I need some Edelbrock 1406 install pointers

#1

I need some Edelbrock 1406 install pointers

Right after I got the new carb I started a new job so I'm only just now getting to install it. I was going to do it today, but have questions about hooking up the various vacuum lines.

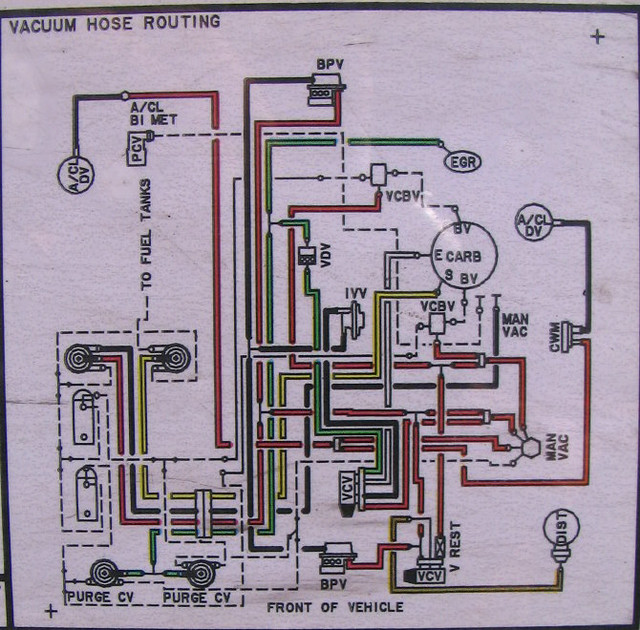

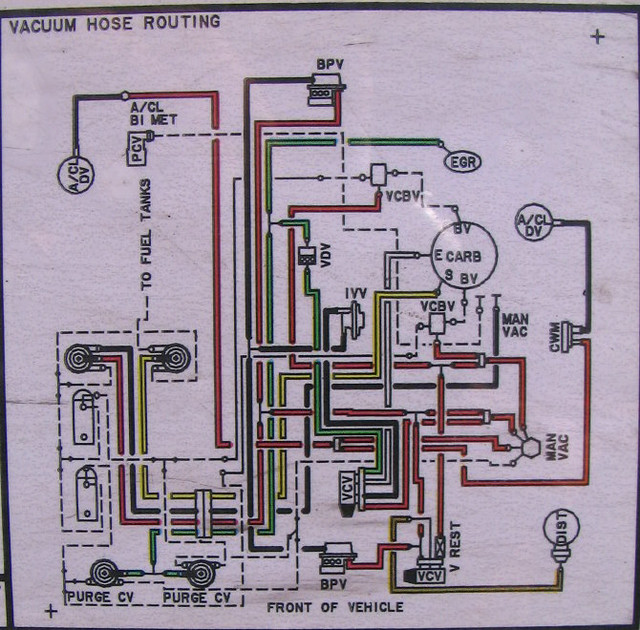

Here's what I'm looking at.

It seems pretty straight forward that line C on the 4180 connects to a fitting I'll need to get for the threaded port for the 1406

I'm guessing line A on the 4180 connects to port A on the 1406.

F on the 4180 appears to be on the spacer plate between the carb and manifold so I guess it's not an issue.

That leaves 3 lines, C, D & E (which is large) on the 4180 and only two ports on the 1406, B & C.

I don't know which goes where, if it matters, and have people connected two in to one with a 'T'?

If so, which two?

Here's what I'm looking at.

It seems pretty straight forward that line C on the 4180 connects to a fitting I'll need to get for the threaded port for the 1406

I'm guessing line A on the 4180 connects to port A on the 1406.

F on the 4180 appears to be on the spacer plate between the carb and manifold so I guess it's not an issue.

That leaves 3 lines, C, D & E (which is large) on the 4180 and only two ports on the 1406, B & C.

I don't know which goes where, if it matters, and have people connected two in to one with a 'T'?

If so, which two?

#2

When I had a 1406 on my engine, the guy I bought it from installed it pretty much the way you are thinking. I removed all of that garbage, the front main port is for PCV. The small left port is for your vacuum advance (timed vacuum) and the small right port is manifold vacuum. Also the rear threaded port is for your vacuum brakes if it's not already hooked up to a tree in the intake manifold.

#3

Someone that can see better than I correct me if I am wrong, but on the old carb, line "A" and "C" are both bowl vent lines correct? If so, you will eliminate these lines, the new carb does not have fuel bowl vents correct?

Line "A" on the new carb is usually for the PCV line from the valve cover. I don't see it in the old carb photo. Does line "E" on the old carb go to the PCV valve in the valve cover?

