Dying Cow under the hood...

#1

Dying Cow under the hood...

My power steering and brake hydroboost system has always been stone dead quiet... until last night!!

Due to a blown seal on a pressure hose fitting, I replaced both pressure hoses on the system last night in a parking lot. No leaks now, but the system now sounds like a cow is dying under the hood, and I can't STAND IT!!

I expect there is still some air in the system which will take a little time to work out, but after running it a bit last night (after repairs), the noise did not quiet down or diminish at all.

More specifics about my installation and observations...

- old hoses removed (both, one after the other)

- new hoses connected (again, one after the other, hydroboost to gear box was the first one connected)

- poured in about a pint of fluid and let it settle, some air purging took place during this process, but only by gravity

- started the Excursion

- as the fluid level dropped, I continued to fill until near full

- pump chattered and generated some fluid foaminess in the process

- hydroboost started groaning while the fluid was being installed

- fluid level settled down and stabilized

- let the engine run for several minutes and shut it off

- topped off the fluid level again (only took a couple of ounces this time)

- let the vehicle sit for a few minutes

- restarted the engine and revved the engine a couple of times (nothing extreme)

- power steering pump chatter was gone, but the hydroboost groan was still present

- drove the vehicle around the parking lot for about 5 minutes, and the groaning never subsided or diminished, and it gets much louder when the brake pedal is pressed

- turning the steering wheel neither increases nor decreases the groaning

Have I simply not run it long enough, or is there some technique I failed to follow to expel all the air when I did the hose R&R yesterday evening?

As always, all insight and instructive wisdom is greatly appreciated.

UPDATE on 05.29.14 @ 8:14am

Last night, we had some serious rain and thunderstorms, so I did not (could not) get the flush done. In the throws of other "life happenings", I forgot to snap some pics of the hose fitting failure, but I still have it in the bed of my truck.

Regardless, my wife tells me that while running a very short errand yesterday (only about 4-5 miles or so), by the time she got home, the noise was completely gone. I have not listened to it myself, but if she is right, then it was only air-induced noise and I now need to re-check fluid levels again. I'm still going to do the flush and purge and protect regimen prescribed below, but with the noise being either gone or greatly diminished, it can wait until I have a cooperative weather weekend for the work.

ALSO... For your download convenience, Y2KW57's procedure for Flush-Purge-Protect is compiled into a PDF document and attached in Post #20 below.

Due to a blown seal on a pressure hose fitting, I replaced both pressure hoses on the system last night in a parking lot. No leaks now, but the system now sounds like a cow is dying under the hood, and I can't STAND IT!!

I expect there is still some air in the system which will take a little time to work out, but after running it a bit last night (after repairs), the noise did not quiet down or diminish at all.

More specifics about my installation and observations...

- old hoses removed (both, one after the other)

- new hoses connected (again, one after the other, hydroboost to gear box was the first one connected)

- poured in about a pint of fluid and let it settle, some air purging took place during this process, but only by gravity

- started the Excursion

- as the fluid level dropped, I continued to fill until near full

- pump chattered and generated some fluid foaminess in the process

- hydroboost started groaning while the fluid was being installed

- fluid level settled down and stabilized

- let the engine run for several minutes and shut it off

- topped off the fluid level again (only took a couple of ounces this time)

- let the vehicle sit for a few minutes

- restarted the engine and revved the engine a couple of times (nothing extreme)

- power steering pump chatter was gone, but the hydroboost groan was still present

- drove the vehicle around the parking lot for about 5 minutes, and the groaning never subsided or diminished, and it gets much louder when the brake pedal is pressed

- turning the steering wheel neither increases nor decreases the groaning

Have I simply not run it long enough, or is there some technique I failed to follow to expel all the air when I did the hose R&R yesterday evening?

As always, all insight and instructive wisdom is greatly appreciated.

UPDATE on 05.29.14 @ 8:14am

Last night, we had some serious rain and thunderstorms, so I did not (could not) get the flush done. In the throws of other "life happenings", I forgot to snap some pics of the hose fitting failure, but I still have it in the bed of my truck.

Regardless, my wife tells me that while running a very short errand yesterday (only about 4-5 miles or so), by the time she got home, the noise was completely gone. I have not listened to it myself, but if she is right, then it was only air-induced noise and I now need to re-check fluid levels again. I'm still going to do the flush and purge and protect regimen prescribed below, but with the noise being either gone or greatly diminished, it can wait until I have a cooperative weather weekend for the work.

ALSO... For your download convenience, Y2KW57's procedure for Flush-Purge-Protect is compiled into a PDF document and attached in Post #20 below.

The following users liked this post:

#5

#7

Trending Topics

#8

#9

#10

Ford Power Steering Flush and Purge Procedures

My power steering and brake hydroboost system has always been stone dead quiet... until last night!! No leaks now, but the system now sounds like a cow is dying under the hood, and I can't STAND IT!! I expect there is still some air in the system which will take a little time to work out, but after running it a bit last night (after repairs), the noise did not quiet down or diminish at all.

Have I simply not run it long enough, or is there some technique I failed to follow to expel all the air when I did the hose R&R yesterday evening?

Have I simply not run it long enough, or is there some technique I failed to follow to expel all the air when I did the hose R&R yesterday evening?

Probably both... more time needed than you had last night, and more technique needed than could be mustered on an emergency just get it home without a tow bill triage in a public parking lot. BTW, congratulations on your success!

Where did you end up getting your replacement power steering lines?

The reason why I ask is because some lines make more noise than others. Ford found out early on that they needed to upgrade the design of the power steering hose between the steering pump and the hydroboost power brake unit, in order to make it quieter, due to customer complaints not unlike yours.

If your hoses are aftermarket, it is possible that while they might have been manufactured to Ford's initial specifications, they may not have been manufactured to Ford's updated improvement, which might be protected by patents. Ford improved the pressure hose by incorporating a tuning cable which cancels the harmonic noise that is generated by the inherent restriction on the pump due to feeding fluid through the hydroboost power brake system first.

You have an Excursion, but I forgot what year it is. Excursions were introduced as model year 2000, but production of them began much earlier in 1999. If your Excursion was built prior to February 5, 2000, then it did not originally come equipped with an updated design hose, so this might rule out a before and after comparison with the hose you have today. UNLESS, prior to your ownership, the power steering hose was replaced with an updated part.

Do you still have the old hose? Is there a label on it that has a part number? The updated hose with the tuning cable is part number YC3Z-3A717-AA.

On the other hand, if your Excursion was built AFTER February 5, 2000, then your Ex came equipped from the factory with the quieter "tuned" steering hose, making the comparison between how the old hose sounded when it wasn't leaking versus the new aftermarket hose today more significant.

Brakes and steering are components where I would lean toward using OEM parts, but I lean that way all the time, so nevermind me. I just thought I would mention this engineering change on the power steering line that is not evident by looking at the parts themselves, and unknown to many without prior knowledge of the update.

All that being said, and assuming that the hoses you installed are just fine, there is still a lot to do to finish up your install of these new lines, in order to kill that cow whining under the hood. You hit the nail on the head: Air.

Ford warns that if the air is not purged from the power steering system correctly, "premature power steering pump failure could result."

