Help me build/swap 'factory' r134a A/C

#1

Help me build/swap 'factory' r134a A/C

Howdy all,

Posted this a few days ago on another forum but haven't got any responses.

Regardless, I've been on here a while on and off. Always dreamed about buying an old bullnose like I remember my dad having when I was younger. Finally had the opportunity early last year when I just happened to be searching through craigslist. A few texts, phone calls, and a 2 hour drive later I was taking a look at what would be my first truck. She's a 1986 F250 4x4, 460 w/ T19, 93K original miles. An absolutely beautiful truck (other than the aged grey paint), 1 owner, zero rust, completely unmolested. And if 'zero rust' sounds odd being that I'm from NY, you're correct to question. The truck was originally from Oregon and bought from a dealer who, on the side, finds these rust old free trucks and brings 'em back to NY to sell. Anyway, sealed the deal on the truck for a bit more than I wanted to spend, but for rust free and as clean a truck as it is, it was completely worth it. The truck is an XL. Not completely optionless but it does lack A/C which I would prefer to have when cruising in hotter weather with the GF. The wing windows do a pretty good job by themselves but sometimes they just aren't enough with the humid heat we tend to have.

And just to get it out of the way, I'm completely capable of such a swap. I'm very mechanically inclined and have some past experience working on car A/C systems. I have access to A/C tools, vacuum pumps, gauges, etc. The truck is just an occasional driver when its nice out so I have no time crunch when the swap does occur. I have hours just in reading Ford truck forums about A/C swaps but I still haven't found all the info I need, especially since my laptop hard drive failed and I lost all the associated A/C links and threads I had with it. So, what I lack is year specific knowledge about Ford HVAC systems in pickups and BKOs. My A/C swap will not be as straight forward as most because I'm piecing together R134a specific front end components to work with the remaining original system.

First question. I obviously need all the interior duct work, dash, wiring, and vent box out of a similar year truck. Does the year matter? I seem to recall their being difference in 83- A/C trucks vs 84-86 but I can't remember what it was and if that would dictate what year to swap from. Bear in mind I'm not concerned with any of the front end components for this part of the swap, just wiring and interior A/C parts.

Second, with wiring I know I'm basically just swapping in the factory A/C harness and adding in the high pressure safety cutoff switch that goes to the compressor. Am I correct with this or is there more to be wired?

In regards to all the front end components, I plan on using the condenser, accumulator, evap core, etc from a mid-90s ford since they all systems transitioned to r134a in 1994. I already happen to have an exterior HVAC/evap box from an '84 F350, so I'll be switching out the factory r12 evaporator, accumulator, and orfice tube for the newer oe r134a components. The compressor however, I plan on using a V-band driven Sanden, designed for r134a. Obviously, my truck is pre-serpentine belt era, and I really have no need or interest in doing a serpentine belt swap or else I'd be using an oe compressor as well.

As far as A/C lines, I'm confident that an oe liquid line that goes from the condenser to the evap box will work, but the evap box to the compressor may have to be custom made as I'm not confident the fittings will match. Regardless, I have the ability to have lines made at a local shop if that happens to be the case.

Does all this seem reasonable and is there anything else I need to consider?

I'm sure I'll have additional questions but if anyone could answer those, that would help considerably.

Thanks, Morgan

Posted this a few days ago on another forum but haven't got any responses.

Regardless, I've been on here a while on and off. Always dreamed about buying an old bullnose like I remember my dad having when I was younger. Finally had the opportunity early last year when I just happened to be searching through craigslist. A few texts, phone calls, and a 2 hour drive later I was taking a look at what would be my first truck. She's a 1986 F250 4x4, 460 w/ T19, 93K original miles. An absolutely beautiful truck (other than the aged grey paint), 1 owner, zero rust, completely unmolested. And if 'zero rust' sounds odd being that I'm from NY, you're correct to question. The truck was originally from Oregon and bought from a dealer who, on the side, finds these rust old free trucks and brings 'em back to NY to sell. Anyway, sealed the deal on the truck for a bit more than I wanted to spend, but for rust free and as clean a truck as it is, it was completely worth it. The truck is an XL. Not completely optionless but it does lack A/C which I would prefer to have when cruising in hotter weather with the GF. The wing windows do a pretty good job by themselves but sometimes they just aren't enough with the humid heat we tend to have.

