Driveway 6.0 bulletproofing. List check.

#46

#47

#48

#49

With this build I'm not hinging any decision on cheap vs. expensive but what is best. I had originally jumped on the 6.4 bandwagon but continued my research and decided against them. The 6.0 and 6.4 banjos were designed for different engines with different plumbing systems. I do not need a banjo debate in this thread since it is focused on the headgaskets. I appreciate the input about the washers and they are added to my shopping list.

#50

I live in Sacramento also... I got my headgaskets, oil cooler & studs from Sinister http://sinisterdiesel.com that located in Roseville. They are identical that being sold from Ford dealer. The guy who did my bulletproof said that Sinister buys them in big bulks from Ford & re-sell them.

#51

With this build I'm not hinging any decision on cheap vs. expensive but what is best. I had originally jumped on the 6.4 bandwagon but continued my research and decided against them. The 6.0 and 6.4 banjos were designed for different engines with different plumbing systems. I do not need a banjo debate in this thread since it is focused on the headgaskets. I appreciate the input about the washers and they are added to my shopping list.

#52

I live in Sacramento also... I got my headgaskets, oil cooler & studs from Sinister Sinister Diesel - Diesel Performance Products and Accessories that located in Roseville. They are identical that being sold from Ford dealer. The guy who did my bulletproof said that Sinister buys them in big bulks from Ford & re-sell them.

YES! Thanks for finding that.

#54

#55

I've never seen blisters like that on heads before. I'm not sure what caused the metal to blister like that and am concerned if I just deck them it will create weak spots that may cause problems again. My first goal is trying to find a reputable shop in the Sacramento and surrounding area that can check my heads. I should have been searching before so I would be ready to send them out instead of now having to wait another week or two.

#56

#57

You don't necessarily have to. I had 5 or 7 thousandths taken off my heads and didn't change a push rod

#58

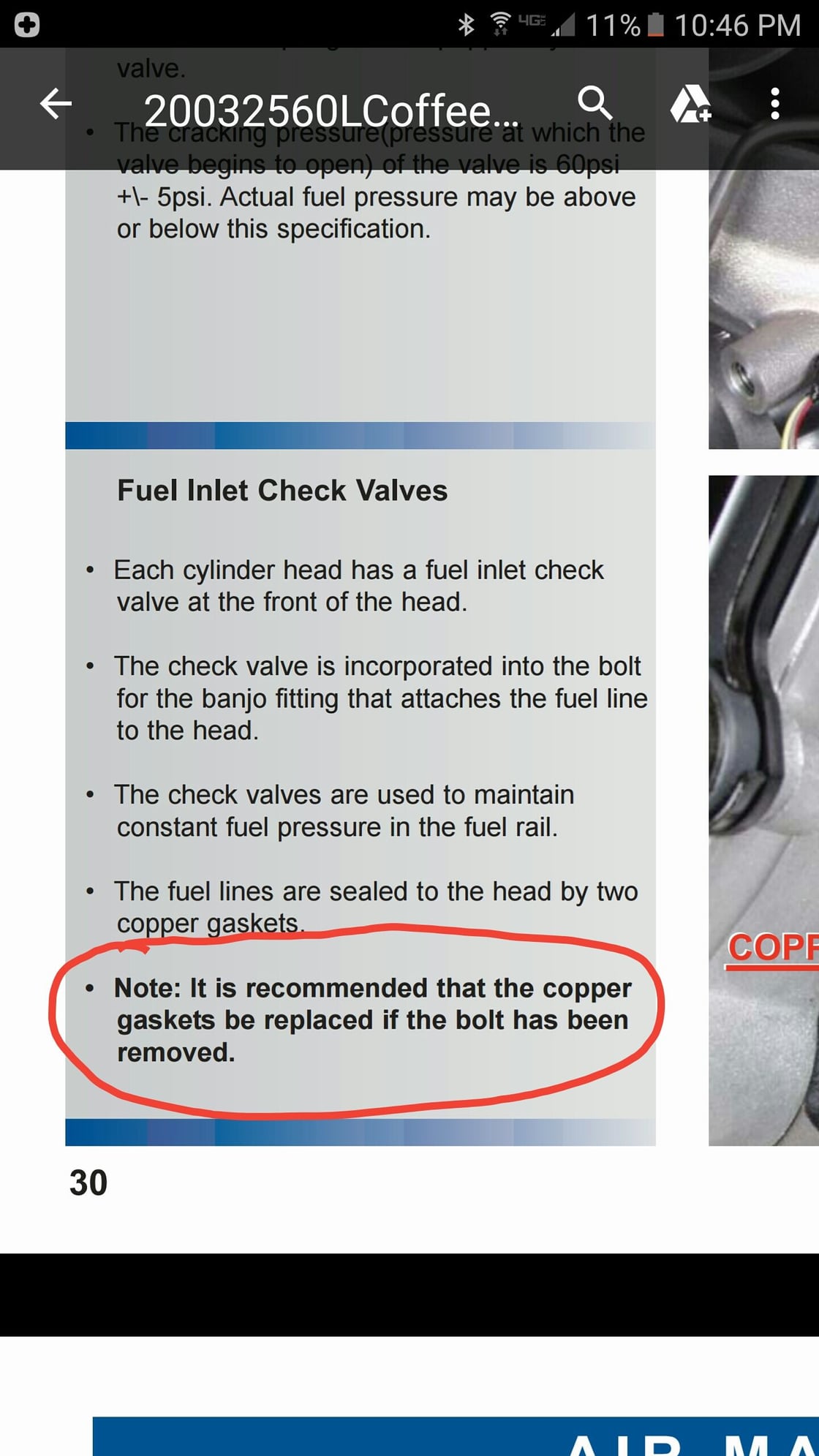

I'm finding little things not mentioned in other builds also. Like the EGR cooler metal gaskets. Never read in a single post to replace them but from what I understand about metal gaskets and what I have read, they are not reusable. Also, I have never read about replacing banjo gaskets on any stud job but they also should be replaced. Learning as I go and hope this helps other people as I get through it.

#59

The shorter pushrods are just piece of mind imo especially after machining the heads. I'll be pulling my lifters for inspection & replacing if anything looks off. Of course this adds a little to the cost but it's definitely not something you want to fail 50k miles after the job.

I agree about the egr gaskets & other misc gaskets not mentioned. I have about $200 in my budget for the oddball stuff. Always best to prepare for the worst of everything.

I agree about the egr gaskets & other misc gaskets not mentioned. I have about $200 in my budget for the oddball stuff. Always best to prepare for the worst of everything.

#60

So here's where I'm at after spending all morning scouring the web and on the phone.

Shop A

What do you think?

Shop A

- Will measure head thickness to check prior machining and run a straight edge to check warping for free.

- Has never found a head without cracks and will recondition with hardened seats as needed for $1750.

- No specified warranty.

- No freebies.

- $225 a head to tear down and check everything.

- $250 a head to deck only.

- $1950 to recondition with hardened seats as needed.

- No specified warranty.

- (out of area) $250 to ship.

- Wash, pressure test, peen.

- $1650 reconditioned, new guides, hardened seats, reuse valves springs unless new needed, deck.

- $600 core (Ford only)

- Lifetime warranty

- (out of area) $250 to ship.

- Wash, pressure test, peen.

- $1950 reconditioned, new guides, hardened seats, reuse valves springs unless new needed, deck, o- ring.

- $700 core (Ford only)

- 3 month warranty

What do you think?

Last edited by herojeep; 02-27-2017 at 05:20 PM. Reason: Add warranty info