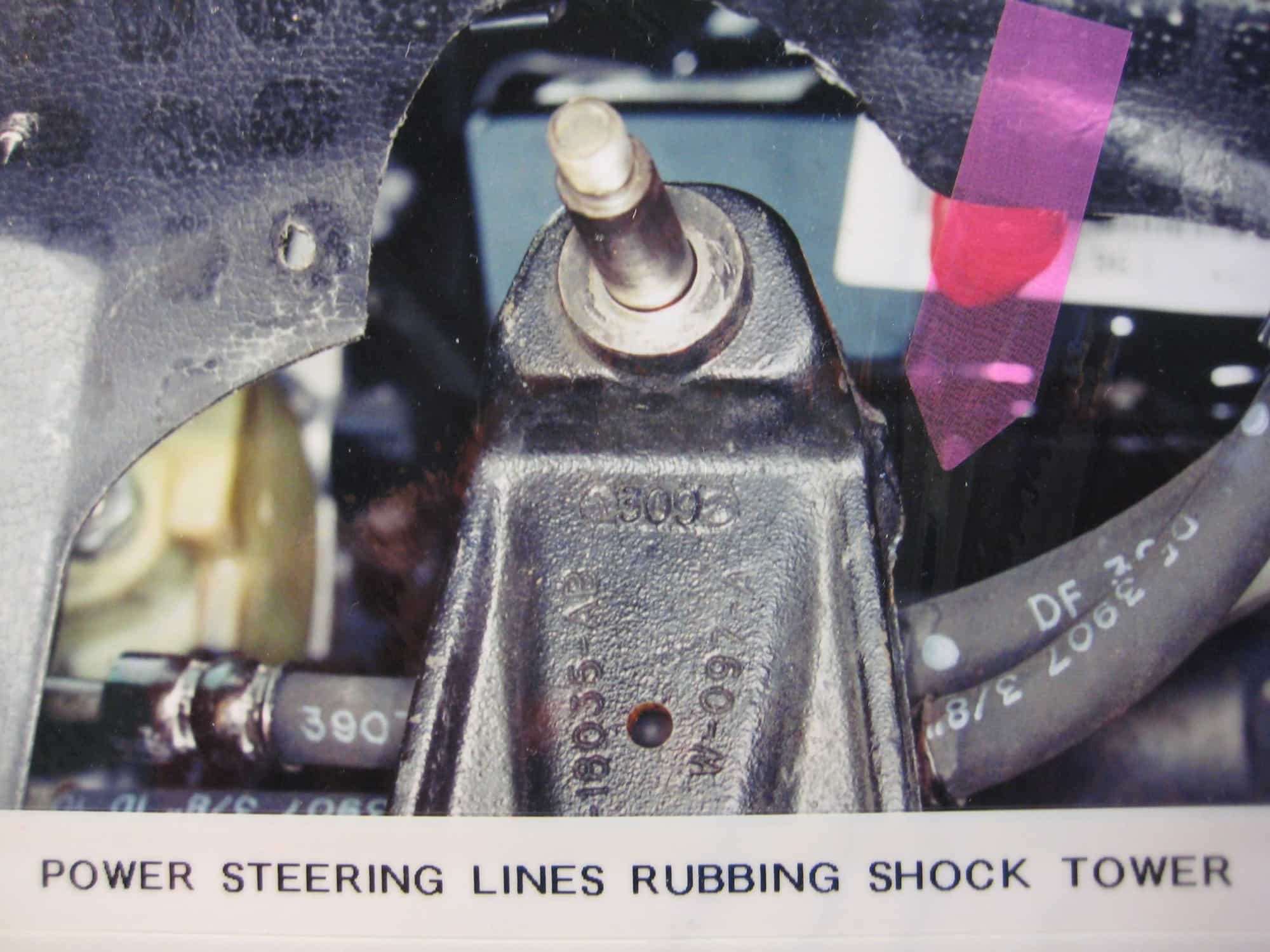

A whine heard from the power steering pump may be caused by air in the system, as you suspect. And... noise also can be caused, or amplified, if the power steering lines are touching anything other than their brackets. If they are in hard contact up against something, they can transmit more noise.

Because you also say your fluid is old, and possibly contaminated even before you did the emergency repair, and because of the probability of the fluid and lines becoming aerated when the system was opened up, and because two lines were replaced, a full attack on all three fronts is in order.

A. FLUSH

B. PURGE

C. PROTECT

FLUSH

- Park on a level surface if possible. Pick and commit to a place where the entire procedure can be performed completely without moving the vehicle, because you are about to disable it temporarily.

- Insure that you have good batteries, or put the passenger side battery on a charger while you are working. Cables on the driver's side battery will be in your way, and you will need vehicle power to do this.

- Pull the RELAY to the Injector Driver Module, so that you can crank the engine over and over for 15 second intervals without it starting up on you.

- Remove the hot side (driver's side) CAC duct, for easier access to the power steering pump reservoir pump fill neck for unimpeded fluid refills, later on, and more immediately, to more easily do the next step:

- Remove the power steering reservoir return hose. You will want to direct this hose into a suitable container. Sometimes, I find that empty plastic gallon size jugs with narrow necks that the hose end can fit inside are less spill prone than open containers. I tuck these jugs down near the frame some where. I like using 1/2 gallon clear juice bottles too. Whatever works to catch the fluid you are getting ready to flush out of the entire system.

- Plug the fitting that you removed the power steering return hose from. You are going to be supplying the "return" fluid fresh from new bottles poured through the large fill/dipstick hole. We don't want the system returning any old fluid into the reservoir.

- Manually withdraw as much old fluid from the reservoir as you can. The reason for doing this is so that you can begin the first 15 second flush cycle with a reservoir full of fresh clean fluid, not mixed fluid. This will help with identifying the fluid color break change through the return hose in your container, indicating that all the old fluid has been pushed out.

- A turkey baster and a small dish are handy to get that initial batch of old fluid out before you let the crank do the rest of the pumping for you (after you immediately refill the reservoir with fresh fluid):

Thus far, all the foregoing steps were recommended to be done now, while the vehicle is still on the ground and low enough to more easily reach inside the engine bay, only for ease of access. At this point though, and prior to the first crank cycle for flushing, the front of the vehicle should be lifted slightly off the ground.

- Raise the vehicle high enough to be able to freely turn the wheels lock to lock without the resistance of tires rubbing on the ground. No need to weaken tread blocks or burnish black rubber circles on the driveway, because the wheel will be turned lock to lock quite a few times during both this FLUSH and the following PURGE procedures.

- Support the vehicle with jack stands... it will be a while getting all the air worked out, at elevated RPMs.

- I chocked my rear tires, and removed my front tires so I didn't have to raise the truck so high, because my driveway was slightly inclined, and I needed to reduce that angle to keep the truck more level for filling purposes. If you are on a dead flat surface, then this extra measure won't be needed.