And just to get it out of the way, I'm completely capable of such a swap. I'm very mechanically inclined and have some past experience working on car A/C systems. I have access to A/C tools, vacuum pumps, gauges, etc. The truck is just an occasional driver when its nice out so I have no time crunch when the swap does occur. I have hours just in reading Ford truck forums about A/C swaps but I still haven't found all the info I need, especially since my laptop hard drive failed and I lost all the associated A/C links and threads I had with it. So, what I lack is year specific knowledge about Ford HVAC systems in pickups and BKOs. My A/C swap will not be as straight forward as most because I'm piecing together R134a specific front end components to work with the remaining original system.

First question. I obviously need all the interior duct work, dash, wiring, and vent box out of a similar year truck. Does the year matter? I seem to recall their being difference in 83- A/C trucks vs 84-86 but I can't remember what it was and if that would dictate what year to swap from. Bear in mind I'm not concerned with any of the front end components for this part of the swap, just wiring and interior A/C parts.

Second, with wiring I know I'm basically just swapping in the factory A/C harness and adding in the high pressure safety cutoff switch that goes to the compressor. Am I correct with this or is there more to be wired?

In regards to all the front end components, I plan on using the condenser, accumulator, evap core, etc from a mid-90s ford since they all systems transitioned to r134a in 1994. I already happen to have an exterior HVAC/evap box from an '84 F350, so I'll be switching out the factory r12 evaporator, accumulator, and orfice tube for the newer oe r134a components. The compressor however, I plan on using a V-band driven Sanden, designed for r134a. Obviously, my truck is pre-serpentine belt era, and I really have no need or interest in doing a serpentine belt swap or else I'd be using an oe compressor as well.

As far as A/C lines, I'm confident that an oe liquid line that goes from the condenser to the evap box will work, but the evap box to the compressor may have to be custom made as I'm not confident the fittings will match. Regardless, I have the ability to have lines made at a local shop if that happens to be the case.

Does all this seem reasonable and is there anything else I need to consider?

I'm sure I'll have additional questions but if anyone could answer those, that would help considerably.

Thanks, Morgan

#2

I don't have any answers for you so think of this more as a bump.

I am also following as I am kind of doing the same thing.

I am starting with 81 F100 non-A/C truck. I found a 2nd 81 F100 with A/C and will move ever thing from it to the non-A/C truck. I can not swap cabs as the A/C truck was rolled so the roof is caved in.

I will also be changing it over to R134 and what I have found in searches is I need to change all the rubber O rings from black to green and change the expansion valve but don't remember the color I need as of now.

IIRC there was a post with part numbers for the rings & what color valves to use with what cab ie: SDT/Xten/Crew

I also have found when switching from R12 to R134 the condenser should be bigger to work right. I have not looked into a bigger cond. yet but I have to replace it as the parts truck one was damaged when I bought the truck.

I was also told the fire walls are different between A/C and non-A/C trucks. I have not stripped the parts truck down yet but I do see a little difference between the two but think with just a little opening and drilling of holes it should work.

If not I can cut the fire wall out of the parts truck and weld it into the non-A/C truck to get the A/C to bolt to the fire wall. Heck that should be easy after welding in rockers & floors.

I never do stuff the easy way but I did give it some thought of going with something like Vintage Air and maybe and under dash unit. I think the under dash units look cheap so did not want to go that way.

Good luck

Dave ----

I am also following as I am kind of doing the same thing.

I am starting with 81 F100 non-A/C truck. I found a 2nd 81 F100 with A/C and will move ever thing from it to the non-A/C truck. I can not swap cabs as the A/C truck was rolled so the roof is caved in.

