Burning Up Solenoids

#46

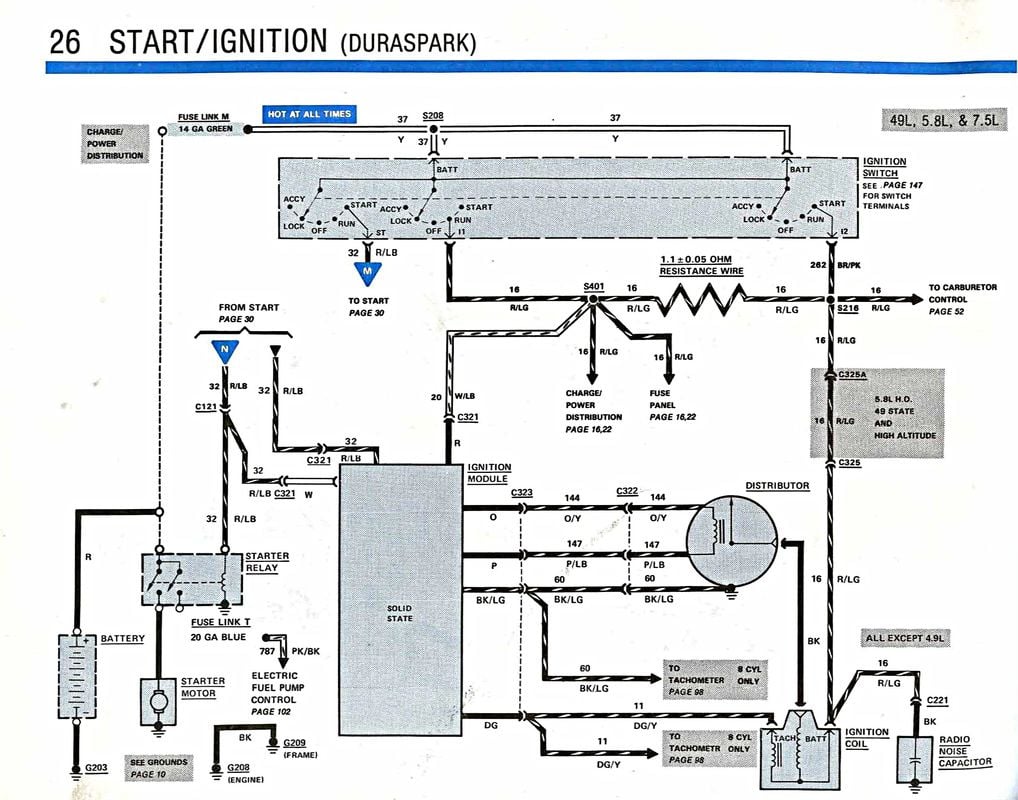

For my understanding, can you please confirm if page 26 here is correct for your truck. I want to make sure I understand the S and I labels correctly:

Start & Ignition - ???Gary's Garagemahal

Here's page 26 lifted directly from Gary's website, from the 1986 EVTM. Note how Fuse Link T is not properly illustrated, crossing underneath the starter relay:

1986 EVTM - Background color missing from Fuse Link T

Here's the same page from my 1984 EVTM, showing the background color present for Fuse Link T. I also added labels for what I think are terminals S and I, just to be sure we are talking about the same thing:

1984 EVTM

Hopefully this should help clarify the terminal labels, although I was probably the only one confused. I will have to admit this one has me stumped, and I chase electrons for a living.

On one hand, you mentioned the relay stayed engaged even with S and I terminals disconnected, and wouldn't relax until smacked. That would seem to indicate the relay mechanically sticking, such as from welded contacts, internal binding, etc.

However, you also mentioned cutting apart one relay that had stuck closed over ten times, and there was no evidence of arcing at the big contacts. Based on that, I think we can safely rule out welding of the contacts.

We might be getting into twilight zone stuff here.

How about this one? Your alternator has a failing diode pack and is pumping out AC ripple? All alternators have AC ripple, and is generally under 0.5 VAC. If excessive, could there be something weird like the relay is getting magnetized and maintaining a weak hold even after power is removed?

A long shot, I know, but it's easy to check for AC ripple. Put your voltmeter's (+) lead on the big output terminal on the back of the alternator. Put the meter's (-) lead on the alternator case. (You want to get this reading directly at the alternator, as close to the source as possible, not at the battery) Start the engine and run it at various RPM levels, with and without heavy loads such as the headlights and heater fan. With your meter set to AC (Not a typo, reading alternating current), the reading should never exceed 0.5 VAC. If above that limit, most likely a diode has failed in the alternator.

If you want to try that quick test, I'll continue scratching my head over this one...

Edit: Can you also take a DC volt reading at terminal S when the key is in the start position? Just another long shot, wondering if the alternator's DC output is too high and somehow causing a magnetism issue.

