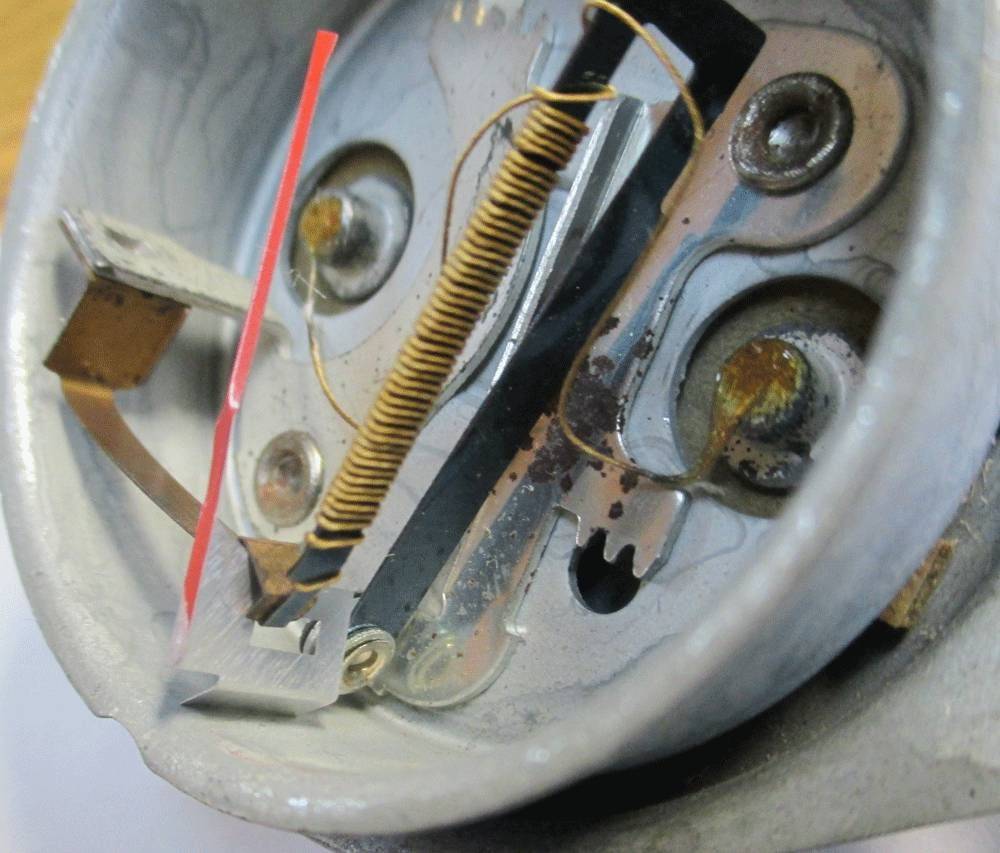

Signal Stat 700 switch

#61

Today was the day. I started re-doing my signal light wiring using the terminal blocks Mark suggested. And Bob was right. There was a fault in one of the ground wires caused by an improperly crimped connector. I should be good to go now, and using the terminal blocks should make a neater more professional looking job. I really should replace my $3.00 wire stripper and crimper though.

Jim

Jim

The good one in the reference isn't more than a good pair of pliars. Good luck! http://www.advanceautowire.com/midmgb.pdf

The good one in the reference isn't more than a good pair of pliars. Good luck! http://www.advanceautowire.com/midmgb.pdf

#62

Thanks Wayne. For all the smaller connectors going to the relays, I used my friend's Snap-on crimper, and they were all good. The one crimp made with my $3.00 tool failed. Going forward, I'll use a decent tool, have the seam of the connector properly positioned before the crimp, and solder as a final step. With proper remedial help, and timely one-on-one intervention, even the slowest of students can make progress. LOL.

Jim

Jim

#63

I'm giving this thread a little nudge in hopes that someone will come a long with advice on my temp gauge situation. I'd rather not have to go digging around in my under dash wiring after the signal light switch wiring has been finalized.

