Help with my AC issue

#1

Help with my AC issue

05 F250 V10. Here's what I've got going on, hoping someone can help out. When I first turn the truck on, the AC will work normally and blow cold. After a few minutes, it will no longer blow cold at all. If you turn the truck off and let it sit for a while, then start it, you will get normal cold AC for say 5 minutes. I bought a recharge kit to test low pressure side, didn't add anything. I don't remember the reading, but it was well into the good range, so I didn't add any. I can check it again if you want actual numbers, but it was in the middle of the green range, didn't really pay attention, just figure I was good there so I moved on. I did notice the vacuum line on the Heater control valve had come off, so I reconnected it and thought maybe I had the problem fixed, but that didn't help. Heater control valve appears to be functioning as expected. Clutch engages, I did take the truck out for a drive and waited until it wouldn't blow cold, then popped the hood to see if the compressor was still engaging. With Max AC selected and fan set to high, it would come on for 2 seconds, off for 2 seconds, back on, off, and so on cycling very fast. Normally I'd point that to low Freon but when the guage said it was OK and not to add, it left me stumped so I decided to see if anyone had some better ideas. Let me know what you think!

#3

OK so what exactly am I looking for? Low pressure side is approximately 40 lbs. High pressure side should be in what range? I see 3 possible scenarios when I hook up gauges to the high pressure side:

1) Pressure is OK - so what do I look into next?

2)Pressure is high - so what does that tell me and what do I look into next?

3)Pressure is low - so what that tell me and what do I look into next?

Long story short, I'm looking for information on what could be the most likely cause/solution to this issue. I don't have a problem watching the gauges, but if I don't know where that leads me it doesn't really do anything for me at this point. I should note this is the standard system, select AC or Max AC and one of 4 fan speeds, it isn't an overly complicated climate control system or anything like that.

1) Pressure is OK - so what do I look into next?

2)Pressure is high - so what does that tell me and what do I look into next?

3)Pressure is low - so what that tell me and what do I look into next?

Long story short, I'm looking for information on what could be the most likely cause/solution to this issue. I don't have a problem watching the gauges, but if I don't know where that leads me it doesn't really do anything for me at this point. I should note this is the standard system, select AC or Max AC and one of 4 fan speeds, it isn't an overly complicated climate control system or anything like that.

#5

Join Date: Mar 2005

Location: Marlboro Mental Hospital.

Posts: 61,003

Received 3,114 Likes

on

2,173 Posts

the cheap gauge you are using says the low side is 40. that may not be true though.

you need a good manifold set to monitor pressures on both low and high side when running and blowing cold, and also when short cycling and not blowing cold.

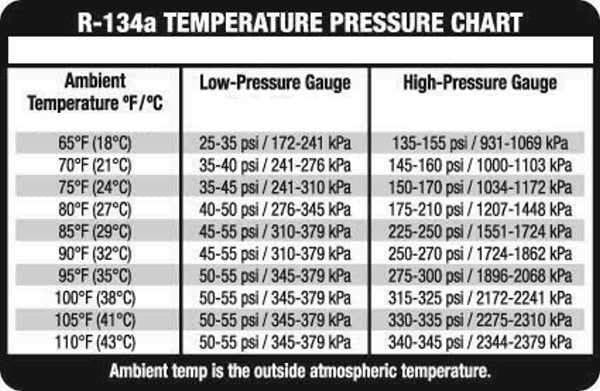

you can not just say "40 low and 200 high is good" because ambient temperature will effect system pressures.

a properly charges system will see 25-35 psi low and 135-155 psi high at 65 degrees.

this same charged system will see 50-55 psi low and 315-325 psi high at 100 degrees.

when the system stops blowing cold, try turning the heat on and see if you get air blowing out of it after a minute or two. if the evaporator core freezes, the compressor clutch will short cycle and you will not get any air from the blower through the evaporator.

you need a good manifold set to monitor pressures on both low and high side when running and blowing cold, and also when short cycling and not blowing cold.

you can not just say "40 low and 200 high is good" because ambient temperature will effect system pressures.

a properly charges system will see 25-35 psi low and 135-155 psi high at 65 degrees.

this same charged system will see 50-55 psi low and 315-325 psi high at 100 degrees.

when the system stops blowing cold, try turning the heat on and see if you get air blowing out of it after a minute or two. if the evaporator core freezes, the compressor clutch will short cycle and you will not get any air from the blower through the evaporator.

