That seal type is new to me but then again the newest one I worked on back in the 80's was on a E350 460/C6 van before that a few late 60's early 70's F350 tow trucks.

Dave ----

They look more for fly wheel or flex plate bolts.

When you put it back together again I would look at maybe using grade 8 studs and nuts this way you know the nuts will tighten down on the flange.

Bolts can bottom out and still look like they are tight and not be.

That seal type is new to me but then again the newest one I worked on back in the 80's was on a E350 460/C6 van before that a few late 60's early 70's F350 tow trucks.

Dave ----

#12

On the two that are broken off inside, I think I got a good hole centered enough to begin tapping. I was able to drill right through the bolt, so it wasn't bottomed out unless the threads don't go all the way back.

The other three are broken off about flush-- I'm going to weld a nut on them, say a few prayers and hope they come out. I still need to remove the bolts on the other side, no idea what kind of mess that's going to be!

The other three are broken off about flush-- I'm going to weld a nut on them, say a few prayers and hope they come out. I still need to remove the bolts on the other side, no idea what kind of mess that's going to be!

#13

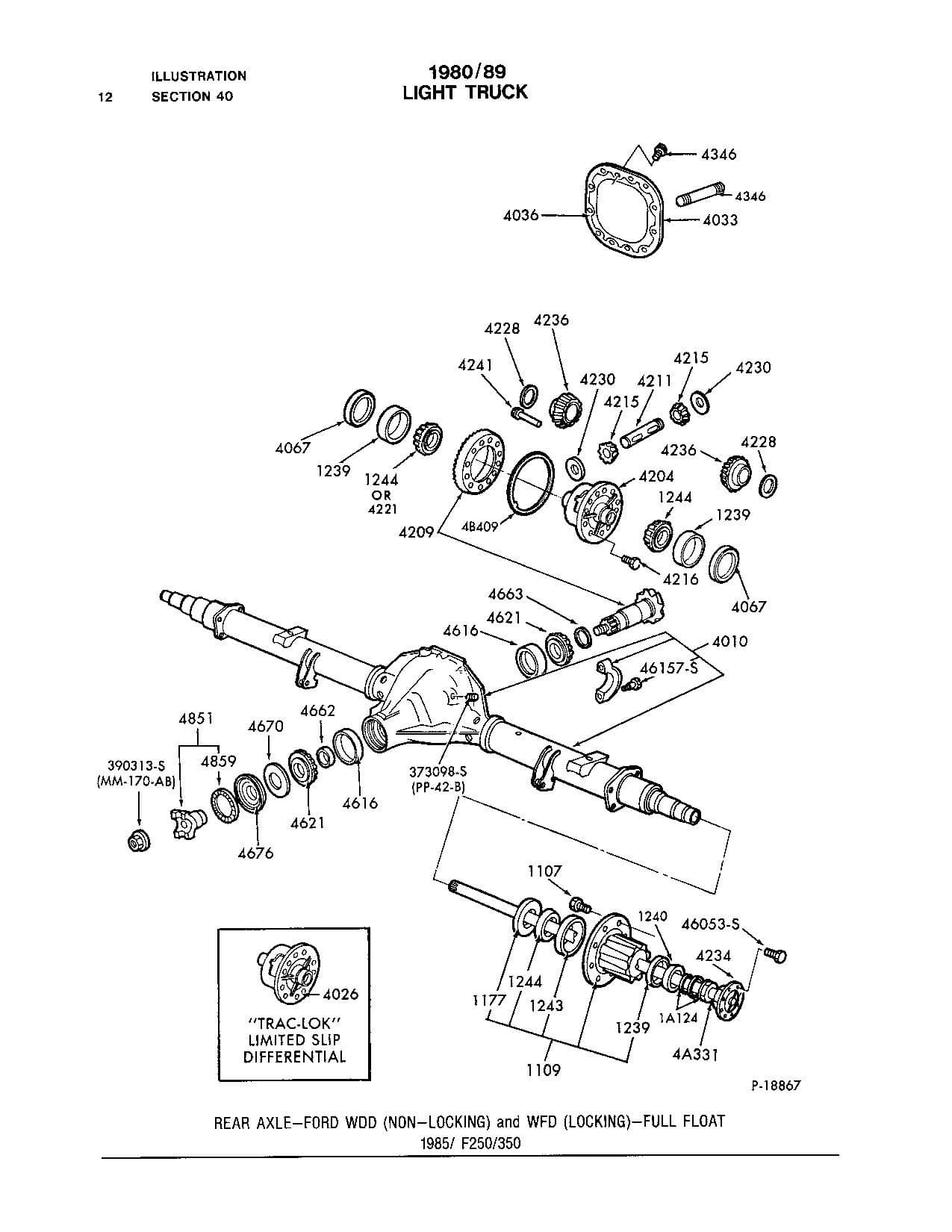

My Chilton's manual has a parts breakdown pretty much identical to what numberdummy posted. The Ford Sterling 10.25 axle is shown to have bolts only, however the Dana 60 axle parts diagram shows bolt AND washer.

So I'm fairly certain I'm not supposed to have washers on the bolt (can anyone with a 10.25 rear end confirm?), therefore I'm a little perplexed why the bolts never tightened up--

So I'm fairly certain I'm not supposed to have washers on the bolt (can anyone with a 10.25 rear end confirm?), therefore I'm a little perplexed why the bolts never tightened up--

46053-S100 .. Bolt - Hexagon Slotted Head - SELF LOCKING / 7/16" -14 x 1 3/8" long.

Self locking bolts like this should never be reused, as they won't tighten properly.

Note: Parts catalog pic (see post #2) shows 46053-S but pics don't usually show the complete suffix of standard parts.

#14

Sterling 10.25:

46053-S100 .. Bolt - Hexagon Slotted Head - SELF LOCKING / 7/16" -14 x 1 3/8" long.

Self locking bolts like this should never be reused, as they won't tighten properly.

Note: Parts catalog pic (see post #2) shows 46053-S but pics don't usually show the complete suffix of standard parts.

46053-S100 .. Bolt - Hexagon Slotted Head - SELF LOCKING / 7/16" -14 x 1 3/8" long.

Self locking bolts like this should never be reused, as they won't tighten properly.

Note: Parts catalog pic (see post #2) shows 46053-S but pics don't usually show the complete suffix of standard parts.

They can be reused as they are not torque to yield. They have an aerosol type thread locker sprayed on them. The manual says to replace them as they have no procedure for reapplying aerosol thread locker... But in the real world they can be cleaned and re-installed with a non permanent type thread locker either spray on such as Vibra stop or one of the non permanent thread lockers.

Regardless the axle bolts used on the Sterling axles are a **** poor design . Unlike the Dana 60/70 and GM 14 bolt that have a shoulder on them to tightly locate the axle flange on the bolt. The Sterling bolts do not have a shoulder and are threaded the full length, if the bolts back off the axles have more play and the bolt threads will chew up up the hole. The axle shown is now NFG and should be replaced as there is way to much slop in the holes.

#15