I've pretty well established that both my sending unit and gauge were purchased from classic Haulers. It doesn't appear likely that they would be "electrically" mismatched in some way. If the parts are good, and the wires are good, what else is there that needs to be considered? The gauge is in the cluster, but the cluster is not yet fastened (and grounded) to the dash. Would the gauge perform differently if the cluster was re-installed in the dash? I've performed this little task probably four or five times, but a recent spinal disc fracture doesn't make crawling around under the dash any easier. Thanks.

Jim

I've pretty well established that both my sending unit and gauge were purchased from classic Haulers. It doesn't appear likely that they would be "electrically" mismatched in some way. If the parts are good, and the wires are good, what else is there that needs to be considered? The gauge is in the cluster, but the cluster is not yet fastened (and grounded) to the dash. Would the gauge perform differently if the cluster was re-installed in the dash? I've performed this little task probably four or five times, but a recent spinal disc fracture doesn't make crawling around under the dash any easier. Thanks.

Jim

#64

#65

Agreed. Take a jumper wire from the back of your gauge and run it to a clean grounding point somewhere on your dash.

#66

I finally set aside a day to work on the truck. Abe and Bob are correct about the necessity of grounding the gauge cluster. With the cluster grounded, the needle goes all the way to cold with the key on and the engine running. As the engine warms up, the needle unfortunately still climbs all the way to hot after just a few minutes of idling. When the gauge needle reaches hot, the temp at the water pump /thermostate reads 165 degrees as measured by an infrared thermometer. Something is still not right.

I got my terminal blocks and relays all wired up. I used a high quality crimper and used connectors that allow for soldering. Amazingly, everything is still working. I feel good about not having to call my friend back (again) to fix my mistakes.

Now I just need to get the temp gauge sorted out. Should I try adjusting the needle? Thanks.

Jim

PS. Wayne I looked at your link and had allusions that I could do something neat and professional looking. I was envisioning my terminal blocks and relays all nicely mounted on a piece of sheet metal and attached to the fire wall. Needless to say, what really happened today looks nothing like what I was hoping for. It seemed like I had no choice but to make my connections based on the length and position of the wires coming out of the wiring harness if I wanted to avoid splices. As a result, the terminal blocks and relays had no chance of ending up neatly mounted on the fire wall. What I have is actually kind of a disappointing mess that I'll have to tuck up under the dash and hope no one sees it. Everything is nicely and crimped and soldered, however--and it works--which, I guess, is the main thing.

I got my terminal blocks and relays all wired up. I used a high quality crimper and used connectors that allow for soldering. Amazingly, everything is still working. I feel good about not having to call my friend back (again) to fix my mistakes.

Now I just need to get the temp gauge sorted out. Should I try adjusting the needle? Thanks.

Jim

PS. Wayne I looked at your link and had allusions that I could do something neat and professional looking. I was envisioning my terminal blocks and relays all nicely mounted on a piece of sheet metal and attached to the fire wall. Needless to say, what really happened today looks nothing like what I was hoping for. It seemed like I had no choice but to make my connections based on the length and position of the wires coming out of the wiring harness if I wanted to avoid splices. As a result, the terminal blocks and relays had no chance of ending up neatly mounted on the fire wall. What I have is actually kind of a disappointing mess that I'll have to tuck up under the dash and hope no one sees it. Everything is nicely and crimped and soldered, however--and it works--which, I guess, is the main thing.

#67

A forum search turned up some good instructions for adjusting the gauge needle at the "zero" and mid-gauge positions. I also saw someone who used a 50 ohm 1/2 watt resistor to correct his gauge to read at the mid point at normal operating temperatures. His truck was a 55, and I'm wondering if his gauge operates on the same principle as my 52. Thanks.

Jim

Jim

#68

The following users liked this post:

#69

Thanks Ross. I've noticed that grounding the cluster seems to make a difference in getting the needle to go all the way to cold with the key on. My cluster is hanging loose under the dash. I've been grounding the cluster with a jumper wire, not the gauge.

