Front drum rebuild and questions

#1

Front drum rebuild and questions

I finally decided to do the front brakes (drum) while waiting to find a disc setup. Glad I did as the old grease in between the bearings was not in a "grease" state anymore. I was almost a solid and had caked up with cracks in it. Pulled everything but the backing plates including everything new from hoses to hardware, rebuilt pressure valve, and master cylinder.

My first question is what type of grease should I use? I know the new style hi temp red grease was not an option when these were built, but should I use the old gray style grease or the hi temp? Meaning is there a reason I have to use the gray as I think the red hi temp would be a better choice.

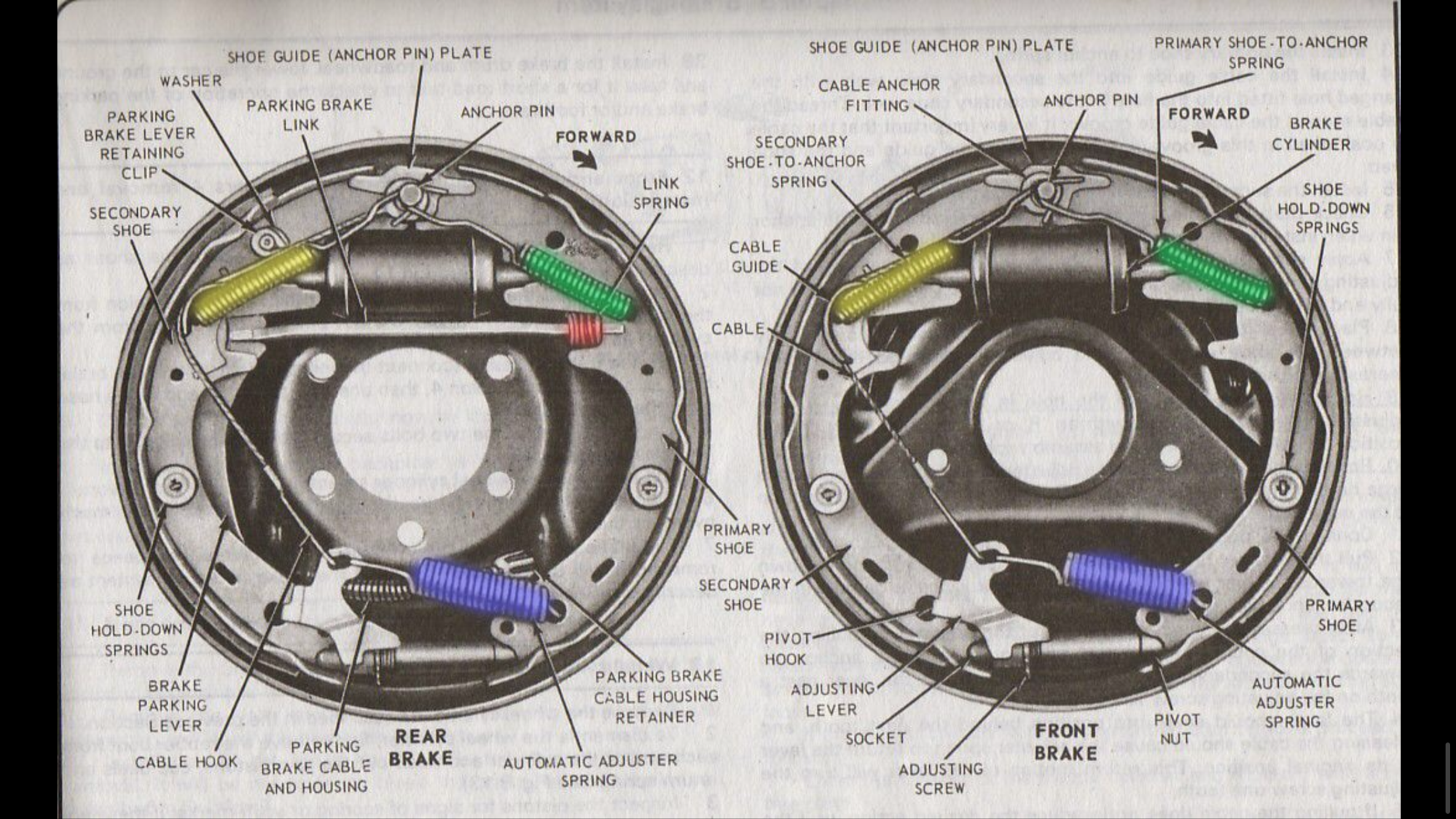

Second, when I tore it down, the adjuster or star wheel on the LH side had to be rotated backward according to the repair manual to back it off and loosen it. I had to rotate it down in order to loosen the pads to remove the hub/drum assembly. Should both sides be rotated downward to loosen and do the adjusters mount in only one direction or could this have been installed backwards at one point? It's possible I missed something or misunderstood something in the manual but I want to make sure before I start the install today.