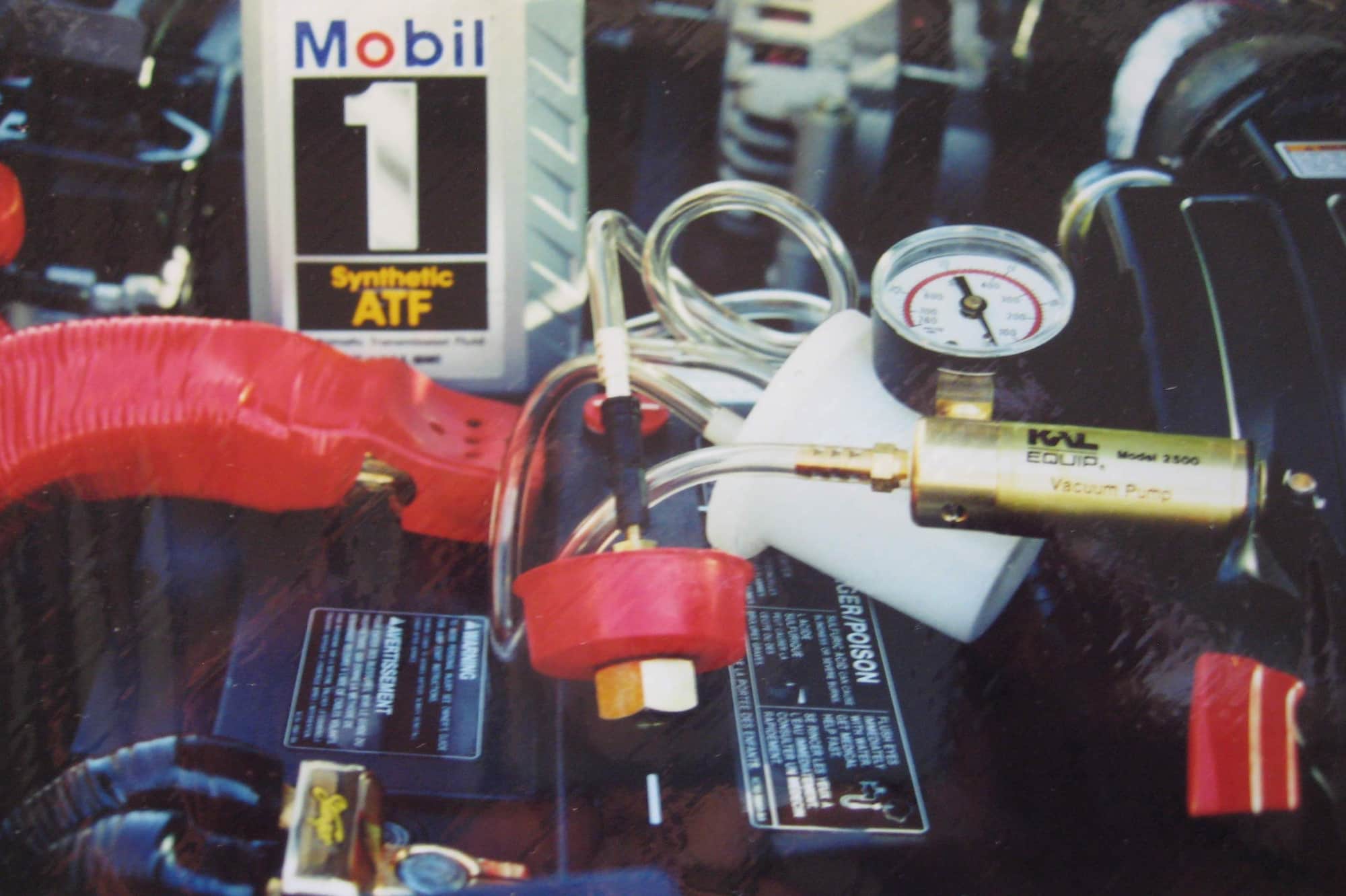

- Stage your quarts of fluid in an easily accessible space near the engine bay. You no doubt already know what fluid to use, but since this post has morphed into a full write up, for the sake of future readers who may acquire a new to them used Ford truck without a manual in the glove box, the original specification for this power steering system is Ford Mercon transmission fluid. I use and highly recommend synthetic transmission fluid by Mobil 1, which meets Mercon and Mercon V specs.

- Fill the manually drained reservoir with fresh synthetic fluid

- Check that the return hose is extended (add your own clear tubing extension if necessary) into a suitable catch container and safely secured to prevent fluid from squirting where you don't want.

- Double check that the container and hose are not interfering with moving engine parts, and not interfering with the intermediate steering shaft rotation.

- BEGIN FLUSH. Crank engine starter for 15 seconds (IDM Relay should be removed) while turning steering wheel lock to lock.

- Do not allow the steering wheel to stay at a stop for more than 4 seconds

- Stop cranking, add new fluid to reservoir, note color and condition of old fluid expelled into the catch container

- Start cranking, again for 15 seconds, while turning the wheel lock to lock, pausing at either end for no longer than 4 seconds. Stop and refill again.

- Repeat this flush cycle until you are satisfied that all of the fluid in the system has been fully flushed and replaced with the new fluid you added.

- Remove the plug or stopper you placed over fluid return hose fitting.

- Remove whatever extension you may have placed on the power steering return hose, and restore the hose end to the reservoir fitting. Some air will be in system because of this.

- Reinstall the the hot side Charge Air Cooler duct

- Disconnect battery charger, if connected earlier.

- Restore the IDM Relay

- The system is now FLUSHED of the old fluid, condensation, and contaminants, but NOT PURGED of air. Yet...

PURGE

- Leave the Ex (or truck) on the jack stands from the flushing procedure, but double check that it is supported safely enough to be able to run the engine for extended periods. Although the holding power of Ford's drum in hat parking brake isn't great, it is still a good idea to set the parking brake anyway, and chock the rear tires too if you're OCD, like, ahem.

- Obtain a hand operated vacuum pump. I use a professional metal one made by Kal Equip that has a built in gauge and pulls a vacuum really well, and holds it steady until I release it.

- You do NOT need a two port one man brake bleeding covered cup, because you are not using the vacuum pump to suck fluid. No power steering fluid will come in contact with the vacuum inlet source. We just need to pull a steady vacuum on the pump reservoir fill neck in order to purge that pesky air out of the system.

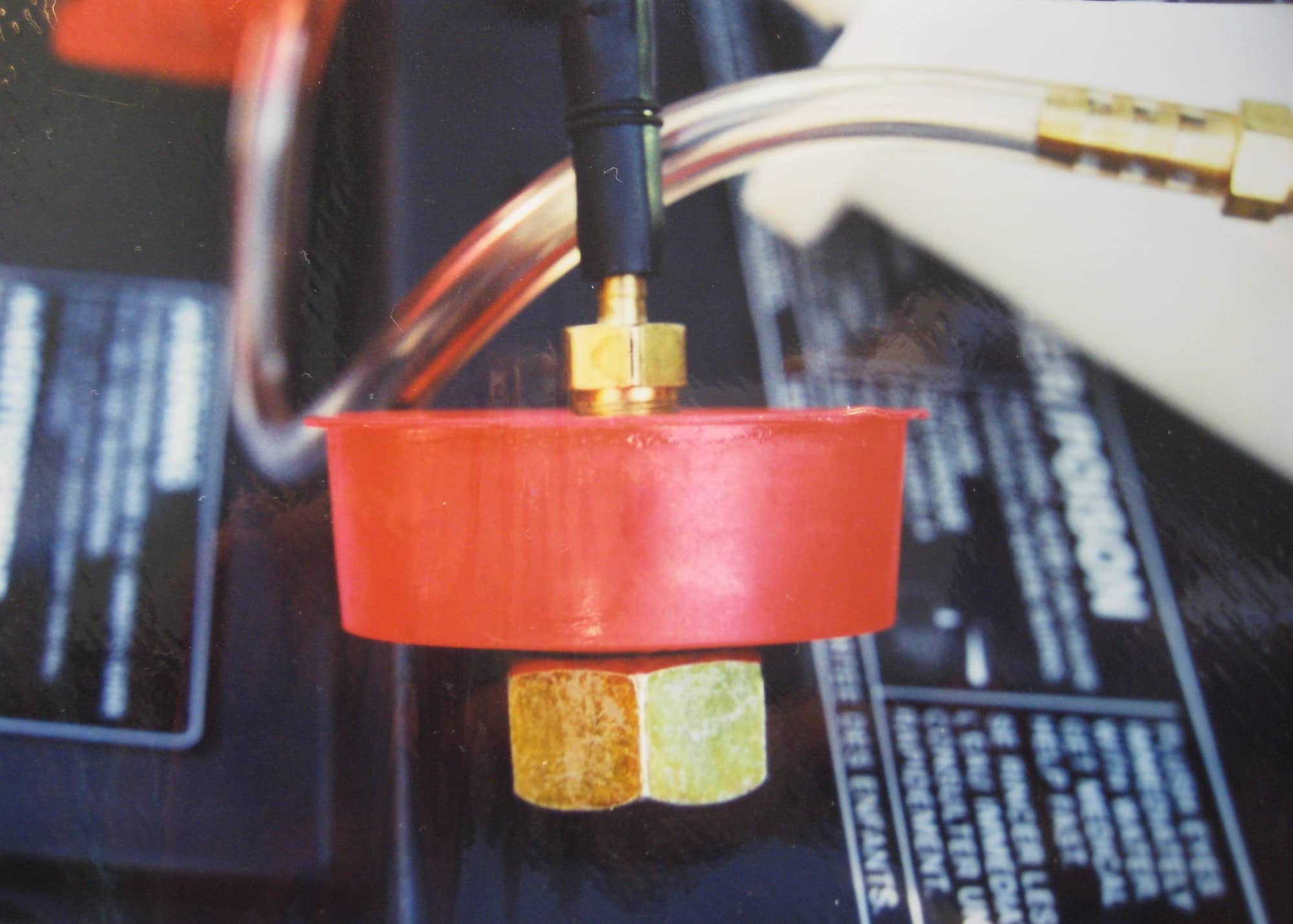

- Obtain, or fabricate, a fill neck stopper. This stopper needs to sit snugly against the power steering reservoir fill neck's inside diameter (with the cap/dipstick removed). It should fit tight enough to hold all the vacuum you can squeeze out of that hand pump. This is probably THE MOST DIFFICULT STEP... finding a good stopper. If there is a commercially made solution readily available to you, then BUY it and happily skip the aggravating hunt in this step and the time robbing fabrication of the next step.