#47

#48

kr98664 I did not have time to read the schematic this morning but the truck is exactly how you explained it. The wires are not backwards, with a test light the red w/light blue stripe gets power only when key is in start position. The I wire is fuel pump cause I put power to it just to see and the fuel pump starts running. I had the same thought that maybe something was backwards so I swapped wires and nothing happened.

I still do not understand why it will not crank when jumping solenoid with a screwdriver unless the I wire is hooked up. This is just crazy to me. I can hold screwdriver in place with I wire unhooked and it will not crank, touch I wire to solenoid and it will start cranking. Also one time the solenoid stuck I unplugged both the S and I wire and it still remained stuck...a very light tap on solenoid and it quits. Again I cut old solenoid apart and it had no burn spots what so ever...looked brand new like it had never been used.

I still do not understand why it will not crank when jumping solenoid with a screwdriver unless the I wire is hooked up. This is just crazy to me. I can hold screwdriver in place with I wire unhooked and it will not crank, touch I wire to solenoid and it will start cranking. Also one time the solenoid stuck I unplugged both the S and I wire and it still remained stuck...a very light tap on solenoid and it quits. Again I cut old solenoid apart and it had no burn spots what so ever...looked brand new like it had never been used.

#49

#50

Are you using the screwdriver to jump the two large studs or are you jumping from + stud to 'S' stud?

The relay grounds through its mounting ears and will not pull in unless it has a solid ground path.

Sanding some paint off the fender where it mounts and having a ground strap from radiator support to battery negative terminal would eliminate that situation.

I agree, it's very odd that the relay won't operate without the fusible link attached to 'I'.

***Edit*** I see Blackduck & I are thinking the same at the same time..

The relay grounds through its mounting ears and will not pull in unless it has a solid ground path.

Sanding some paint off the fender where it mounts and having a ground strap from radiator support to battery negative terminal would eliminate that situation.

I agree, it's very odd that the relay won't operate without the fusible link attached to 'I'.

***Edit*** I see Blackduck & I are thinking the same at the same time..

#51

This is definitely a strange one. Here's a troubleshooting guide that may help:

Your present scenario (jumpering power to the S terminal does nothing if I terminal is disconnected) would imply a defective relay. Even if the relay was not properly grounded, the I terminal shouldn't have any effect on the actuating coil. The actuating coil runs only between S and the grounded case. It should be 100% isolated from the I terminal and the big cable terminals.

Sometimes I get a vexing problem like this at work (previous shift mantra at turnover: "All you gotta do...") The toughest part is to mentally shift gears and start at square one in search of anything that was overlooked. So if you don't mind, please indulge me a bit.

1) I think you previously mentioned you ran a ground wire from a relay mount bolt to the battery's (-) post. Please confirm it's there and is making good contact at both ends.

2) Did any of the previous relays have the no crank issue when jumpered with the I terminal disconnected? That really sounds like a defective relay.

3) Please confirm the relay only has 4 terminals: The 2 big cable terminals, and the small I and S terminals.

4) Please unhook all wires from the present relay and run these continuity checks with an ohmmeter. If you have any of the previous relays, please check another for comparison:

A) S to the mounting ears (this is the actuating coil) should be around 10 ohms or so. I'm not positive on the value, but it shouldn't be open nor should it be a dead short. If anybody else has a spare relay handy, can you please get a reading for comparison?

B) With the relay unpowered, all other terminals should be 100% isolated from each other and the case. Any continuity with each other or to the case (except S to the case) indicates a bad relay.

C) With everything else disconnected from the relay, hook up a jumper between the battery's (-) post and the relay case. Run a second jumper from the battery's (+) post to the S terminal. You should get a big satisfying clunk as the relay coil is energized. If not, the relay is bad. I realize this is basically the same scenario as when it won't energize by jumpering with a screwdriver with the I terminal disconnected, but I want the big cables off in case there's some funkiness somehow going on through there.

D) With the relay coil still energized using the pair of jumpers, check continuity between the two big cable terminals and the I terminal. All 3 should have good continuity with each other.

E) With the relay coil still energized, check continuity from the relay case to the two big cable terminals and the I terminal. None of those terminals should have any continuity to the case.

I know some of this stuff is pretty basic, but that's all I can think to verify right now. The whole "won't energize if I terminal is disconnected" sure seems like a defective relay. Unknowingly introducing bad parts during troubleshooting can be a nightmare.

I'd also suggest checking for AC ripple and measuring the DC voltage at the S terminal, as detailed in an earlier post.

Anybody else got any ideas?

#52

Am I missing something here? It is the Starter motor sticking causing the solenoid burn ups, correct?

If so find out what is making the starter stay in the flywheel... messed up teeth????

Not aligned properly????