BTW I had the original ones cut as there were tons of meat left in them. Got to love the old guys at NAPA. Didn't ask the info on the truck and didn't even mic them. He said come back in an hour or two and they would be done. And that they were. They were even hot tanked so I figured I should do them justice by prepping and repainting them before installation.

My first question is what type of grease should I use? I know the new style hi temp red grease was not an option when these were built, but should I use the old gray style grease or the hi temp? Meaning is there a reason I have to use the gray as I think the red hi temp would be a better choice.

Second, when I tore it down, the adjuster or star wheel on the LH side had to be rotated backward according to the repair manual to back it off and loosen it. I had to rotate it down in order to loosen the pads to remove the hub/drum assembly. Should both sides be rotated downward to loosen and do the adjusters mount in only one direction or could this have been installed backwards at one point? It's possible I missed something or misunderstood something in the manual but I want to make sure before I start the install today.

BTW I had the original ones cut as there were tons of meat left in them. Got to love the old guys at NAPA. Didn't ask the info on the truck and didn't even mic them. He said come back in an hour or two and they would be done. And that they were. They were even hot tanked so I figured I should do them justice by prepping and repainting them before installation.

#2

#3

#4

Thanks for the info. Yeah the NAPA here has an old school machine shop here that does it all still. I have had rotors done there in the past and guys are constantly coming and going with complete short blocks and heads from there. They do solid work.

I will double check the adjusters and see if they are marked. Since mine are a 3/4 ton 8 lug they are slightly different and the adjuster sat below the star IIRC. Took lots of pics of the before for reference, just wanted to make sure they go back together correctly. I'll post some pics once I am done.

I will double check the adjusters and see if they are marked. Since mine are a 3/4 ton 8 lug they are slightly different and the adjuster sat below the star IIRC. Took lots of pics of the before for reference, just wanted to make sure they go back together correctly. I'll post some pics once I am done.

#6

I knew about the casting of the max runout, it was just funny to find guys who know enough still to look at the drums and state they were not going to be a problem. One guy wears legit overalls and the other looks like a really old Smokey Yunick, hat and all.

Not that all the chain store counter guys are dumb, but the O'Riellys by my house is even more challenged than the majority. Sent me across town today as I forgot I only ordered on hardware kit at Rock Auto (snagged the last wholesaler closeout for $1.99 and didn't go back to order a second normally price drop kit). Between all the stuff I ordered I needed the adjuster arm spring and the cable.

Store by my house said only available in full kit for $32 but only the across town store had it. NAPA didn't and I really wanted to at least get it buttoned up this morning so away I went. The counter guy said Gee if you only need those two items why not get the $8 kit? Because your manager across town couldn't figure that out even when I asked about it that's why. Then I explained the issue with turning the drums and the area manager happened to be standing behind the counter to overhear this. I think somebody is going to find a new job tomorrow morning.

Not that all the chain store counter guys are dumb, but the O'Riellys by my house is even more challenged than the majority. Sent me across town today as I forgot I only ordered on hardware kit at Rock Auto (snagged the last wholesaler closeout for $1.99 and didn't go back to order a second normally price drop kit). Between all the stuff I ordered I needed the adjuster arm spring and the cable.

Store by my house said only available in full kit for $32 but only the across town store had it. NAPA didn't and I really wanted to at least get it buttoned up this morning so away I went. The counter guy said Gee if you only need those two items why not get the $8 kit? Because your manager across town couldn't figure that out even when I asked about it that's why. Then I explained the issue with turning the drums and the area manager happened to be standing behind the counter to overhear this. I think somebody is going to find a new job tomorrow morning.

#7

The lack of knowledge about parts isn't limited to your local O'Reilly store. I've found it's prevalent at every O'Reilly's store I've ever been to.

I finally figured out it's best for me to go on their website, before I actually walk into the store, look the part up and get the part number before hand or, just print the page off with the part number and a picture of the part to give to them when I go in the store.

They want to know what vehicle you're working on to punch it into the computer. They get all confused when I tell them I have a '69 F100 but I need a part for an '82 F150 with a 300 (power steering pump for example, because I have an '82 F150 Ford C-2 PS pump on my '69 240). If I just give them a part number to start with, without going through what I have vs what I need, it cuts out a lot of their confusion and I can get on my way a lot quicker.

I finally figured out it's best for me to go on their website, before I actually walk into the store, look the part up and get the part number before hand or, just print the page off with the part number and a picture of the part to give to them when I go in the store.

They want to know what vehicle you're working on to punch it into the computer. They get all confused when I tell them I have a '69 F100 but I need a part for an '82 F150 with a 300 (power steering pump for example, because I have an '82 F150 Ford C-2 PS pump on my '69 240). If I just give them a part number to start with, without going through what I have vs what I need, it cuts out a lot of their confusion and I can get on my way a lot quicker.

