Verify TPS Testing Procedure

#1

Verify TPS Testing Procedure

I’ve been trouble-shooting a few issues since re-installing a rebuilt E4OD this year. I’ve had some possibly related shifting issues, stalling into reverse & low (just above 500 to 600, 650) idle RPM when at operating temp. Cold start goes to 1100 then drops to 900 or so.

I have swapped in a different IAC & seen an improvement in idle stalling, but the RPMs Hot are still dropping low.

If you would, please review my understanding of testing & measurements of the throttle position sensor, as well as “check my math” & correct me where I’m wrong.

I haven’t seen a concise, simple listing of the voltage & resistances.

The former FFI (Ford Fuel Injection) site has listings of measurements & +/- ranges but I see no test procedures.

The FSB link which is posted frequently has some really good information as posted by member “Seattle FSB” but its scattered across 2 pages doesn’t really spell it out for the inexperienced.

(Correct anything I’ve got wrong please)

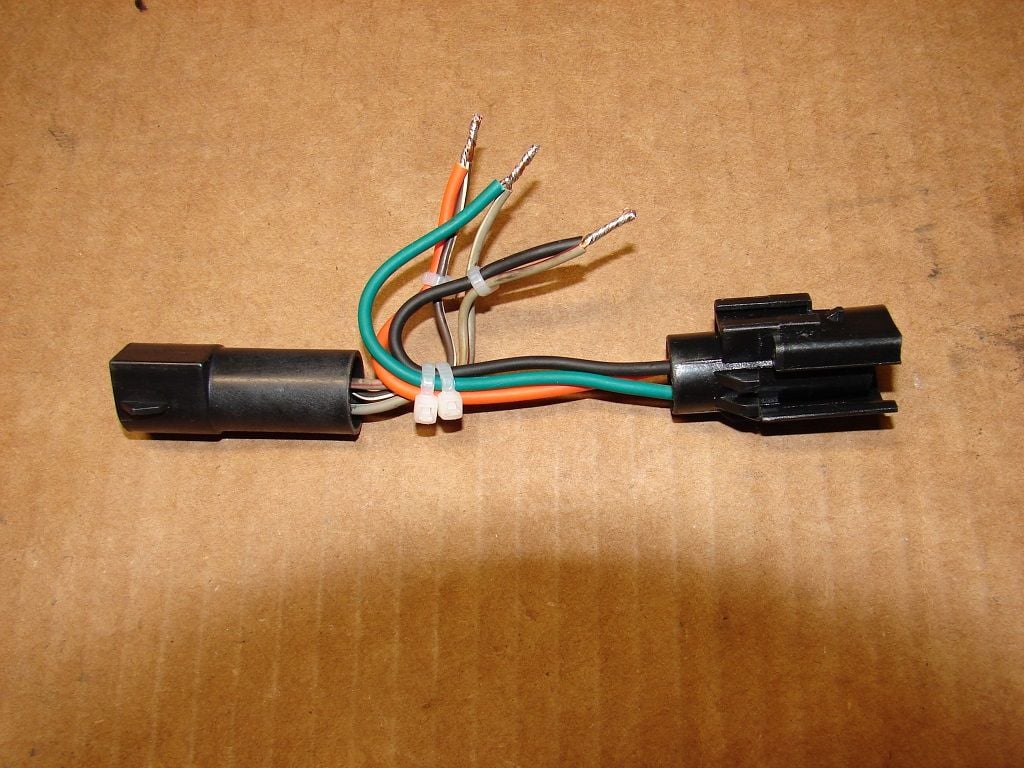

1) TPS Reference voltage is best checked between Orange & Battery Ground or Orange & Black.

(I’m seeing 5.02)

The TPS Signal voltage is checked between Green and Black. The signal voltage should be less than 1 volt with the throttle body closed and increase to less than 4.8 volts at WOT.

Some recommendations say .99 is best, .98 better & the former FFI says .901 volts.