I will also be changing it over to R134 and what I have found in searches is I need to change all the rubber O rings from black to green and change the expansion valve but don't remember the color I need as of now.

IIRC there was a post with part numbers for the rings & what color valves to use with what cab ie: SDT/Xten/Crew

I also have found when switching from R12 to R134 the condenser should be bigger to work right. I have not looked into a bigger cond. yet but I have to replace it as the parts truck one was damaged when I bought the truck.

I was also told the fire walls are different between A/C and non-A/C trucks. I have not stripped the parts truck down yet but I do see a little difference between the two but think with just a little opening and drilling of holes it should work.

If not I can cut the fire wall out of the parts truck and weld it into the non-A/C truck to get the A/C to bolt to the fire wall. Heck that should be easy after welding in rockers & floors.

I never do stuff the easy way but I did give it some thought of going with something like Vintage Air and maybe and under dash unit. I think the under dash units look cheap so did not want to go that way.

Good luck

Dave ----

#3

Ok just thinking you are using the 86 evap coil and newer 94+ condenser/dryer. Do you know if the evaps and cond. are the same size between the 2? if so you could just use the 86 stuff.

When I say size both measurements and number of tubes, tube size and fins per-inch on tubes.

But if the evap is larger on the 86 will it work the same?

Just some of the things I would think when mix-n-matching parts.

I got to stop thinking so much ;_(

Dave ----

When I say size both measurements and number of tubes, tube size and fins per-inch on tubes.

But if the evap is larger on the 86 will it work the same?

Just some of the things I would think when mix-n-matching parts.

I got to stop thinking so much ;_(

Dave ----

#4

Ok just thinking you are using the 86 evap coil and newer 94+ condenser/dryer. Do you know if the evaps and cond. are the same size between the 2? if so you could just use the 86 stuff.

When I say size both measurements and number of tubes, tube size and fins per-inch on tubes.

But if the evap is larger on the 86 will it work the same?

Just some of the things I would think when mix-n-matching parts.

I got to stop thinking so much ;_(

Dave ----

When I say size both measurements and number of tubes, tube size and fins per-inch on tubes.

But if the evap is larger on the 86 will it work the same?

Just some of the things I would think when mix-n-matching parts.

I got to stop thinking so much ;_(

Dave ----

Think of this A/C swap as having 2 major parts:

1: Swapping in all the factory 80-86 interior A/C components- Dash, dusts, wiring, airbox, etc

2: Swapping in factory 94+ A/C (R134a) components- Condensor, evaporator core, accumulator, lines, etc, (with the exception of my compressor choice of a R134a v-belt driven Sanden).

No component from the firewall forward will be from the original R-12 system other than possibly the evap core/blower motor housing.

Generally speaking, components of R134a systems tend to be sized larger compared to their R-12 counterparts. This is due to R134a requiring higher pressures and therefore requiring more effective condensing to be efficient. While the evaporator cores between 80-86 and 94+ OBS trucks seem to be sized about the same, the design was updated for increased efficiency for the newer 94+ R134a systems. I believe the original system used a older style tube and fin evap core while the newer style evap core was a parallel flow type. (Could be wrong on that though.) Regardless, I want my system to use R134a as efficiently as possible. And hence, my reasoning for switching out all the front end components for the newer R134a components.

Here's an R-12 to R134a conversion thread you may find useful: http://www.f150online.com/forums/hva...4a-how-do.html

#5

1st off, I have never done it but remember posts on here of people who have tried it, and converting a non-A/C truck to a factory A/C truck is a horribly complicated and time consuming job. Mainly because there are holes to be cut in the firewall to make it all work, and that's not easy. A lot of guys on here do cab swaps, and that is one of the big decisions when they do it, do they want A/C or not and if they do, start with a A/C cab. I believe that is also the reason why they made dealer add-on units that are sort of oddball, it was too difficult to change a truck around to factory A/C.

