A/C Compressor squeal

#1

A/C Compressor squeal

I'm new at this, so please excuse anything I'm leaving out. I have a 2010 F250 Super Duty with 78,000 miles. A loud squeal is only heard when the A/C or defroster is turned on, and the noise is coming from the A/C Compressor area. I replaced the Serpentine belt, but this did not fix the problem. With the belt off, I noticed a little bit of play when wiggling the A/C clutch. The clutch turns freely by hand. It moves when the A/C or defroster is turned on. Since the loud squeal seems to be from the belt, is it possible the clutch is slightly binding when engaged, and therefore the pulley is not turning freely and therefore causing the loud squeak?

#4

Sounds like your A/C compressor is binding...only squeals when running...otherwise free pulley.

Could also be the air gap has gone out of spec between the clutch plate on the compressor, or even a worn clutch plate. Both easy fixes.

Get your blade feelers and check the air gap on the compressor. Spec is 0.014-0.026 in. Adjusted by adding/subtracting "spacers" which are basically #8 washers. Can be done on the vehicle-no need to dismount compressor or evac the system...

#5

You may have a failing compressor. The air gap is not the problem. Most likely culprit is a weak tensioner, they are relatively cheap and easy to replace. One other possiblity is a bad belt, even though you just replaced it, what brand did you use? Some aftermarket belts don't have the grip the OEM belt does, I put a Dayco on my '03 which should be a good belt but had to replace it with Motorcraft when I finished the trip to eliminate squealing.

#7

Trending Topics

#8

Sounds like your A/C compressor is binding...only squeals when running...otherwise free pulley.

Could also be the air gap has gone out of spec between the clutch plate on the compressor, or even a worn clutch plate. Both easy fixes.

Get your blade feelers and check the air gap on the compressor. Spec is 0.014-0.026 in. Adjusted by adding/subtracting "spacers" which are basically #8 washers. Can be done on the vehicle-no need to dismount compressor or evac the system...

#9

There really should be no "play" in anything on the compressor. Clutch face should be absolute parallel to the compressor housing-no wiggles at all. From what you are describing, I fear your A/C shaft may be toast. Unfortunately, that means a new compressor.

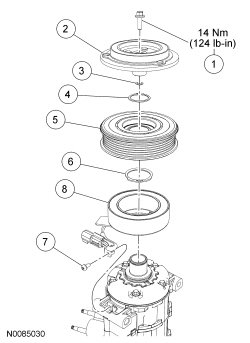

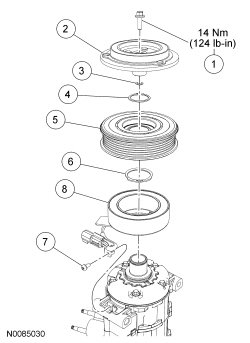

You could take apart the clutch assembly and see if there is something amiss. Your clutch pulley could have a out of round condition and your shaft is spared. Tolerances are pretty tight on the shaft to pulley interface. There are two snap rings-in front of and behind-the pulley. Maybe the bearing on the pulley toasted itself somehow...be aware of the "washers"/shims between the clutch plate-that is how you set the air gap-sometimes they fall out, sometimes they stick in the clutch. But you already know that by now. There really isn't much more to the A/C system than that.

Found this after a 10 second search on e-bay: https://www.ebay.com/itm/Universal-A...pZJ2HL&vxp=mtr

Good luck, let us know what you find!

You could take apart the clutch assembly and see if there is something amiss. Your clutch pulley could have a out of round condition and your shaft is spared. Tolerances are pretty tight on the shaft to pulley interface. There are two snap rings-in front of and behind-the pulley. Maybe the bearing on the pulley toasted itself somehow...be aware of the "washers"/shims between the clutch plate-that is how you set the air gap-sometimes they fall out, sometimes they stick in the clutch. But you already know that by now. There really isn't much more to the A/C system than that.

Found this after a 10 second search on e-bay: https://www.ebay.com/itm/Universal-A...pZJ2HL&vxp=mtr

Good luck, let us know what you find!

#10

#11

Hard to say without seeing what you are seeing. Shafts and bearings can act strange. One may give the impression the shaft is shot, but its actually the bearing or clutch plate-or vice versa.

One thing that I just thought of...check the bolt hole on the clutch plate...the clutch bolt may have backed a bit and caused the plate to wobble on the bolt and thus oval the bolt hole on the plate. Be acutely aware of torque settings and centering. As I mentioned: There should be no "wiggle" or "wobble" anywhere...

One thing that I just thought of...check the bolt hole on the clutch plate...the clutch bolt may have backed a bit and caused the plate to wobble on the bolt and thus oval the bolt hole on the plate. Be acutely aware of torque settings and centering. As I mentioned: There should be no "wiggle" or "wobble" anywhere...

#13

#14

A pully bearing issue would normally squeal continiously as the pully spins while the shaft remains stationary while a/c is off. The center hub of the clutch face where the bolt attaches should spin with some small amount of resistance and no axial or side play. If the clutch center has play or movement, its li,ely a bad compressor bearing. Also, The outer portion of the clutch is movable in and out and what gets pulled in to engage the compressor. As said above, the face of the clutch hub should begin spinning when the A/C is engaged during cooling or defrost.

As others,said, Low belt tension or a bad belt cause do this but Ive never had this issue personally. The fact that the system has not lost pressure points to this as a potential cause.

If you decide to pull the compressor, replace the drier/dessicant unit and install a new orifice tube after fully flushing the system to removed debris. In fact, sometimes mechanics pull the tube first to fully confirm compressor problems before removing the compressor as an extra measure of confidence. Usually compressor seal material and/or dessicant (from a leaky dessicant bag in the drier) will be typically be present.

As others,said, Low belt tension or a bad belt cause do this but Ive never had this issue personally. The fact that the system has not lost pressure points to this as a potential cause.

If you decide to pull the compressor, replace the drier/dessicant unit and install a new orifice tube after fully flushing the system to removed debris. In fact, sometimes mechanics pull the tube first to fully confirm compressor problems before removing the compressor as an extra measure of confidence. Usually compressor seal material and/or dessicant (from a leaky dessicant bag in the drier) will be typically be present.

#15