(My sweep is from 1.01 closed to 4.60 WOT.)

2) TPS Resistance Testing is normally done on the unplugged TPS on the TPS SIG (Green) and VREF (Orange) wires. You are looking for resistance values of less than 4000 ohms at closed throttle and greater than 350 ohms at WOT.

When testing resistance on the TP SIG and VREF wires, the resistance will decrease.

(I’m seeing 2920 ohms closed & 360/370 ohms WOT)

3) When testing resistance on the TP SIG and SIG RTN wires, the resistance will increase. Unfortunately I can’t seem to find values for this unless they are right under my nose. (Happens frequently, sorry)

(I get 820 ohms closed & 3350 WOT.)

So, I’m looking at closed signal voltage too high. (could be adjusted out by opening up screwhole) and sig & vref out of spec, (360/370 too high, not under 350) it would seem that although it is less that 4K, 2920 ohms would be too “less than” 4K

Any feedback appreciated.

I have swapped in a different IAC & seen an improvement in idle stalling, but the RPMs Hot are still dropping low.

If you would, please review my understanding of testing & measurements of the throttle position sensor, as well as “check my math” & correct me where I’m wrong.

I haven’t seen a concise, simple listing of the voltage & resistances.

The former FFI (Ford Fuel Injection) site has listings of measurements & +/- ranges but I see no test procedures.

The FSB link which is posted frequently has some really good information as posted by member “Seattle FSB” but its scattered across 2 pages doesn’t really spell it out for the inexperienced.

(Correct anything I’ve got wrong please)

1) TPS Reference voltage is best checked between Orange & Battery Ground or Orange & Black.

(I’m seeing 5.02)

The TPS Signal voltage is checked between Green and Black. The signal voltage should be less than 1 volt with the throttle body closed and increase to less than 4.8 volts at WOT.

Some recommendations say .99 is best, .98 better & the former FFI says .901 volts.

(My sweep is from 1.01 closed to 4.60 WOT.)

2) TPS Resistance Testing is normally done on the unplugged TPS on the TPS SIG (Green) and VREF (Orange) wires. You are looking for resistance values of less than 4000 ohms at closed throttle and greater than 350 ohms at WOT.

When testing resistance on the TP SIG and VREF wires, the resistance will decrease.

(I’m seeing 2920 ohms closed & 360/370 ohms WOT)

3) When testing resistance on the TP SIG and SIG RTN wires, the resistance will increase. Unfortunately I can’t seem to find values for this unless they are right under my nose. (Happens frequently, sorry)

(I get 820 ohms closed & 3350 WOT.)

So, I’m looking at closed signal voltage too high. (could be adjusted out by opening up screwhole) and sig & vref out of spec, (360/370 too high, not under 350) it would seem that although it is less that 4K, 2920 ohms would be too “less than” 4K

Any feedback appreciated.

#3

All of the values are posted in that thread you mentioned in your first post

FSB Forums - View Single Post - Throttle Position Sensor Testing, Replacement and Adjustment

Also make sure the MLPS on the driver side of the transmission is adjusted correctly as that can cause shifting issues.

FSB Forums - View Single Post - Throttle Position Sensor Testing, Replacement and Adjustment

Also make sure the MLPS on the driver side of the transmission is adjusted correctly as that can cause shifting issues.

#4

Thank you for your reply.

#5

The PCM Computer takes the CT value when you start the engine (if you do not touch the throttle).

Is the RPM low or high?

A high RPM is to much air going into the intake. Either by a gasket leak, throttle plates not closed, purge line or by way of the IAC valve.

Low RPM is lack of air most of the time from the IAC valve or its wiring.

#6

The resistance test on your TPS looks fine. The only thing that may be of issue is the fact that when your throttle is closed you are at 1 volt. But I am pretty sure your tps is fine and you have another issue Maybe adjust it closer spec and see if that helps?