Line "A" on the new carb is usually for the PCV line from the valve cover. I don't see it in the old carb photo. Does line "E" on the old carb go to the PCV valve in the valve cover?

#4

Someone that can see better than I correct me if I am wrong, but on the old carb, line "A" and "C" are both bowl vent lines correct? If so, you will eliminate these lines, the new carb does not have fuel bowl vents correct?

Line "A" on the new carb is usually for the PCV line from the valve cover. I don't see it in the old carb photo. Does line "E" on the old carb go to the PCV valve in the valve cover?

Line "A" on the new carb is usually for the PCV line from the valve cover. I don't see it in the old carb photo. Does line "E" on the old carb go to the PCV valve in the valve cover?

#5

When I had a 1406 on my engine, the guy I bought it from installed it pretty much the way you are thinking. I removed all of that garbage, the front main port is for PCV. The small left port is for your vacuum advance (timed vacuum) and the small right port is manifold vacuum. Also the rear threaded port is for your vacuum brakes if it's not already hooked up to a tree in the intake manifold.

I don't know anything about 4106's, but I can help on 1406's.

First, your Holley has connections you won't have on the E'brock. For one, it is set up for sucking gas fumes out of the charcoal canister, and the E'brock doesn't do that. Instead, the 1406 Eddy has two connections you will use: PCV and vacuum to the advance. Those connections are explained here, but Matthew is spot-on. So your PCV hose, which should be the one from the fitting in the valve cover, goes to the big port in the front. The vacuum line from the distributor goes to the small port on the left. And you will cap the small port on the right and plug the big port in the rear.

As for the other lines on the Holley, I don't know what they are. But your line from the vapor or charcoal canister won't have anywhere to go. Beyond that, if I knew what the ones on the Holley were I might be able to help.

#6

Thanks guys...I really did read the instructions.

I guess a two weeks worth of sleep deprivation was having a worse affect than I thought.

I also knew the post didn't look right, but it wasn't until later that I figured out it was the glaring "4106".

On a related note, is there a downside to installing the 1465 off-road needle valves and adjusting the floats? Described here: http://www.edelbrock.com/automotive_.../1000/1465.pdf

I bought the set, but am wondering if there's a downside, since I don't do much serious off-roading with my pickup but do drive on some rough roads and go off-pavement some, getting firewood or whatnot, sometimes at some fairly significant side hills. All I've found is references to the fact they help prevent bouncing of the needle valve (which could apply on a really rough road I'd think) and operating at angles, but no indication how steep an angle.

I guess a two weeks worth of sleep deprivation was having a worse affect than I thought.

I also knew the post didn't look right, but it wasn't until later that I figured out it was the glaring "4106".

On a related note, is there a downside to installing the 1465 off-road needle valves and adjusting the floats? Described here: http://www.edelbrock.com/automotive_.../1000/1465.pdf

I bought the set, but am wondering if there's a downside, since I don't do much serious off-roading with my pickup but do drive on some rough roads and go off-pavement some, getting firewood or whatnot, sometimes at some fairly significant side hills. All I've found is references to the fact they help prevent bouncing of the needle valve (which could apply on a really rough road I'd think) and operating at angles, but no indication how steep an angle.

#7

Trending Topics

#8

Actually, I have a brand new pair of those needles and seats laying on the bench. But I got pretty strong guidance on here not to install them on my street-driven 1406. I believe it was Bill (85lebaront2) that gave me one of the negative votes, and given his 40 years or so of running a carb & ignition shop I go to the bank with what he says in those areas.

#9

I'm going to go from memory here, but I think it's right.

From the ported vacuum on the carb to a T. One side goes to the dizzy, the other side goes to a blue 2-port, 128° vacuum control valve to the EGR (if installed). This keeps the EGR from functioning below 128°. The valve threads into the manifold coolant port somewhere.

If you have a vacuum operated heat valve system on the intake or exhaust like the 351 HO then you will take manifold vacuum to a yellow 160° 3-port vacuum control valve. The middle port will go to the vacuum controlled heat valves in the intake/exhaust. The top port goes to manifold vacuum and the bottom goes to atmosphere. Below 160° there should be manifold vacuum on the middle port, above there should not be. If you have a vacuum operated throttle kicker, that's hooked up here as well so you get a higher idle when cold. (The TK is optional, if needed). There's also some A/C parts to kick the idle up when the compressor comes on. I can look at my notes for anyone who has such a system and needs it to be functional.