- Bore a hole through the stopper you scrounged, and tightly attach a leak proof fitting to connect the vacuum hose of your hand pump to. Here is a close up of what I kludged together. There are infinitely better ways to skin this cat, but miraculously, this combination of random object ore mined out of my garage held enough vacuum to get the job done, according to the gauge.

OK, with tools in hand, we are ready to purge air out of the PS system.

- Verify fluid level is correct in the PS reservoir, via the cap dipstick.

- Install the stopper snugly, but ensure there is at least a 3/4" air gap between the top of the fluid at correct level, and the inlet port to the vacuum line. More gap is safer, but there are unknown constraints... such as your stopper depth and the angle of inclination your are working with.

- TIP: Whatever you do, don't turn your wheels without the engine running!

- BEGIN > Start engine. Apply 30 inches of vacuum on the hand pump (connected to the installed stopper in the reservoir). Let run for 4 minutes at idle.

- Release vacuum. Temporarily remove stopper to check fluid level. Top off to correct fill level if necessary. Reinstall stopper. Reapply 30" of vacuum.

- Allow engine to continue to idle for another 6 minutes, while turning steering wheel fully to the left and fully to the right every 30 seconds, pausing for no more than 3 seconds at each fully turned steering stop.

- Release vacuum. Temporarily remove stopper to check fluid level. Hopefully you will not have to add any, but if you do, then do so, and reinstall the stopper, reapply the vacuum, and repeat another 6 minute idle period while cycling the steering wheel stop to stop every 30 seconds, pausing for no more than 3 seconds at each extreme wheel turn.

- By this time, the air should be purged. And I do mean time, as it takes TIME to get that air out, time that a lot of techs cannot afford to take... but this is the procedure that Ford recommends (even though Ford may not have allowed enough flat rate book time to do it!)

- Turn off engine, release vacuum, remove stopper, reinstall dipstick cap. You're purged. Move on to the third front of this battle against power steering noise...

PROTECT

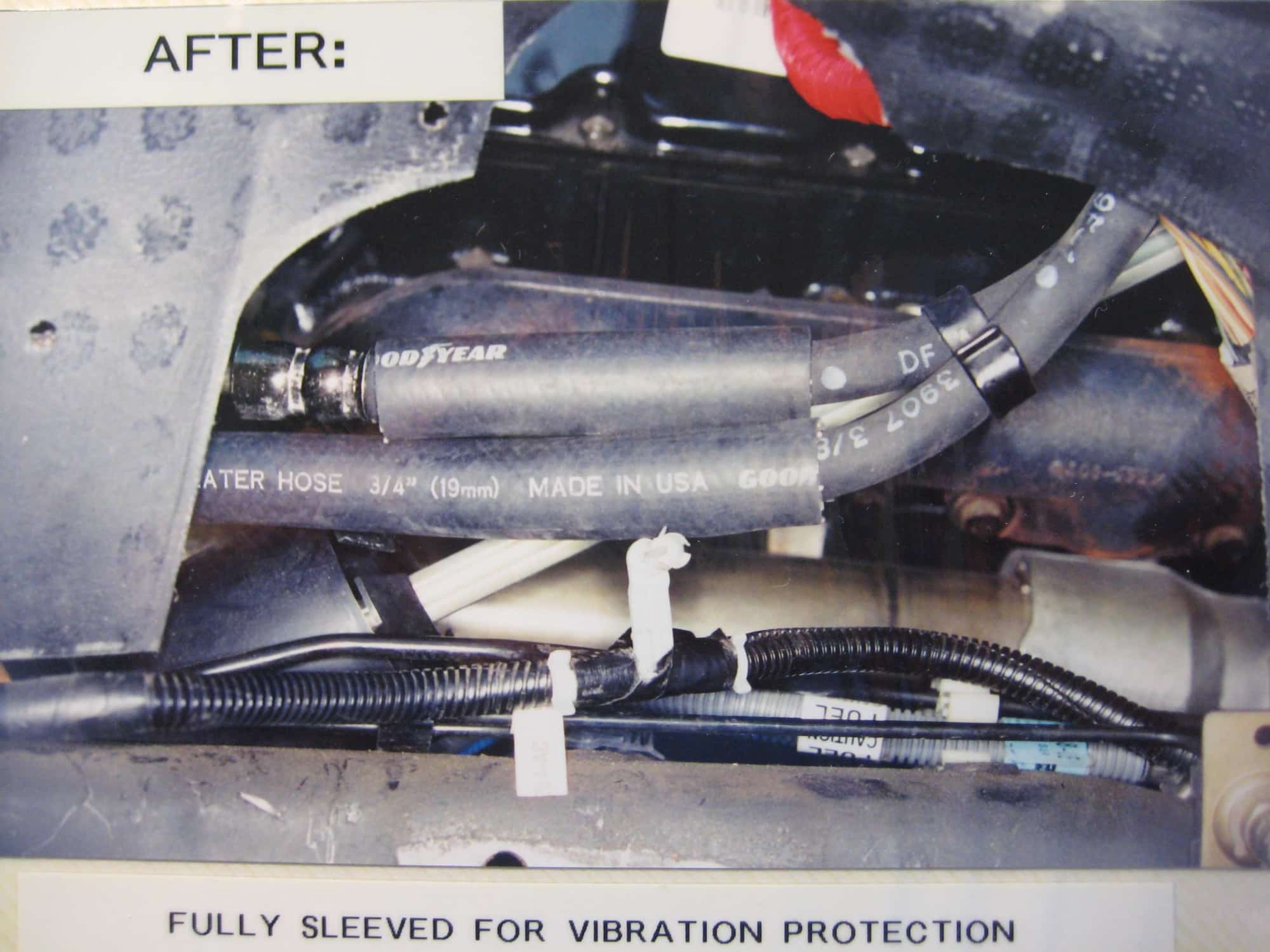

If the lines are in contact with other components, like a stethoscope, the noise can travel and thus be amplified. Everyone knows about the contact with intercooler duct. But there are a lot more up and down the lines, top to bottom, from the loop out of the Hydroboost unit, down to the power steering cooler under the radiator, and many points in between.