Remove the starter and see if it "goes in and out", "in and out" like good S#$!

Then install again. Going in and staying there????????

If so find out what is making the starter stay in the flywheel... messed up teeth????

Not aligned properly????

Remove the starter and see if it "goes in and out", "in and out" like good S#$!

Then install again. Going in and staying there????????

#53

kr98664, I did not see the diagrams you put on the post this morning sorry, but yes that is exactly how mine is. I am not with truck at this time so cannot do other checks but will try as I can. I am willing to try anything at this point.

reamer, it is not a mechanical sticking it is electrical. Besides I have replaced starter 3-4 times and flywheel is fine. Again I can barely tap on solenoid and it will disengage starter.

Someone asked about the old solenoid I cut apart, yes it looked brand new(which it was) when taken apart. Absolutely no signs of arcing or welding together.

The not cranking with the I terminal not hooked up has only recently been figured out...do not know if it was this way with other solenoids or not.

Yes relay only has 4 terminals, two big and two little and solenoid is mounted in factory position and location all grounds have been checked but will be checked again.

Alternator has also been replaced during this scenario but I will do test when can

when I say jumping the solenoid with a screwdriver I am touching the big post on battery side to the "S" post

reamer, it is not a mechanical sticking it is electrical. Besides I have replaced starter 3-4 times and flywheel is fine. Again I can barely tap on solenoid and it will disengage starter.

Someone asked about the old solenoid I cut apart, yes it looked brand new(which it was) when taken apart. Absolutely no signs of arcing or welding together.

The not cranking with the I terminal not hooked up has only recently been figured out...do not know if it was this way with other solenoids or not.

Yes relay only has 4 terminals, two big and two little and solenoid is mounted in factory position and location all grounds have been checked but will be checked again.

Alternator has also been replaced during this scenario but I will do test when can

when I say jumping the solenoid with a screwdriver I am touching the big post on battery side to the "S" post

#54

86 F-250 460, solenoids keep getting stuck so starter stays engaged. I have put 10+ solenoids in last year. Am I missing something here or is there a common problem that may cause this. I have replaced starter 3 times just to make sure it isn't the problem. I know stuff isn't made like it use to be but I would think I would get one good one out of 10 plus.

I haven't read through all of the posts but....given what you've spent already (tripping over dollars to save pennies), I would suggest going with a gear reduction starter from a reputable source (not AZ, O'Whoever, etc.). I liken that to driving 50 miles to a store to save 50% off of a bag of onions.

(yes, I used onions in tribute to Gary Lewis' analogy).

#55

#56

Guess where I was heading with checking the continuity through the solenoid is there are 4 terminal solenoids that use the 2 small terminals for the pull in coil.

1 takes power and the other goes to ground.

Update

OK, have a solenoid UN10208 (ex 85 F350- 460V8). "S" terminal to mounting plate 3.2 ohms, no continuity to any other terminals.

"I" terminal has no continuity to any terminal until solenoid is active then goes live.

Cheers Steve

1 takes power and the other goes to ground.

Update

OK, have a solenoid UN10208 (ex 85 F350- 460V8). "S" terminal to mounting plate 3.2 ohms, no continuity to any other terminals.

"I" terminal has no continuity to any terminal until solenoid is active then goes live.

Cheers Steve

#59

What would happen if line was connected to the load lug of the relay?

I know that the 'I' terminal would always be hot...

Is there some way that the pull down coil is seeing voltage to both sides, and therefore no potential?

This seems to be acting like a latching relay, and won't release until *all power* is disrupted.

I know it's really out there in the twilight zone, but who knows what else the harness of this truck has seen in the last 30 years?

I know that the 'I' terminal would always be hot...

Is there some way that the pull down coil is seeing voltage to both sides, and therefore no potential?

This seems to be acting like a latching relay, and won't release until *all power* is disrupted.

I know it's really out there in the twilight zone, but who knows what else the harness of this truck has seen in the last 30 years?

#60

What would happen if line was connected to the load lug of the relay?

I know that the 'I' terminal would always be hot...

Is there some way that the pull down coil is seeing voltage to both sides, and therefore no potential?

This seems to be acting like a latching relay, and won't release until *all power* is disrupted.

I know that the 'I' terminal would always be hot...

Is there some way that the pull down coil is seeing voltage to both sides, and therefore no potential?

This seems to be acting like a latching relay, and won't release until *all power* is disrupted.

There's only a single coil to actuate the relay, right? That's what the EVTM shows, but who knows. I know some big relays and solenoids have two coils. One is a heavy pull-in coil. The other is a light holding coil. Both operate together at first to pull the heavy core into place. Once actuated, the pull-in coil drops off, to reduce the amp draw. All of the switching is done internally.

Could there be something like that at play here? Not sure it would matter though...