Trending Topics

#8

With brakes especially, a Shop Manual is your Friend. It's good to take pictures, but are you certain it was done correctly in the past? If it wasn't, might just be faithfully replicating the error. I don't know what the percentage is but an awful lot of DIY drum brake jobs are put together wrong.

One of the things to look at on a drum is the chamfer. It's a way to quickly eyeball whether it's been turned excessively. As long as the chamfer is there it's technically OK basically. Assuming no cracks or runout, out of roundness. Oversize drums should get oversize linings probably.

One of the things to look at on a drum is the chamfer. It's a way to quickly eyeball whether it's been turned excessively. As long as the chamfer is there it's technically OK basically. Assuming no cracks or runout, out of roundness. Oversize drums should get oversize linings probably.

#9

#10

I just had the guy at the auto store tell me that my truck couldn't have roller bearings on the rear axle, that they where only used on front hubs. I have a Dana 44 rear end and they use tapered roller bearings, but he never heard of that before and said I must be wrong.

#11

Yep, those are the run away fast stores. Thanks for the help guys, reading through made me go back to the beginning and slow it down a bit.

So there was an error on my part in reading the shop manual. I set it up for the page for the F250 and in the breeze it shifted a page or at least that is what I am claiming! Actually I think I was in a hurry and had the page open to the F100 front without paying attention and read directions wrong.

At any rate, I took lots of pics of the before and placed everything on a drip tray as it came off for reference. Everything got put back into place and buttoned up nice. I repainted the inside of the backing plates and the outside of the drums just to clean them all up.

Now I just have to go back to square one on the system. I have another thread I started on a system failure with no pedal/spongy pedal. Should have just combined them but it was fricking hot under that truck on the blacktop and I was cooked and frustrated. So please follow along that fun journey at:

https://www.ford-trucks.com/forums/1...re-spongy.html

Now I get to run through the whole system!

So there was an error on my part in reading the shop manual. I set it up for the page for the F250 and in the breeze it shifted a page or at least that is what I am claiming! Actually I think I was in a hurry and had the page open to the F100 front without paying attention and read directions wrong.

At any rate, I took lots of pics of the before and placed everything on a drip tray as it came off for reference. Everything got put back into place and buttoned up nice. I repainted the inside of the backing plates and the outside of the drums just to clean them all up.

Now I just have to go back to square one on the system. I have another thread I started on a system failure with no pedal/spongy pedal. Should have just combined them but it was fricking hot under that truck on the blacktop and I was cooked and frustrated. So please follow along that fun journey at:

https://www.ford-trucks.com/forums/1...re-spongy.html

Now I get to run through the whole system!

#12

The lack of knowledge about parts isn't limited to your local O'Reilly store. I've found it's prevalent at every O'Reilly's store I've ever been to.

I finally figured out it's best for me to go on their website, before I actually walk into the store, look the part up and get the part number before hand or, just print the page off with the part number and a picture of the part to give to them when I go in the store.

They want to know what vehicle you're working on to punch it into the computer. They get all confused when I tell them I have a '69 F100 but I need a part for an '82 F150 with a 300 (power steering pump for example, because I have an '82 F150 Ford C-2 PS pump on my '69 240). If I just give them a part number to start with, without going through what I have vs what I need, it cuts out a lot of their confusion and I can get on my way a lot quicker.

I finally figured out it's best for me to go on their website, before I actually walk into the store, look the part up and get the part number before hand or, just print the page off with the part number and a picture of the part to give to them when I go in the store.

They want to know what vehicle you're working on to punch it into the computer. They get all confused when I tell them I have a '69 F100 but I need a part for an '82 F150 with a 300 (power steering pump for example, because I have an '82 F150 Ford C-2 PS pump on my '69 240). If I just give them a part number to start with, without going through what I have vs what I need, it cuts out a lot of their confusion and I can get on my way a lot quicker.

#14

#15

I just had the guy at the auto store tell me that my truck couldn't have roller bearings on the rear axle, that they where only used on front hubs.

I have a Dana 44 rear end and they use tapered roller bearings, but he never heard of that before and said I must be wrong.

bearings, but he never heard of that before and said I must be wrong.

I have a Dana 44 rear end and they use tapered roller

bearings, but he never heard of that before and said I must be wrong.

bearings, but he never heard of that before and said I must be wrong.If it's the axle shaft bearings, there was no such thing as tapered roller bearings until 1974.

F100: ALL 1957/73 9" & 1959/68 Dana 44 & 1963/66 Dana 60.2 & 1966/68 Dana 60.3 have ball type axle bearings.

All these Dana's came with Limited Slip, because Ford didn't offer the 9" with Limited Slip in F100's until 1968.

1974/79 9's could have ball type or tapered roller bearings. Tapered roller bearing uses a different axle shaft seal than 9."

Some 1976/79 F100/150 have Dana 44 rear axles with or without Limited Slip.