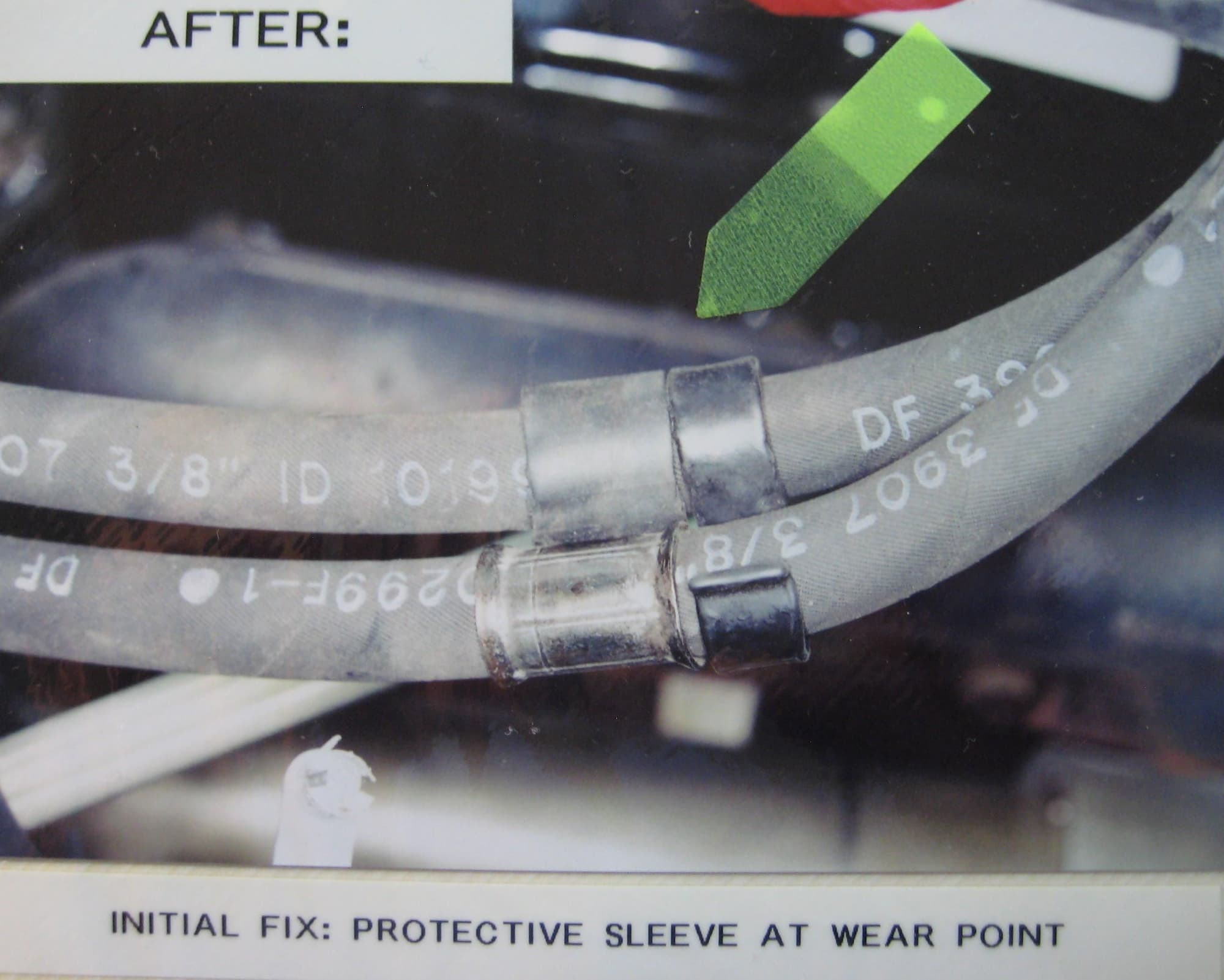

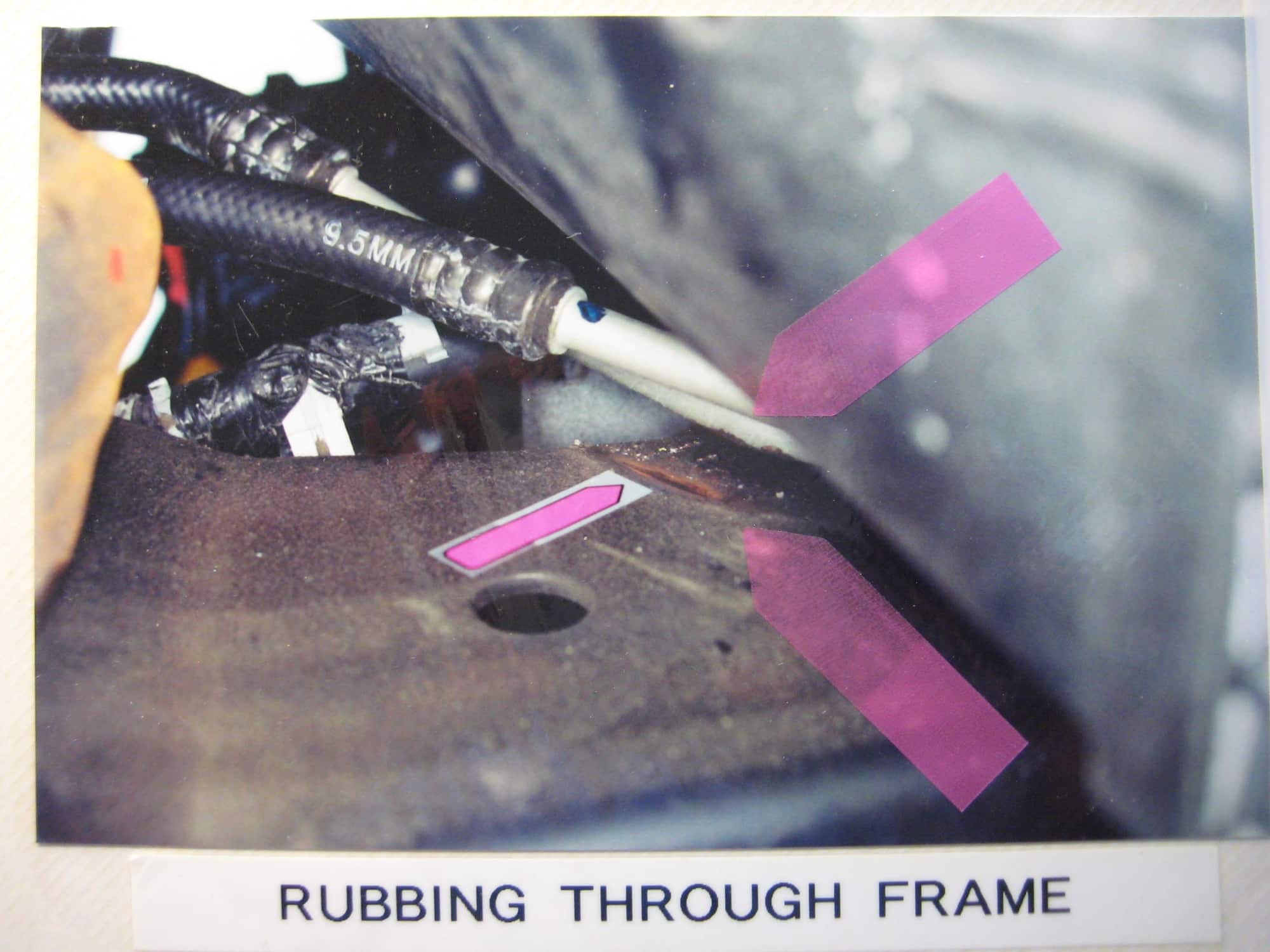

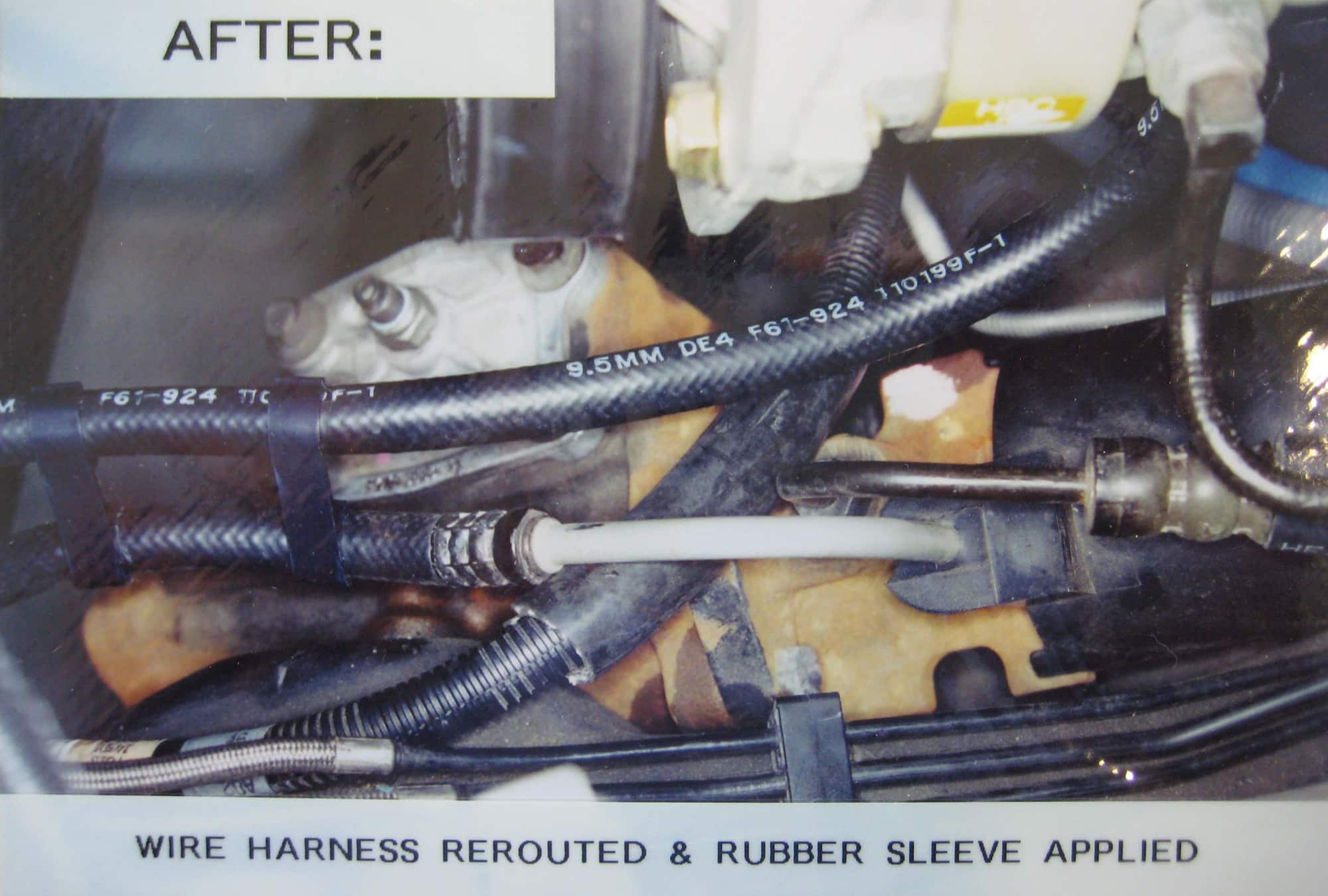

The problem contact areas and their fixes are self evident once known about. The issue is knowing about them when they are hidden from general view. So I'll just close this post out with a few more pictures of some common contact points of power steering lines in the Super Duty and Excursion, as found on my truck:

To fully access and fix this frame rubbing point, which extended beyond the image immediately above into an area between the frame and heat exchangers that was visibly and physically inaccessible, I had to remove the radiator, intercooler and transmission cooler.

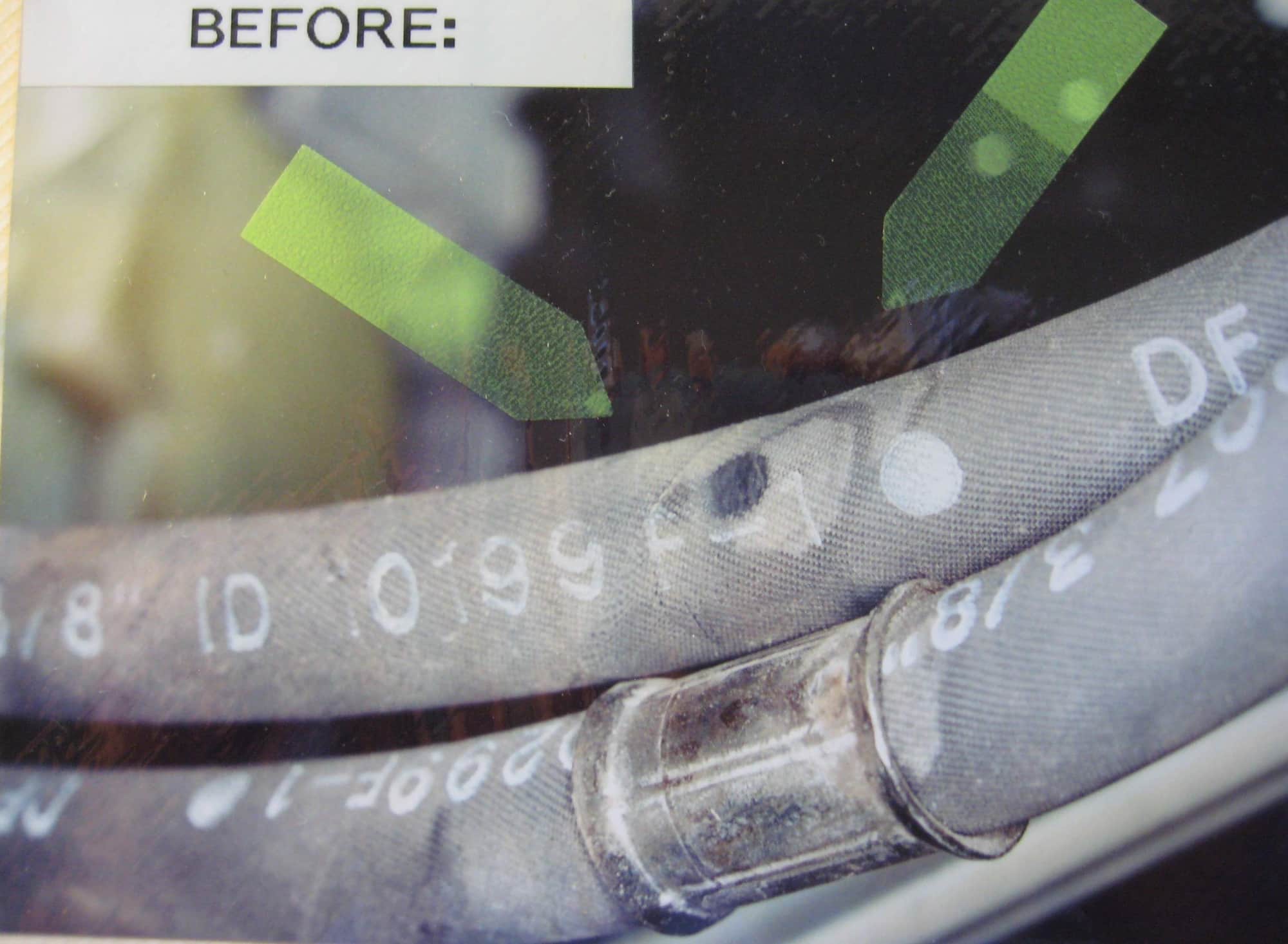

Another thing to fix in power steering lines is any sharp bends in the flexible portion of the lines. I found one by the steering box, just aft of the frame and radiator rubbing issues addressed above.