On to the subject of r143a conversion, yes you can use the later factory r134a components, though you might find it difficult to get the later condensor mounted in the older frontend, but you could make some sort of brackets if you had to. Same with the later compressor, they started using different mounting brackets later on and finding the proper bracket to work with your older v-belt system may be a problem.

The good thing is, you can use all the older r12 components and then just use the r134a in that. Will it cool as good as the r134a components? No. Will it cool good enough for most people? Yes. If I am driving along on a hot summer day and have to turn the fan down because I am getting cold, I would say that is good enough. I know some of you guys live down south and need all you can get, but for most people the stock system with 134a works well.

Most new hoses you buy now are r134a compatible. Just watch out for NOS hoses you can sometimes buy on ebay. Old hoses already exposed to r12 seem to work fine when converted, and older o-rings already exposed to r12 work ok also.

You will see a lot of differing info on the net. And a list of requirements to convert a system to 134a. But there are so many systems out there now and so many conversion kits that have been sold where the r12 is just taken out and the r134a is installed, it can't really be debated anymore, it will work.

On to the subject of r143a conversion, yes you can use the later factory r134a components, though you might find it difficult to get the later condensor mounted in the older frontend, but you could make some sort of brackets if you had to. Same with the later compressor, they started using different mounting brackets later on and finding the proper bracket to work with your older v-belt system may be a problem.

The good thing is, you can use all the older r12 components and then just use the r134a in that. Will it cool as good as the r134a components? No. Will it cool good enough for most people? Yes. If I am driving along on a hot summer day and have to turn the fan down because I am getting cold, I would say that is good enough. I know some of you guys live down south and need all you can get, but for most people the stock system with 134a works well.

Most new hoses you buy now are r134a compatible. Just watch out for NOS hoses you can sometimes buy on ebay. Old hoses already exposed to r12 seem to work fine when converted, and older o-rings already exposed to r12 work ok also.

You will see a lot of differing info on the net. And a list of requirements to convert a system to 134a. But there are so many systems out there now and so many conversion kits that have been sold where the r12 is just taken out and the r134a is installed, it can't really be debated anymore, it will work.

#6

MEvans043: I thought the evap was part of the air box and why I said check when mix-n-matching parts.

If the 94 air box/evap unit will fit that would be the way to go as it has all worked together before. I am still following to see how this turns out.

Franklin2: I was told the same thing on the A/C & non-A/C firewall not being the same. My non-A/C truck is stripped and can see the FW. My A/C parts truck has not been stripped yet but can see a little of the FW and yes it is different but will not know how much till it is stripped. What I see looks like I can drill a few holes and open up larger ones to make it work. If not I will cut that part of the FW out and weld it into the other truck.

Yes a lot of work but I don’t have the option of a cab swap as the A/C truck is a roll over and has no roof. Also the banker (wife) said my loans are cut off so buying another truck is out. Besides who doesn’t like to use a plasma cuter and welder

Dave----

If the 94 air box/evap unit will fit that would be the way to go as it has all worked together before. I am still following to see how this turns out.

Franklin2: I was told the same thing on the A/C & non-A/C firewall not being the same. My non-A/C truck is stripped and can see the FW. My A/C parts truck has not been stripped yet but can see a little of the FW and yes it is different but will not know how much till it is stripped. What I see looks like I can drill a few holes and open up larger ones to make it work. If not I will cut that part of the FW out and weld it into the other truck.

Yes a lot of work but I don’t have the option of a cab swap as the A/C truck is a roll over and has no roof. Also the banker (wife) said my loans are cut off so buying another truck is out. Besides who doesn’t like to use a plasma cuter and welder

Dave----

#7

Ah...

She, who must be obeyed.... (to borrow a term used by NumberDummy Bill )

)

Man, I wish I could meet up with you and take some lessons and learn some stuff, I know absolutely nada about how to use that stuff... I have what I think is an old Sears arc welder (from the 70s?) but I don't have electricity to power it nor do I know how to use it... I think about taking a class at a local community college, will do some more homework once I get 220V into the garage... sometime... other stuff keeps arising and interfering....

