Horn Parts Missing

#16

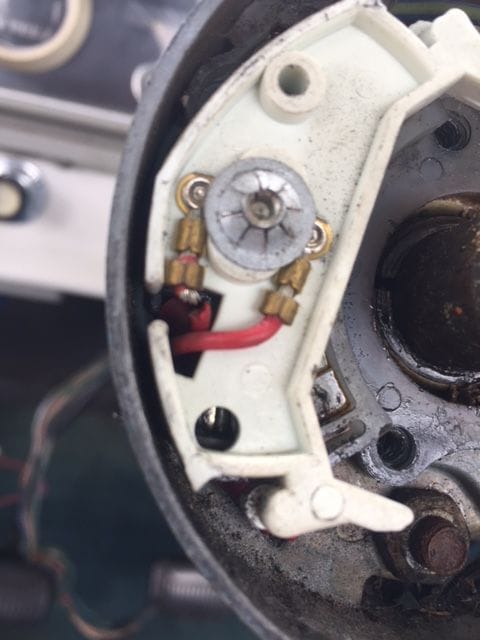

So the turn signal issue is fixed, broken red wire in the picture.

I replaced all the horn parts on the steering wheel, when i push to initiate the horn i can hear the relay click but no beep. I touched a wire to positive of battery and to the spade connector on the horn and nothing happened. So guessing my horn is bad?

Was there supposed to be 2 horns on this truck?

Thanks,

Howie

#17

I replaced all the horn parts on the steering wheel, when i push to initiate the horn i can hear the relay click but no beep. I touched a wire to positive of battery and to the spade connector on the horn and nothing happened.

So guessing my horn is bad? Was there supposed to be 2 horns on this truck?

#19

The horn may not be bad. These horns are adjustable. Over time, they may corrode inside and need to be refurbished.

My 65 F250 has dual horns, one works and one doesn't most of the time. I plan to work on it sometime in the future to see if I can get it to work properly.

I looked for the adjustment procedure in the Shop Manual, but as it is for many things, that manual is worthless. I should have saved my money.

There is an adjustment screw on the horns. You might try moving it slightly in either direction to see if it will sound. Tapping on it with a hammer might loosen the corrosion, but don't go overboard.

My 65 F250 has dual horns, one works and one doesn't most of the time. I plan to work on it sometime in the future to see if I can get it to work properly.

I looked for the adjustment procedure in the Shop Manual, but as it is for many things, that manual is worthless. I should have saved my money.

There is an adjustment screw on the horns. You might try moving it slightly in either direction to see if it will sound. Tapping on it with a hammer might loosen the corrosion, but don't go overboard.

#20

OK, this horn is killing me. I rebuilt horn assembly at steering wheel with all new parts, bought a new horn from Dennis Carpenter. Still not working. My horn relay is clicking, I have 12+ volts at horn wire connection, I cleaned the paint off new horn bracket and cleaned the surface where it mounts to for a better ground. I ran a temporary wire to a better ground from the horn bracket to see if that helped, it didn't... Anyone have any thoughts!!

#21

OK, this horn is killing me. I rebuilt horn assembly at steering wheel with all new parts, bought a new horn from Dennis Carpenter. Still not working. My horn relay is clicking, I have 12+ volts at horn wire connection, I cleaned the paint off new horn bracket and cleaned the surface where it mounts to for a better ground. I ran a temporary wire to a better ground from the horn bracket to see if that helped, it didn't... Anyone have any thoughts!!

I refurbished the horns on my 51 F4 and one had to be adjusted to work. I used a battery charger to supply voltage to the horn while I adjusted the screw. You might want to wear ear protection.

#23

#24

#25

#26

And does anyone know which horn is on the passenger side of a Custom Cab? Is it the low or high pitch? I'm thinking it would be the high pitch, as the drivers side on all models should be the low pitch.

#28

While this shouldn't make any difference regarding it not working with 12V applied to it, that horn may not be correct for your truck, although I think it's the correct part number. Here's the DC applications listing for it. And it is the high pitch horn. Is that what you're looking for?

Dennis Carpenter does not list a 1966 F100 horn on their website.

Mac's lists both the low and high pitch horns for 66 F100.

https://www.macsautoparts.com/ford_t...nail-type.html

https://www.macsautoparts.com/ford_t...nail-type.html

I don't know where they're made or if they work, but they are at least shown as truck horns.

#29

Looks like i ordered the wrong one. regardless it still should work with 12v applied. Below is the correct number i think from DC.

And this may be wrong also, could be the part number for the LO Pitch.Horn Assembly

1961 - 86

C7TZ-13833-A MakeModelBody StyleNotesYearFordTruckF100/350Front1961-79FordBroncoU-Series#1966-72FordBroncoU-Series-1978-86

And this may be wrong also, could be the part number for the LO Pitch.Horn Assembly

1961 - 86

C7TZ-13833-A MakeModelBody StyleNotesYearFordTruckF100/350Front1961-79FordBroncoU-Series#1966-72FordBroncoU-Series-1978-86

Last edited by Howie Long; 04-20-2018 at 10:09 PM. Reason: Adding to Post

#30

Looks like i ordered the wrong one. regardless it still should work with 12v applied. Below is the correct number i think from DC.

And this may be wrong also, could be the part number for the LO Pitch.Horn Assembly

1961 - 86

C7TZ-13833-A MakeModelBody StyleNotesYearFordTruckF100/350Front1961-79FordBroncoU-Series#1966-72FordBroncoU-Series-1978-86

And this may be wrong also, could be the part number for the LO Pitch.Horn Assembly

1961 - 86

C7TZ-13833-A MakeModelBody StyleNotesYearFordTruckF100/350Front1961-79FordBroncoU-Series#1966-72FordBroncoU-Series-1978-86