The fuel bowl vents are eliminated as said before. There should be three canister purge valves, two of which go to the carb vents and one for the tank vent line. The two carb ones can be eliminated and the remaining valve hooked back up. The fuel vent line goes directly to the canister and I believe it's the middle port that's connected to ported vacuum, T'd into the EGR side of things, through a delay valve. Of the other two ports, one connects to the canister, the other T's into the PCV or other suitable manifold vacuum source. The charcoal in the canister holds the hydrocarbons from the fuel vapors like a magnet. When the engine is running, typically at cruise speed, a vacuume signal on the middle port of the purge valve opens it up and the hydrocarbons are sucked back into the engine to be burned.

All of my knowledge comes from dissecting the systems on my 86 and 87 351 HO's. The EGR system works on any engine with EGR. The fuel tank/canister purge is also generic and should work on all. The heat valves and vacuum throttle kicker may or may not be there on other systems, I think it's just a 351HO thing.

Since non of my trucks have a functioning AIR system or their parts I never bothered to figure out that system. My believe is that the EGR, PCV and Canister on the fuel vents constitute a significant role in emissions and the loss of the air system and bowl vents on a limited number of vehicles that drive a limited number of miles has a minimal effect on global emissions. Certainly much less than the impact china has making iPhones... If I were dictator for a day I would mandate that for older vehicles, say 15 or 20+ years old that a best effort is made to reduce emissions and that non functional and non economically repairable systems can be left inoperative. That's never going to happen so I'll just drift off into my dream world and hope that I've helped people get some systems working again.

From the ported vacuum on the carb to a T. One side goes to the dizzy, the other side goes to a blue 2-port, 128° vacuum control valve to the EGR (if installed). This keeps the EGR from functioning below 128°. The valve threads into the manifold coolant port somewhere.

If you have a vacuum operated heat valve system on the intake or exhaust like the 351 HO then you will take manifold vacuum to a yellow 160° 3-port vacuum control valve. The middle port will go to the vacuum controlled heat valves in the intake/exhaust. The top port goes to manifold vacuum and the bottom goes to atmosphere. Below 160° there should be manifold vacuum on the middle port, above there should not be. If you have a vacuum operated throttle kicker, that's hooked up here as well so you get a higher idle when cold. (The TK is optional, if needed). There's also some A/C parts to kick the idle up when the compressor comes on. I can look at my notes for anyone who has such a system and needs it to be functional.

The fuel bowl vents are eliminated as said before. There should be three canister purge valves, two of which go to the carb vents and one for the tank vent line. The two carb ones can be eliminated and the remaining valve hooked back up. The fuel vent line goes directly to the canister and I believe it's the middle port that's connected to ported vacuum, T'd into the EGR side of things, through a delay valve. Of the other two ports, one connects to the canister, the other T's into the PCV or other suitable manifold vacuum source. The charcoal in the canister holds the hydrocarbons from the fuel vapors like a magnet. When the engine is running, typically at cruise speed, a vacuume signal on the middle port of the purge valve opens it up and the hydrocarbons are sucked back into the engine to be burned.

All of my knowledge comes from dissecting the systems on my 86 and 87 351 HO's. The EGR system works on any engine with EGR. The fuel tank/canister purge is also generic and should work on all. The heat valves and vacuum throttle kicker may or may not be there on other systems, I think it's just a 351HO thing.

Since non of my trucks have a functioning AIR system or their parts I never bothered to figure out that system. My believe is that the EGR, PCV and Canister on the fuel vents constitute a significant role in emissions and the loss of the air system and bowl vents on a limited number of vehicles that drive a limited number of miles has a minimal effect on global emissions. Certainly much less than the impact china has making iPhones... If I were dictator for a day I would mandate that for older vehicles, say 15 or 20+ years old that a best effort is made to reduce emissions and that non functional and non economically repairable systems can be left inoperative. That's never going to happen so I'll just drift off into my dream world and hope that I've helped people get some systems working again.

#10

Actually, I have a brand new pair of those needles and seats laying on the bench. But I got pretty strong guidance on here not to install them on my street-driven 1406. I believe it was Bill (85lebaront2) that gave me one of the negative votes, and given his 40 years or so of running a carb & ignition shop I go to the bank with what he says in those areas.

#11

Then there's this

Actually, I have a brand new pair of those needles and seats laying on the bench. But I got pretty strong guidance on here not to install them on my street-driven 1406. I believe it was Bill (85lebaront2) that gave me one of the negative votes, and given his 40 years or so of running a carb & ignition shop I go to the bank with what he says in those areas.