She, who must be obeyed.... (to borrow a term used by NumberDummy Bill

)

)Man, I wish I could meet up with you and take some lessons and learn some stuff, I know absolutely nada about how to use that stuff... I have what I think is an old Sears arc welder (from the 70s?) but I don't have electricity to power it nor do I know how to use it... I think about taking a class at a local community college, will do some more homework once I get 220V into the garage... sometime... other stuff keeps arising and interfering....

Trending Topics

#8

I am no expert by any means. As they say I know enough to be dangerous

In the old days we would gas weld and for body panels braze them.

Arc welding (stick) is used for thicker metals and has slag youhave to hammer and wire brush off. I used this type to build roll cages for 4x4’sI raced off road. The thing with the “stick” is they have to stay dry or theyturn to junk and can’t be used.

MIG, gas or flux, for the home owner you can get to run off 110v.I have a Lincoln 130 gas but can use flux (not as clean weld) that I use forsheet metal work. I have also used it to weld the center section of a rear axleto the tubes and braced up the spring perches on my drag car. Just have towatch the duty cycl.

The plasma cutter I have is an “all in one” 110v unit made justfor sheet metal but has cut thru some thicker stuff. I have not used it much indoing body panel replacement, more a toy.

As with any of the above tools the more you use them the betteryou get. I would say if you are looking for a welder look at a MIG that can useboth flux & gas in the 110volt to start with. Watch some YouTube and thenuse the welder on scrap metal. Some MIG units can also do Alum with somechanges. Mine can but I have not used it for that yet.

Next on my list is a TIG welder toplay with.

Dave ----

In the old days we would gas weld and for body panels braze them.

Arc welding (stick) is used for thicker metals and has slag youhave to hammer and wire brush off. I used this type to build roll cages for 4x4’sI raced off road. The thing with the “stick” is they have to stay dry or theyturn to junk and can’t be used.

MIG, gas or flux, for the home owner you can get to run off 110v.I have a Lincoln 130 gas but can use flux (not as clean weld) that I use forsheet metal work. I have also used it to weld the center section of a rear axleto the tubes and braced up the spring perches on my drag car. Just have towatch the duty cycl.

The plasma cutter I have is an “all in one” 110v unit made justfor sheet metal but has cut thru some thicker stuff. I have not used it much indoing body panel replacement, more a toy.

As with any of the above tools the more you use them the betteryou get. I would say if you are looking for a welder look at a MIG that can useboth flux & gas in the 110volt to start with. Watch some YouTube and thenuse the welder on scrap metal. Some MIG units can also do Alum with somechanges. Mine can but I have not used it for that yet.

Next on my list is a TIG welder toplay with.

Dave ----

#9

1st off, I have never done it but remember posts on here of people who have tried it, and converting a non-A/C truck to a factory A/C truck is a horribly complicated and time consuming job. Mainly because there are holes to be cut in the firewall to make it all work, and that's not easy. A lot of guys on here do cab swaps, and that is one of the big decisions when they do it, do they want A/C or not and if they do, start with a A/C cab. I believe that is also the reason why they made dealer add-on units that are sort of oddball, it was too difficult to change a truck around to factory A/C.

On to the subject of r143a conversion, yes you can use the later factory r134a components, though you might find it difficult to get the later condensor mounted in the older frontend, but you could make some sort of brackets if you had to. Same with the later compressor, they started using different mounting brackets later on and finding the proper bracket to work with your older v-belt system may be a problem.

On to the subject of r143a conversion, yes you can use the later factory r134a components, though you might find it difficult to get the later condensor mounted in the older frontend, but you could make some sort of brackets if you had to. Same with the later compressor, they started using different mounting brackets later on and finding the proper bracket to work with your older v-belt system may be a problem.

I'm more or less not afraid of what I'll run into during the swap as much as making sure I have everything I need for it before I dive in.