What do you think of the idea of using resistors to correct the gauge from reaching all the way to hot at only 160 degrees?

Jim

What do you think of the idea of using resistors to correct the gauge from reaching all the way to hot at only 160 degrees?

Jim

#70

#71

Thanks Ross. While I was in town this morning, I picked up items to make manual adjustments to the gauge and to add resistors, if that seemed the best route to take. Resistors are like $.35 each, so I picked up a selection so I could vary the ohms to what gave the best results. I'm all set-up to do the manual adjustment as well, and will try that first, as you suggest. One of our members, in 2014, gave Tom (from Maine) detailed instructions on just how to do it.

Jim

Jim

#72

...So my attempt at manually adjusting my temp gauge went horribly wrong! First, I tried adjusting the "zero" (no power to the unit) position. I thought it would be good to get the needle to rest a little off the H. The needle didn't seem to respond very well to moving the wheel, but after awhile, I did get it slightly off the H. I moved the wheel way more than I thought I should though.

Next, I tried to set the mid gauge position with a 1.5V battery. The needle read about 2/3 of the way to H when I first powered it up, and I thought, Ah Ha--that's my problem! The adjustment wheel for the mid gauge position worked pretty well, and I was able to dial the needle back to just on the C side of half way. When I took the power off, however, the needle did not go back to H. It only went about 3/4 of the way, and it seemed that no amount of adjusting with the first wheel I messed with was going to get it back close to the H again.

In frustration, I eventually gave up and decided to just re-install the thing and see what I had. Re-installing was a huge problem. It just didn't seem to fit. It felt like trying to put a round peg in a square hole. Finally I got it, but the gauge may very well have been damaged in the process. With everything wired up and the gauge cluster grounded, the needle wasn't even close to the H with the key off. With the key on, the needle hardly moved before the breaker began to click in and out, and smoke could be seen coming from the instrument cluster.

So that's the story today. Another first class debacle!

Jim

Next, I tried to set the mid gauge position with a 1.5V battery. The needle read about 2/3 of the way to H when I first powered it up, and I thought, Ah Ha--that's my problem! The adjustment wheel for the mid gauge position worked pretty well, and I was able to dial the needle back to just on the C side of half way. When I took the power off, however, the needle did not go back to H. It only went about 3/4 of the way, and it seemed that no amount of adjusting with the first wheel I messed with was going to get it back close to the H again.

In frustration, I eventually gave up and decided to just re-install the thing and see what I had. Re-installing was a huge problem. It just didn't seem to fit. It felt like trying to put a round peg in a square hole. Finally I got it, but the gauge may very well have been damaged in the process. With everything wired up and the gauge cluster grounded, the needle wasn't even close to the H with the key off. With the key on, the needle hardly moved before the breaker began to click in and out, and smoke could be seen coming from the instrument cluster.

So that's the story today. Another first class debacle!

Jim

#73

#74

Yes, my gauge has two wheels. The one on the C side of the gauge is for setting the "no power" position. The other one, on the H side, is for the mid-gauge position. I'm missing one of my metal strips, and instead use a jumper wire from one of the terminals on the temp gauge to a terminal on the fuel gauge. I sure thought I kept all the wires straight--there were only three--but I could try switching them up. I don't see anything touching the jumper wire or the metal strip.

Jim

Jim

#75

I just went out and removed the non-functioning temp gauge and the jumper wire that powered it, taped off the other wire, and put the instrument cluster back in the dash (never a pleasant task). The smoking wires and clicking circuit breaker are fixed. It will be awhile before getting a working temp gauge becomes a priority again. The only bright spot in today's debacle is that the signal and brake lights still work! I was half expecting that all the messing around today with the instrument cluster would have somehow goofed up yesterday's progress with the turn signals and brake lights.

Jim

Edit: Changed Stu to Ross.

Jim

Edit: Changed Stu to Ross.