David(f100beater), thanks for the lengthy description, I'll need to reread it and compare to what my 460 non-catalytic emissions are set up like, but here's a brief description.

Line 'B' on my 4180 goes to the lower (green and blue) of these two temp sensors screwed in to the thermostat elbow

Line 'D' goes down to the right side of the engine, connects to this

And then to what I think is the charcoal canister purge valve

The distributor vacuum line goes to the upper (yellow) sensor in the first photo. At least one line from that goes a multi-port valve of some sort screwed in to the manifold

The large line from that (connected to my copper elbow fix on the right) goes down to one of the canister purge valves which is also connected to the little black cylinder the bowl vent feeds through.

It appears the vacuum for the advance comes through unit screwed in to the manifold. I need to look further and compare it to a printout of what you wrote.

I haven't noticed anything associated with my AC, but I'll look further.

Apologies for appearing so dense. This is 100% new territory for me. My experience is all with older diesels, pre-75 vehicles and '95 and newer EFI.

Converting my F-250 to diesel is getting more appealing.

#13

B is the EGR port and you can use a ported source on the 1406 as a substitute.

The blue/green 4-port VCV is the 4 port version of the one I listed above. If you remove it, it should be stamped 128° on the bottom - if you want to confirm. Other temps include 95 and 150°. Ford's PN for it is - D8TE-9B473-B2A

The yellow valve is a 160° valve and is used to provide either manifold vacuum or manifold vacuum with a restrictor depending on the temperature.

The 3rd picture is the purge vent and you may actually have 4 of these valves. One shuts off the vent to the fuel vent from the tank (yellow line), two appear to be purge for the canister Tee'd of the EGR (green line) and the last one I'm not sure about. From the looks of it, follow the lines back from the bowl vents to the Tee's by the purge valves and remove. Cap or remove the Tee's and leave the other valves.

The blue/green 4-port VCV is the 4 port version of the one I listed above. If you remove it, it should be stamped 128° on the bottom - if you want to confirm. Other temps include 95 and 150°. Ford's PN for it is - D8TE-9B473-B2A

The yellow valve is a 160° valve and is used to provide either manifold vacuum or manifold vacuum with a restrictor depending on the temperature.

The 3rd picture is the purge vent and you may actually have 4 of these valves. One shuts off the vent to the fuel vent from the tank (yellow line), two appear to be purge for the canister Tee'd of the EGR (green line) and the last one I'm not sure about. From the looks of it, follow the lines back from the bowl vents to the Tee's by the purge valves and remove. Cap or remove the Tee's and leave the other valves.

#14

I am assuming you do not have emissions inspections in your area? Of course putting this carb on the engine violates the emissions certification, but it can be hid pretty good if you use the original air cleaner.

Study and take note how everything was hooked up and worked, but I would get rid of most of it if it was my truck. No EGR, one straight line from the carb to the dist, keep the original air cleaner and it's vacuum lines and pipes, keep the line going to the firewall vacuum tree, keep the line to the brake booster, keep the line to the PCV valve in the valve cover, keep the line from the other valve cover to the aircleaner with the little steel wool like filter.

Study and take note how everything was hooked up and worked, but I would get rid of most of it if it was my truck. No EGR, one straight line from the carb to the dist, keep the original air cleaner and it's vacuum lines and pipes, keep the line going to the firewall vacuum tree, keep the line to the brake booster, keep the line to the PCV valve in the valve cover, keep the line from the other valve cover to the aircleaner with the little steel wool like filter.

#15

Well, life and work has finally allowed me to install my 1406 on my 460. I have a question about this gasket supplied with the carburetor.

It seems if I use that it leaves a gap so that all 4 barrels are open between one another via a gap the thickness of the gasket. Admittedly not much, but it doesn't seem right

Anyway, I decided to leave it out and install the Edelbrock directly on the thick fiber spacer that the 4180 sat on but am now having second thoughts so wanted to see what the "right" way is to do it. The install instructions seem vague.

I still have to hook up the various vacuum lines and won't be able to get to that until tomorrow. Hopefully I can get an answer about the gasket before then.

It seems if I use that it leaves a gap so that all 4 barrels are open between one another via a gap the thickness of the gasket. Admittedly not much, but it doesn't seem right

Anyway, I decided to leave it out and install the Edelbrock directly on the thick fiber spacer that the 4180 sat on but am now having second thoughts so wanted to see what the "right" way is to do it. The install instructions seem vague.

I still have to hook up the various vacuum lines and won't be able to get to that until tomorrow. Hopefully I can get an answer about the gasket before then.