#10

This was one of the thread posts I was looking for but couldn't find until just now:

Link to original thread here: http://www.fullsizebronco.com/forum/...ml#post2924765

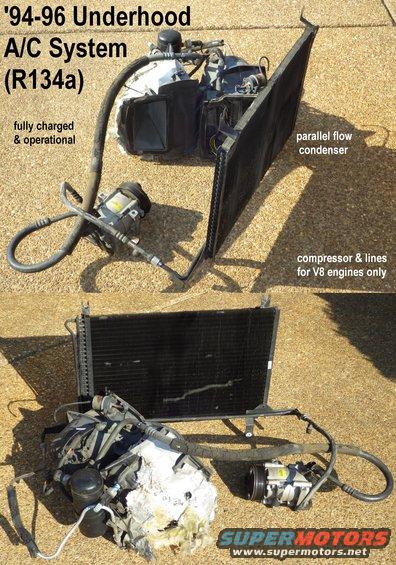

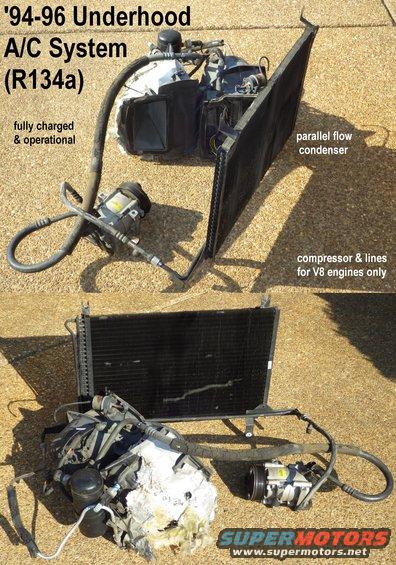

Also, here's a couple reference photos to those who are interested:

(Photos owned by "Steve83" of FullSizeBronco.com, I take no credit for them.)

"...The entire A/C refrigerant system can be removed as a unit from all '80-96 gasoline (& probably diesel) F-series & Broncos without much trouble. The fan & shroud have to come out so the radiator can tilt back, and the belt has to come off, of course. But no coolant, refrigerant, or other fluid lines have to be opened..."

Source: by Steve83 (Steve, That dirty old truck) at SuperMotors.net

AC Diagram by Stev

THE IMAGE IS TOO SMALL, click it.

The compressor (4) pulls low-temp./press. refrigerant vapor (11) from the accumulator (3) and raises its pressure & temperature. As it flows through the condenser ( 8 ), the refrigerant's higher-than-ambient temperature causes heat to flow out into the airstream, allowing the refrigerant to condense into a high-temp./press. liquid (14). The pressure is a result of the precise restriction caused by the orifice tube (9). As the refrigerant flows slowly through it, the pressure drops suddenly, causing the refrigerant to flash-boil from a low-press. liquid (13) into a low-temp./press. vapor (11). To change from liquid to vaport, the refrigerant must absorb heat through the evaporator, which cools the cabin airstream. The refrigerant then returns to the accumulator where it continues to boil & is dried by a dessicant.

If refrigerant leaks out OR the cabin airstream is too cold, the pressure in the evaporator will be too low to keep the cycling switch (2) ON below ~20psi. If the system is overcharged OR the ambient airstream is too hot, pressure in the condenser will cause the pressure cut-off switch (6) to turn OFF above ~400psi. If that fails, then the pressure relief valve (5) will vent refrigerant above ~500psi.

/C System Components (late R-12 system shown)

Separate suction & discharge hoses were used until ~'92. Mid-years (~'86-90) used square-drive shutoff valves at the compressor ports. Early models ('80~84) used an autmatic shutoff valve & filter in the connection between the condenser & the condenser-to-evaporator hose.

The low pressure switch screws onto an automatic valve on the accumulator.

R-134a models have a hi-press. cutout switch on the discharge hose

Source: by Steve83 (Steve, That dirty old truck) at SuperMotors.net

AC Diagram by Stev

THE IMAGE IS TOO SMALL, click it.