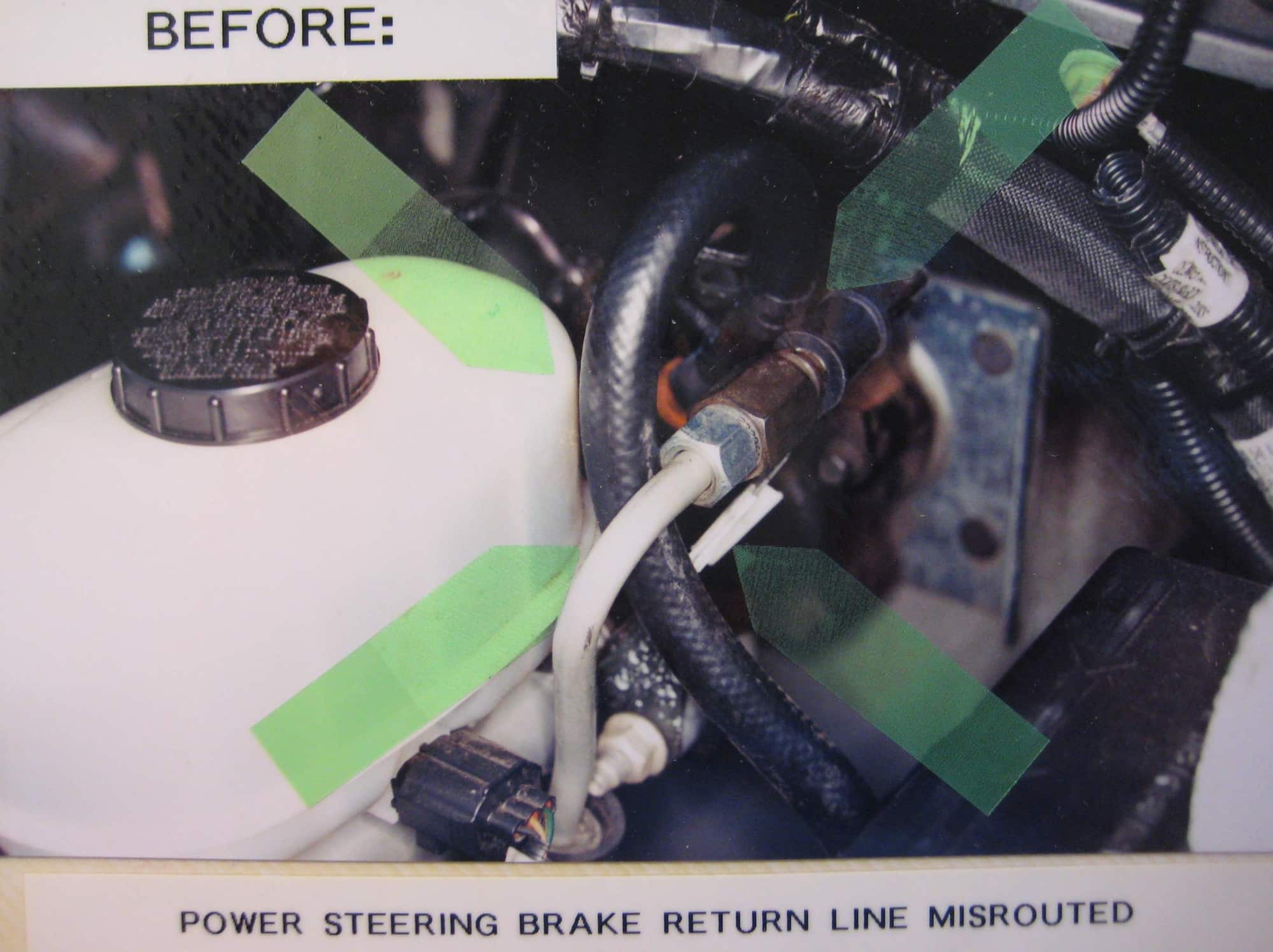

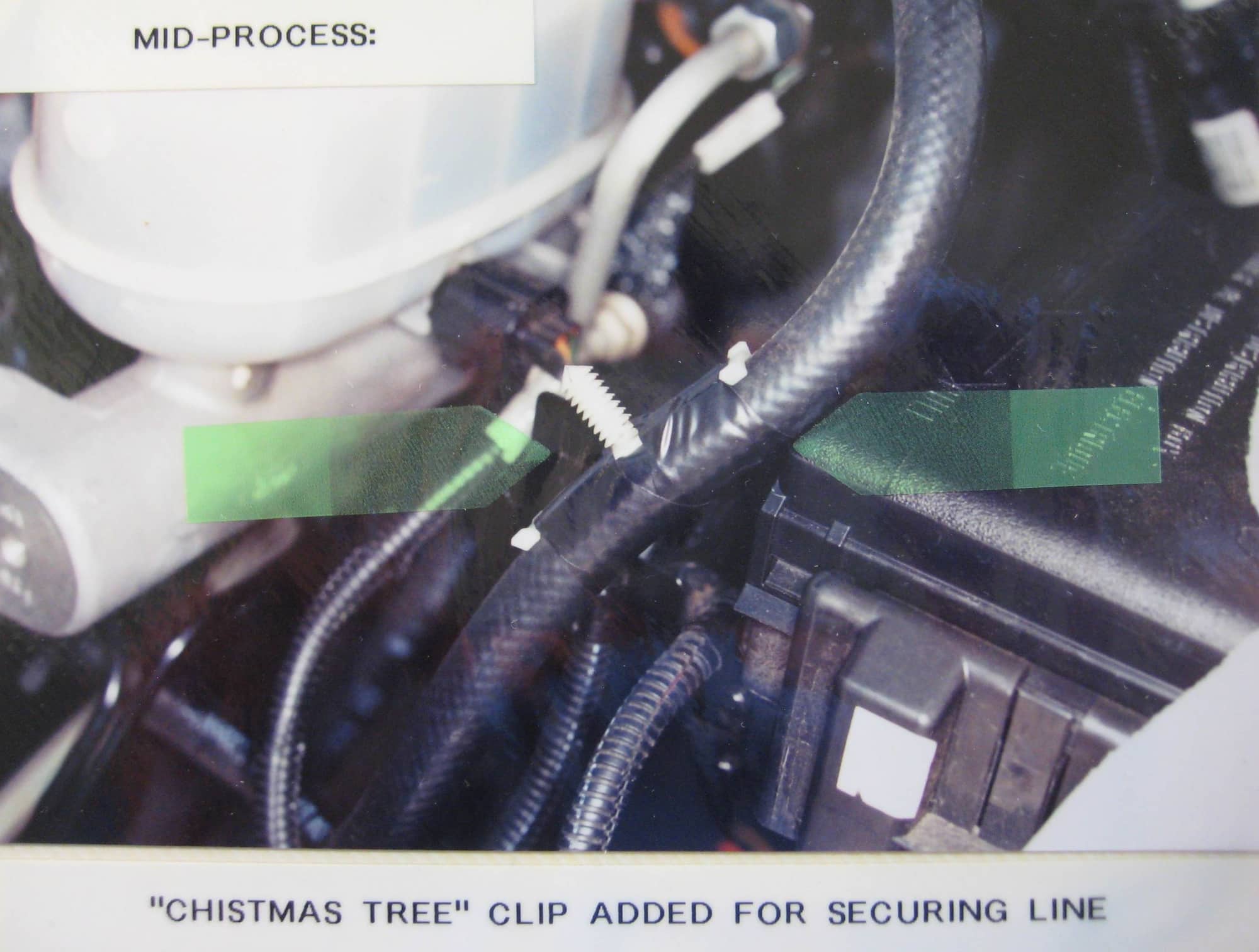

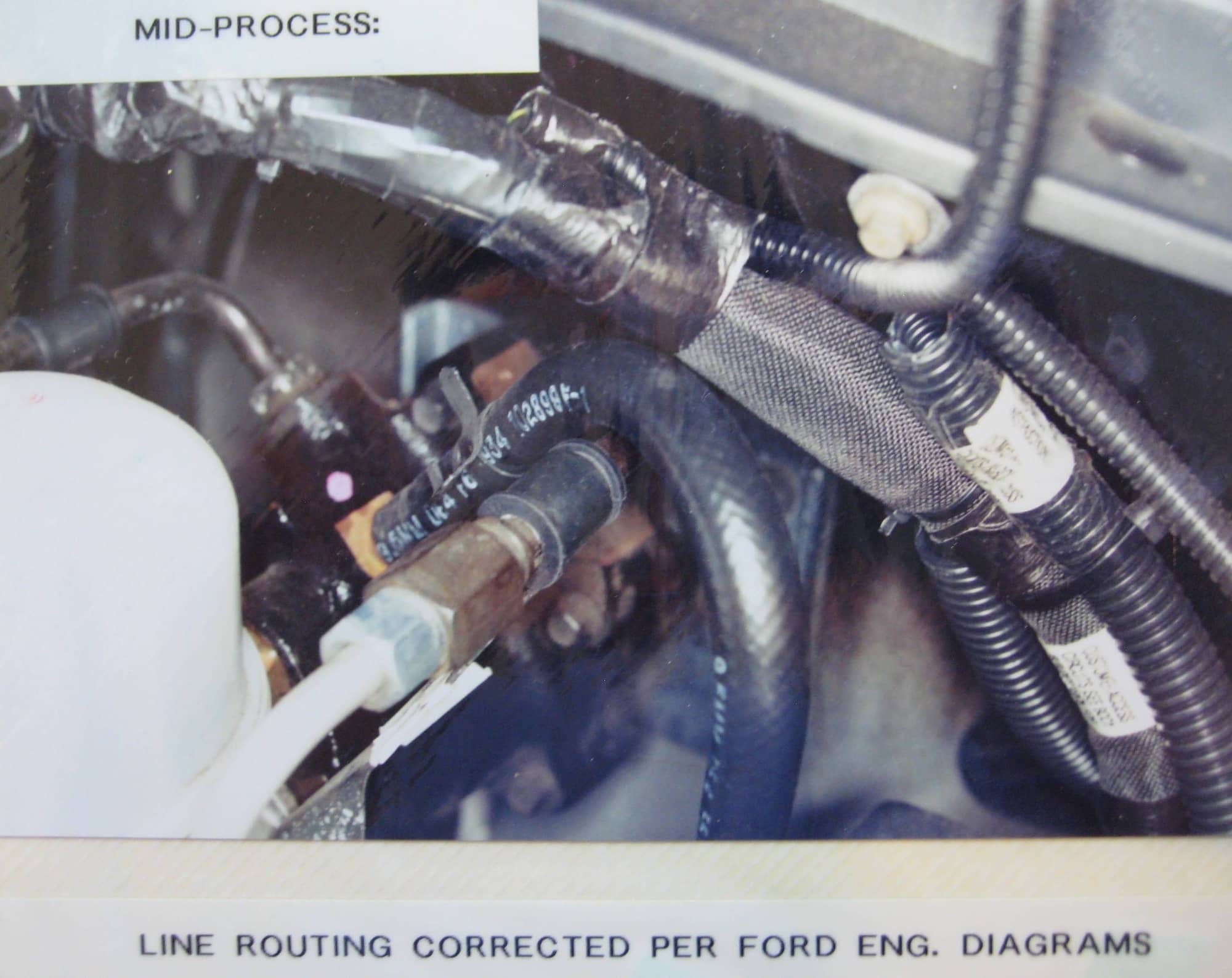

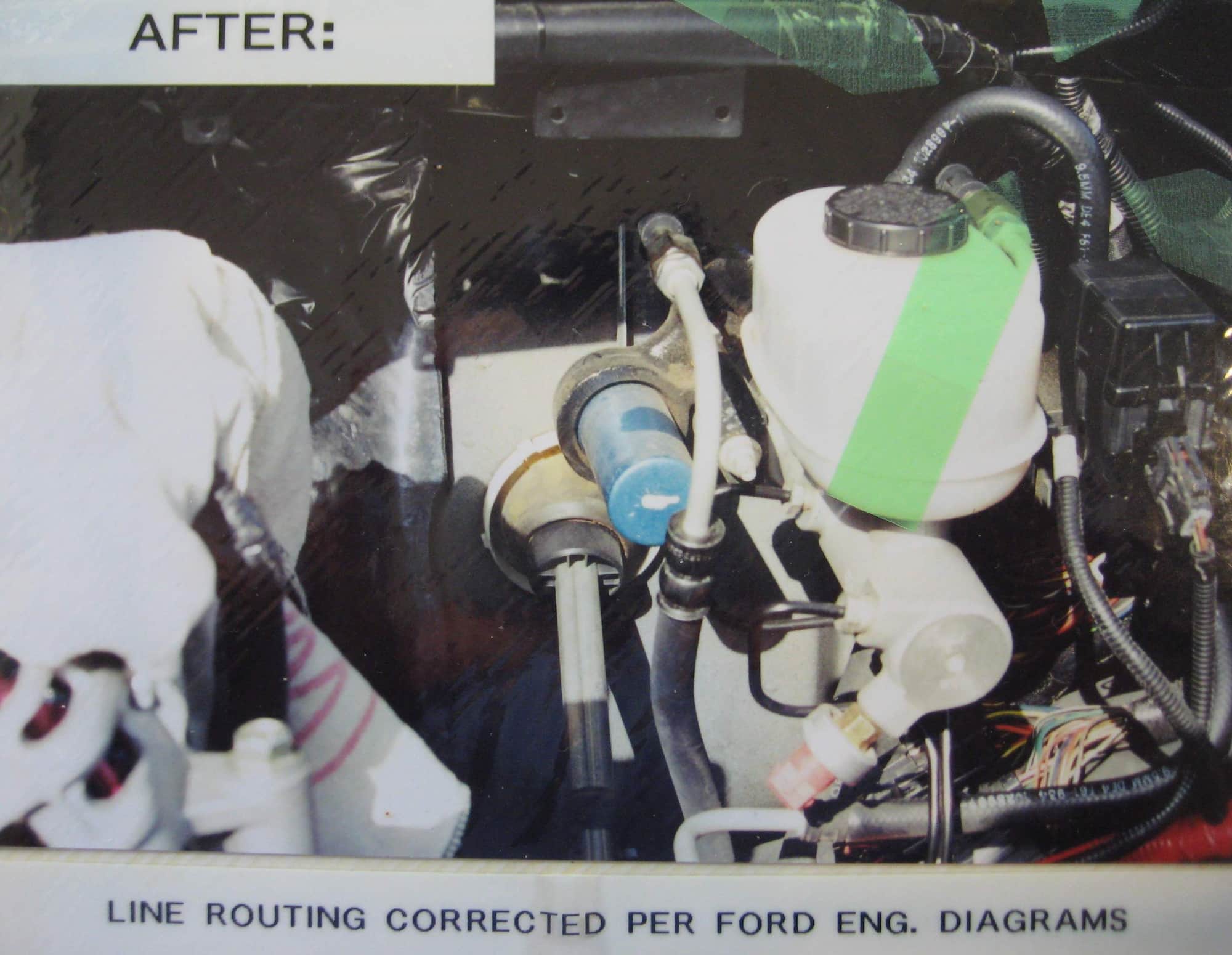

Now here is an issue related to the RETURN line. It can be misrouted at the factory. A little late now, being a decade and a half later, but I discovered this early within the first year of owning the truck, and fixed it then. If replacing lines, keep in mind that the existing lines as found may not necessarily be the way they were supposed to be routed. I researched this one quite a bit back in 2000, and changed the "as found" routing to match the design drawings, which reduced or eliminated a few contact points.

Note that in the above pic, the job is not quite done yet. The hose was rerouted up and over the hard lines, instead of bent down in between them, but the arch was not yet positioned to clear high enough over the rub sleeve to clear it altogether. Contrast the pic above with the high arch of the finished routing pic below:

And finally, last but not least, the power steering line wear point that everyone knows about, because it is the most visible. Solved by splitting some rubber hose and sliding it over the metal part of the return line as shown below:

(All images shot on film.)

Y2KW57

#12

Awesome info. Just what I was hoping to get. I can do the purge tonight, but the rest will probably have to wait for the weekend (so I can secure a vacuum pump and get enough time to complete the job). Once all the pics are uploaded, I'll generate a PDF which can be easily downloaded by all.

Thanks.

Thanks.

#13

I have done the whole flush procedure and after that didn't work, I replaced the power steering pump all together. Then flushed again. But still the same outcome. No change in what has been my problem with this truck since I bought it two years ago. When the brake is pressed down and at a stop, there is no way to turn the wheels. Let go of the break, and steering returns a bit, hit the gas and steering power is back to full. I gave up and just lived with the problem. From what I have been reading, some people have it and some don't. The pump is quiet as a mouse. Just have to work on my arm strength...

#14

F250's complaint is with the noise, not with the inherent characteristics of hydroboost steering systems, which is prioritized and routed to supply brake boost first.