#6

Thanks Tom! I'll check into that and see if the behavior follows. It was upwards of 90 degrees when I checked with the cheapo kit on the 40 PSI reading. I have an old set of gauges that I haven't used in 20 years - they won't connect to the new fittings. I'm not sure if I can get adaptors or not. They are actually for the R12, so not even sure they'd work properly anyway, but I'm hesitant so buy another set of gauges to sit in a cabinet for 20 years again lol. That being said, maybe I can find someone I can borrow a set from.

I was thinking about waiting until it starts the short cycle behavior and then checking with the cheapo set, maybe even adding some while watching the gauge and compressor to see if it slows down the cycling. If it doesn't , I can just stop before it says I'm too full. This just sure seems to be a classic case of low refrigerant in my mind at least. The AC in the truck has never been touched and it is 13 years old, so it makes sense it could be low. I don't really drive the truck with AC on all that much because when it's hot out I drive one of the toys, and we get short summers in MT so I just drive with the windows open a lot not using the AC. I also need to check the condenser to make sure nothing like a mouse or bird got in there or something. I keep my truck very clean and don't really drive in too dirty of conditions, but we do have mice around the yard where I park at work, so it's worth taking a closer look at that too.

I very much appreciate the help and I'll be sure to check back in when I get time to look at it!

I was thinking about waiting until it starts the short cycle behavior and then checking with the cheapo set, maybe even adding some while watching the gauge and compressor to see if it slows down the cycling. If it doesn't , I can just stop before it says I'm too full. This just sure seems to be a classic case of low refrigerant in my mind at least. The AC in the truck has never been touched and it is 13 years old, so it makes sense it could be low. I don't really drive the truck with AC on all that much because when it's hot out I drive one of the toys, and we get short summers in MT so I just drive with the windows open a lot not using the AC. I also need to check the condenser to make sure nothing like a mouse or bird got in there or something. I keep my truck very clean and don't really drive in too dirty of conditions, but we do have mice around the yard where I park at work, so it's worth taking a closer look at that too.

I very much appreciate the help and I'll be sure to check back in when I get time to look at it!

#7

Join Date: Mar 2005

Location: Marlboro Mental Hospital.

Posts: 61,003

Received 3,114 Likes

on

2,173 Posts

Trending Topics

#9

Ok hereís some new info. I checked the condenser and it looks clean. Got the truck to doing the short cycle and checked with gauges. Low on both sides. So I added refrigerant. As I added a can the compressor started working and the ac began blowing cold. Perfect I thought. Drove it for about a half hour and it quit blowing cold, short cycling again. Checked gauges and everything seemed semi ok. It acts like the pressures start low, then build to high, short cycling when itís too low and too high. Pressure drops pretty good when the compressor comes on then builds when it is off. High was at about 275 climbing slowly. Low pressure would start at about 30 then after a while start jumping as high as 70. 100 degree ambient temp.

#10

Well it looks like I found the culprit. plugged/collapsed orifice tube. $1.99 part. Replaced that and while I was at it replaced O-Rings and accumulator since I was able to find some info on another site that it is common for the dessicant in them to come apart and plug the orifice tube. Flushed the system since it was apart with a spray can of stuff and filled it back up with oil and refrigerant. Seems to be working good now. Pressures are holding steady.

#11

Join Date: Mar 2005

Location: Marlboro Mental Hospital.

Posts: 61,003

Received 3,114 Likes

on

2,173 Posts

Thread

Thread Starter

Forum

Replies

Last Post

Drenalin

1999 - 2003 7.3L Power Stroke Diesel

57

06-23-2023 05:39 AM