The compressor (4) pulls low-temp./press. refrigerant vapor (11) from the accumulator (3) and raises its pressure & temperature. As it flows through the condenser ( 8 ), the refrigerant's higher-than-ambient temperature causes heat to flow out into the airstream, allowing the refrigerant to condense into a high-temp./press. liquid (14). The pressure is a result of the precise restriction caused by the orifice tube (9). As the refrigerant flows slowly through it, the pressure drops suddenly, causing the refrigerant to flash-boil from a low-press. liquid (13) into a low-temp./press. vapor (11). To change from liquid to vaport, the refrigerant must absorb heat through the evaporator, which cools the cabin airstream. The refrigerant then returns to the accumulator where it continues to boil & is dried by a dessicant.

If refrigerant leaks out OR the cabin airstream is too cold, the pressure in the evaporator will be too low to keep the cycling switch (2) ON below ~20psi. If the system is overcharged OR the ambient airstream is too hot, pressure in the condenser will cause the pressure cut-off switch (6) to turn OFF above ~400psi. If that fails, then the pressure relief valve (5) will vent refrigerant above ~500psi.

/C System Components (late R-12 system shown)

Separate suction & discharge hoses were used until ~'92. Mid-years (~'86-90) used square-drive shutoff valves at the compressor ports. Early models ('80~84) used an autmatic shutoff valve & filter in the connection between the condenser & the condenser-to-evaporator hose.

The low pressure switch screws onto an automatic valve on the accumulator.

R-134a models have a hi-press. cutout switch on the discharge hose

Also, here's a couple reference photos to those who are interested:

(Photos owned by "Steve83" of FullSizeBronco.com, I take no credit for them.)

#11

#12

Mine is a dealer A/C unit and I have to say 100* outside and my vent registry temp at the right side instrument cluster vent holds a steady 58* F. That is pretty damn cold at 100*F ambient air temp in a truck with a metal roof and a bunch of huge glass windows.

I have thought personally of getting a more modern condenser up front for R134a but mine being dealer installed its an oddball half sized condenser that the inlet and outlet are on the same side where as dealer has the inlet on the driver side and the outlet on the passengerside. Mine is both on the driver side and goes through two holes cut in the firewall just inboard of the throttle pedal assembly.

If you are simply looking to go with a A/C system in a non Air truck I would suggest looking at vintage air. We install their products at work and if you are not after a show car finish under the hood you can get one done in two days easily. They also work great and they are designed for 134A. I also believe Old Air products also sell a A/C update kit for factory A/C vehicles that want to update to the 134a systems.

Be warned though at work we have been getting a bunch of fliers that they are going to start phasing out R134a for a new type of refrigerant.

I have thought personally of getting a more modern condenser up front for R134a but mine being dealer installed its an oddball half sized condenser that the inlet and outlet are on the same side where as dealer has the inlet on the driver side and the outlet on the passengerside. Mine is both on the driver side and goes through two holes cut in the firewall just inboard of the throttle pedal assembly.

If you are simply looking to go with a A/C system in a non Air truck I would suggest looking at vintage air. We install their products at work and if you are not after a show car finish under the hood you can get one done in two days easily. They also work great and they are designed for 134A. I also believe Old Air products also sell a A/C update kit for factory A/C vehicles that want to update to the 134a systems.

Be warned though at work we have been getting a bunch of fliers that they are going to start phasing out R134a for a new type of refrigerant.

Thread

Thread Starter

Forum

Replies

Last Post

tkerkela

1987 - 1996 F150 & Larger F-Series Trucks

4

07-07-2018 10:01 AM

JLennon22

1973 - 1979 F-100 & Larger F-Series Trucks

2

09-13-2017 02:12 PM

four-sixty-power

1973 - 1979 F-100 & Larger F-Series Trucks

3

08-07-2011 12:29 AM

bowedup2003

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

3

03-20-2006 07:19 AM