If the brakes are fully applied, and they work, then the truck isn't going anywhere, so it doesn't matter which way the wheels are turned... the truck is stopped.

A technique for less stressful steering, and more significantly, less TIRE WEAR on the steering axle, is to roll steer. Let the foot off of the brake, and steer as the truck is rolling, or rollable. Quickly if necessary. Don't try and "pre steer" ahead of time while fully braked standing still. Steer with movement. Works easily, every time.

My first truck was a 1963 F100 unibody, all manual, 3 on the tree, drop center I beam front axle, no power steering. That's how I learned to drive. That was how I was taught to drive, by anyone older than me who "steered" me along. New generations learn to drive with power everything, because that is what all vehicles have. But power steering used to be like Navigation Radios were 15-20 years ago. A novelty, not the norm.

I added eleven more power steering rub point pics to my post. I lost the 12th pic in cyberspace somehow.

If the brakes are fully applied, and they work, then the truck isn't going anywhere, so it doesn't matter which way the wheels are turned... the truck is stopped.

A technique for less stressful steering, and more significantly, less TIRE WEAR on the steering axle, is to roll steer. Let the foot off of the brake, and steer as the truck is rolling, or rollable. Quickly if necessary. Don't try and "pre steer" ahead of time while fully braked standing still. Steer with movement. Works easily, every time.

My first truck was a 1963 F100 unibody, all manual, 3 on the tree, drop center I beam front axle, no power steering. That's how I learned to drive. That was how I was taught to drive, by anyone older than me who "steered" me along. New generations learn to drive with power everything, because that is what all vehicles have. But power steering used to be like Navigation Radios were 15-20 years ago. A novelty, not the norm.

I added eleven more power steering rub point pics to my post. I lost the 12th pic in cyberspace somehow.

#15

A technique for less stressful steering, and more significantly, less TIRE WEAR on the steering axle, is to roll steer. Let the foot off of the brake, and steer as the truck is rolling, or rollable. Quickly if necessary. Don't try and "pre steer" ahead of time while fully braked standing still. Steer with movement. Works easily, every time.

.