Unplugged TPS Resistance - 350 ohms those are you resistance specs for both tests btw.

The IAC you swapped in...is it new or just an extra you had sitting around?

Unplugged TPS Resistance - 350 ohms those are you resistance specs for both tests btw.

The IAC you swapped in...is it new or just an extra you had sitting around?

#7

I am basing my conclusions on the measurements I'm taking and the apparent out of range conditions on those. Hence my asking for verification.

As mentioned earlier, I've changed out the IAC & the result was an improvement. I'm not having a stall when going into reverse at operating temperature but that the RPM drops into the 500-650 range when warm still. I don't feel confident when lifting from the gas pedal completely while coasting to a stop.

From cold start I have 1100 for 10-15-20 seconds, then it drops to 900 or so & will idle perfectly for ever how long it takes to open the 195* thermostat. If driven to operating temp, I feel compelled to pedal the accelerator when the RPMs drops.

As mentioned earlier, I've changed out the IAC & the result was an improvement. I'm not having a stall when going into reverse at operating temperature but that the RPM drops into the 500-650 range when warm still. I don't feel confident when lifting from the gas pedal completely while coasting to a stop.

From cold start I have 1100 for 10-15-20 seconds, then it drops to 900 or so & will idle perfectly for ever how long it takes to open the 195* thermostat. If driven to operating temp, I feel compelled to pedal the accelerator when the RPMs drops.

Trending Topics

#8

#9

ok. Your tps seems fine, i'd adjust the tps closer to .98 or so with the throttle closed....but that's me. I'd still Clean the IAC (even though the swap showed an improvement)...you seem to know how to search, there are plenty threads on it. Also i'd still check out the wiring. Wiggle the wires at the connector around and other stuff.

Have you pulled any codes on your truck?

Have you pulled any codes on your truck?

#10

It also looks like his meter is reading 0.02 Volts high or he has a bad regulator in the PCM.

The reading of 1.01 should be OK with the PCM Computer and it will just take that as the CT.

I would open the PCM up and check the caps.

#11

When I replaced my TPS Mine had a small amount of movement to get close to .98.

#12

I pull the codes after almost every test drive. There is nothing new (so far) since I swapped out a different VSS recently. This is the next issue I'm tackling.

I've cleaned a few IACs before. There is no carbon in this one.

I've cleaned a few IACs before. There is no carbon in this one.

#13

See last post. It is what led me to the VSS issue you're aware of.

https://www.ford-trucks.com/forums/1...nd-thread.html

I'm waiting on some caps & another chapter member is going to take a swing at changing them out.

https://www.ford-trucks.com/forums/1...nd-thread.html

I'm waiting on some caps & another chapter member is going to take a swing at changing them out.

#14

forgive me if im posting in wrong place im horrible on computer im having issues with my f super duty 1989 7.5 l i was testing tps and signal v is .5 and 3.5 wot i cant find vehicle specific values and wanted to verify it was bad before replacement it stumbles when accelerated going down road but not at idle i unplugged it an drove it and it seemed to have no change i have no experience with efi i thought it was fuel at first dropped and cleaned tanks new filter any help will be plenty thanks

#15

forgive me if im posting in wrong place im horrible on computer im having issues with my f super duty 1989 7.5 l i was testing tps and signal v is .5 and 3.5 wot i cant find vehicle specific values and wanted to verify it was bad before replacement it stumbles when accelerated going down road but not at idle i unplugged it an drove it and it seemed to have no change i have no experience with efi i thought it was fuel at first dropped and cleaned tanks new filter any help will be plenty thanks

One of them, VREF should have 5.0 Volts. The SIG RTN should have near zero volts and the TP should have around 0.90 Volts at close throttle and around 4.5 Volts at WOT. All voltage are DC with the key in the run position.

The readings you posted do not make much sense to me.

If you do not get the right TP voltage above and the other two are right on then yes you would need a new TPS from a Ford dealer.

/